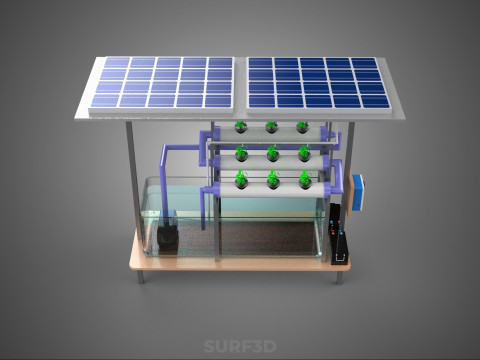

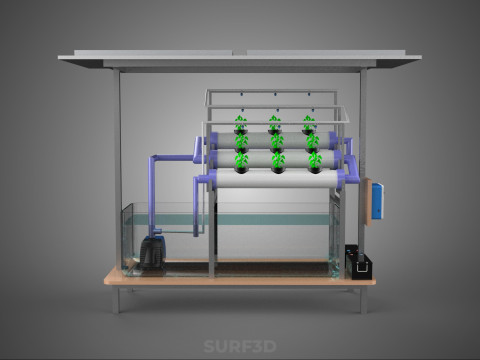

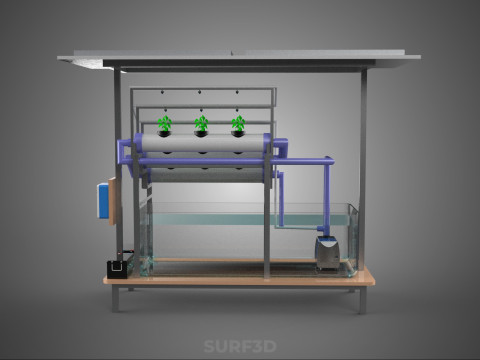

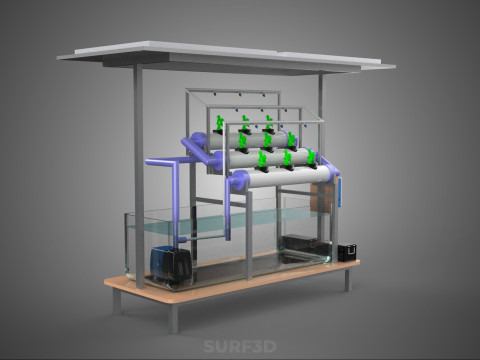

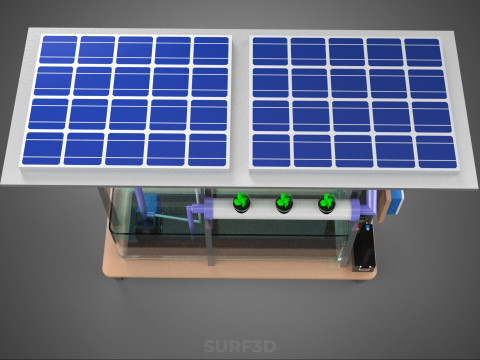

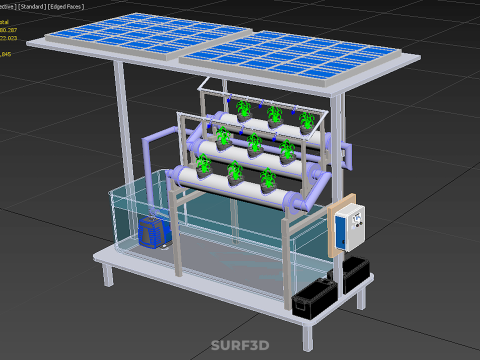

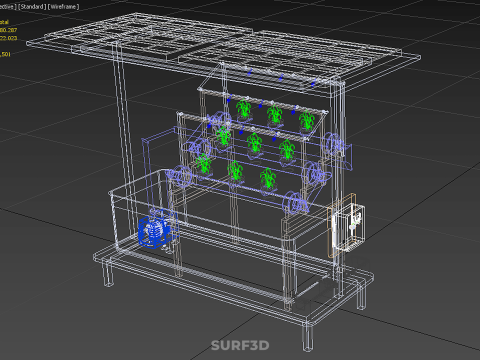

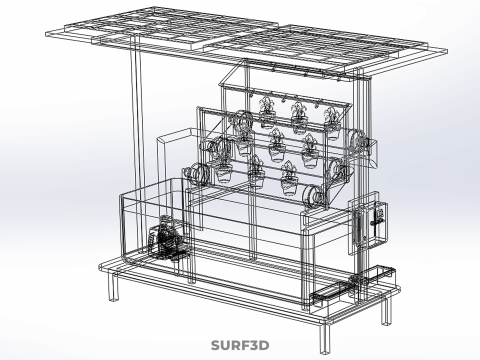

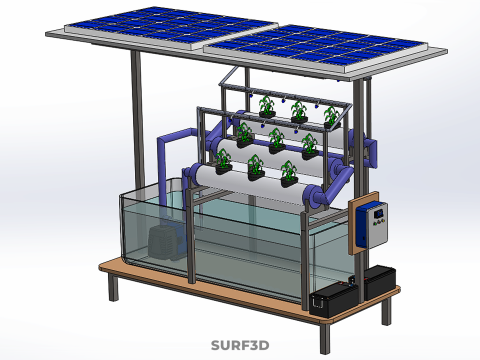

HYDROPONIC PANEL SOLAR CELL POWERED FARM PLANT WATER PUMP SPRAY 3D 模型

- 可用的格式: Rhinoceros (.3dm) 13.70 MB3D Studio (.3ds) 1.96 MBBlender3D (.blend) 5.22 MBCollada (.dae) 4.29 MBAutodesk AutoCAD (.dwg) 5.85 MBAutodesk FBX (.fbx) 7.32 MBGLB (.glb / .gltf) 2.51 MBIGES (.iges) 3.25 MBAutodesk 3DS MAX (.max) 11.62 MBWavefront OBJ (.obj) 3.43 MBACIS(.sat) 5.68 MBSketchUp (.skp) 3.79 MBSTEP (.step) 3.65 MBStereolithography (.stl) 4.05 MB

- 多边形:280287

- 顶点:222023

- 动画:No

- 纹理:No

- 操纵:No

- 材料:

- 低聚:No

- 集合:No

- UVW 贴图:No

- 使用插件:No

- 打印准备:No

- 3D扫描:No

- 成人内容:No

- PBR:No

- 人工智能培训:No

- 几何:Poly NURBS

- 包装 UVs:Unknown

- 日期:151

- 日期: 2025-08-26

- 项目 ID:594962

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.***) – Provided for Rhino users

Model Info

• - All files are checked and ****ed for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

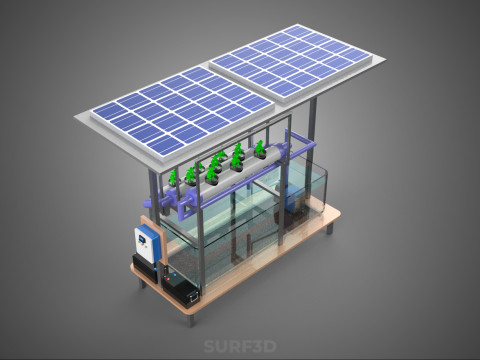

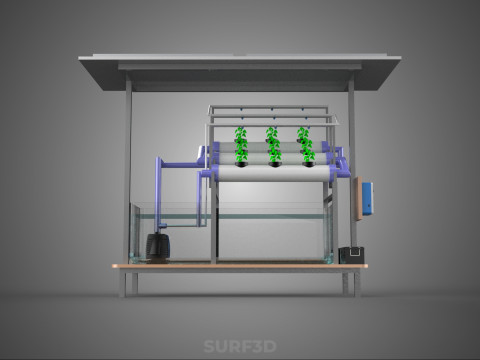

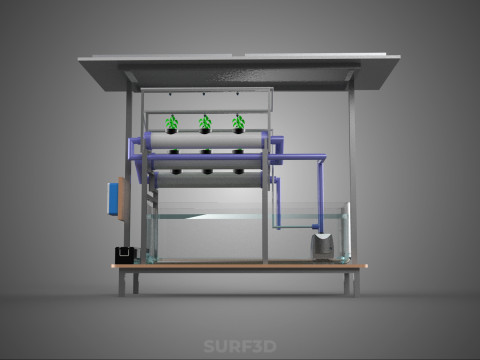

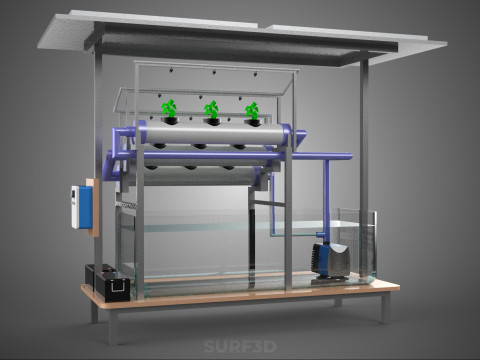

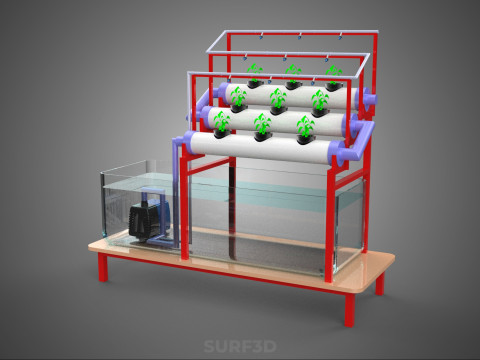

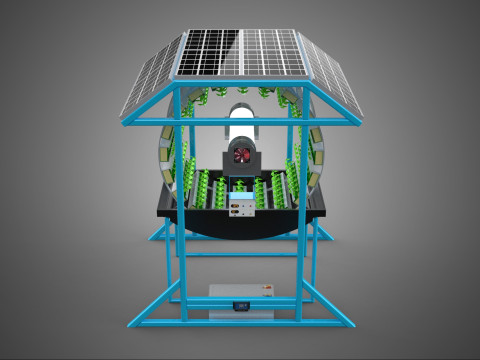

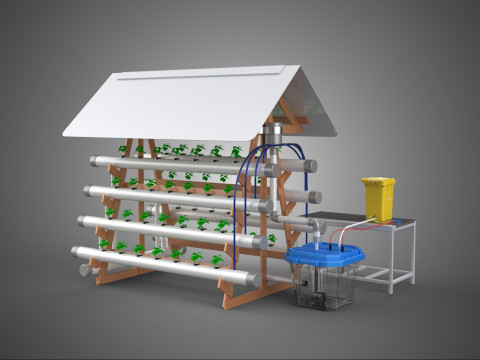

A "Hydroponic Panel Solar Cell Powered Farm Plant Water Pump Spray" system represents an advanced, integrated approach to sustainable agriculture, combining soilless cultivation with renewable energy and precise resource management. This technology is designed to maximize crop yield and efficiency while minimizing environmental impact and operational costs.

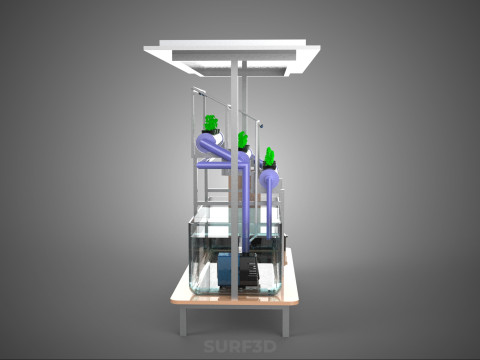

**System Overview:**

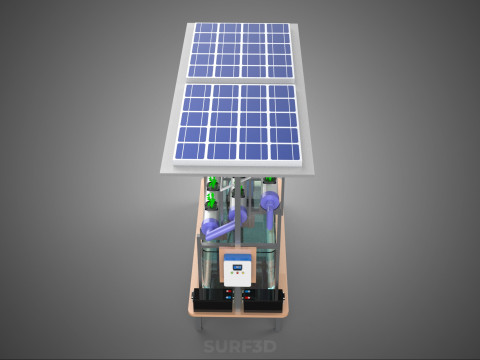

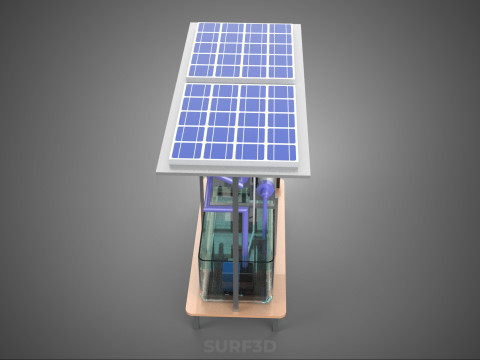

The system fundamentally comprises a hydroponic gro***g array, typically configured as panels; a photovoltaic (solar cell) system for electricity generation; a water pump responsible for circulating nutrient-rich water; and a spray or misting mechanism for precise delivery of this solution to plant roots. This integrated setup operates as a self-sustaining agricultural unit, often in a closed-loop configuration.

**Core Components and Functionality:**

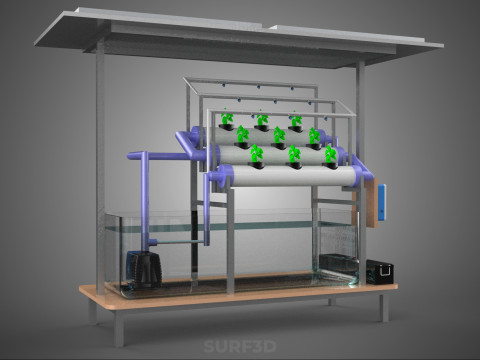

1. **Hydroponic Panel System:**

Hydroponics is a method of cultivating plants without soil, instead utilizing mineral nutrient solutions dissolved in water. "Hydroponic panels" often refer to modular gro***g structures, such as channels used in Nutrient Film Technique (NFT), rafts for Deep Water Culture (DWC), or stacked tiers for vertical farming. These panels provide the physical support for plants, allo***g their roots direct access to the circulating nutrient solution. NFT panels, for instance, facilitate the flow of a thin film of nutrient solution over the roots, ensuring oxygenation and nutrient absorption. The panel design aims to optimize space utilization, particularly in vertical farming applications, which significantly enhances yield per square foot. Advantages include substantial water savings (up to 90% compared to traditional field farming), accelerated growth rates, and reduced land requirements.

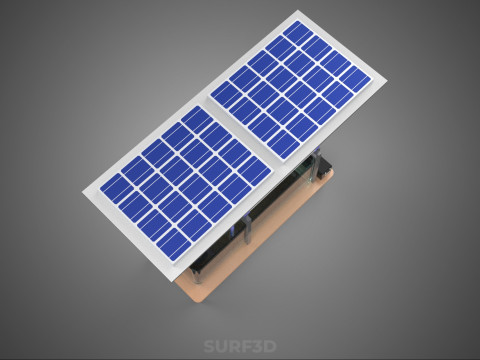

2. **Solar Cell Powered System:**

The energy independence of this farm system is achieved through "solar cell powered" components. Photovoltaic (PV) cells convert solar radiation directly into direct current (DC) electricity. A typical solar power setup for such a farm includes solar panels, a charge controller to regulate the flow of electricity, and often a battery bank to store surplus energy. The battery bank is crucial for ensuring continuous operation of the water pump and any auxiliary components (e.g., sensors, controllers) during periods of low sunlight, at night, or when peak demand exceeds instantaneous solar generation. This reliance on renewable energy dramatically reduces operational costs, eliminates dependence on grid electricity, and lowers the carbon footprint associated with food production.

3. **Plant Water Pump and Spray Mechanism:**

The "plant water pump" is a critical active component, responsible for circulating the nutrient solution. It draws the prepared solution from a reservoir and delivers it to the hydroponic panels. The "spray" mechanism refers to the method by which the nutrient solution is applied to the plants. This can manifest in several ways:

* **Aeroponics:** In this highly efficient method, the pump pressurizes the nutrient solution, which is then atomized into a fine mist by specialized nozzles and sprayed directly onto the roots of suspended plants. This maximizes oxygen availability to the roots and nutrient uptake.

* **Nutrient Film Technique (NFT) Distribution:** While NFT primarily involves a flo***g film, the initial distribution of the solution from the pump into the channels often utilizes a manifold system that can incorporate spray emitters or drip points to ensure an even, consistent flow across all plant roots.

* **Micro-Sprayers or Drip Emitters:** For certain hydroponic configurations or larger panel systems, the pump might supply a network of micro-sprayers or drip emitters that deliver precise, controlled volumes of nutrient solution directly to the root zone of individual plants.

The pump's efficiency and the precision of the spray or delivery mechanism are paramount for optimizing nutrient delivery, preventing water waste, and mitigating issues such as root disease or nutrient deficiencies.

**Integrated System Functionality:**

The entire "farm" operates as a self-contained, often automated, ecosystem. Solar panels generate electricity, which powers the water pump. The pump circulates the nutrient-rich solution from a dedicated reservoir, through the chosen spray or distribution method, to the roots of plants in the hydroponic panels. After passing over the roots, the solution drains back into the reservoir, completing a closed loop. This recirculation significantly conserves water and nutrients. More sophisticated systems often integrate sensors for monitoring parameters like pH, Electrical Conductivity (EC – indicating nutrient concentration), and water temperature, with microcontrollers automating pump schedules and nutrient adjustments to maintain optimal gro***g conditions.

**Advantages and Applications:**

This integrated system offers compelling benefits:

* **Sustainability:** Harnesses renewable solar energy and drastically reduces water and fertilizer consumption.

* **Resource Efficiency:** Optimizes gro***g space, enables cultivation in non-arable lands, and minimizes the need for pesticides.

* **Environmental Impact:** Decreases nutrient runoff, reduces transportation emissions (when localized), and lowers the overall carbon footprint of food production.

* **Yield and Quality:** Offers controlled gro***g environments that can lead to faster growth cycles, higher yields, and consistent crop quality.

* **Versatility:** Facilitates food production in diverse environments, including urban centers, arid regions, remote areas, and even indoor settings.

**Future Prospects:**

The convergence of hydroponics and solar power represents a vital pathway toward resilient and decentralized food production systems. Ongoing advancements in solar energy efficiency, battery storage, pump technology, and hydroponic design continue to enhance the viability and scalability of these systems.

如果你需要一个不同的格式,请打开一个新的支持票和为此请求。我们可以转换到 3D 模型: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 我们不转换 3d 场景 以及 .step, .iges, .stp, .sldprt 等格式。!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी