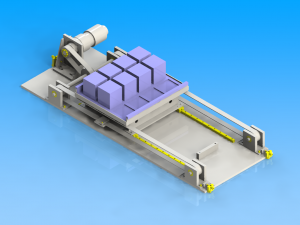

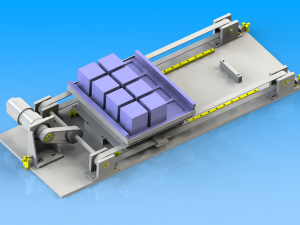

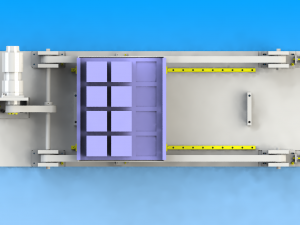

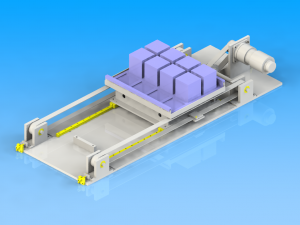

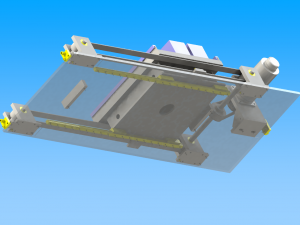

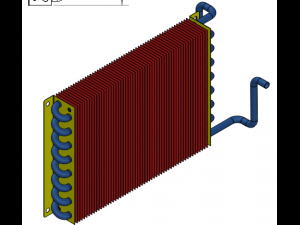

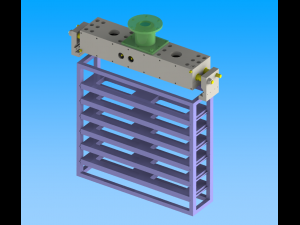

traverse mechanism of heavy workpiece 로우 폴리곤 3D 모델

$

5.00

- 이용 가능한 포맷: SolidWorks (.sldprt) 7.79 MB

- 텍스쳐드:

- 리그드:

- 재료:

- 로우 폴리곤:

- 컬렉션:

- UVW 매핑:No

- 플러그인 사용 됨:No

- 프린트 준비:No

- 3D 스캔:No

- 성인용 콘텐츠:No

- PBR:No

- 지오메트리:Polygonal

- 언래핑 된 UVs:Unknown

- 조회:2744

- 날짜: 2020-07-15

- 아이템 ID:301991

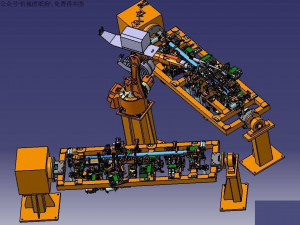

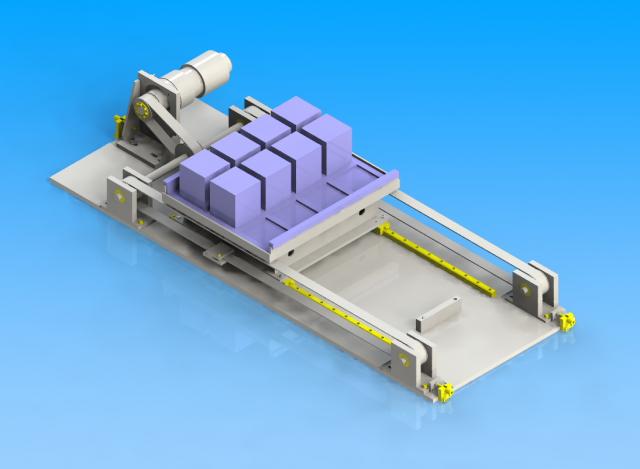

purpose and action

through the linear guide rail to support the load, reduce the transverse movement mechanism of power transmission.

through the shaft, pulley and belt, the rotary motion generated by the servo motor and the plate on the linear guide rail are converted into the shuttle mechanism of linear motion.

environment and operability

automatic mechanism based on servo motor.

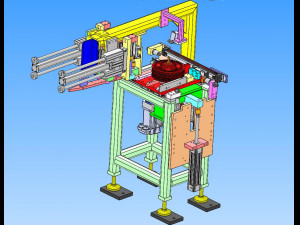

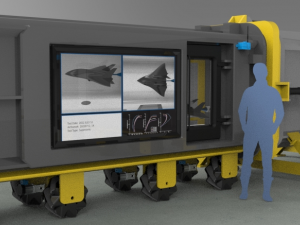

object artifact

large pallet + workpiece

shape: w125 × d125 × h150mm (one pallet can hold 12 at most)

workpiece weight: 535kg

characteristic

specification and size

sliding stroke: 500mm

dimension: w700 × d1890 × h228mm

accuracy and load

repeat accuracy of pallet positioning: ± 0.02mm

weight: 535 × μ (= 0.03) = 16.05kg

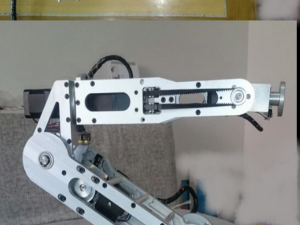

selection basis of main parts

motor

for high precision positioning.

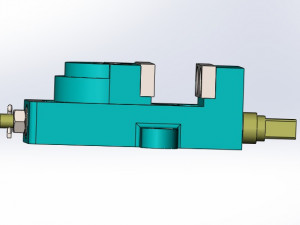

linear guide rail

reduce the weight of the conveyor.

in order to obtain the forward precision of reciprocating straight line.

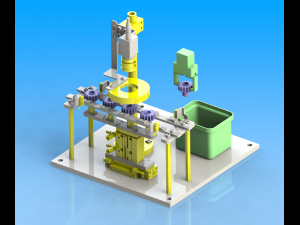

key points of design

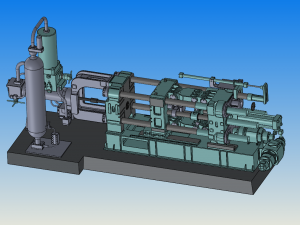

calculation process of main parts

verify whether the synchronous toothed belt and servo motor can bear the load and meet the required transmission speed.

synchronous toothed belt

allowable tension: 4320n

maximum torque of servo motor: 14.4n · m

motor shaft diameter: 0.035m

the maximum torque of the part with 0.098m pulley diameter: 14.4 × 0.098 / 0.035 = 40.3n · m

force of one belt: f = (40.3 × 2 / 0.098) / 2 = 408n

408 n < 4320n, no problem

servo motor

motor speed: 0 ~ 2000 (rpm)

internal reduction ratio (ia): 1 / 9

external reduction ratio (ib): 40 (φ 80) / 49 (φ 98)

diameter of rotating pitch circle (dp): 80mm

transmission speed: (ns) × (dp) × π× (ia) × (ib) × 1 / 60

=600×80×π×(1/9)×(40/49)×1/60=228mm/sec

(according to the operating speed (ns): 600rpm)

key points of structure making and design

rotary servo motor, horizontal movement of the tray mechanism.

the l-shaped synchronous toothed belt with stable and synchronous transmission is selected to configure the core wire in parallel. 프린트 준비: 아니오

더 보기through the linear guide rail to support the load, reduce the transverse movement mechanism of power transmission.

through the shaft, pulley and belt, the rotary motion generated by the servo motor and the plate on the linear guide rail are converted into the shuttle mechanism of linear motion.

environment and operability

automatic mechanism based on servo motor.

object artifact

large pallet + workpiece

shape: w125 × d125 × h150mm (one pallet can hold 12 at most)

workpiece weight: 535kg

characteristic

specification and size

sliding stroke: 500mm

dimension: w700 × d1890 × h228mm

accuracy and load

repeat accuracy of pallet positioning: ± 0.02mm

weight: 535 × μ (= 0.03) = 16.05kg

selection basis of main parts

motor

for high precision positioning.

linear guide rail

reduce the weight of the conveyor.

in order to obtain the forward precision of reciprocating straight line.

key points of design

calculation process of main parts

verify whether the synchronous toothed belt and servo motor can bear the load and meet the required transmission speed.

synchronous toothed belt

allowable tension: 4320n

maximum torque of servo motor: 14.4n · m

motor shaft diameter: 0.035m

the maximum torque of the part with 0.098m pulley diameter: 14.4 × 0.098 / 0.035 = 40.3n · m

force of one belt: f = (40.3 × 2 / 0.098) / 2 = 408n

408 n < 4320n, no problem

servo motor

motor speed: 0 ~ 2000 (rpm)

internal reduction ratio (ia): 1 / 9

external reduction ratio (ib): 40 (φ 80) / 49 (φ 98)

diameter of rotating pitch circle (dp): 80mm

transmission speed: (ns) × (dp) × π× (ia) × (ib) × 1 / 60

=600×80×π×(1/9)×(40/49)×1/60=228mm/sec

(according to the operating speed (ns): 600rpm)

key points of structure making and design

rotary servo motor, horizontal movement of the tray mechanism.

the l-shaped synchronous toothed belt with stable and synchronous transmission is selected to configure the core wire in parallel. 프린트 준비: 아니오

다른 포맷이 필요하세요?

다른 포맷이 필요하시면, 새로운 지원 티켓을 열어 요청하세요. 저희는 3D 모델을 다음으로 변환할 수 있습니다: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 우리는 3D 장면을 변환하지 않습니다 .step, .iges, .stp, .sldprt와 같은 형식도 포함됩니다.!

다른 포맷이 필요하시면, 새로운 지원 티켓을 열어 요청하세요. 저희는 3D 모델을 다음으로 변환할 수 있습니다: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 우리는 3D 장면을 변환하지 않습니다 .step, .iges, .stp, .sldprt와 같은 형식도 포함됩니다.!

traverse mechanism of heavy workpiece 3D 모델 sldprt, 발신 tzd

traverse mechanism이 아이템에 대한 코멘트 없음.

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी