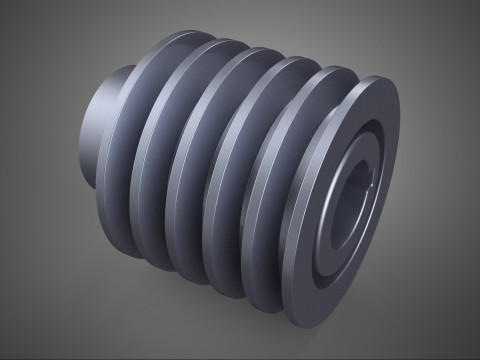

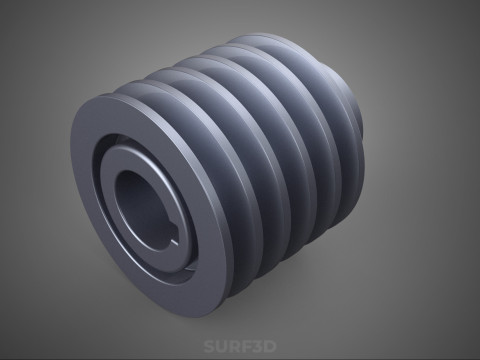

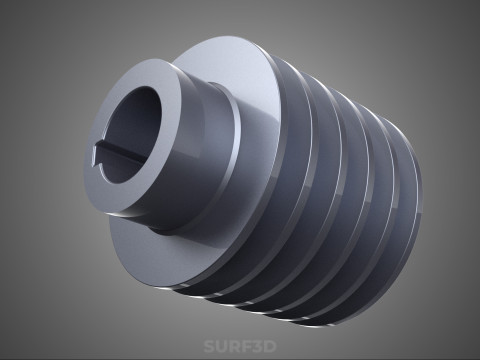

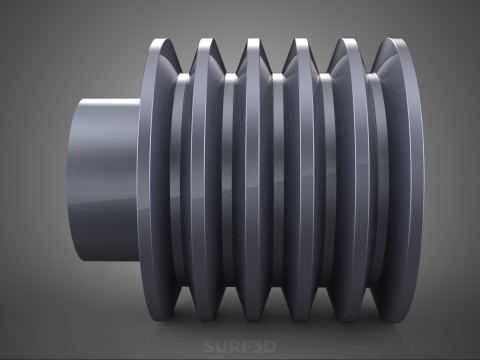

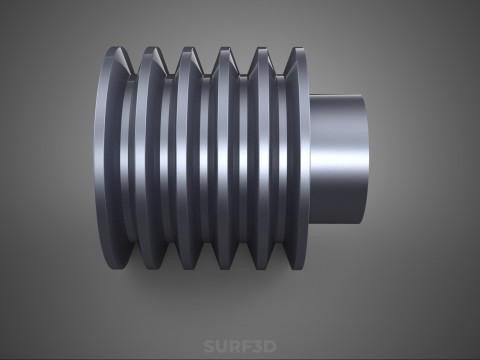

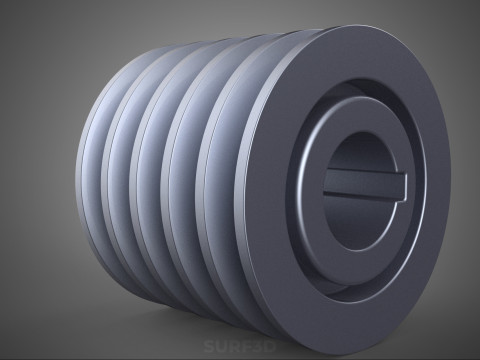

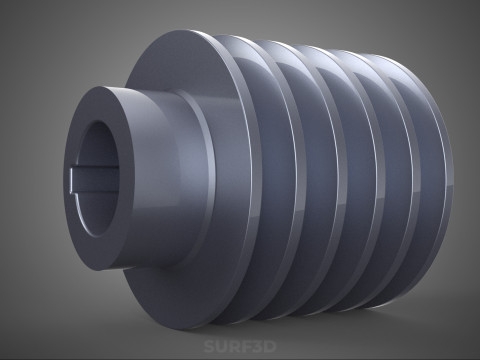

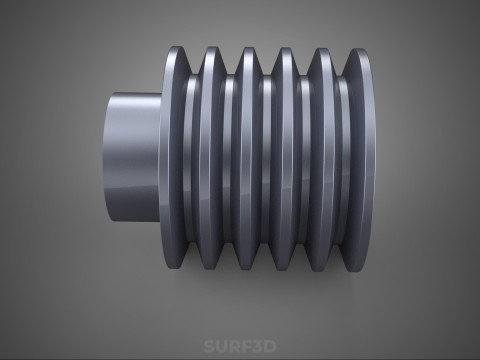

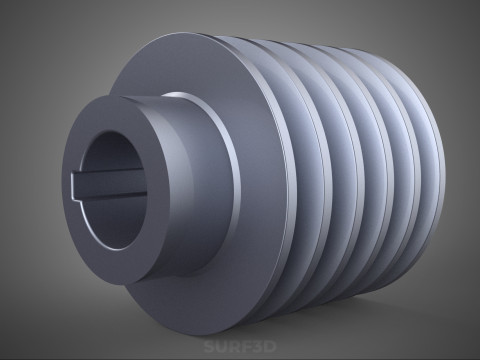

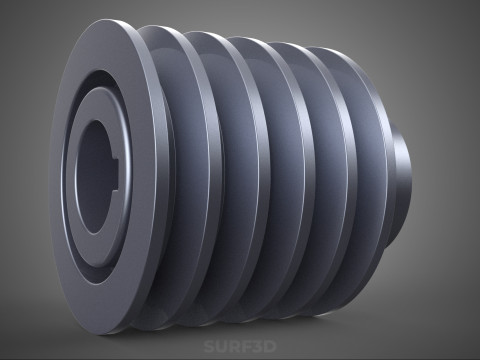

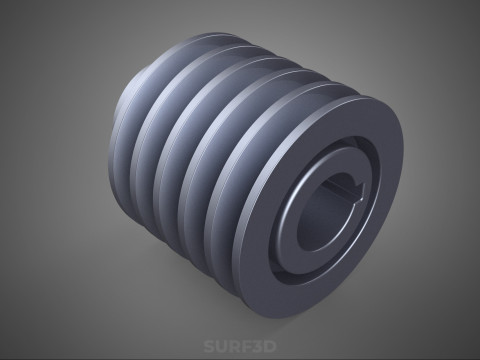

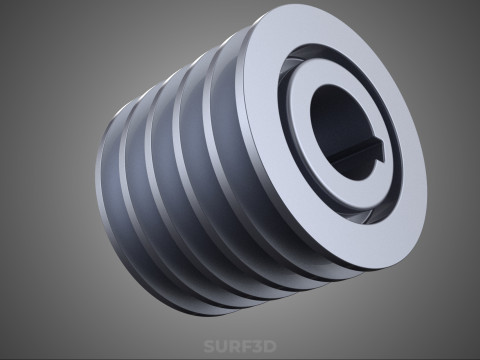

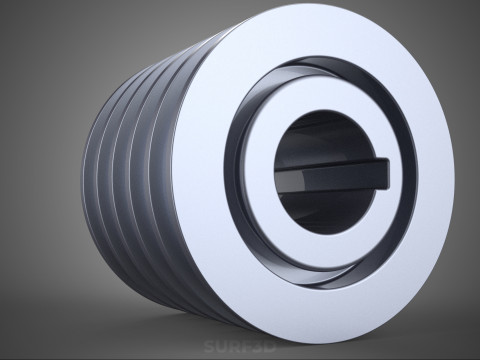

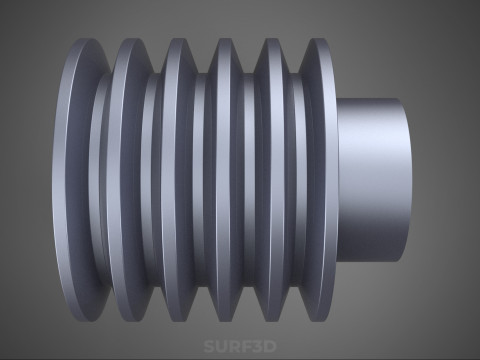

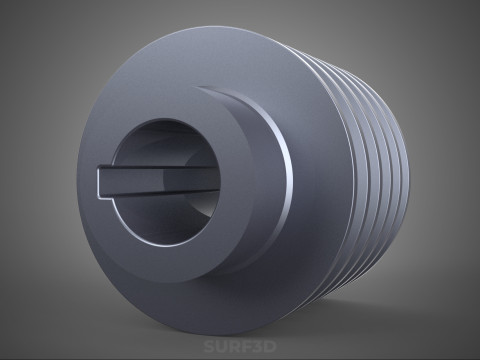

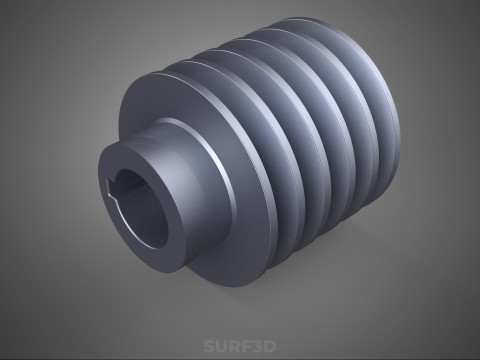

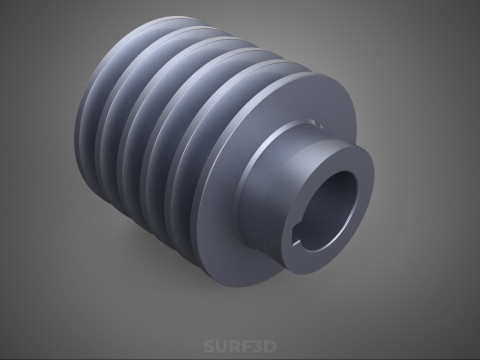

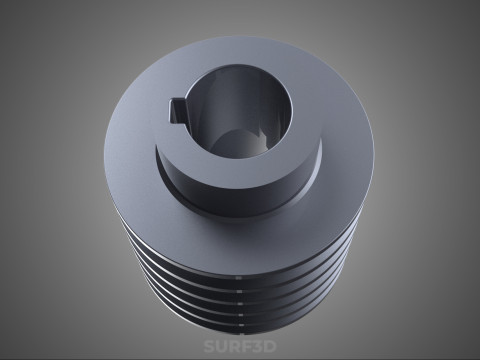

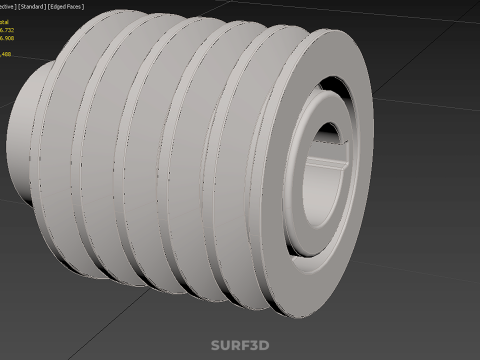

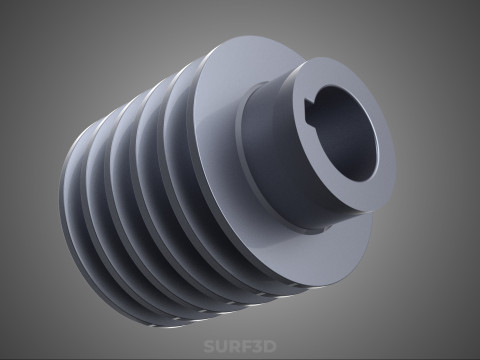

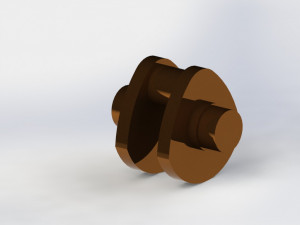

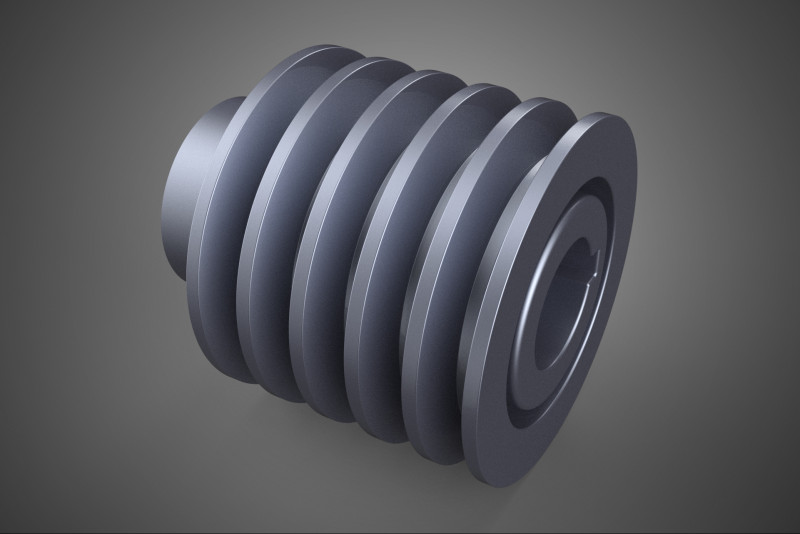

СТАНДАРТНЫЙ 5 ШКИВ С ПЯТЬЮ ПЯТЬЮ КАНАВКАМИ, ШКИВ, КОЛЕСНЫЙ РЕМЕНЬ 3D Модель

- Запросить поддержку продукта

- Доступные форматы:

- ID Продукта:622032

- Дата: 2026-01-08

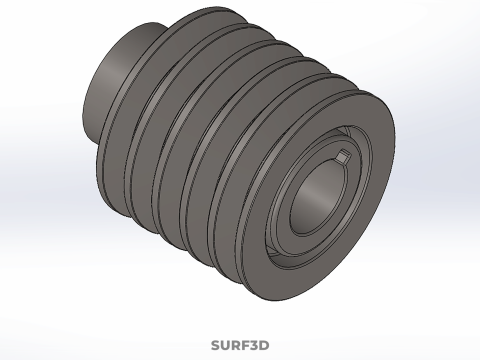

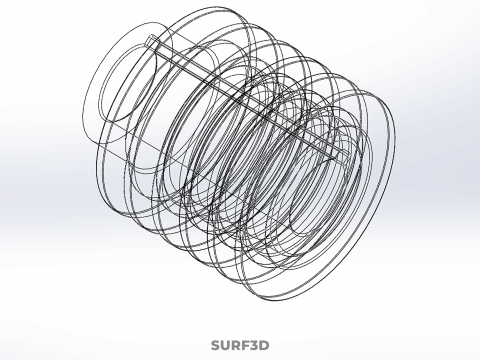

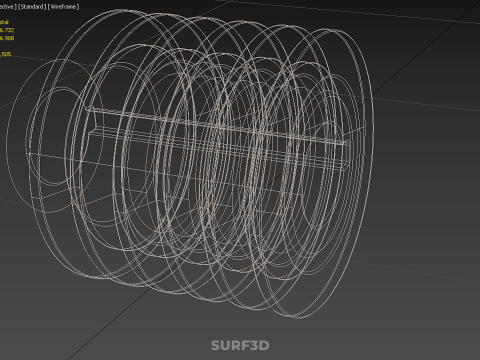

- Полигоны:26732

- Вершины:16908

- Анимированная:No

- Текстуры:No

- Скелет:No

- Материалы:

- Лоу-поли:No

- Коллекция:No

- UVW mapping:No

- Плагины:No

- Для печати:No

- 3D Скан:No

- Контент для взрослых:No

- PBR:No

- AI Обучение:No

- Геометрия:Poly NURBS

- Unwrapped UVs:Unknown

- Просмотры:214

Описание

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

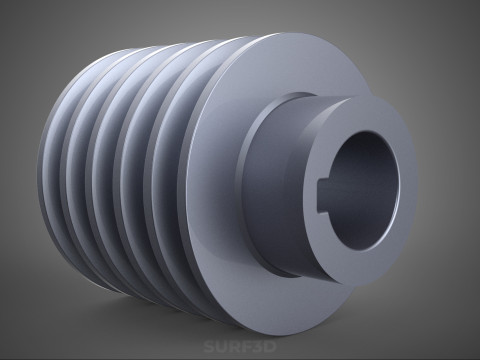

The Standard Five (5) Quintuple Groove Track Pulley Sheave Wheel Belt, often referred to as a five-rib sheave or multiplex pulley, is a specialized mechanical component utilized in high-power, high-torque industrial power transmission systems. This apparatus is designed to accommodate five separate, contiguous V-belts or banded belts, enabling the distribution of substantial radial and torsional loads across multiple parallel interfaces.

### Nomenclature and Configuration

The term "quintuple groove" denotes the presence of five precisely machined circumferential channels, or grooves, on the sheave’s periphery. These grooves are engineered to specific dimensional standards (e.g., Classical A, B, C, D profiles, or Narrow 3V, 5V, 8V profiles, standardized by organizations such as ISO and ANSI/ARPM) corresponding to the cross-sectional geometry of the intended V-belt. The design is crucial for achieving high power density and system redundancy.

Unlike single-groove pulleys used for lighter duties, the quintuple sheave is characterized by exceptional structural rigidity and an increased effective surface area for frictional engagement. The primary function of employing multiple belts is three-fold:

1. **Load Distribution:** Dividing the total required horsepower across five belts significantly reduces the mechanical strain and heat generation on any single belt.

2. **Reliability and Redundancy:** In the event of a single belt failure, the remaining four belts can continue to transmit power, allowing for planned maintenance rather than catastrophic shutdown.

3. **Increased Torque Capacity:** The total transmissible torque is proportional to the number of engaged belts, making the quintuple configuration ideal for driving high-inertia loads such as crushers, large compressors, or centralized HVAC systems.

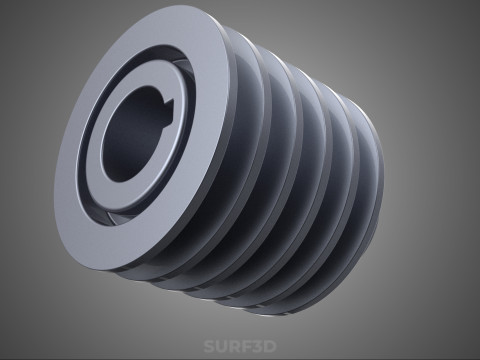

### Mechanical Design and Operation

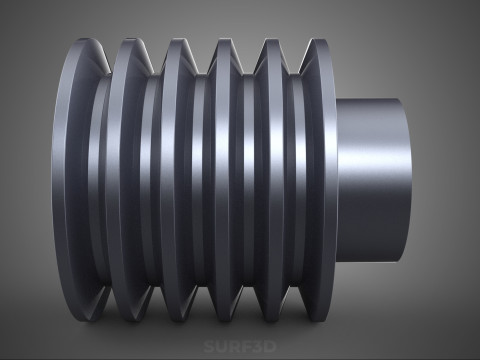

The power transmission mechanism relies fundamentally on the wedging action created by the angular sides of the V-belt pressing into the corresponding angled walls of the groove. This wedging multiplies the effective coefficient of friction, allowing for high torque transfer with minimal belt tension relative to flat belts.

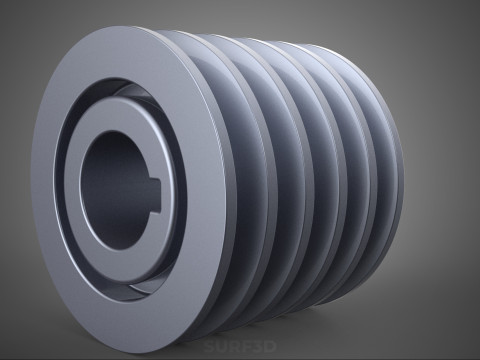

Critical geometric parameters include the **pitch diameter** (the theoretical diameter where the pitch line of the belt lies), the **outside diameter (OD)**, and the precise **center-to-center spacing** of the grooves. Precision machining and tight tolerance control are mandatory to ensure that the tension and load are evenly shared among all five belts. Discrepancies in pitch diameter or groove spacing lead to unequal load distribution, potentially causing premature failure of the highest-tensioned belt.

Quintuple sheaves designed for high operational speeds typically undergo **dynamic balancing** procedures (often rated to ISO G16 or G6.3 standards) to minimize vibration, reduce noise, and prevent excessive bearing wear caused by centrifugal imbalance.

### Materials and Manufacturing

Due to the demands of heavy industrial environments, quintuple groove sheaves are typically manufactured from materials exhibiting high strength, durability, and resistance to wear. Common materials include:

* **Cast Iron (e.g., Class 30 or 40 Gray Cast Iron):** Offers excellent dampening characteristics, rigidity, and cost-effectiveness for moderate to high-speed applications.

* **Ductile Iron or Forged Steel:** Utilized in extreme high-torque applications or those subject to heavy shock loading.

* **Aluminum Alloys:** Reserved for applications requiring reduced weight and rotational inertia, often featuring a protective hard-anodized coating for increased surface hardness and wear resistance.

Manufacturing processes involve casting or forging followed by precision CNC machining of the bore, keyway, and crucial groove profiles. The finished sheave is commonly mounted onto the driving or driven shaft using tapered bushings (e.g., Taper-Lock, QD, or Split Taper systems) to ensure secure, concentric locking and facilitate easy installation and removal.

KEYWORDS: Quintuple Groove, Five-Rib Sheave, Multi-Groove Pulley, V-Belt Drive, Power Transmission, Torsional Load, High Torque, Quintuple Track, Drive Component, Mechanical Sheave, V-Belt Profile, Dynamic Balancing, Pitch Diameter, Outside Diameter, Industrial Machinery, Load Distribution, Redundancy, Cast Iron Sheave, Taper Bushing, Wedging Action, Synchronous Drive, Shaft Mounting, Groove Spacing, Centrifugal Force, Belt Tensioning, Drive Ratio, Industrial Pump, Compressor Drive, Belt Track, Mechanical Rigidity.

Нужно больше форматов?

Если вам необходим другой формат, пожалуйста, сделайте запрос при помощи тикета поддержки. Мы можем cконвертировать 3D модели в такие форматы: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Бесплатное конвертированиеМы не конвертируем 3d сцены и такие форматы, как .step, .iges, .stp, .sldprt и т. д.!

Информация об использовании

СТАНДАРТНЫЙ 5 ШКИВ С ПЯТЬЮ ПЯТЬЮ КАНАВКАМИ, ШКИВ, КОЛЕСНЫЙ РЕМЕНЬ - Вы можете использовать эту бесплатную 3D модель как в личных, так и в коммерческих целях в соответствии с Базовой или Расширенной лицензией.Базовая лицензия охватывает большинство стандартных вариантов использования, включая цифровую рекламу, проекты дизайна и визуализации, бизнес-аккаунты в социальных сетях, нативные приложения, веб-приложения, видеоигры, а также физические или цифровые конечные продукты (как бесплатные, так и платные).

Расширенная лицензия включает в себя все права, предоставленные в рамках Базовой лицензии, без ограничений по использованию и позволяет использовать 3D модель в неограниченном количестве коммерческих проектов на условиях безвозмездной оплаты.

Подробней

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский 中國

中國 हिंदी

हिंदी