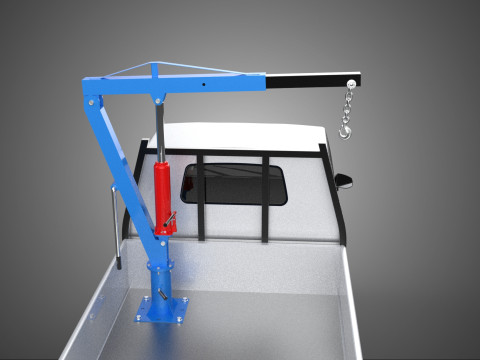

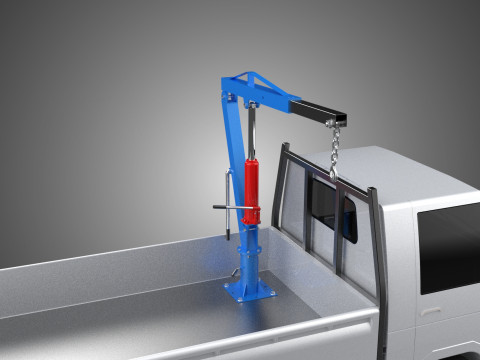

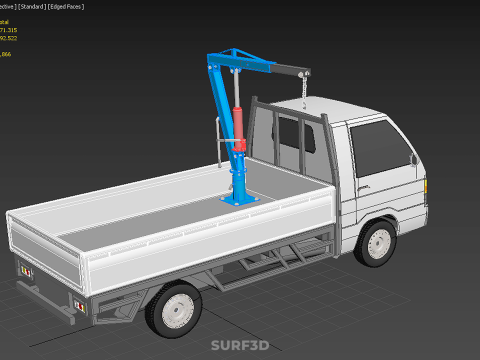

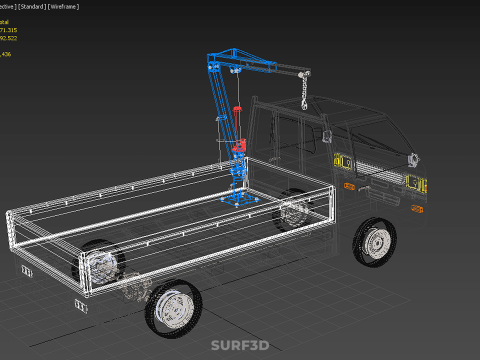

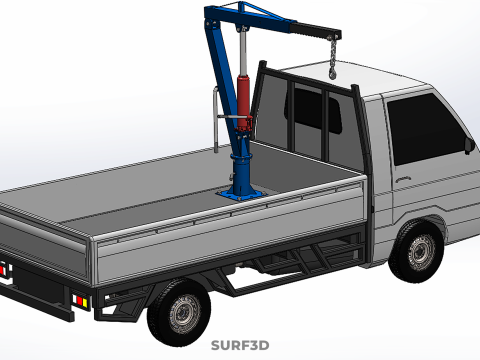

MANUAL HYDRAULIC JACK LIFTING HOIST JIB CRANE HOOK PICKUP TRUCK 3D 模型

- 可用的格式: Rhinoceros (.3dm) 25.97 MB3D Studio (.3ds) 3.66 MBBlender3D (.blend) 9.01 MBCollada (.dae) 9.71 MBAutodesk AutoCAD (.dwg) 18.18 MBAutodesk FBX (.fbx) 11.49 MBGLB (.glb / .gltf) 4.77 MBIGES (.iges) 6.88 MBAutodesk 3DS MAX (.max) 22.84 MBWavefront OBJ (.obj) 6.84 MBACIS(.sat) 14.72 MBSketchUp (.skp) 7.55 MBSTEP (.step) 6.97 MBStereolithography (.stl) 7.23 MB

- 多边形:471315

- 顶点:392522

- 动画:No

- 纹理:No

- 操纵:No

- 材料:

- 低聚:No

- 集合:No

- UVW 贴图:No

- 使用插件:No

- 打印准备:No

- 3D扫描:No

- 成人内容:No

- PBR:No

- 人工智能培训:No

- 几何:Poly NURBS

- 包装 UVs:Unknown

- 日期:190

- 日期: 2025-08-18

- 项目 ID:593058

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and ****ed for integrity and correct content

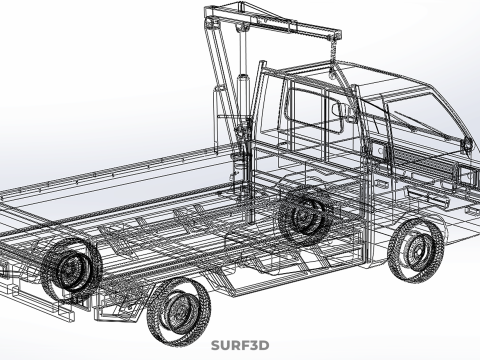

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

A "Manual Hydraulic Jack Lifting Hoist Jib Crane Hook attached on a Pickup Truck" describes a specialized, self-contained mobile lifting apparatus. This integrated system combines a jib crane mechanism, powered by a manual hydraulic jack, onto the cargo bed or chassis of a pickup truck, terminating in a lifting hook. This configuration creates a portable, versatile, and independent lifting solution for various light to medium-duty applications, particularly in environments where conventional powered equipment is impractical or unavailable.

**Purpose and Function:**

The primary purpose of this system is to facilitate the lifting, lowering, and lateral positioning of heavy or ******* loads within a restricted radius around the vehicle. It is engineered for tasks requiring the manipulation of objects too heavy for manual handling, leveraging the truck's inherent mobility to bring the lifting capability directly to the point of need without relying on external power sources.

**Component Breakdown:**

1. **Pickup Truck:** Serves as the mobile base and stable foundation for the entire lifting system. The crane assembly is securely mounted to the truck's frame, chassis, or reinforced cargo bed, ensuring structural integrity and stability during operation. The truck's gross vehicle weight rating (GVWR), payload capacity, and axle ratings are critical factors to consider, as they dictate the maximum permissible load and overall system stability. Some more robust systems may incorporate deployable outriggers or stabilizers to enhance lateral stability and prevent vehicle tipping when lifting heavier loads, especially those extended far from the truck's center of gravity.

2. **Jib Crane:** This structural component provides the reach and rotational capability of the system. It typically consists of two main parts:

* **Mast (or Pillar):** A robust vertical column, firmly anchored to the truck, which serves as the primary support for the jib arm and facilitates its rotation.

* **Jib Arm (or Boom):** A horizontal or slightly angled beam extending outwards from the mast. Its length defines the crane's working radius and thus the area over which loads can be maneuvered.

* **Sle***g Mechanism:** This allows the jib arm to rotate horizontally around the mast. In manual systems, this typically involves a simple pivot bearing or bushing, requiring manual force to position the arm over the desired lifting point.

3. **Manual Hydraulic Jack:** This is the core lifting mechanism, distinguishing this system from electric or engine-driven hoists. It operates on the principle of hydraulic power, where a hand-operated pump forces incompressible hydraulic fluid into a cylinder, extending a ram. This linear extension is then translated into vertical lifting motion. The jack may be directly integrated into the jib arm's structure, or it might act upon a chain, cable, or linkage system to provide the lift. Manual hydraulic jacks offer precise control over the ascent and descent of the load, are independent of external electrical power, and are known for their reliability, though they operate at a slower speed than powered hoists.

4. **Hook:** The terminal end-effector of the lifting system. It is specifically designed for secure attachment to the load being lifted, often featuring a safety latch to prevent accidental disengagement of the load during movement or when under strain.

**Operation:**

Operation involves positioning the pickup truck in close proximity to the load. The jib arm is manually slewed into position over the object. The hook is then securely attached to the load. The manual hydraulic jack is actuated by repetitive pumping of its handle, incrementally lifting the load to the desired height. Once elevated, the jib arm can be manually rotated to move the load horizontally. Lowering is achieved by slowly releasing the hydraulic pressure via a control valve, allo***g for a controlled descent.

**Advantages:**

This integrated system offers significant advantages, including high mobility, complete independence from external power sources (making it ideal for remote or off-grid operations), relatively lower acquisition and maintenance costs compared to larger, powered crane solutions, and ease of deployment. Its self-contained nature eliminates the need for separate lifting equipment and transport vehicles.

**Limitations and Safety Considerations:**

Key limitations include slower lifting speeds compared to powered hoists, reliance on manual effort, and a restricted lifting capacity dictated by the hydraulic jack's rating, the structural integrity of the crane components, and crucially, the pickup truck's stability and payload limits. Safety is paramount during operation; critical considerations include:

* **Load Capacity:** Strict adherence to the rated lifting capacity of the crane assembly, the hydraulic jack, and the truck's payload limits to prevent structural failure or tipping.

* **Stability:** Ensuring the truck is positioned on level, firm ground and, if equipped, properly deploying any outriggers to prevent overturning. Lifting operations generate significant overturning moments that must be counteracted.

* **Center of Gravity:** Understanding the load's center of gravity and the crane's load chart to maintain stability throughout the lifting and sle***g process.

* **Clearance:** Maintaining adequate clearance from overhead obstructions and personnel during all movements.

* **Proper Attachment:** Ensuring the load is securely and balancedly attached to the hook to prevent slippage or uncontrolled s***ging.

**Applications:**

Typical applications for this system are diverse and include, but are not limited to, loading and unloading heavy equipment or materials in construction, agriculture, landscaping, automotive repair (e.g., engine removal/installation), light logistics (e.g., managing heavy packages or machinery), roadside assistance, and various field service operations where a portable, self-sufficient, and cost-effective lifting capability is required.

如果你需要一个不同的格式,请打开一个新的支持票和为此请求。我们可以转换到 3D 模型: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 我们不转换 3d 场景 以及 .step, .iges, .stp, .sldprt 等格式。!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी