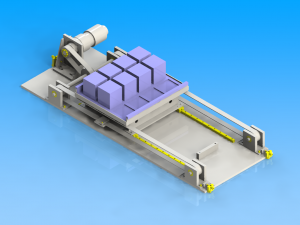

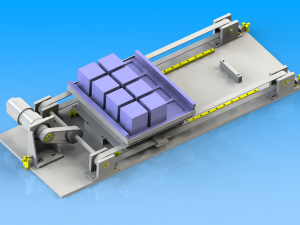

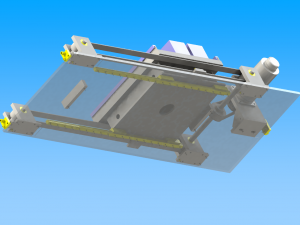

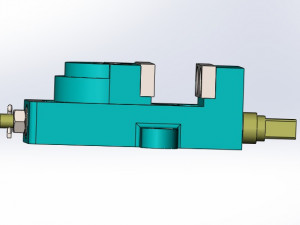

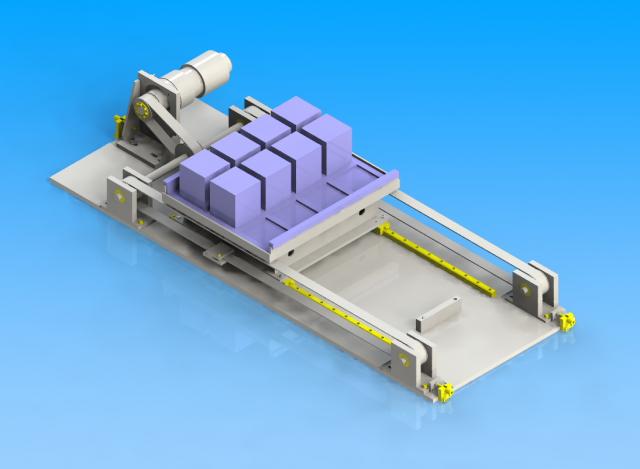

traverse mechanism of heavy workpiece Лоу-поли 3D Модель

$

5.00

У вас есть $0.00 Кредиты. Купить Кредиты

- Доступные форматы: SolidWorks (.sldprt) 7.79 MB

- Текстуры:

- Скелет:

- Материалы:

- Лоу-поли:

- Коллекция:

- UVW mapping:No

- Плагины:No

- Для печати:No

- 3D Скан:No

- Контент для взрослых:No

- PBR:No

- Геометрия:Polygonal

- Unwrapped UVs:Unknown

- Просмотры:2805

- Дата: 2020-07-15

- ID Продукта:301991

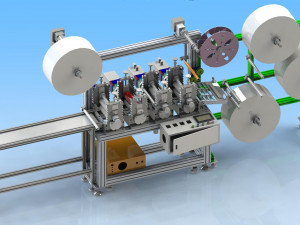

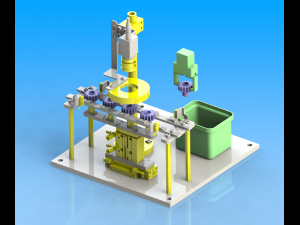

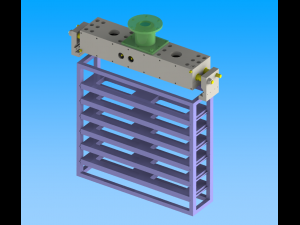

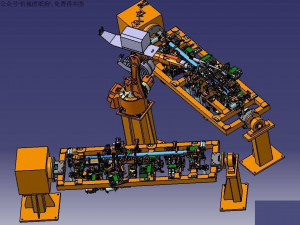

purpose and action

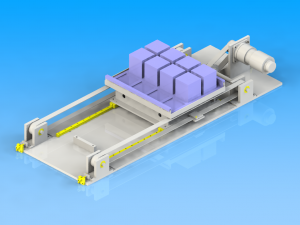

through the linear guide rail to support the load, reduce the transverse movement mechanism of power transmission.

through the shaft, pulley and belt, the rotary motion generated by the servo motor and the plate on the linear guide rail are converted into the shuttle mechanism of linear motion.

environment and operability

automatic mechanism based on servo motor.

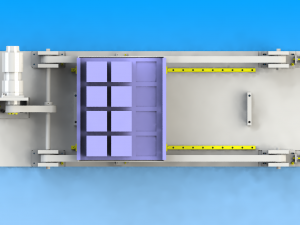

object artifact

large pallet + workpiece

shape: w125 × d125 × h150mm (one pallet can hold 12 at most)

workpiece weight: 535kg

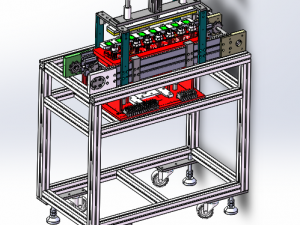

characteristic

specification and size

sliding stroke: 500mm

dimension: w700 × d1890 × h228mm

accuracy and load

repeat accuracy of pallet positioning: ± 0.02mm

weight: 535 × μ (= 0.03) = 16.05kg

selection basis of main parts

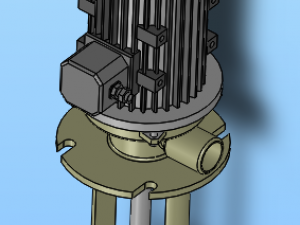

motor

for high precision positioning.

linear guide rail

reduce the weight of the conveyor.

in order to obtain the forward precision of reciprocating straight line.

key points of design

calculation process of main parts

verify whether the synchronous toothed belt and servo motor can bear the load and meet the required transmission speed.

synchronous toothed belt

allowable tension: 4320n

maximum torque of servo motor: 14.4n · m

motor shaft diameter: 0.035m

the maximum torque of the part with 0.098m pulley diameter: 14.4 × 0.098 / 0.035 = 40.3n · m

force of one belt: f = (40.3 × 2 / 0.098) / 2 = 408n

408 n < 4320n, no problem

servo motor

motor speed: 0 ~ 2000 (rpm)

internal reduction ratio (ia): 1 / 9

external reduction ratio (ib): 40 (φ 80) / 49 (φ 98)

diameter of rotating pitch circle (dp): 80mm

transmission speed: (ns) × (dp) × π× (ia) × (ib) × 1 / 60

=600×80×π×(1/9)×(40/49)×1/60=228mm/sec

(according to the operating speed (ns): 600rpm)

key points of structure making and design

rotary servo motor, horizontal movement of the tray mechanism.

the l-shaped synchronous toothed belt with stable and synchronous transmission is selected to configure the core wire in parallel. Для печати: Нет

Подробнейthrough the linear guide rail to support the load, reduce the transverse movement mechanism of power transmission.

through the shaft, pulley and belt, the rotary motion generated by the servo motor and the plate on the linear guide rail are converted into the shuttle mechanism of linear motion.

environment and operability

automatic mechanism based on servo motor.

object artifact

large pallet + workpiece

shape: w125 × d125 × h150mm (one pallet can hold 12 at most)

workpiece weight: 535kg

characteristic

specification and size

sliding stroke: 500mm

dimension: w700 × d1890 × h228mm

accuracy and load

repeat accuracy of pallet positioning: ± 0.02mm

weight: 535 × μ (= 0.03) = 16.05kg

selection basis of main parts

motor

for high precision positioning.

linear guide rail

reduce the weight of the conveyor.

in order to obtain the forward precision of reciprocating straight line.

key points of design

calculation process of main parts

verify whether the synchronous toothed belt and servo motor can bear the load and meet the required transmission speed.

synchronous toothed belt

allowable tension: 4320n

maximum torque of servo motor: 14.4n · m

motor shaft diameter: 0.035m

the maximum torque of the part with 0.098m pulley diameter: 14.4 × 0.098 / 0.035 = 40.3n · m

force of one belt: f = (40.3 × 2 / 0.098) / 2 = 408n

408 n < 4320n, no problem

servo motor

motor speed: 0 ~ 2000 (rpm)

internal reduction ratio (ia): 1 / 9

external reduction ratio (ib): 40 (φ 80) / 49 (φ 98)

diameter of rotating pitch circle (dp): 80mm

transmission speed: (ns) × (dp) × π× (ia) × (ib) × 1 / 60

=600×80×π×(1/9)×(40/49)×1/60=228mm/sec

(according to the operating speed (ns): 600rpm)

key points of structure making and design

rotary servo motor, horizontal movement of the tray mechanism.

the l-shaped synchronous toothed belt with stable and synchronous transmission is selected to configure the core wire in parallel. Для печати: Нет

Нужно больше форматов?

Если вам необходим другой формат, пожалуйста, сделайте запрос при помощи тикета поддержки. Мы можем cконвертировать 3D модели в такие форматы: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Мы не конвертируем 3d сцены и такие форматы, как .step, .iges, .stp, .sldprt и т. д.!

Если вам необходим другой формат, пожалуйста, сделайте запрос при помощи тикета поддержки. Мы можем cконвертировать 3D модели в такие форматы: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Мы не конвертируем 3d сцены и такие форматы, как .step, .iges, .stp, .sldprt и т. д.!

traverse mechanism of heavy workpiece 3D Модель sldprt, от tzd

traverse mechanismК данному товару нет ни одного комментария.

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी