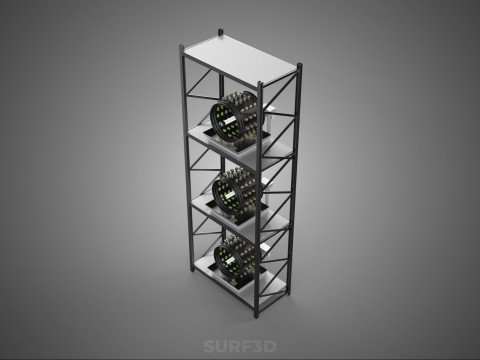

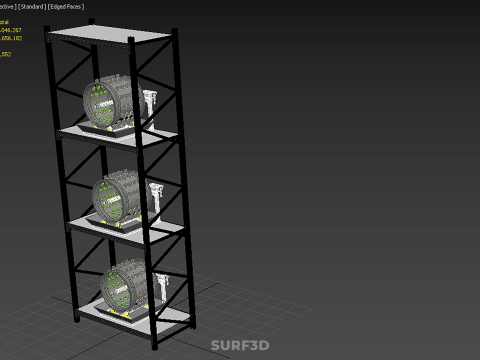

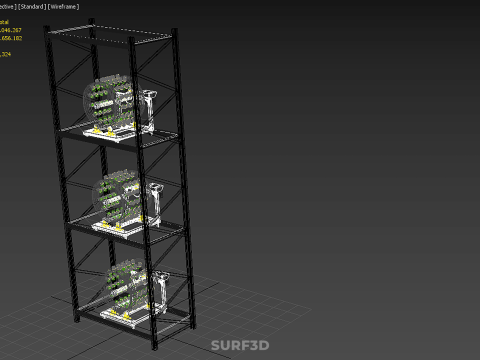

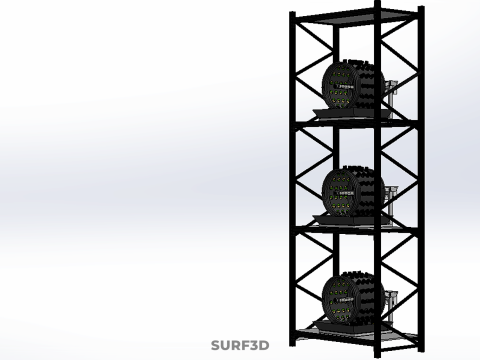

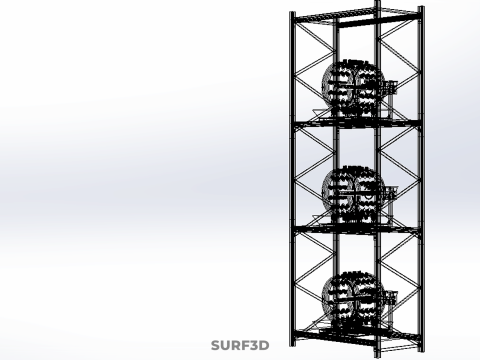

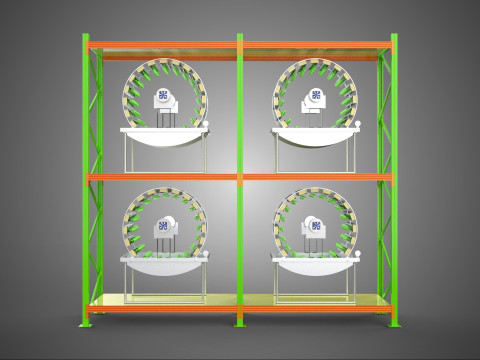

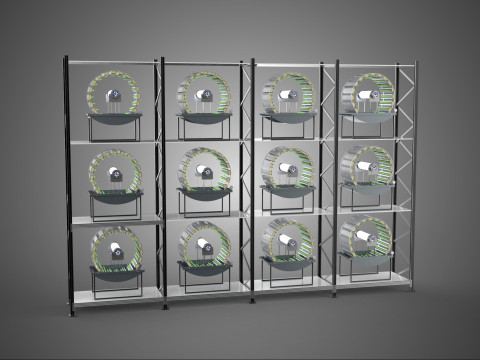

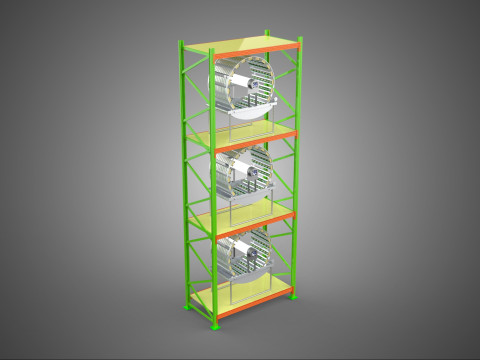

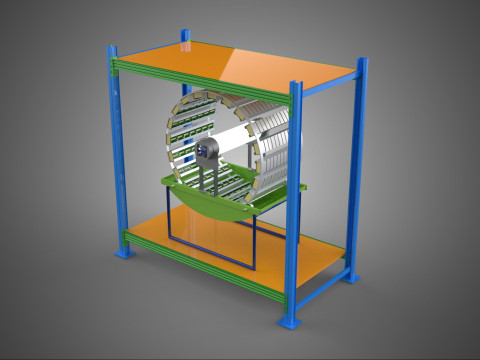

VERTICAL STACK GARDEN TOWER FRAME ROTARY HYDROPONIC PLANT FARM 3D Model

- Hazır formatlar: Rhinoceros (.3dm) 12.86 MB3D Studio (.3ds) 27.06 MBBlender3D (.blend) 102.40 MBCollada (.dae) 87.18 MBAutodesk AutoCAD (.dwg) 29.41 MBAutodesk FBX (.fbx) 143.26 MBGLB (.glb / .gltf) 34.94 MBIGES (.iges) 3.96 MBAutodesk 3DS MAX (.max) 168.13 MBWavefront OBJ (.obj) 74.46 MBACIS(.sat) 63.50 MBSketchUp (.skp) 4.48 MBSTEP (.step) 4.14 MBStereolithography (.stl) 66.22 MB

- Poligonlar:7046267

- Noktalar:5656182

- Animasyon:No

- Dokulu:No

- Rigged:No

- Malzemeler:

- Low-poly:No

- Koleksiyon:No

- UVW mapping:No

- Kullanılan Eklentiler:No

- Baskıya Hazır:No

- 3D Tarama:No

- Yetişkin(+18) içerik:No

- PBR:No

- AI Eğitim:No

- Geometri:Poly NURBS

- Unwrapped UVs:Unknown

- Görüntülemeler:10

- Tarih: 2025-10-05

- Ürün ID:603410

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

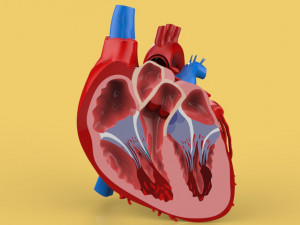

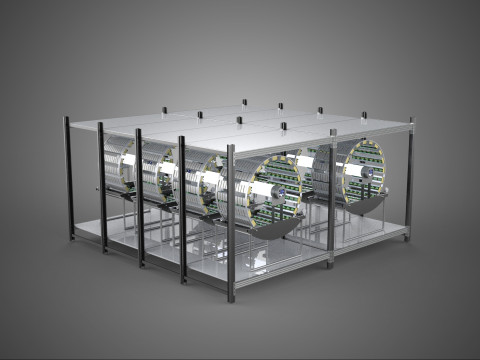

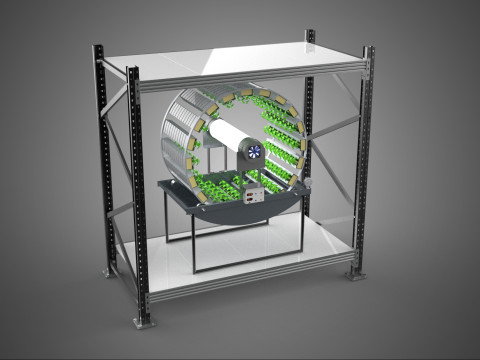

A Vertical Stack Garden Tower Frame Rotary Hydroponic Plant Farm is an advanced horticultural system engineered for intensive, soil-less cultivation of plants within a compact, vertically oriented structure. This innovative agricultural technology integrates multiple principles: vertical farming for optimized space utilization, hydroponics for efficient nutrient delivery, and a rotary mechanism to ensure uniform exposure to light and nutrients for all cultivated specimens. It represents a significant advancement in controlled environment agriculture, designed to maximize productivity in minimal footprints.

The core functionality of this system revolves around three primary engineering and biological principles:

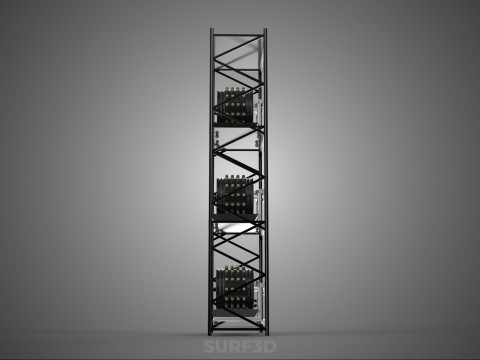

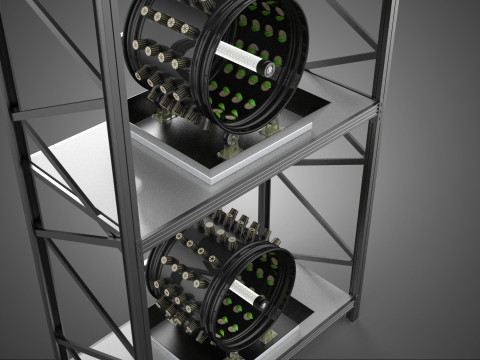

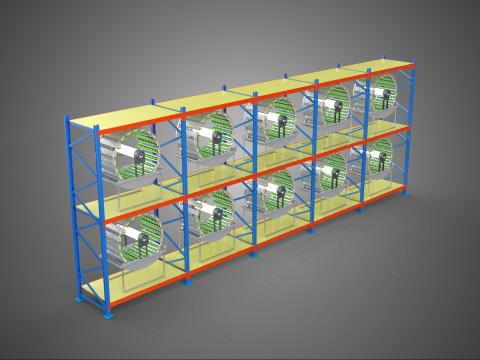

1. **Vertical Stacking:** Plants are arranged in multiple tiers or layers, significantly increasing the crop density per unit of ground area. This configuration is supported by a robust tower frame, which provides structural integrity and modularity, allowing for scalable expansion. The vertical design capitalizes on cubic space rather than linear land area, making it ideal for urban or space-constrained environments.

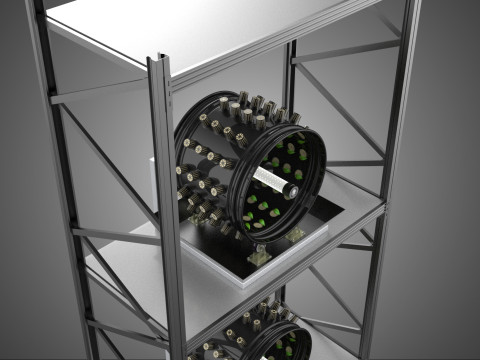

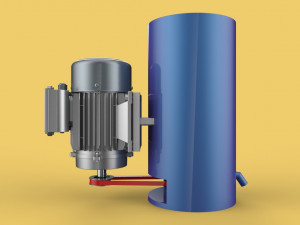

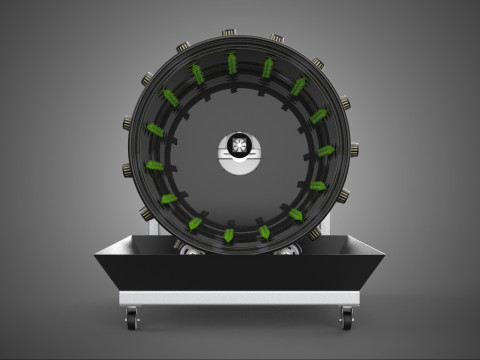

2. **Rotary Mechanism:** A crucial feature is the integration of a motorized rotary system. This mechanism facilitates the continuous or intermittent rotation of the plant-holding modules, or the entire tower structure itself, around a central light source (typically high-efficiency LED grow lights). This rotation ensures that all plants receive equitable and consistent light exposure, mitigating issues of shading and promoting uniform growth across all tiers. Furthermore, rotation can aid in air circulation around the plants and facilitate more uniform nutrient solution distribution, preventing localized nutrient depletion or buildup.

3. **Hydroponic Cultivation:** Plants are grown without soil, their roots immersed in or intermittently exposed to a precisely formulated, nutrient-rich water solution contained within a reservoir. A submersible pump circulates this solution through an intricate irrigation system to deliver essential minerals directly to the root zone. Common hydroponic methods employed in such systems include Nutrient Film Technique (NFT), Deep Water Culture (DWC) for individual modules, or drip irrigation from a top-fed distribution system, all designed to optimize nutrient uptake and minimize water waste.

Key components of a typical Vertical Stack Garden Tower Frame Rotary Hydroponic Plant Farm include:

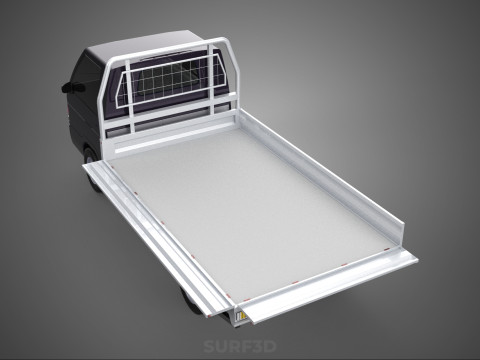

* **Tower Frame:** The foundational support structure, often constructed from durable, corrosion-resistant materials such as PVC, ABS, or aluminum, designed to safely hold multiple plant tiers and the rotary mechanism.

* **Plant Holding Modules:** Individual pots, net cups, or specialized trays integrated into the vertical structure, designed to cradle plants and allow unimpeded root access to the nutrient solution.

* **Rotary Drive System:** Comprising a low-RPM electric motor, reduction gears, and robust bearings, responsible for the controlled, smooth rotation of the plant modules or the entire tower.

* **Nutrient Reservoir:** A tank located at the base of the system, holding the carefully balanced water and nutrient solution, which is periodically replenished and adjusted for pH and electrical conductivity (EC).

* **Submersible Pump:** Circulates the nutrient solution from the reservoir through the irrigation system to the plant roots.

* **Irrigation System:** A network of tubing, manifolds, and emitters that precisely distribute the nutrient solution to each plant module.

* **Lighting System:** Typically a central column of high-intensity, full-spectrum LED grow lights, strategically placed to maximize photosynthetic efficiency. The rotary design allows a single central light source to efficiently illuminate a large number of plants uniformly.

* **Control System:** An automated system utilizing sensors and microcontrollers to monitor and regulate critical environmental and nutritional parameters such as light cycles, nutrient pump cycles, pH levels, EC, and sometimes ******t temperature and humidity.

The deployment of such systems offers numerous advantages for modern agriculture:

* **Space Efficiency:** Maximizes crop production in minimal footprints, making it ideal for urban environments, vertical farms, or areas with limited arable land.

* **Water Conservation:** Hydroponic systems recirculate water, reducing consumption by up to 90% compared to traditional soil-based agriculture, contributing significantly to water resource management.

* **Accelerated Growth and Higher Yields:** Optimized nutrient delivery, precise environmental control, and consistent light exposure often lead to faster plant growth rates and increased crop yields per cycle.

* **Reduced Resource Use:** Minimizes land use and, in enclosed environments, eliminates the need for conventional pesticides and herbicides.

* **Year-Round Production:** Enables cultivation independent of seasonal weather conditions, providing a consistent supply of fresh produce.

* **Automated Management:** High potential for automation reduces manual labor requirements and human error.

* **Localized Food Production:** Facilitates hyper-local food production, reducing transportation costs, fuel consumption, and carbon footprint associated with long-distance food supply chains.

Despite its benefits, implementing a Vertical Stack Garden Tower Frame Rotary Hydroponic Plant Farm presents certain challenges:

* **Initial Investment:** The capital outlay for specialized hardware, advanced lighting, and sophisticated control systems can be substantial.

* **Technical Complexity:** Requires specialized knowledge in hydroponics, plant physiology, water chemistry, and system maintenance for optimal operation.

* **Energy Consumption:** While LED lighting is efficient, the continuous operation of lighting and pump systems can represent a significant ongoing electrical cost.

* **System Vulnerability:** A single point of failure (e.g.

Farklı bir formata ihtiyaç duyuyorsanız lütfen destek ekibimize bir talep açarak ihtiyacınızı belirtiniz. 3D modelleri şu formatlara dönüştürebiliriz: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 3d sahneleri dönüştürmüyoruz ve .step, .iges, .stp, .sldprt gibi formatlar.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी