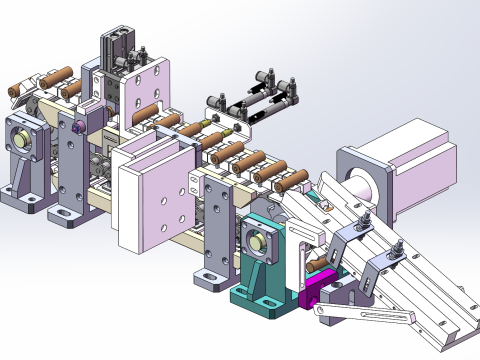

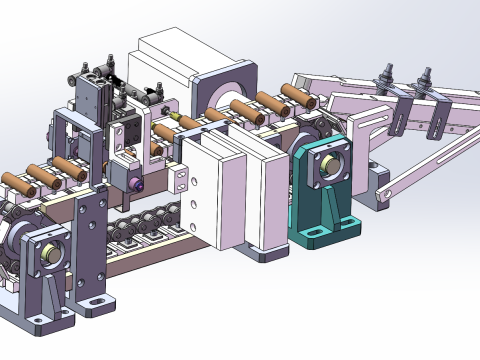

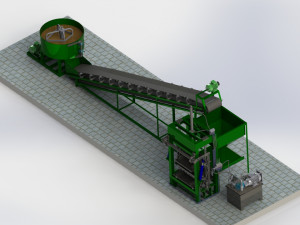

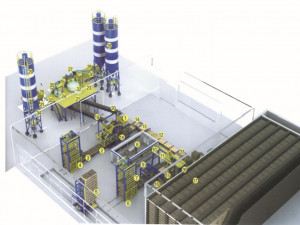

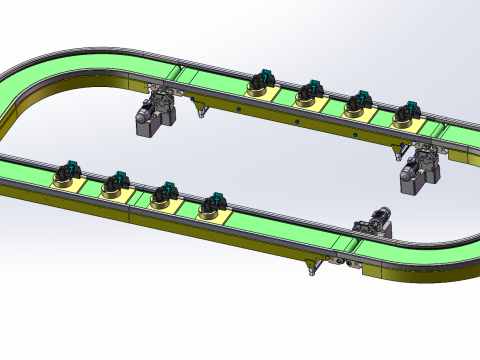

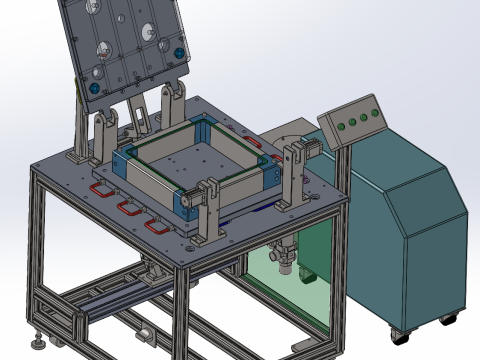

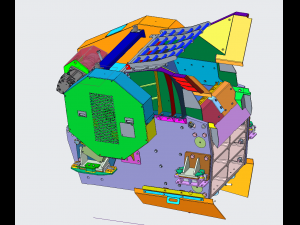

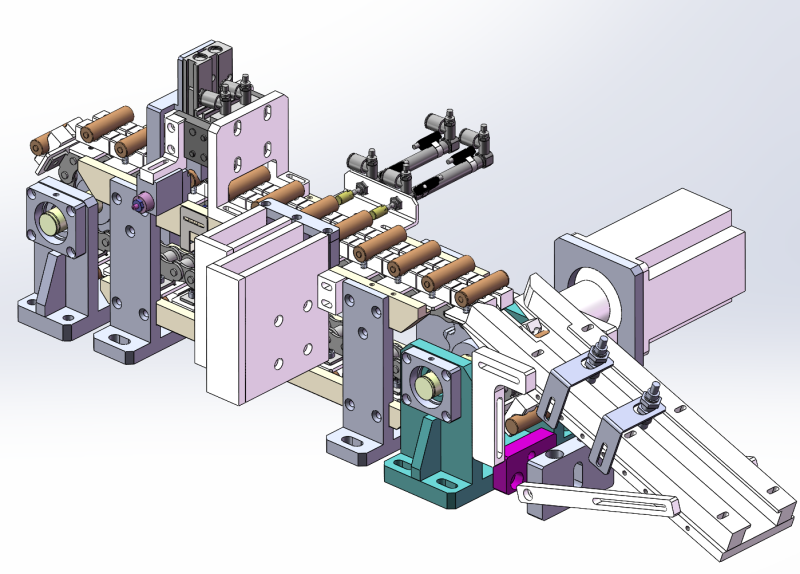

电池标签涂布设备设计 3D 模型

- 请求作者的产品支持

- 可用的格式:

- 项目 ID:614633

- 日期: 2025-11-29

- 动画:No

- 纹理:No

- 操纵:No

- 材料:

- 低聚:No

- 集合:No

- UVW 贴图:No

- 使用插件:No

- 打印准备:No

- 3D扫描:No

- 成人内容:No

- PBR:No

- 人工智能培训:No

- 几何:Polygonal

- 包装 UVs:Unknown

- 日期:34

描述

The design of battery label coating equipment is a specialized device for printing and coating labels on the surface of batteries. The design of this device needs to consider factors such as the size, shape, and material of the battery to ensure that the label can be accurately attached to the surface of the battery and has good adhesion and durability.

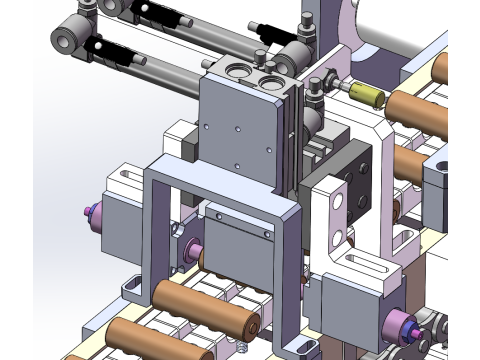

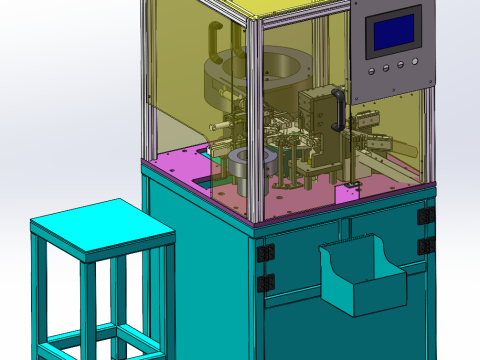

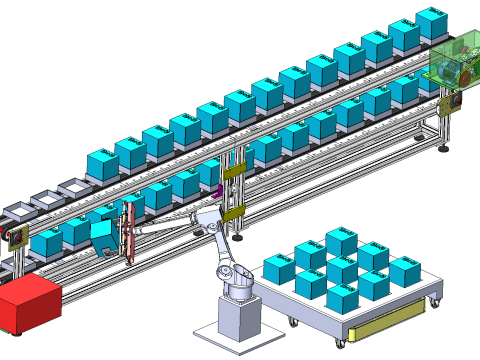

Firstly, the battery label coating equipment needs to have a high-precision positioning system to ensure that the label can be accurately attached to the surface of the battery. This can be achieved through the use of advanced sensors and control systems, such as laser positioning or optical recognition systems. These systems can monitor the position and orientation of the battery in real time and make adjustments as needed to ensure accurate labeling.

Secondly, the battery label coating equipment needs to have an efficient printing and coating system. This can be achieved through the use of high-speed inkjet printing technology or thermal transfer printing technology. These technologies can quickly print high-quality labels on the surface of batteries, and have the characteristics of high speed and efficiency. At the same time, the coating system also needs to have the ability to apply uniformly to ensure consistent color and quality of the labels.

In addition, battery label coating equipment also needs to have an automated control system to improve production efficiency and reduce manual operations. This can be achieved through the use of PLC (Programmable Logic Controller) or industrial computers. These control systems can achieve automated operation of equipment, including functions such as automatic loading, automatic printing, automatic painting, and automatic unloading. This can reduce manual errors and improve production efficiency.

Finally, the battery label coating equipment also needs to have a safety protection system to ensure the safety of operators. This can be achieved by setting up safety devices such as emergency stop buttons, safety barriers, and protective covers. These devices can stop the operation of the equipment in a timely manner in case of equipment failure or operator misoperation, to protect the safety of the operators.

In summary, the design of battery label coating equipment needs to consider the characteristics and requirements of the battery, and combine advanced positioning systems, printing and coating systems, automation control systems, and safety protection systems to achieve efficient, accurate, and safe battery label printing and coating processes.

打印准备: 否需要更多的格式吗?

如果你需要一个不同的格式,请打开一个新的支持票和为此请求。我们可以转换到 3D 模型: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 免费格式转换我们不转换 3d 场景 以及 .step, .iges, .stp, .sldprt 等格式。!

使用信息

电池标签涂布设备设计 - 您可以根据基本许可或扩展许可,将此免版税 3D 模型用于个人或商业用途。基本许可涵盖大多数标准用例,包括数字广告、设计和可视化项目、商业社交媒体账户、原生应用、Web 应用、视频游戏以及实体或数字最终产品(免费和出售)。

扩展许可包含基本许可授予的所有权利,没有任何使用限制,并允许在免版税条款下将 3D 模型用于无限的商业项目。

阅读更多

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी