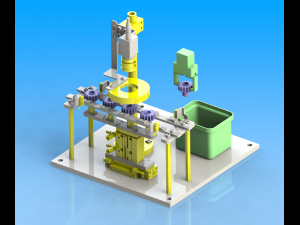

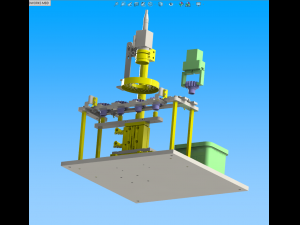

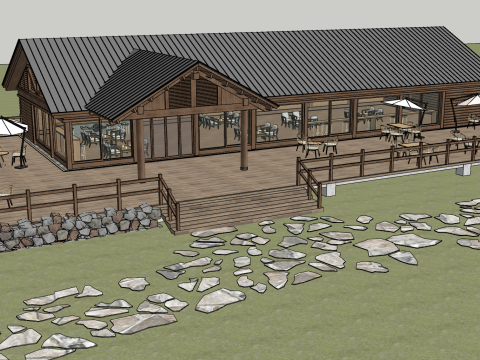

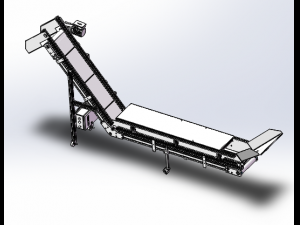

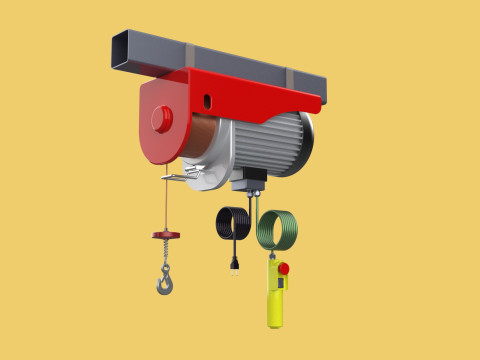

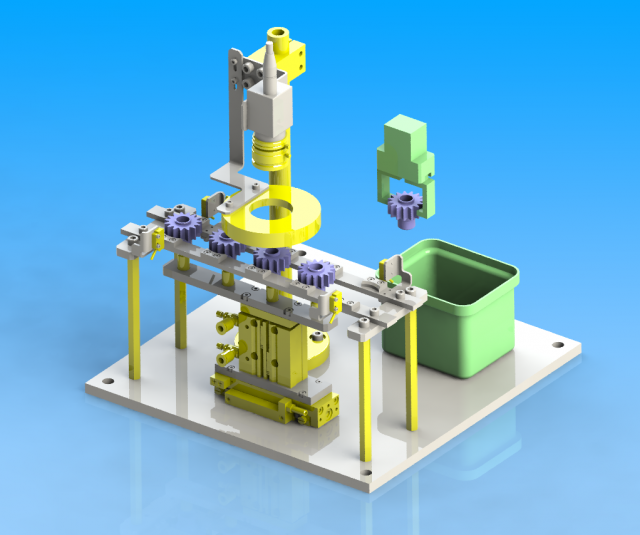

lifting transfer mechanism solidworks2016 3D 모델

CYBER MONDAY

SALE 50% OFF

$

4.00 USD

- 작성자에게 제품 지원 요청

- 이용 가능한 포맷:

- 아이템 ID:301983

- 날짜: 2020-07-15

- 애니메이티드:No

- 텍스쳐드:No

- 리그드:No

- 재료:

- 로우 폴리곤:No

- 컬렉션:No

- UVW 매핑:No

- 플러그인 사용 됨:No

- 프린트 준비:No

- 3D 스캔:No

- 성인용 콘텐츠:No

- PBR:No

- 지오메트리:Polygonal

- 언래핑 된 UVs:Unknown

- 조회:2822

설명

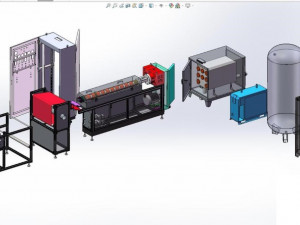

lifting transfer mechanismspecifications

purpose and action

check the pinion by image recognition.

object artifact

resin gear

workpiece specification: φ 34, height 29mm

characteristic

specification and size

overall dimension: 320 × 320 × 341mm

total height: 341 mm

up and down stroke: 30mm

feed stroke: 50mm

specification and size

workpiece feed positioning accuracy: ± 0.5

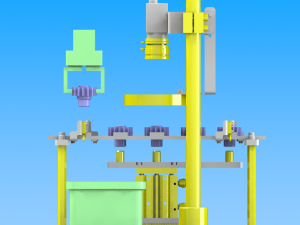

selection basis of main parts

compared with the ordinary cylinder with guide rod, its cross-sectional area is about 1 / 2, and its size is small.

key points of design

calculation process of main parts

the cylinder diameter is selected according to the workpiece load conditions, and the camera and lens are selected according to the inspection resolution.

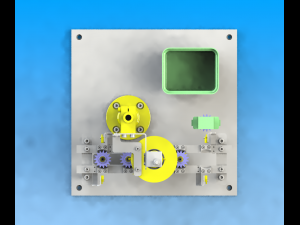

select inner diameter of pneumatic linear sliding cylinder

service conditions: horizontal installation

condition value: load weight m = 0.5kg

friction coefficient μ = 0.2

according to the gravity acceleration g = 9.8m/s

actual load f = μ mg = 0.2 × 0.5 × 9.8 = 0.98n

service pressure p = 0.4mpa

according to the load rate η = 50%

required cylinder force f0 = (f / η) × 100 = (0.98 / 50) × 100 = 1.96n

cylinder inner diameter do = √ (1.274 × fo / p) = √ (1.274 × 1.96 / 0.4) = 2.50mm

the inner diameter of the cylinder is 12mm, no problem.

select inner diameter of cylinder with guide rod

service conditions: vertical installation

condition value: load weight m = 0.21kg

according to the gravity acceleration g = 9.8m/s

actual load f = mg = 0.21 × 9.8 = 2.06 n

service pressure p = 0.4mpa

according to the load rate η = 50%

required cylinder force f0 = (f / η) × 100 = (2.06 / 50) × 100 = 4.12n

cylinder inner diameter do = √ (1.274 × fo / p) = √ (1.274 × 4.12 / 0.4) = 3.62mm

the inner diameter of the cylinder is 12mm, no problem.

select camera, lens

condition: check object workpiece: gear profile 34mm

: inspection of unqualified products (above 0.1 mm)

camera selection: 1 / 1.8 1.92 megapixel (1600 × 1200)

1 / 1.8 ≈ 1 / 2,

field of view 42 × 56 (in accordance with workpiece shape)

wd90mm lens selection close up lens.

{0.035mm for 1 pixel (1600 pixels for 56mm)

·0.1 mm can be checked.

key points of structure making and design

the cylinder with guide rod and pneumatic linear slide table are used in the workpiece conveying.

when the workpiece is unstable in the image inspection position (workpiece floating, etc.), the workpiece posture recognition sensor should be added. 프린트 준비: 아니오

다른 포맷이 필요하세요?

다른 포맷이 필요하시면, 새로운 지원 티켓을 열어 요청하세요. 저희는 3D 모델을 다음으로 변환할 수 있습니다: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 자유 형식 변환우리는 3D 장면을 변환하지 않습니다 .step, .iges, .stp, .sldprt와 같은 형식도 포함됩니다.!

사용 정보

lifting transfer mechanism solidworks2016 - 기본 또는 확장 라이선스에 따라 이 로열티 프리 3D 모델을 개인적 및 상업적 목적으로 사용할 수 있습니다.기본 라이선스는 디지털 광고, 디자인 및 시각화 프로젝트, 비즈니스 소셜 미디어 계정, 네이티브 앱, 웹 앱, 비디오 게임, 그리고 물리적 또는 디지털 최종 제품(무료 및 유료 모두)을 포함한 대부분의 표준 사용 사례를 포괄합니다.

확장 라이선스는 기본 라이선스에 따라 부여된 모든 권리를 포함하며 사용 제한이 없으며, 로열티 프리 조건 하에 3D 모델을 상업적 프로젝트에 무제한으로 사용할 수 있습니다.

더 보기

환불이 보장되나요?

네, 환불을 보장합니다. 작품 구입 후 렌더나 설명에서 오류를 발견하시면, 저희는 최대한 빨리 해당 문제를 수정 할 것입니다. 저희가 해당 오류를 수정 할 수 없는 경우, 저희는 귀하의 주문을 취소하며 아이템 다운로드 24 시간 내에 금액을 환불해드립니다. 더 자세한 정보는 여기를 참조하세요키워드

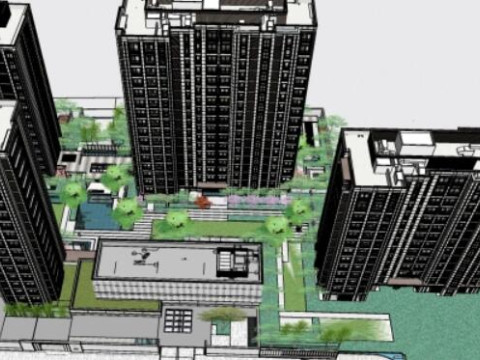

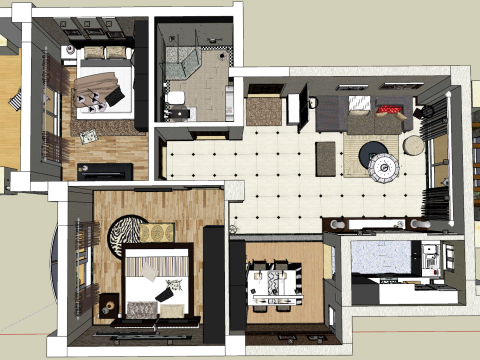

이 저작자의 랜덤 아이템

이 아이템에 대한 코멘트 없음.

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी