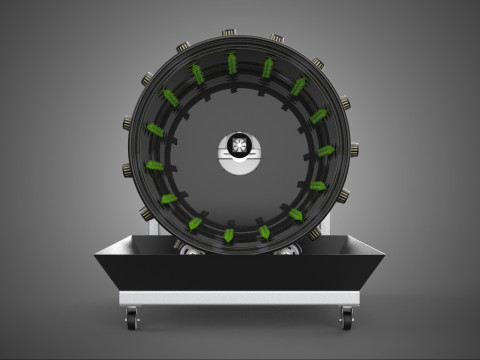

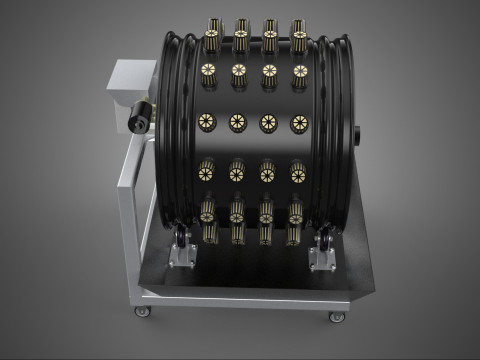

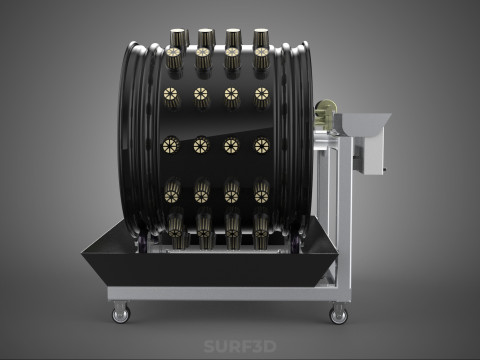

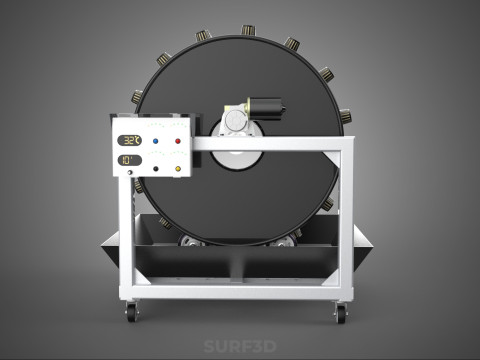

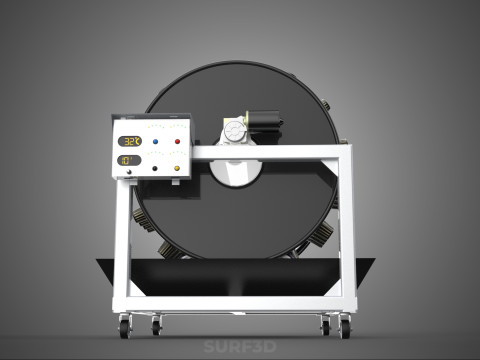

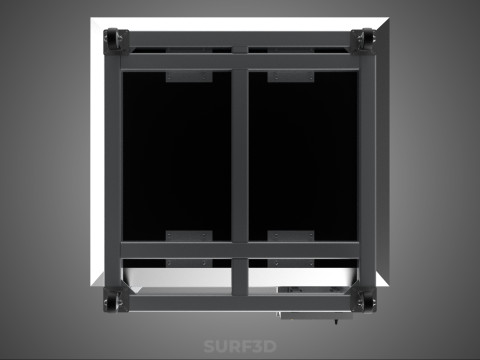

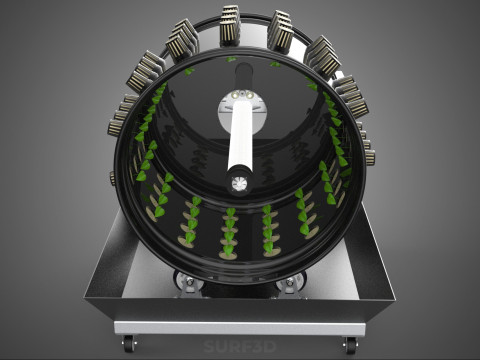

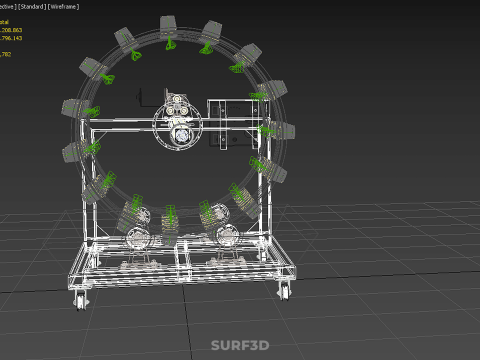

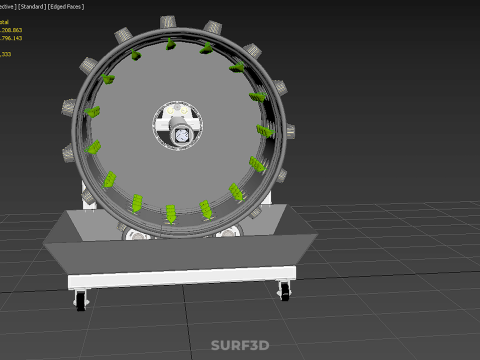

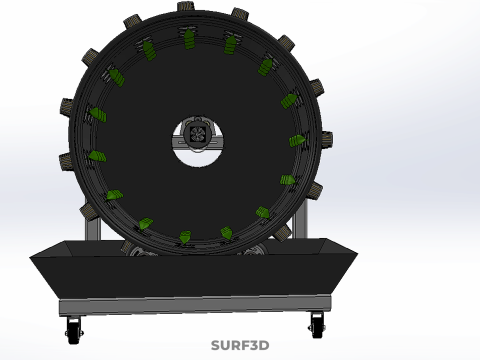

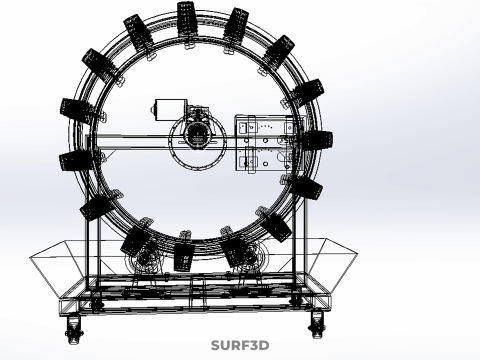

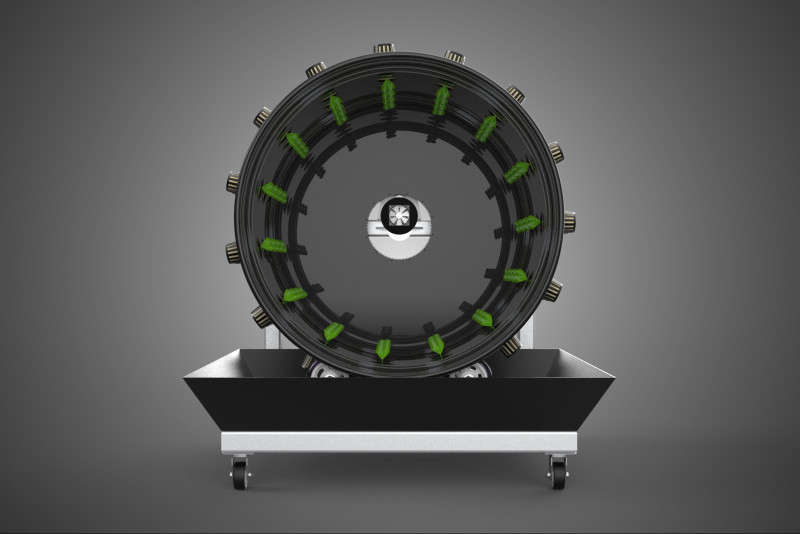

圆形旋转水培园林植物农场系统轮 3D 模型

- 请求作者的产品支持

- 可用的格式:

- 项目 ID:603024

- 日期: 2025-10-03

- 多边形:2208863

- 顶点:1796143

- 动画:No

- 纹理:No

- 操纵:No

- 材料:

- 低聚:No

- 集合:No

- UVW 贴图:No

- 使用插件:No

- 打印准备:No

- 3D扫描:No

- 成人内容:No

- PBR:No

- 人工智能培训:No

- 几何:Poly NURBS

- 包装 UVs:Unknown

- 日期:234

描述

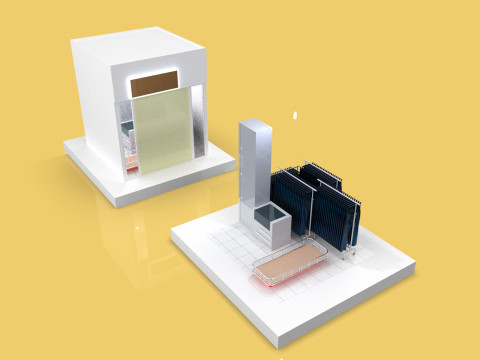

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

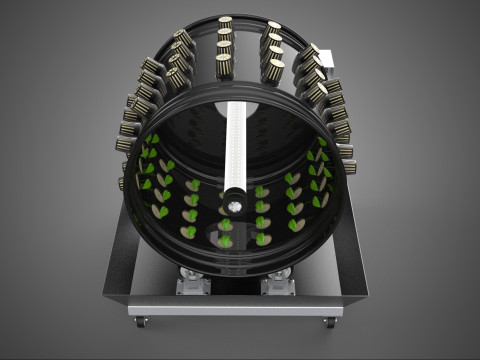

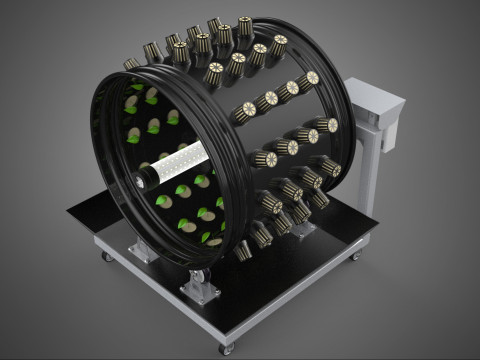

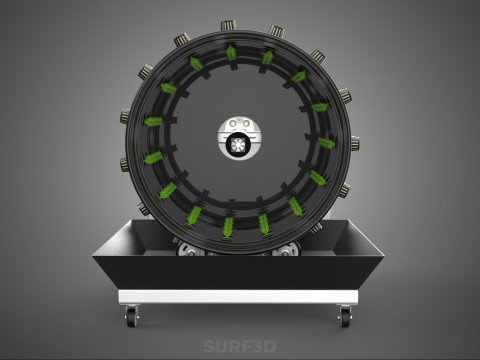

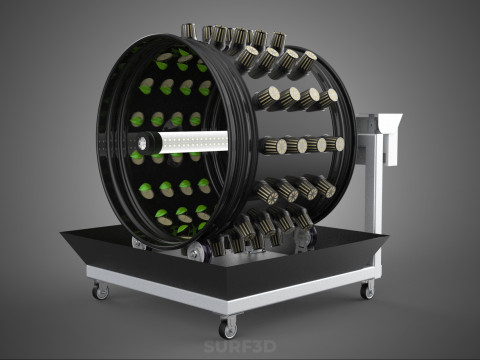

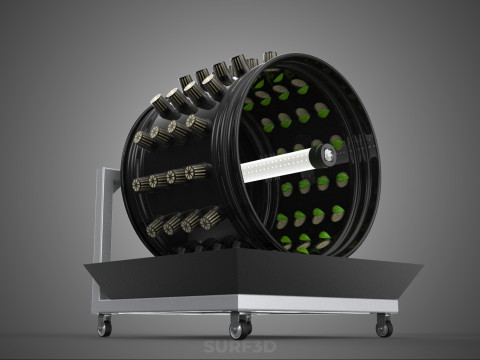

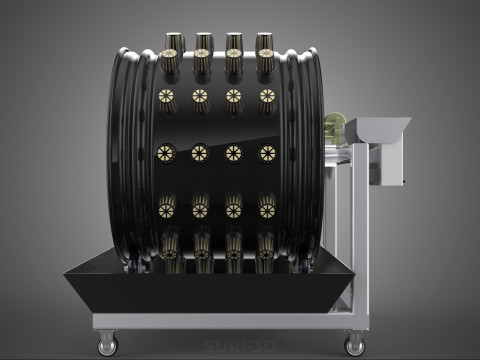

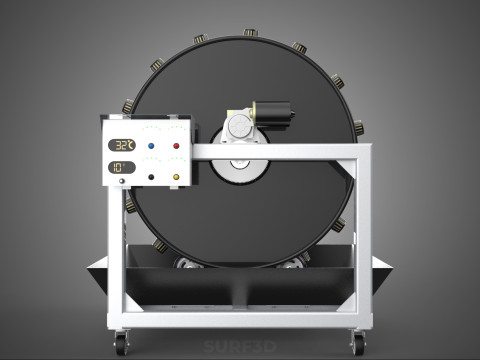

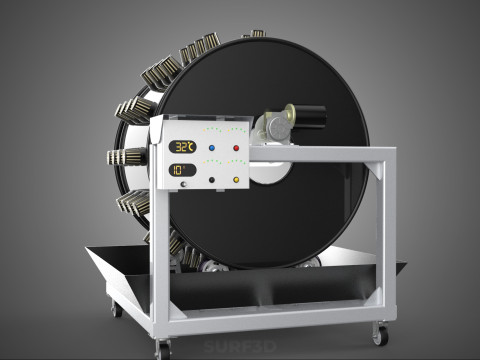

A Circular Spin Rotary Hydroponic Garden Plant Farm System Wheel, frequently termed a rotary hydroponic system, vertical rotary farm, or simply a hydroponic wheel, represents a sophisticated method within Controlled Environment Agriculture (CEA) designed for maximized plant cultivation in a compact footprint. This advanced system integrates soilless hydroponic cultivation with a mechanical rotational mechanism, typically structured as a large, often drum-shaped or Ferris-wheel-like apparatus, to grow plants using nutrient-rich water solutions.

**Principle of Operation:**

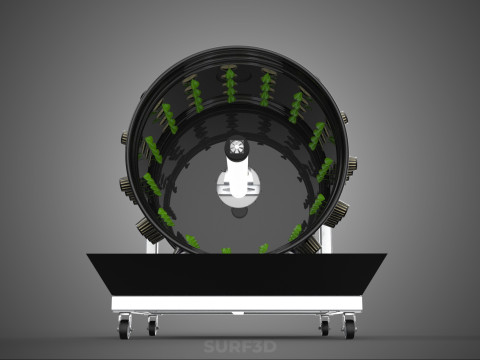

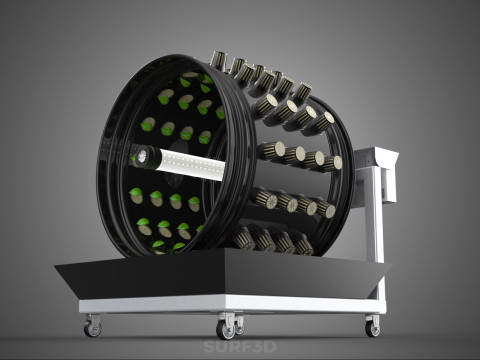

The core operational principle revolves around a central, high-intensity light source—commonly high-intensity discharge (HID) lamps or modern LED arrays—around which plants are radially arranged. These plants are housed in individual growing chambers or trays securely affixed to a slowly rotating structure. As the wheel uniformly revolves, each plant station sequentially passes through the optimal light zone, ensuring consistent and intensive light exposure across all plants. This rotational strategy obviates the need for multiple, spatially distributed light sources, enabling more efficient utilization of a single powerful central light and thereby enhancing energy efficiency per plant unit. Nutrient delivery is accomplished through a closed-loop hydroponic system. A pump circulates precisely formulated nutrient solution from a reservoir to the plant roots via various integrated methods, such as drip irrigation, the Nutrient Film Technique (NFT), or the Deep Flow Technique (DFT), which can be incorporated into the rotating modules or applied at specific watering points during the rotation. The unused solution then drains back into the reservoir, minimizing water and nutrient waste.

**Key Components:**

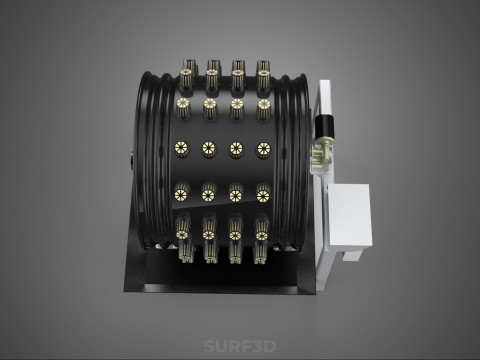

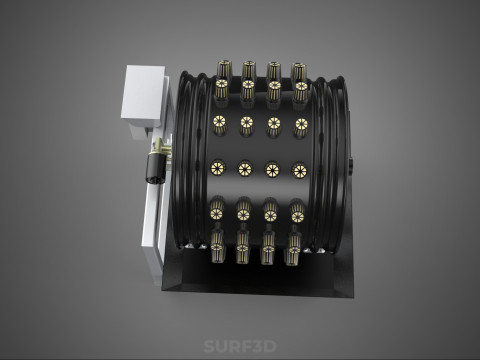

A typical rotary hydroponic system comprises several essential elements:

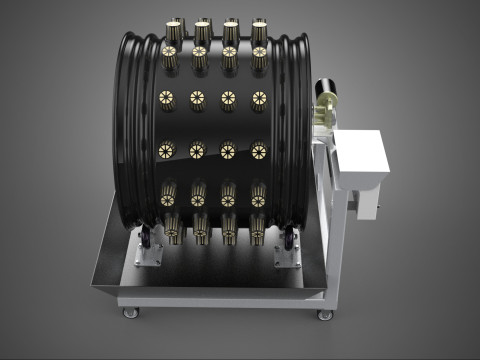

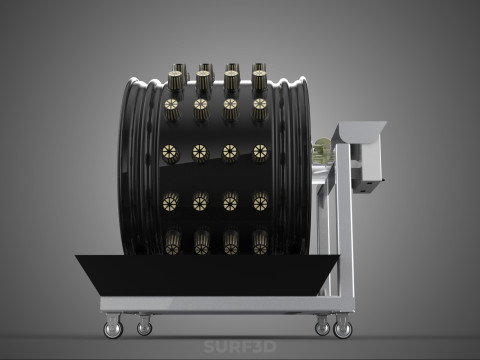

1. **Rotating Structure:** A robust, circular, or drum-shaped frame equipped with pockets or attachment points for individual plant containers, driven by an electric motor and a geared mechanism.

2. **Plant Holders/Modules:** Inert growing media (e.g., net pots, rockwool, coco coir) embedded within secure modules that accommodate the plants' root systems.

3. **Central Light Source:** High-efficiency lamps strategically positioned at the core of the wheel to provide primary illumination.

4. **Nutrient Reservoir:** A tank designed to hold and maintain the precisely balanced hydroponic nutrient solution.

5. **Pumping and Irrigation System:** Pumps, intricate tubing, and emitters or channels responsible for circulating the nutrient solution from the reservoir to the plants.

6. **Environmental Control System:** Advanced sensors and automation platforms to monitor and precisely adjust critical parameters including temperature, humidity, carbon dioxide (CO2) levels, pH, electrical conductivity (EC) of the nutrient solution, and the rotation speed of the wheel.

7. **Support Frame:** A stable, static structure that securely houses the rotating wheel and all ancillary equipment.

**Advantages:**

Rotary hydroponic systems offer a suite of significant benefits in controlled environment agriculture:

* **Exceptional Space Utilization:** By arranging plants vertically and leveraging rotational movement, these systems achieve extraordinarily high plant densities per unit of floor space, making them ideal for urban agriculture and environments with limited land.

* **Superior Water Efficiency:** Operating as a recirculating hydroponic system, water consumption is dramatically reduced, often by up to 90% compared to conventional soil-based farming.

* **Optimized Light Exposure:** The continuous rotation ensures all plants receive uniform, consistent, and precisely timed exposure to the central light source, fostering even growth and development.

* **Accelerated Growth and Yields:** The combination of meticulously controlled environmental conditions, precise nutrient delivery, and optimal light exposure frequently results in faster growth cycles, increased biomass, and higher overall yields.

* **Reduced Pest and Disease Risk:** The isolated, indoor, and often sterile environment significantly minimizes exposure to external pests, pathogens, and weeds, thereby reducing the reliance on pesticides and herbicides.

* **Year-Round Production Capability:** Insulated from external weather and seasonal variations, these systems facilitate continuous, year-round cultivation of crops.

* **High Automation Potential:** Extensive automation capabilities for nutrient delivery, lighting cycles, and environmental regulation minimize manual labor requirements and optimize operational efficiency.

**Disadvantages and Considerations:**

Despite their numerous advantages, rotary hydroponic systems also present challenges:

* **High Initial Investment:** The specialized equipment, construction, and sophisticated automation required entail a substantial upfront capital outlay.

* **Energy Consumption:** While efficient per plant, the cumulative energy demand for lighting, pumps, motors, and climate control can be considerable, necessitating careful energy management.

* **Technical Complexity:** Operation and maintenance require specialized expertise in hydroponics, plant physiology, system engineering, and automation.

* **Plant Suitability Limitations:** Not all plant species are equally well-suited; deep-rooted plants, large vining crops, or those requiring extensive individual space may be challenging to cultivate efficiently in this configuration.

* **Single Point of Failure Risk:** A malfunction in a critical component (e.g., motor, pump, lighting array, environmental controller) can potentially impact a significant portion or the entirety of the crop.

**Applications:**

These systems are predominantly utilized in:

* **Commercial Urban Farms:** For producing fresh, local, and high-quality produce within metropolitan areas.

* **Agricultural Research and Development:** Facilitating precise experimentation in plant science due to their highly controlled growing environments.

需要更多的格式吗?

如果你需要一个不同的格式,请打开一个新的支持票和为此请求。我们可以转换到 3D 模型: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 免费格式转换我们不转换 3d 场景 以及 .step, .iges, .stp, .sldprt 等格式。!

使用信息

圆形旋转水培园林植物农场系统轮 - 您可以根据基本许可或扩展许可,将此免版税 3D 模型用于个人或商业用途。基本许可涵盖大多数标准用例,包括数字广告、设计和可视化项目、商业社交媒体账户、原生应用、Web 应用、视频游戏以及实体或数字最终产品(免费和出售)。

扩展许可包含基本许可授予的所有权利,没有任何使用限制,并允许在免版税条款下将 3D 模型用于无限的商业项目。

阅读更多

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी