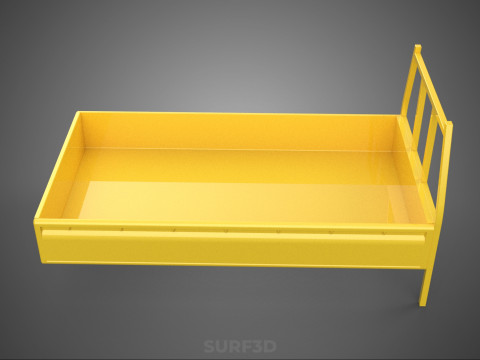

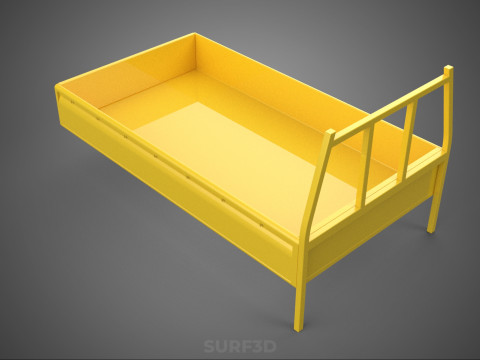

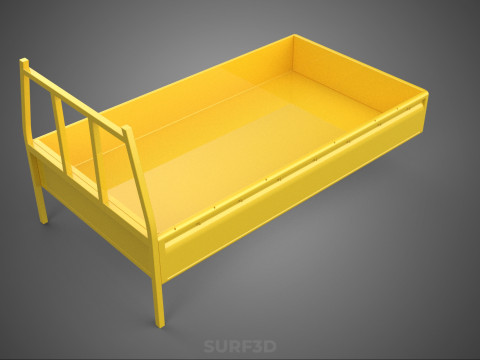

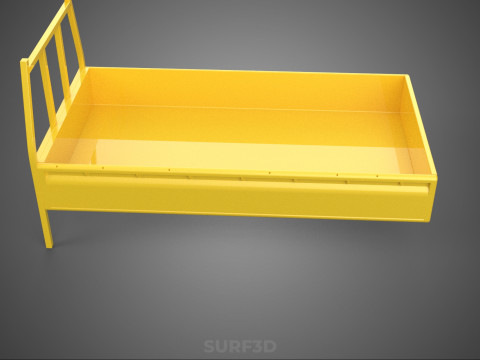

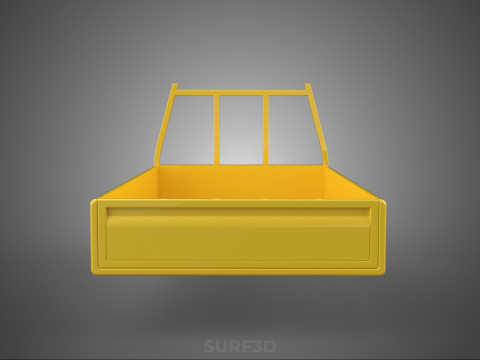

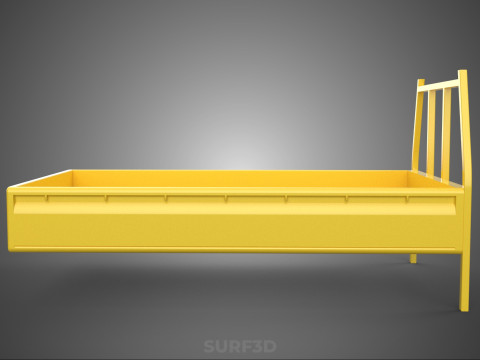

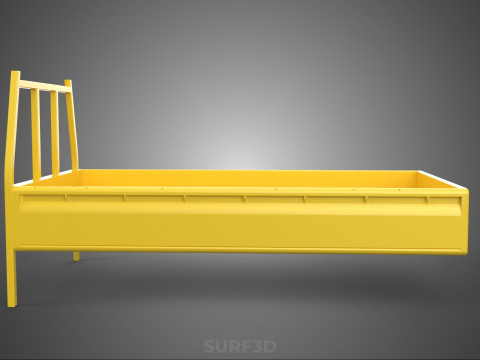

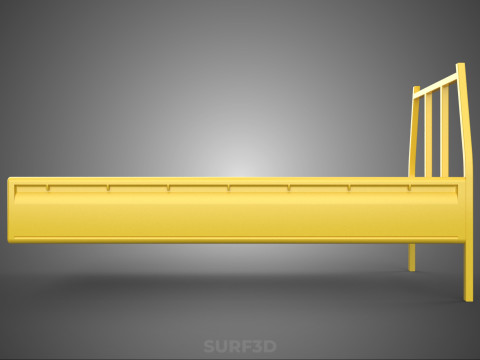

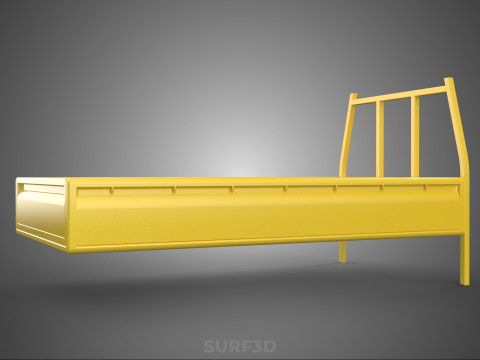

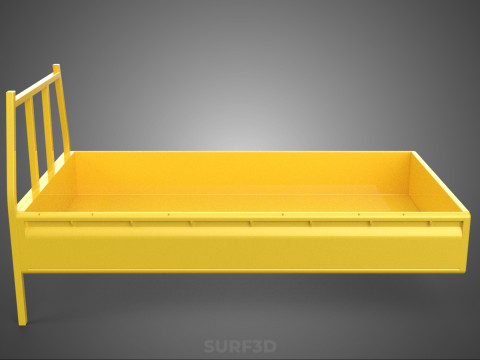

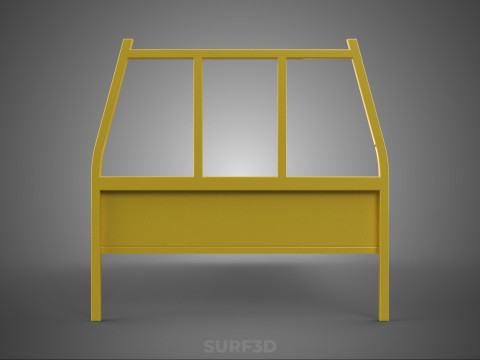

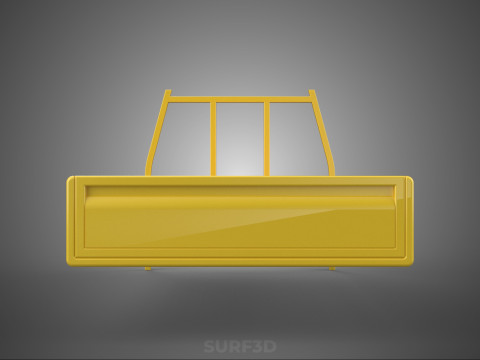

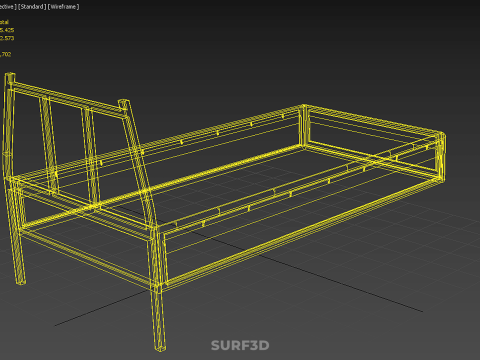

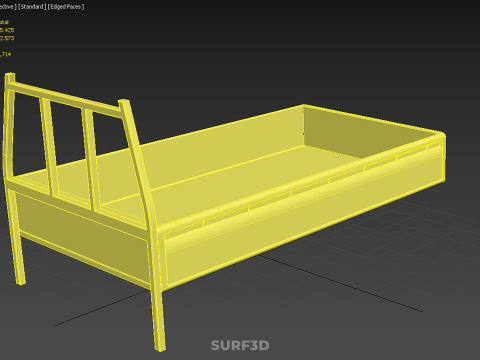

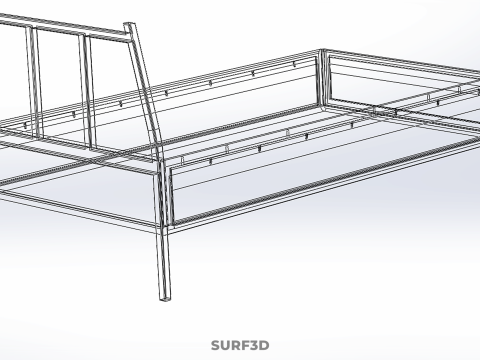

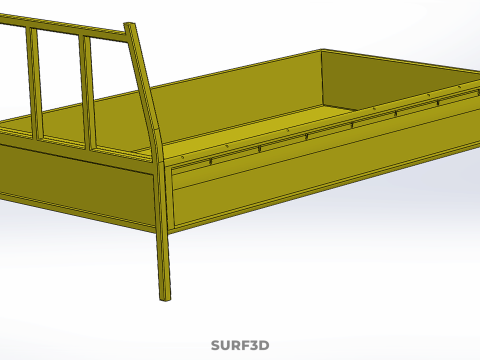

皮卡车货箱平台框架床头板后托盘架 3D 模型

- 可用的格式: Rhinoceros (.3dm) 2.35 MB3D Studio (.3ds) 107.61 kbBlender3D (.blend) 386.50 kbCollada (.dae) 300.24 kbAutodesk AutoCAD (.dwg) 474.95 kbAutodesk FBX (.fbx) 433.79 kbGLB (.glb / .gltf) 160.67 kbIGES (.iges) 315.91 kbAutodesk 3DS MAX (.max) 853.63 kbWavefront OBJ (.obj) 195.11 kbACIS(.sat) 395.78 kbSketchUp (.skp) 641.14 kbSTEP (.step) 291.15 kbStereolithography (.stl) 225.77 kb

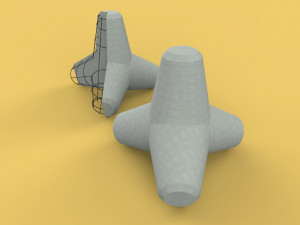

- 多边形:15425

- 顶点:12573

- 动画:No

- 纹理:No

- 操纵:No

- 材料:

- 低聚:No

- 集合:No

- UVW 贴图:No

- 使用插件:No

- 打印准备:No

- 3D扫描:No

- 成人内容:No

- PBR:No

- 人工智能培训:No

- 几何:Poly NURBS

- 包装 UVs:Unknown

- 日期:279

- 日期: 2025-07-27

- 项目 ID:589605

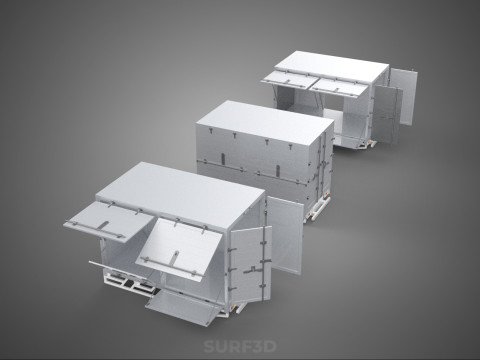

皮卡车货箱平台框架床头板后托盘架 3D 模型 3dm, 3ds, blend, dae, dwg, fbx, glb, iges, max, obj, sat, skp, step, stl, 从 surf3d

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

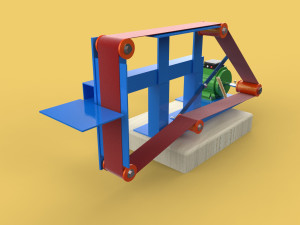

A "Pickup Truck Cargo Bed Platform Frame Headboard Back Tray Rack" refers to a comprehensive, often modular, accessory system designed to significantly enhance the utility, organization, and cargo management capabilities of a standard pickup truck's cargo bed. This multifaceted system integrates several components, each serving distinct functions, to optimize the vehicle's capacity for transporting diverse loads securely and efficiently.

**Core Functionality and Purpose:**

The primary purpose of such a system is to transform the open cargo bed into a more structured and versatile hauling platform. It aims to improve load distribution, secure irregularly shaped or oversized items, protect the vehicle's cabin, and provide specialized storage solutions not inherent in the stock bed design. These systems are particularly beneficial for tradespeople, outdoor enthusiasts, and individuals requiring robust and adaptable cargo transport solutions.

**Component Breakdown:**

1. **Pickup Truck Cargo Bed:** This is the fundamental, open-top rear section of a pickup truck, designed for carrying goods. It typically features a flat floor, side walls, and a hinged tailgate. The described system is installed within, upon, or around this pre-existing structure.

2. **Platform Frame:** This constitutes the foundational structural element of the system. Typically fabricated from robust materials such as heavy-gauge steel or aluminum, the platform frame is installed directly onto or within the cargo bed. Its primary function is to create a sturdy, often elevated, and level base for cargo, improving load distribution and providing integrated anchor points. It may elevate the entire cargo floor, creating under-platform storage, or serve as a secure substructure for mounting other components. The frame ensures rigidity and provides the necessary mounting points for the headboard, back tray rack, and other accessories.

3. **Headboard (or Headache Rack):** Positioned at the front of the cargo bed, directly behind the truck's cab, the headboard is a vertical barrier integrated into or mounted onto the platform frame. Its critical functions include:

* **Cab Protection:** Shielding the rear window and cab of the truck from shifting cargo during acceleration, braking, or collisions.

* **Load Retention:** Preventing items from sliding forward into the cab.

* **Load Support:** Providing a sturdy surface for leaning long items, such as lumber, ladders, or pipes, that extend over the cab.

* **Accessory Mounting:** Often equipped with an integrated grid, mesh, or specific attachment points for lights, tools, or additional tie-down anchors.

4. **Back Tray Rack:** This component is situated at the rear of the cargo bed, typically near or integrated with the tailgate area. While "tray" can imply a contained space, in the context of a "rack," it generally refers to a structural extension or a sub-frame that:

* **Extends Cargo Length:** Provides additional support for items that exceed the length of the cargo bed, particularly when the tailgate is down or removed.

* **Elevated Support:** Similar to the headboard, it can offer a raised platform or support point for longer items, working in conjunction with the headboard to cradle cargo.

* **Containment/Organization:** May include integrated side rails or dividers to create a defined, often elevated, "tray" area for smaller items, preventing them from shifting or falling out.

* **Tie-down Points:** Furnishes additional securement points at the rear of the bed.

* **Modular Utility:** Can be designed to swing out, fold down, or be easily removed for different cargo configurations.

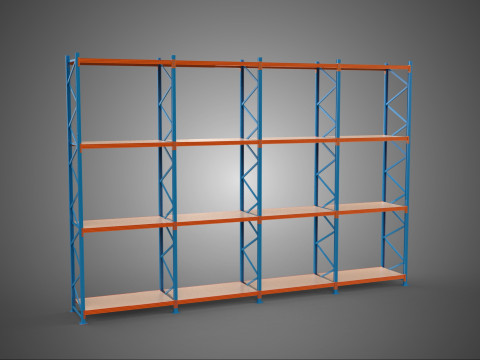

**Materials and Construction:**

These systems are typically constructed from materials chosen for their strength, durability, and resistance to corrosion, including:

* **Steel:** Heavy-duty, robust, and cost-effective, often finished with powder coating or galvanization for weather protection.

* **Aluminum:** Lighter weight, corrosion-resistant, and aesthetically pleasing, though generally more expensive.

* **Composite Materials:** Used for specific components to reduce weight or provide specialized surfaces.

Welding and high-strength fasteners are common construction methods, ensuring structural integrity under demanding loads.

**Applications:**

Such integrated systems are widely utilized by professionals in construction, landscaping, plumbing, electrical work, and general contracting for secure transport of tools, materials, and equipment. They are also popular among recreational users for hauling camping gear, sporting equipment (e.g., kayaks, bikes), or off-road recovery tools.

**Benefits:**

* **Enhanced Cargo Security:** Multiple tie-down points and structured support minimize shifting and potential damage to cargo or the vehicle.

* **Increased Versatility:** Adaptability to carry various types of loads, from small tools to long lumber or ladders.

* **Optimized Space Utilization:** Creation of additional storage layers (e.g., under-platform storage) and better organization of the bed.

* **Vehicle Protection:** Safeguarding the truck's cab and rear window from cargo impact.

* **Durability and Longevity:** Designed to withstand rigorous use and harsh environmental conditions.

In essence, the "Pickup Truck Cargo Bed Platform Frame Headboard Back Tray Rack" represents a sophisticated, integrated solution for maximizing the functional capacity and safety of a pickup truck's primary utility space.

KEYWORDS: Truck accessories, cargo management, pickup truck bed, utility system, load organizer, truck bed frame, platform system, headboard rack, headache rack, back rack, tray rack, cargo containment, heavy duty, commercial vehicle, recreational vehicle, work truck, off-road equipment, material transport, equipment hauling, load security, tie-down points, modular system, custom truck, truck modifications, vehicle enhancement, hauling capacity, professional grade, durable construction, steel rack, aluminum rack.

需要更多的格式吗?

如果你需要一个不同的格式,请打开一个新的支持票和为此请求。我们可以转换到 3D 模型: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 我们不转换 3d 场景 以及 .step, .iges, .stp, .sldprt 等格式。!使用信息

皮卡车货箱平台框架床头板后托盘架 - 您可以根据基本许可或扩展许可,将此免版税 3D 模型用于个人或商业用途。基本许可涵盖大多数标准用例,包括数字广告、设计和可视化项目、商业社交媒体账户、原生应用、Web 应用、视频游戏以及实体或数字最终产品(免费和出售)。

扩展许可包含基本许可授予的所有权利,没有任何使用限制,并允许在免版税条款下将 3D 模型用于无限的商业项目。

阅读更多

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी