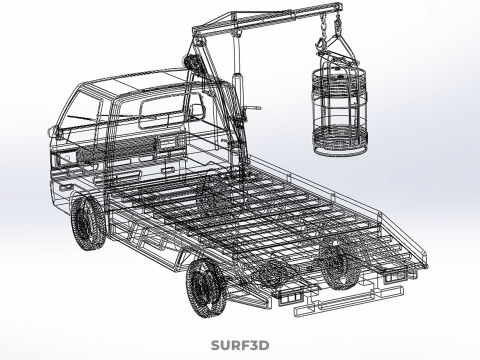

JACK HYDRAULIC CRANE HAND CRANK WINCH JIB DRUM TRUCK PICKUP CAR Modelo 3D

- Formatos disponíveis: Rhinoceros (.3dm) 33.85 MB3D Studio (.3ds) 5.26 MBBlender3D (.blend) 14.25 MBCollada (.dae) 13.91 MBAutodesk AutoCAD (.dwg) 19.55 MBAutodesk FBX (.fbx) 18.10 MBGLB (.glb / .gltf) 6.88 MBIGES (.iges) 8.72 MBAutodesk 3DS MAX (.max) 29.52 MBWavefront OBJ (.obj) 10.72 MBACIS(.sat) 17.04 MBSketchUp (.skp) 13.01 MBSTEP (.step) 9.57 MBStereolithography (.stl) 11.07 MB

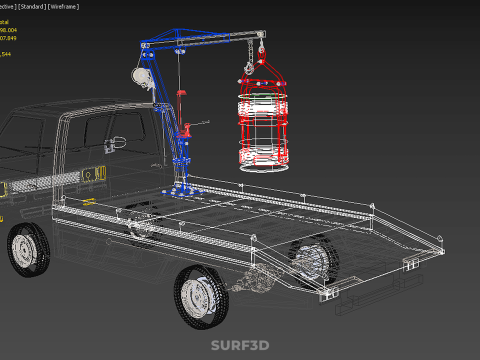

- Polígonos:798004

- Vértices:607849

- Animados:No

- Textura:No

- Equipados:No

- Materiais:

- Low-poly:No

- Coleção:No

- Mapeamento UVW:No

- Plugins Utilizados:No

- Pronto para impressão:No

- Scan 3D:No

- Conteúdo adulto:No

- PBR:No

- Treinamento de IA:No

- Geometria:Poly NURBS

- UVs não embalados:Unknown

- Visualizações:215

- Data: 2025-08-12

- ID do Item:592225

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and ****ed for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

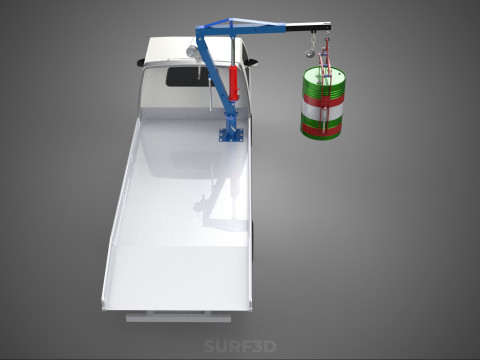

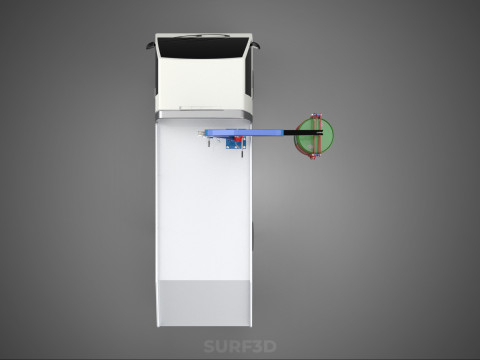

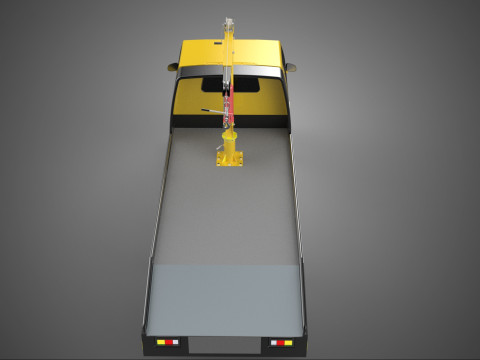

A **Manual Jack Hydraulic Jib Crane with Hand Crank ***ch Attached on Truck/Pickup/Car to Lift the Drum** describes a specialized, self-contained, and portable lifting apparatus designed for the efficient handling of cylindrical containers, typically drums or barrels, by means of vehicular integration. This system combines several mechanical principles to provide a versatile, unpowered material handling solution.

**Description:**

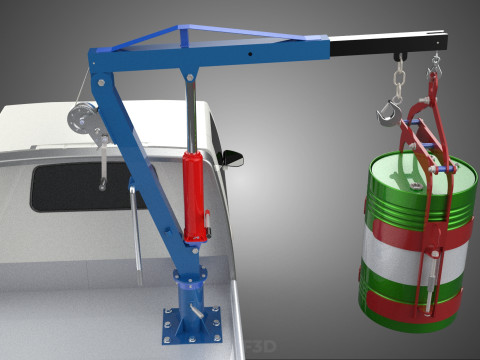

This equipment is fundamentally a compact, vehicle-mounted jib crane system, primarily distinguished by its reliance on manual operation for all lifting and positioning functions. It comprises a robust structural framework, a hydraulic lifting mechanism for boom elevation, and a separate mechanical ***ch for load manipulation, all designed for secure attachment to the cargo bed or chassis of light commercial vehicles such as pickup trucks, utility vehicles, or light trucks.

**Key Components and Functionality:**

1. **Jib Crane Structure:** The core structural element consists of a vertical mast or pillar rigidly bolted or otherwise securely affixed to the vehicle's frame, typically at the rear. Extending from this mast is a horizontal or slightly angled boom (jib), often designed to articulate or slew (rotate horizontally) around the mast axis, providing radial reach over the vehicle's bed and surrounding area. Many designs also feature a foldable boom for compact storage and transport.

2. **Manual Hydraulic Jack System (Boom Elevation):** The primary mechanism for raising and lowering the jib itself is a manually operated hydraulic system. This typically involves a hydraulic cylinder integrated into the mast or boom pivot point, actuated by a hand-operated pump lever (akin to a bottle jack or floor jack). Pumping this lever pressurizes hydraulic fluid, causing the cylinder rod to extend and elevate the jib to the desired working height. A release valve allows for controlled, gravity-assisted lowering of the boom. This hydraulic system sets the vertical position of the boom and, consequently, the maximum height from which the load can be lifted or lowered.

3. **Hand Crank ***ch (Load Lifting):** Mounted directly on the jib, this is the dedicated mechanism for lifting and lowering the actual load (e.g., a drum). It consists of a rotating drum (spool) around which a wire rope or cable is wound. A hand crank handle is manually turned to rotate the spool, thereby ***ding the cable in (lifting the load) or un***ding it (lowering the load). The ***ch is typically equipped with a robust braking system, often a pawl and ratchet mechanism or a friction brake, to safely hold the load at any desired height and prevent accidental descent. A hook, often with a safety latch, is affixed to the end of the cable for attaching to the drum, either directly or via specialized drum grabs or slings.

4. **Vehicle Mounting Platform:** The system is engineered for stable integration with the host vehicle. The mounting point must be capable of withstanding significant static and dynamic loads, including the weight of the crane, the drum, and the forces generated during lifting and sle***g operations. Proper installation ensures that the vehicle's stability is maintained, often requiring consideration of the vehicle's center of gravity and the use of parking brakes, and in some cases, supplementary outriggers or stabilizers (though less common on lighter systems) to prevent tipping.

**Operational Principle:**

To operate, the vehicle is positioned near the drum. The operator manually pumps the hydraulic lever to raise the jib to an appropriate height. The jib is then manually slewed to position the ***ch hook directly over the drum. The hand crank is then turned to lower the hook, attach it securely to the drum, and subsequently raise the drum clear of the ground. The jib is then slewed to position the drum over the vehicle's cargo bed or another designated spot, where it is gently lowered by un***ding the ***ch cable.

**Applications:**

This type of crane is predominantly used for loading and unloading heavy drums (e.g., 55-gallon steel or plastic barrels containing fuels, lubricants, chemicals, waste, or construction materials) onto and off trucks, pickups, or utility vehicles. Its portability and independence from external power sources make it ideal for:

* Field service operations

* Remote construction sites

* Agricultural settings

* Workshops or small businesses without fixed overhead lifting equipment

* Emergency and utility services

* Any situation requiring mobile, medium-duty material handling in areas without readily available power.

**Advantages:**

* **Portability:** Enables lifting capabilities to be brought directly to the point of need.

* **Independence:** Requires no external power, relying entirely on manual hydraulic and mechanical action, making it suitable for remote or off-grid locations.

* **Cost-Effectiveness:** Generally a more economical solution compared to powered mobile cranes, forklifts, or dedicated loading equipment.

* **Simplicity and Reliability:** Fewer complex components lead to easier maintenance and high operational reliability.

**Limitations and Safety Considerations:**

* **Load Capacity:** Limited by the structural integrity of the crane and, critically, the stability of the host vehicle. Exceeding rated capacity can lead to vehicle tipping or structural failure.

* **Speed:** Lifting and lowering operations are significantly slower and more physically demanding compared to powered systems.

* **Ergonomics:** Manual operation can induce fatigue, especially during repetitive or heavy lifts.

* **Vehicle Stability:** Paramount. Operations must be conducted on level, firm ground. The vehicle's parking brake must be engaged, and the load must be within the crane's and the vehicle's safe working limits.

* **Operator Training:** Proper training in safe operation, load rigging, stability principles, and adherence to load charts is essential to prevent accidents.

KEYWORDS: Mobile lifting solution, portable crane, truck crane, pickup crane, vehicle-mounted crane, manual hydraulic crane, jib crane, hand ***ch, drum lifter, material handling, loading aid, unloading aid, heavy lifting, utility crane, field service equipment, workshop crane, agricultural equipment, construction site tool, mechanical advantage, hydraulic pump, boom crane, manual operation, self-contained lifting, industrial drum, barrel lift, light commercial vehicle, cargo lift, compact crane, independent power, on-site lifting, no electricity needed.

Se precisar de um formato diferente, por favor abra um novo Support Ticket e solicite isso. Podemos converter modelos 3D para: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Não convertemos cenas 3D e formatos como .step, .iges, .stp, .sldprt.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी