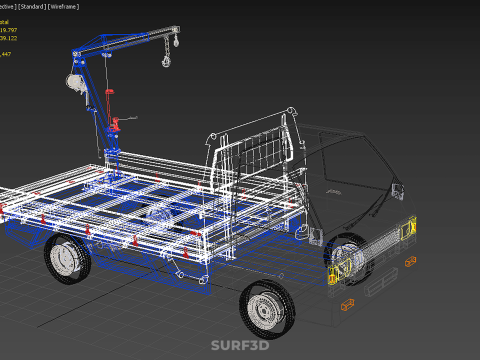

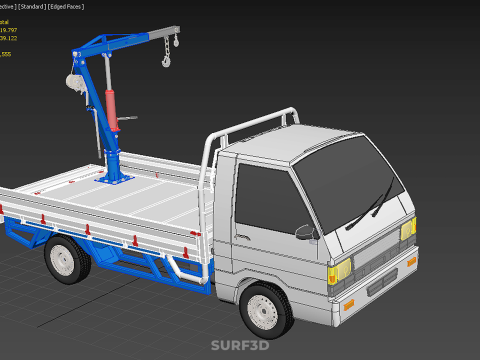

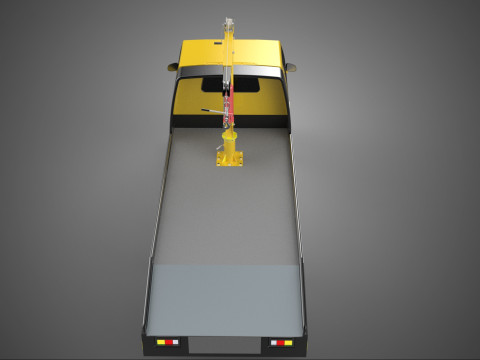

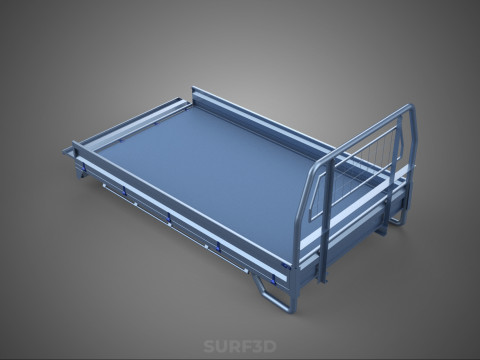

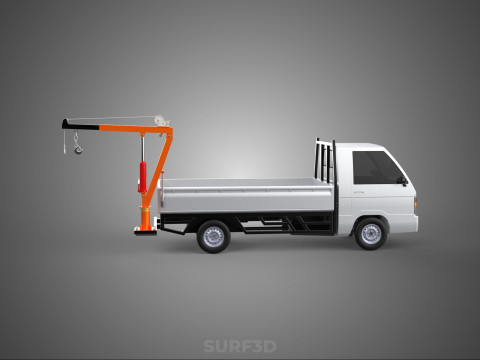

TRUCK PICKUP REAR GATE TAILGATE FOLDING CRANE HAND CRANK WINCH Modelo 3D

- Formatos disponíveis: Rhinoceros (.3dm) 34.02 MB3D Studio (.3ds) 5.37 MBSTEP (.step) 8.43 MBAutodesk AutoCAD (.dwg) 19.37 MBWavefront OBJ (.obj) 10.98 MBACIS(.sat) 16.94 MBAutodesk 3DS MAX (.max) 30.10 MBAutodesk FBX (.fbx) 18.60 MBIGES (.iges) 8.82 MBStereolithography (.stl) 11.12 MBGLB (.glb / .gltf) 7.09 MBSketchUp (.skp) 12.91 MBBlender3D (.blend) 14.56 MBCollada (.dae) 14.02 MB

- Polígonos:819797

- Vértices:639122

- Animados:No

- Textura:No

- Equipados:No

- Materiais:

- Low-poly:No

- Coleção:No

- Mapeamento UVW:No

- Plugins Utilizados:No

- Pronto para impressão:No

- Scan 3D:No

- Conteúdo adulto:No

- PBR:No

- Treinamento de IA:No

- Geometria:Poly NURBS

- UVs não embalados:Unknown

- Visualizações:129

- Data: 2025-08-22

- ID do Item:594103

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

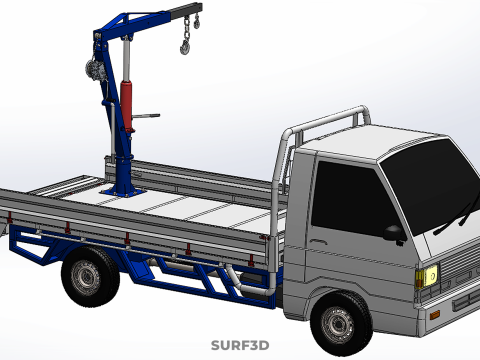

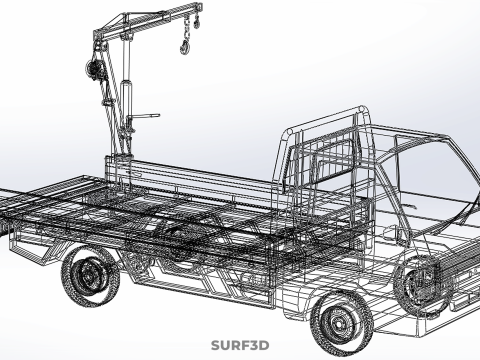

A "Truck Pickup with Rear Gate Tailgate Folding Crane Hand Crank Winch" describes a specific configuration of a light-duty utility vehicle designed to enhance its material handling capabilities without requiring external power sources. This system integrates a compact, manually operated lifting device – specifically a folding crane actuated by a hand crank winch – directly onto or in close conjunction with the rear tailgate of a standard pickup truck. Its primary function is to facilitate the loading and unloading of moderate-weight cargo into and out of the truck bed, thereby increasing the vehicle's versatility for various tasks.

The foundational component is a conventional pickup truck, characterized by an open cargo bed at the rear and a passenger cabin. These vehicles are widely utilized for transportation, light hauling, and diverse vocational applications, serving as an ideal platform for such a modification due to their inherent cargo capacity and accessibility.

The rear gate, or tailgate, of the pickup truck serves as a critical interface for the crane system. In some configurations, the crane mounting assembly is directly affixed to a reinforced tailgate, leveraging its structural integrity. In other designs, the crane is mounted within the truck bed immediately adjacent to the tailgate, which then acts as a support or operational area during loading and unloading. This strategic integration ensures the crane's boom can extend effectively over the rear of the vehicle, allowing for efficient access to ground-level items, objects on trailers, or items positioned at the edge of the truck bed.

The folding crane mechanism is engineered for portability and efficient storage. It typically consists of a steel boom, often telescopic, that can be extended for operational reach and then compactly folded or collapsed when not in use. This folding capability is paramount for maintaining the truck's overall profile, facilitating highway travel, and preserving valuable truck bed space for other cargo. The crane assembly is constructed from high-strength steel or alloys to ensure robust structural integrity and safety during lifting operations. Its pivot point commonly allows for manual rotation, enabling loads to be precisely swung from an external position into the truck bed and vice versa.

The lifting force for the crane is generated by a hand crank winch. This manual mechanism typically comprises a durable drum around which a steel cable or high-strength synthetic rope is wound, a hand-operated crank, and an internal gear reduction system. The gears are crucial, as they significantly multiply the force applied by the operator, thereby enabling the lifting of substantial weights with manageable physical effort. A robust ratcheting or braking mechanism is invariably incorporated to securely hold the load at any desired height and to prevent any uncontrolled or accidental descent. The manual nature of the winch eliminates the requirement for hydraulic power, electrical systems, or internal combustion engines, rendering the entire system self-contained, environmentally less impactful, and operationally independent.

To operate the system, the crane is first unfolded and the boom extended to the desired length. The winch cable is then unwound, and its hook is securely attached to the cargo. The operator rotates the hand crank, progressively lifting the item. Once the load is clear of its original position, the crane boom can be manually swiveled to position the load over the truck bed. The winch is then carefully unwound to lower the item precisely into its designated place. This setup is particularly advantageous for individuals or small businesses that routinely handle items such as generators, air compressors, engine components, heavy tools, building materials, or other moderate-weight equipment. Typical users include landscapers, construction workers, mobile mechanics, farmers, and those involved in light industrial or logistical tasks who require an economical and flexible lifting solution without the complexities of powered systems.

**Advantages:** The primary benefits of this system include its cost-effectiveness, simplicity of operation, complete independence from external power sources, and minimal maintenance requirements. Its compact, folding design preserves cargo space when the crane is not in active use, and its manual operation inherently offers precise control over the lifting and lowering process, which can be crucial for delicate placements.

**Limitations:** The maximum lifting capacity is inherently lower than that of hydraulic or electrically powered cranes and is limited by both the structural integrity of the crane itself and the physical effort that the operator can safely exert. Operation can be slower and more labor-intensive, particularly for heavier loads or during frequent lifting cycles. Safety considerations are paramount, including proper load securement, maintaining vehicle balance during lifts, and strict adherence to the rated load capacities to prevent accidents, injuries, or damage to the equipment or vehicle.

In conclusion, the "Truck Pickup with Rear Gate Tailgate Folding Crane Hand Crank Winch" represents a practical, entry-level material handling solution for pickup trucks. It offers a distinct blend of utility, affordability, and operational independence, making it a valuable asset for various applications where modest lifting capabilities are required without the need for complex, powered mechanical systems.

KEYWORDS: Pickup truck, Truck crane, Tailgate crane, Folding crane, Hand crank winch, Manual winch, Utility vehicle, Material handling, Cargo lift, Load assist, Light-duty crane, Mobile crane, Portable crane, Truck accessory, Lifting equipment, Rear gate, Vehicle modification, Work truck, Self-contained lift, No-power crane, Mechanical advantage, Gear reduction, Boom crane, Small business equipment, Construction tools, Landscaping equipment, Agricultural use, Logistics support, Load transfer system, Manual lifting system

Se precisar de um formato diferente, por favor abra um novo Support Ticket e solicite isso. Podemos converter modelos 3D para: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Não convertemos cenas 3D e formatos como .step, .iges, .stp, .sldprt.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी