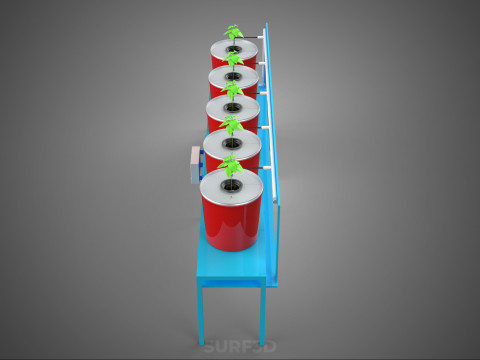

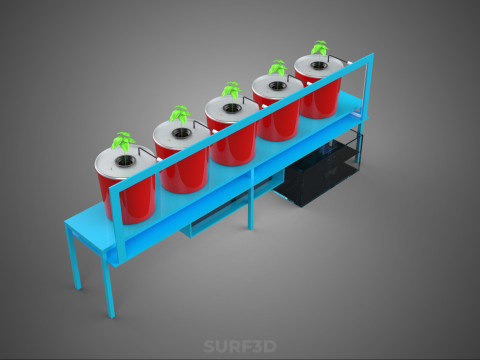

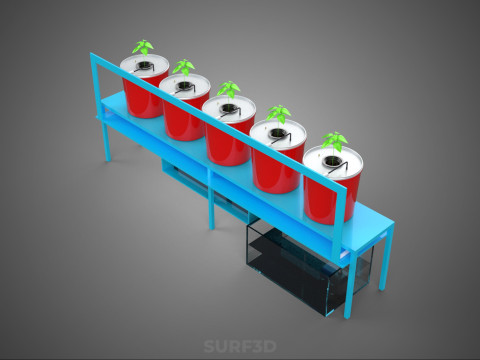

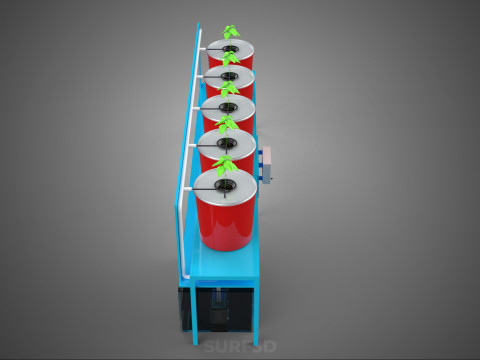

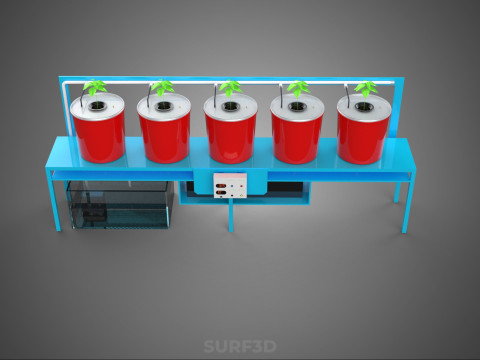

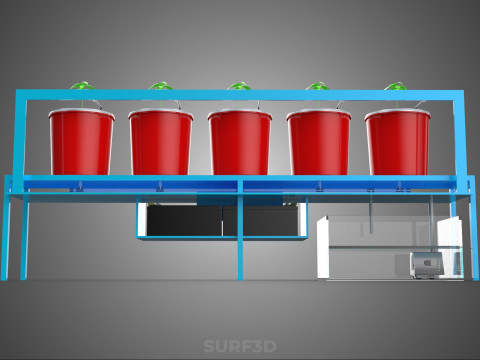

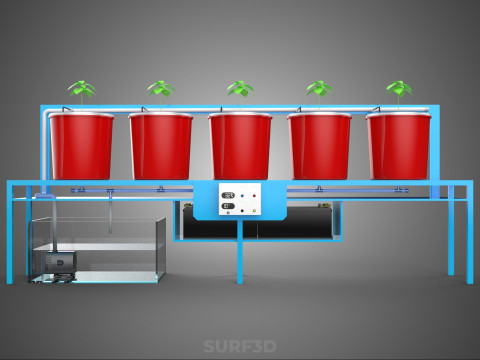

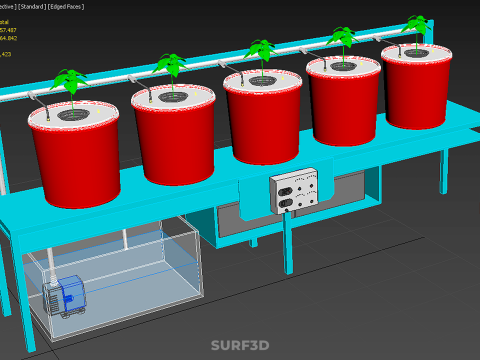

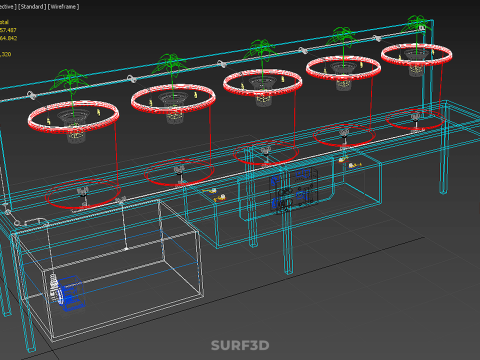

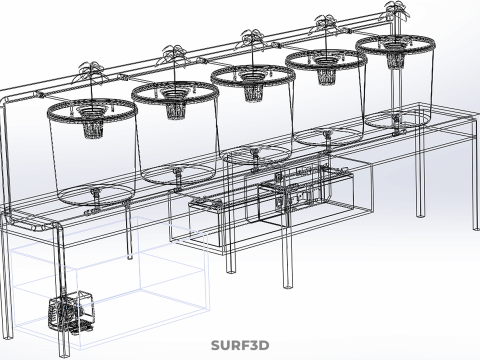

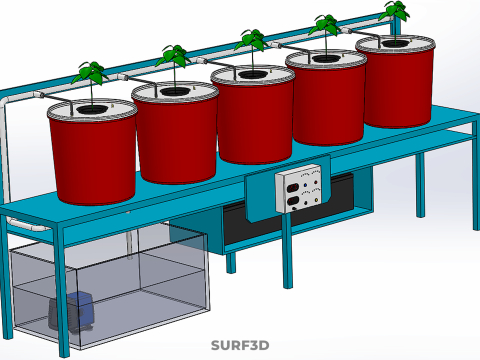

物联网智能控制荷兰桶水培系统设置花盆 3D 模型

- 请求作者的产品支持

- 可用的格式:

- 项目 ID:617587

- 日期: 2025-12-12

- 多边形:457487

- 顶点:364842

- 动画:No

- 纹理:No

- 操纵:No

- 材料:

- 低聚:No

- 集合:No

- UVW 贴图:No

- 使用插件:No

- 打印准备:No

- 3D扫描:No

- 成人内容:No

- PBR:No

- 人工智能培训:No

- 几何:Poly NURBS

- 包装 UVs:Unknown

- 日期:20

描述

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

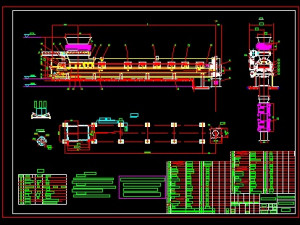

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

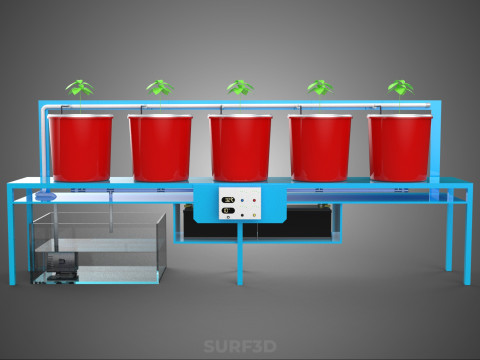

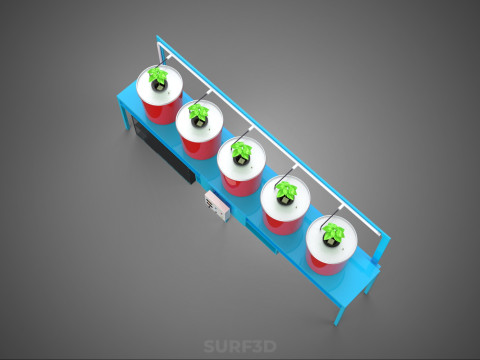

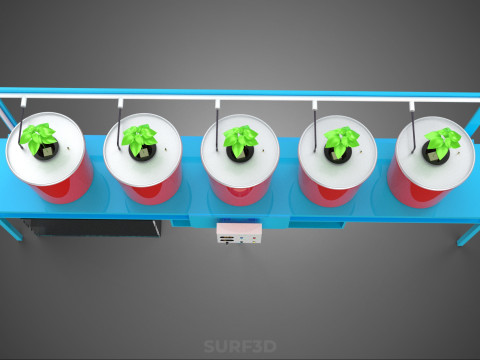

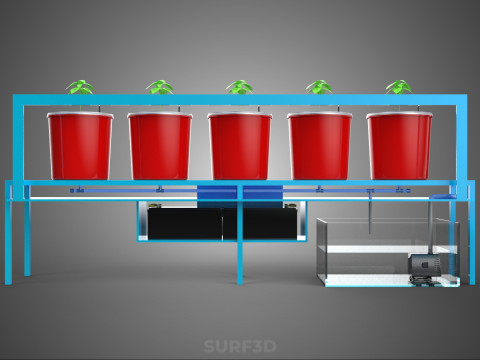

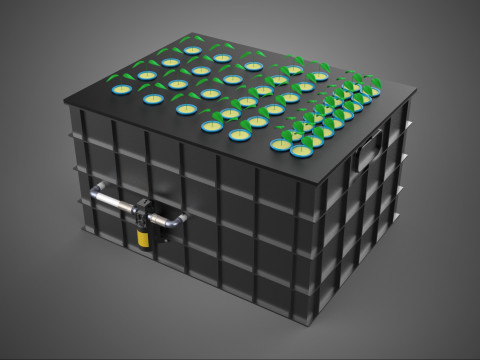

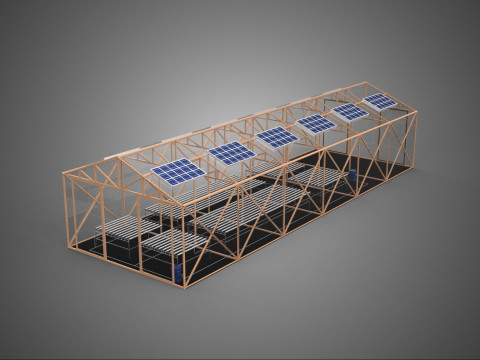

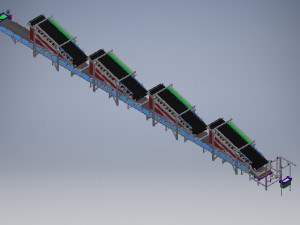

The **IOT Smart Control Dutch Bucket Hydroponic System Setup Plant Pot** defines a sophisticated, soilless cultivation methodology integrating Internet of Things (IoT) technology with the highly efficient Dutch Bucket (Bato Bucket) hydroponic technique. This integrated system is designed for high-yield production of vining and large fruiting crops, offering unparalleled precision in environmental and nutritional management through automated control and remote monitoring.

### 1. Methodology: The Dutch Bucket System

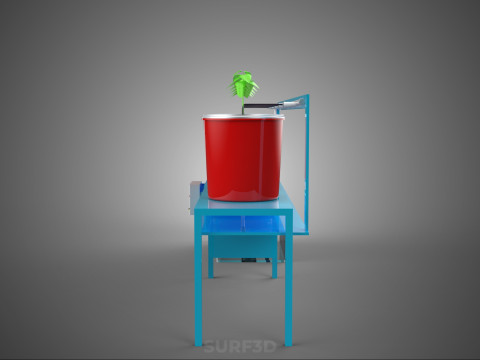

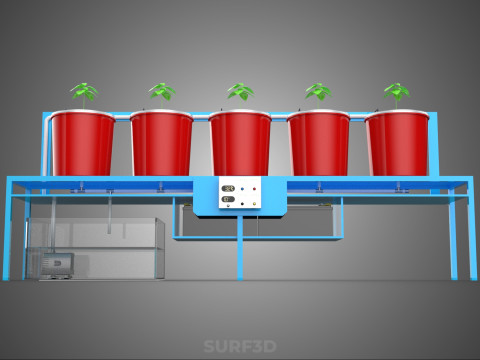

The Dutch Bucket system is a semi-recirculating or drain-to-waste hydroponic setup characterized by individual growing containers (buckets) connected to a shared main nutrient reservoir via a common drain line. Each bucket functions as a discrete "plant pot," typically containing an inert growing medium such as perlite, coco coir, or rockwool.

**Physical Configuration:**

Buckets are positioned above the reservoir and are typically supplied with nutrient solution via drip emitters. Excess solution drains from the bottom of the bucket, preventing root saturation while ensuring continuous aeration. In a recirculating setup, this leachate is returned to the main reservoir for replenishment and reuse. The system is particularly effective for plants requiring substantial vertical support and large root mass, such as tomatoes, cucumbers, peppers, and eggplants.

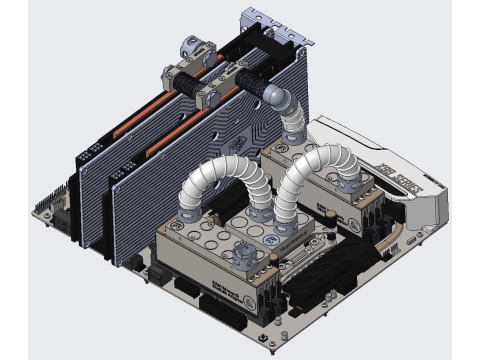

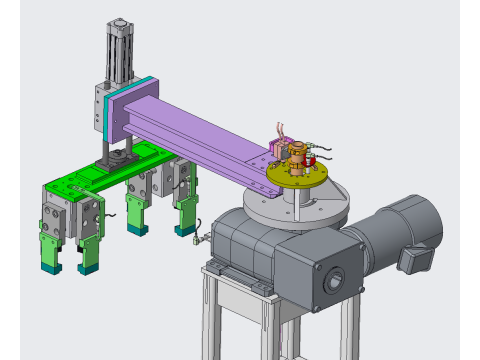

### 2. IOT Smart Control Integration

The core differentiator of the "Smart Control" designation is the implementation of IoT devices for autonomous monitoring, data logging, and execution of operational tasks (actuation). This transforms the traditional Dutch Bucket setup from a manually managed system into a Precision Agriculture tool.

**Monitoring Parameters (Sensors):**

Critical environmental and nutritional parameters are continuously monitored using specialized sensors:

1. **Nutrient Concentration (EC/TDS):** Electrical Conductivity (EC) probes measure the concentration of dissolved mineral salts (Total Dissolved Solids, TDS), ensuring optimal nutrient delivery for the specific crop phase.

2. **pH Level:** pH sensors monitor the acidity or alkalinity of the nutrient solution, a vital factor determining nutrient uptake efficiency.

3. **Temperature:** Water and ambient temperature sensors regulate nutrient solubility and prevent root stress.

4. **Water Level:** Reservoir level sensors prevent pump damage and alert operators to required refills.

**Automated Control (Actuators):**

The IoT control unit processes sensor data and triggers automated responses via actuators, minimizing human intervention:

1. **Automated Dosing:** Peristaltic pumps or solenoid valves inject concentrated acids, bases (pH adjustment), and specific nutrient stocks (A, B, and micronutrients) to maintain the programmed set points for pH and EC.

2. **Irrigation Cycling:** Smart controllers manage the frequency and duration of drip irrigation cycles based on plant growth stage, ambient conditions, and substrate moisture levels.

3. **Environmental Regulation:** Integration often extends to control of auxiliary systems, including fans, heating elements, and grow lights, maintaining optimal photoperiod and microclimate.

### 3. Operational Advantages and Data Analytics

The integration of IoT yields significant operational benefits in resource efficiency and crop yield optimization:

* **Precision Fertigation:** Nutrients are delivered *ad hoc* based on real-time root-zone requirements, reducing nutrient waste and mitigating issues associated with nutrient lockout or deficiency.

* **Remote Management:** Operators can access real-time data dashboards, receive alerts, and adjust system set points remotely via cloud-based platforms or dedicated applications.

* **Data-Driven Decision Making:** The system archives extensive operational data (historical sensor readings, dosage logs, environmental trends). This data facilitates machine learning and advanced analytical processes for "crop steering," leading to continuous yield and quality improvements.

* **Stability and Consistency:** Automated control stabilizes the root zone environment, minimizing the rapid fluctuations in pH and EC that commonly stress plants in manually managed systems.

The IOT Smart Control Dutch Bucket system represents a technological convergence designed to maximize the potential of hydroponic cultivation for high-value crops across both commercial greenhouses and advanced hobbyist environments.

KEYWORDS: IoT, Hydroponics, Dutch Bucket, Bato Bucket, Smart Control, Precision Agriculture, Automated Dosing, Recirculating Hydroponics, Fertigation, Nutrient Solution, pH Monitoring, EC Sensor, Remote Management, Drip Irrigation, Perlite, Coco Coir, Reservoir, Closed-Loop System, Sensor Technology, Actuators, Greenhouse Automation, Crop Steering, Plant Pot, Data Logging, Yield Optimization, Vertical Farming, Root Zone, Drain-to-Waste, Environmental Control, System Setup.

需要更多的格式吗?

如果你需要一个不同的格式,请打开一个新的支持票和为此请求。我们可以转换到 3D 模型: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 免费格式转换我们不转换 3d 场景 以及 .step, .iges, .stp, .sldprt 等格式。!

使用信息

物联网智能控制荷兰桶水培系统设置花盆 - 您可以根据基本许可或扩展许可,将此免版税 3D 模型用于个人或商业用途。基本许可涵盖大多数标准用例,包括数字广告、设计和可视化项目、商业社交媒体账户、原生应用、Web 应用、视频游戏以及实体或数字最终产品(免费和出售)。

扩展许可包含基本许可授予的所有权利,没有任何使用限制,并允许在免版税条款下将 3D 模型用于无限的商业项目。

阅读更多

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी