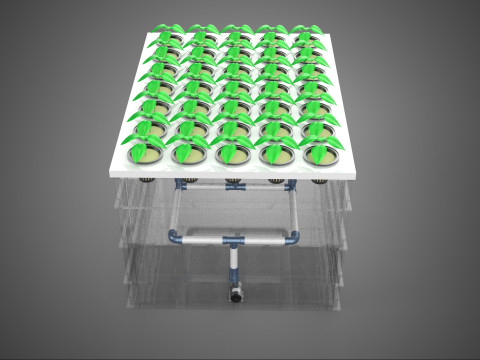

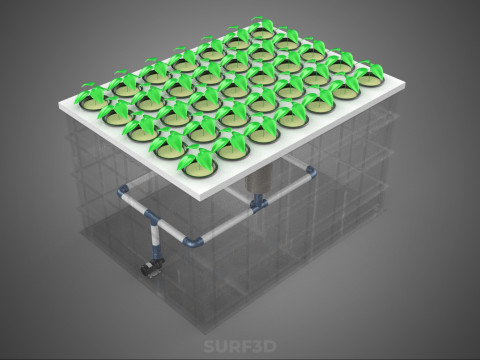

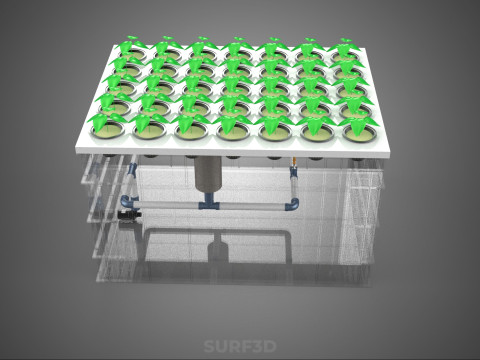

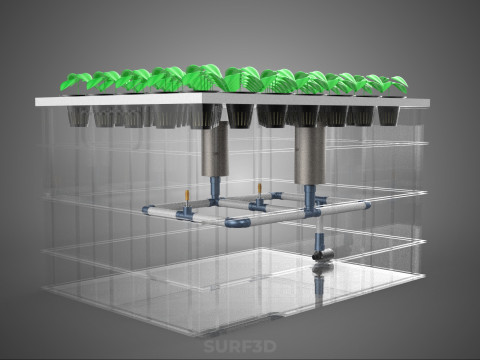

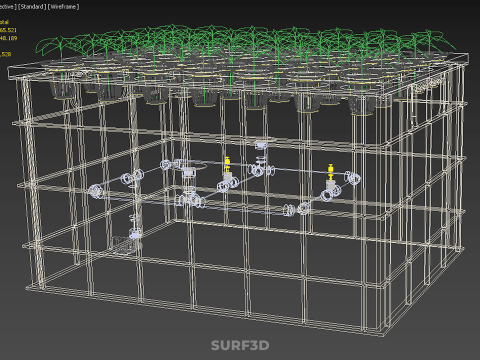

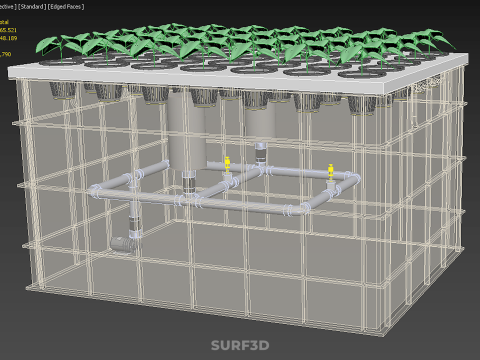

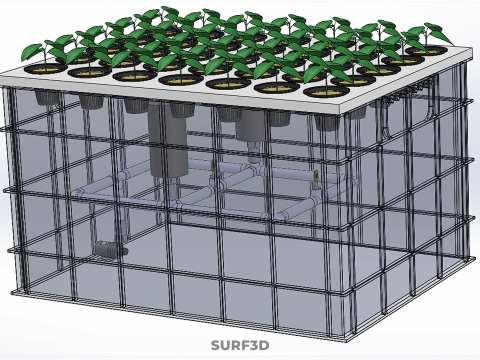

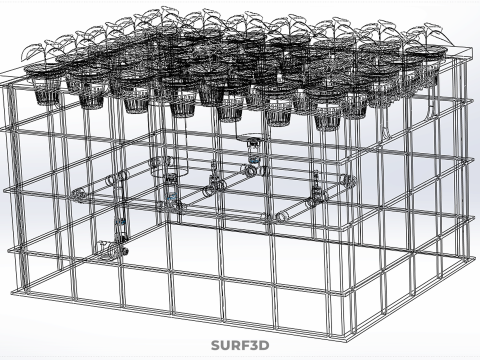

SYSTEM ROZPYLANIA SKŁADNIKÓW ODŻYWCZYCH Z KOMORĄ MGŁY W GOSPODARSTWIE AEROPONICZNYM Model 3D

- Poproś autora o wsparcie produktu

- Dostępne formaty:

- ID produktu:608768

- Data: 2025-10-31

- Wielokąty:465521

- Wierzchołki:348189

- Model animowany:No

- Tekstury:No

- Oparty na szkielecie:No

- Materiał:

- Low-poly:No

- Kolekcja:No

- UVW mapping:No

- Plugins Used:No

- Gotowy do wydruku:No

- 3D Scan:No

- Adult content:No

- PBR:No

- AI Szkolenie:No

- Geometria:Poly NURBS

- Unwrapped UVs:Unknown

- Liczba wyświetleń:176

Opis

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

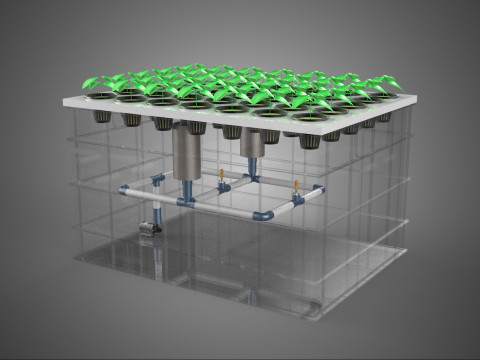

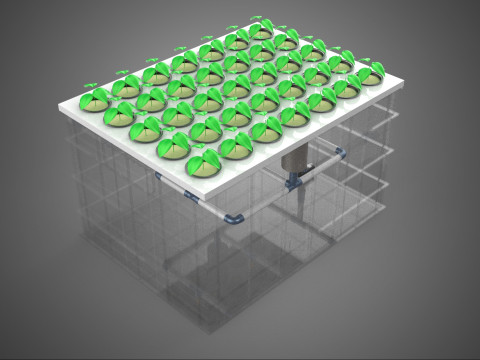

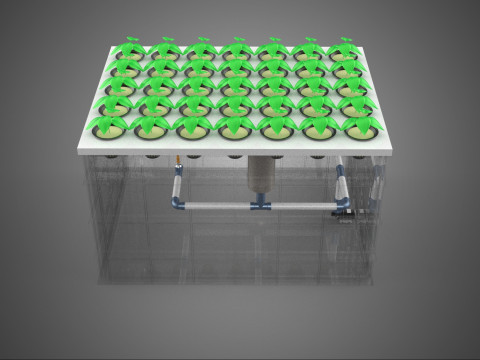

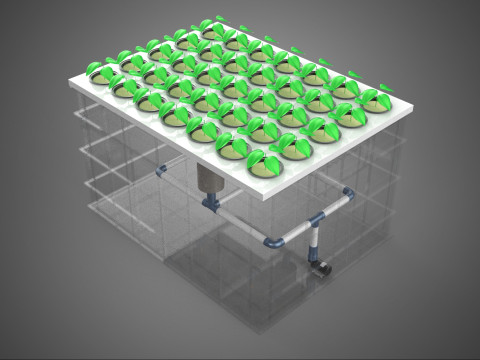

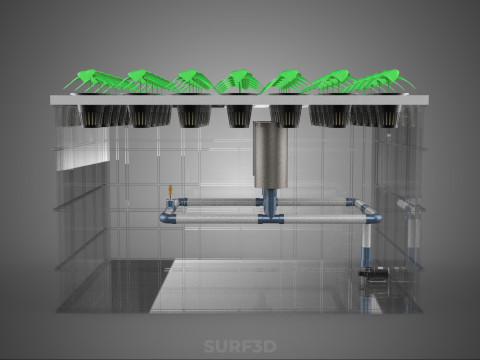

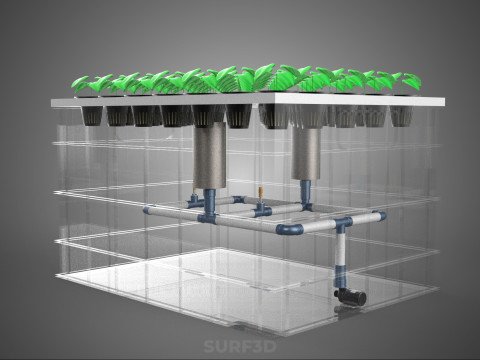

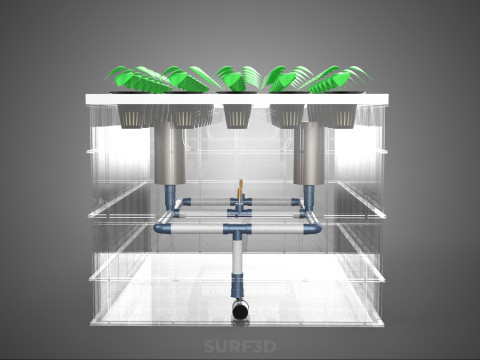

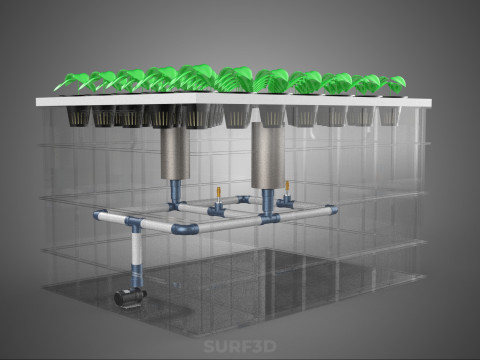

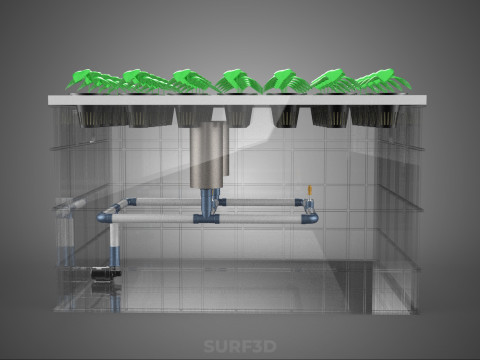

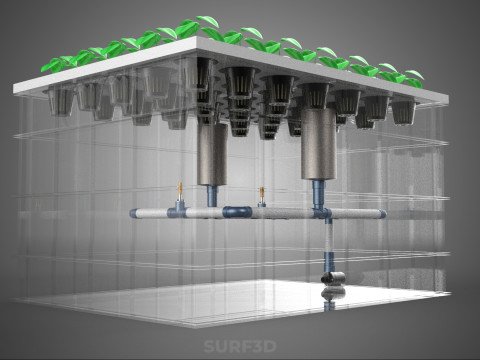

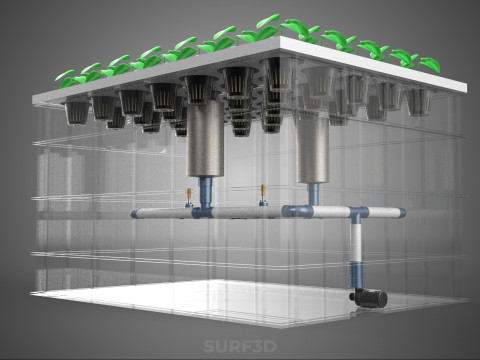

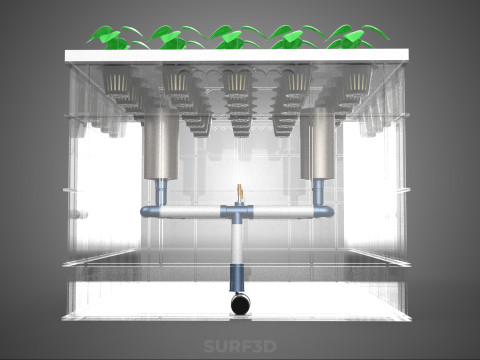

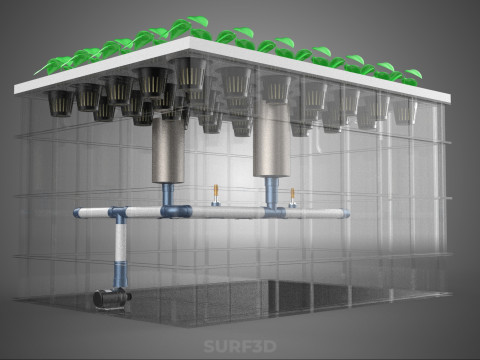

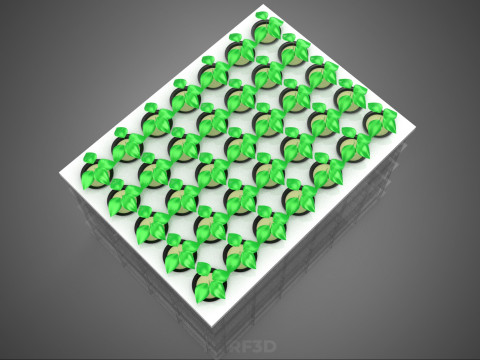

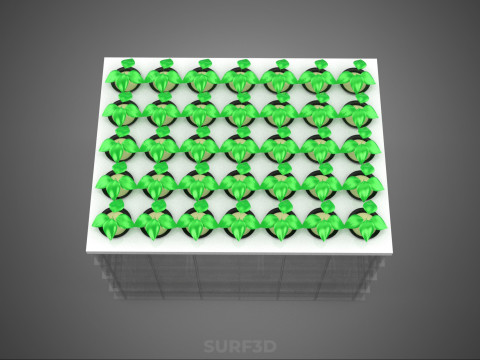

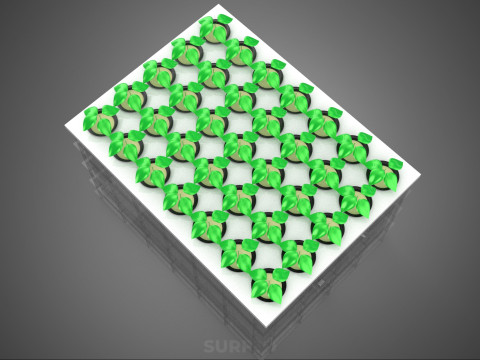

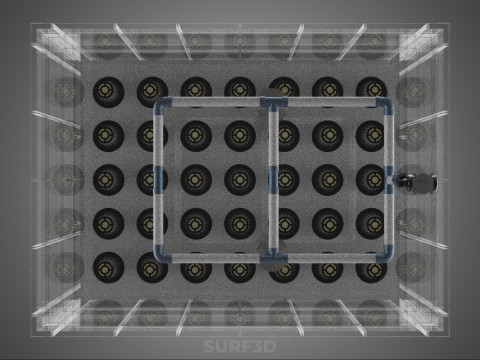

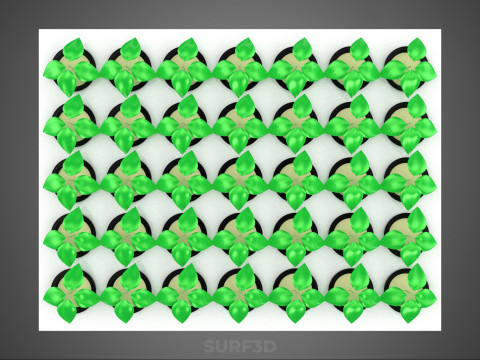

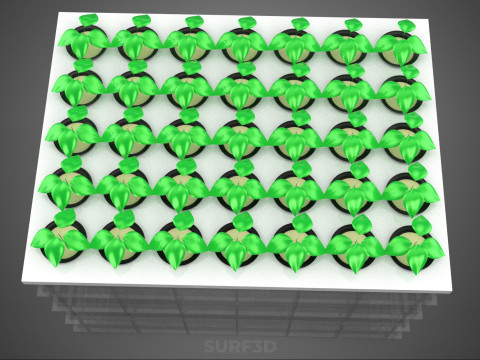

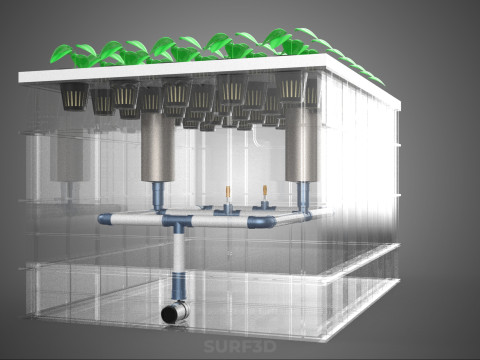

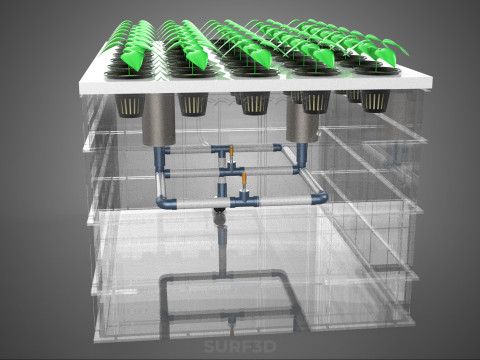

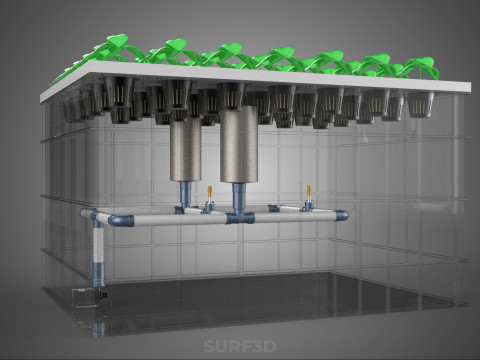

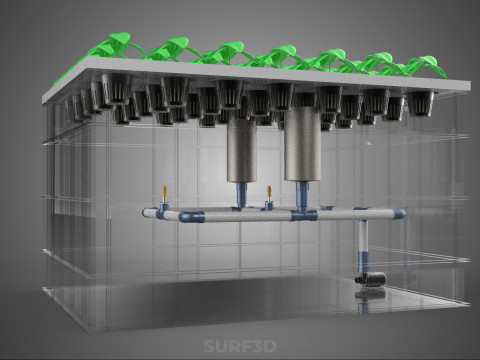

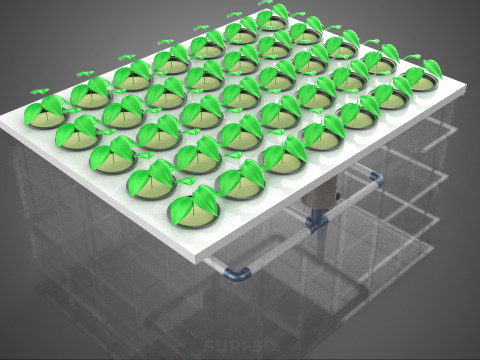

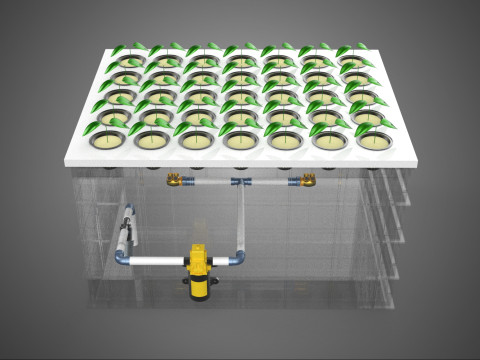

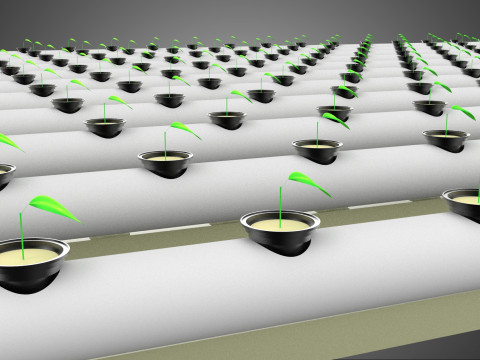

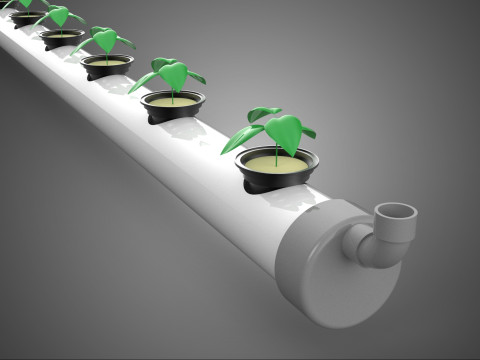

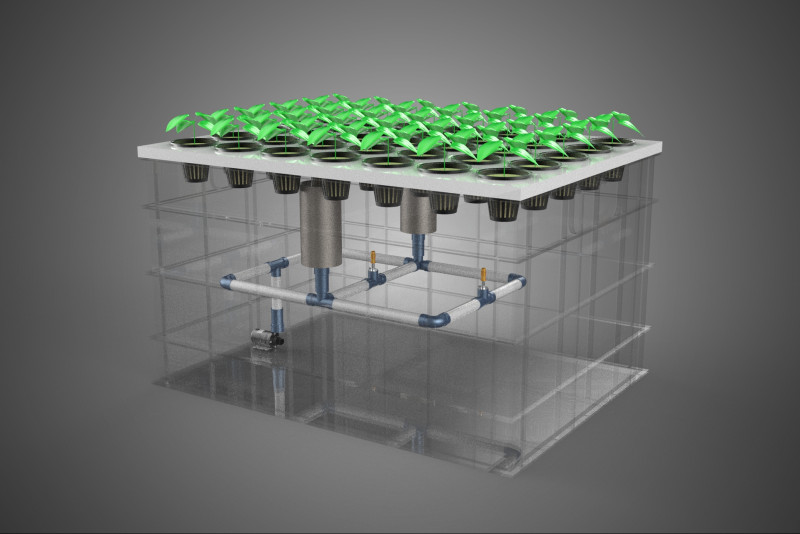

The Aeroponic Farm Misting Chamber Nutrient Delivery Sprayer System constitutes the critical mechanical and hydraulic infrastructure responsible for administering nutrient-rich aqueous solutions to the suspended root systems of crops in controlled environment agriculture (CEA). This sophisticated apparatus is central to high-pressure aeroponics (HPA), a method of soilless cultivation defined by the continuous or intermittent delivery of atomized nutrients, eliminating the need for a solid growth medium.

### Principle of Operation

The primary objective of the sprayer system is the conversion of bulk nutrient solution into a fine aerosolized mist. This mist, typically composed of droplets ranging in diameter from 5 to 50 micrometers (µm), maximizes the surface area contact between the nutrient solution and the plant roots while simultaneously ensuring maximum oxygen exposure within the root zone enclosure (the misting chamber).

Operation begins with the nutrient solution—a carefully calibrated mixture of water, macronutrients (Nitrogen, Phosphorus, Potassium), and micronutrients—stored in a reservoir. Unlike low-pressure systems which rely on foggers or standard spray heads, HPA systems necessitate high pressures, typically operating between 60 to 90 pounds per square inch (psi), or 413 to 620 kilopascals (kPa).

A high-pressure diaphragm or piston pump draws the solution from the reservoir and delivers it through specialized, fine-bore tubing to the atomization nozzles situated within the misting chamber. The pressure, often stabilized by a hydro-pneumatic accumulator, ensures that the nozzles produce the required small droplet size crucial for effective root respiration and rapid nutrient assimilation. Delivery is generally programmed in short bursts (e.g., 5-second bursts every 5 to 15 minutes) to prevent desiccation while maintaining high levels of dissolved oxygen (DO) around the roots.

### System Components

The integrity and efficiency of the aeroponic sprayer system rely on several interconnected components:

1. **High-Pressure Pump Unit:** Typically a positive displacement pump (diaphragm or piston) selected for its capacity to maintain consistent pressure under continuous operational cycles.

2. **Nutrient Reservoir and Dosing System:** Stores the stock solution. Often paired with precision sensors and peristaltic pumps to monitor and automatically adjust pH (potential of Hydrogen) and EC (Electrical Conductivity) levels, ensuring the solution remains within the optimal range for plant species and growth stage.

3. **Hydro-Pneumatic Accumulator:** A pressure vessel containing a pressurized gas (usually air or nitrogen) separated from the fluid by a bladder or diaphragm. This component dampens pump pulsation, stabilizes system pressure, and prevents "water hammer" effects, prolonging the life of the nozzles and seals.

4. **Atomization Nozzles:** The critical delivery mechanism. These precision components, often constructed from stainless steel or specialized ceramics, feature small orifices designed specifically to shear the pressurized liquid into the target mist spectrum (5–50 µm). They are prone to mineral clogging and require frequent maintenance or automated cleaning cycles.

5. **Tubing and Fittings:** Must be chemically inert (e.g., food-grade plastics or stainless steel) and rated for the high operating pressures.

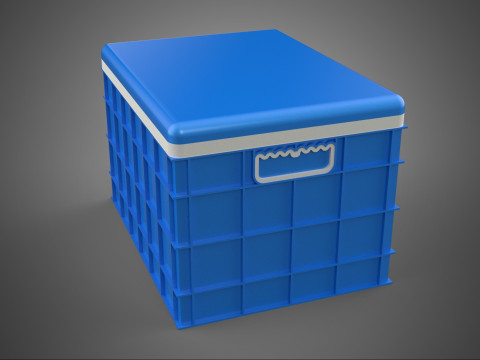

6. **Misting Chamber (Root Zone Enclosure):** The sealed, opaque vessel where the root system is suspended. Opaqueness is essential to prevent light intrusion, which could promote algal growth and compromise the sterility of the root environment.

7. **Electronic Control Unit (ECU):** A programmable logic controller (PLC) or dedicated microcontroller manages the pump cycles, monitors environmental parameters (temperature, humidity within the chamber), and interfaces with the pH/EC dosing equipment.

### Technical Advantages and Maintenance

The precision inherent in the Misting Chamber Nutrient Delivery Sprayer System offers significant advantages over deep water culture (DWC) or drip hydroponics, including reduced water consumption (up to 98% less than traditional farming), high nutrient efficiency, and maximized yield density due to optimal oxygenation.

Due to the sensitive nature of the fine atomization nozzles and the sterile environment required for root health, rigorous maintenance protocols are essential. Maintenance includes periodic flushing of the system with low-acid solutions to prevent mineral precipitation, sterilization of the reservoir and chambers to mitigate pathogens (e.g., *Pythium*), and regular calibration of pH and EC sensors. Failure to maintain the system integrity can lead to nozzle clogging, inadequate nutrient uptake, or the proliferation of root rot diseases, severely impacting crop performance.

KEYWORDS: Aeroponics, High-Pressure Aeroponics (HPA), Nutrient Delivery, Atomization Nozzle, Misting Chamber, Root Zone, CEA, Hydro-Pneumatic Accumulator, Solenoid Valve, Diaphragm Pump, Precision Agriculture, Droplet Size, Micrometer, Controlled Environment, Nutrient Film Technique (NFT), Deep Water Culture (DWC), Sterilization, pH Monitoring, Electrical Conductivity (EC), Pump Cycling, Aerosol, Suspension Culture, Hydroponics, Root Respiration, Water Efficiency, Sensor Calibration, Closed-Loop System, Vertical Farming, Mineral Salts, System Maintenance.

Potrzebujesz plik w innym formacie?

Jeśli potrzebny Ci plik w innym formacie, zgłoś taką potrzebę przez opcję Support Ticket Konwertujemy produkty na następujące formaty: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Dowolna konwersja formatuNie konwertujemy scen 3D oraz formaty takie jak .step, .iges, .stp, .sldprt.!

Informacje o użytkowaniu

SYSTEM ROZPYLANIA SKŁADNIKÓW ODŻYWCZYCH Z KOMORĄ MGŁY W GOSPODARSTWIE AEROPONICZNYM - Możesz używać tego bezpłatnego modelu 3D zarówno do celów osobistych, jak i komercyjnych, zgodnie z Licencją Podstawową lub Rozszerzoną.Licencja Podstawowa obejmuje większość standardowych przypadków użycia, w tym reklamy cyfrowe, projekty projektowe i wizualizacyjne, firmowe konta w mediach społecznościowych, aplikacje natywne, aplikacje internetowe, gry wideo oraz fizyczne lub cyfrowe produkty końcowe (zarówno bezpłatne, jak i sprzedawane).

Licencja Rozszerzona obejmuje wszystkie prawa udzielone na mocy Licencji Podstawowej, bez ograniczeń użytkowania i pozwala na wykorzystanie modelu 3D w nieograniczonej liczbie projektów komercyjnych na warunkach bezpłatności.

Czytaj więcej

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी