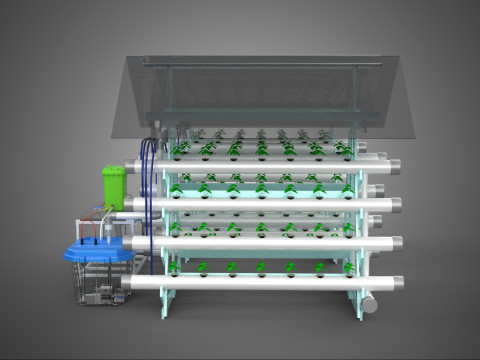

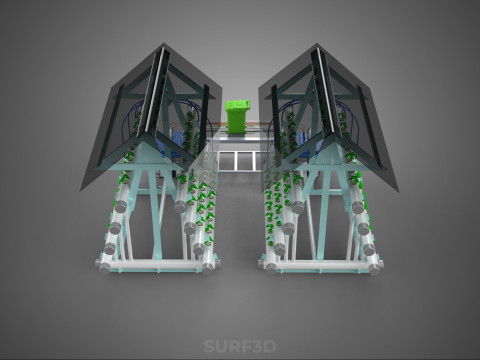

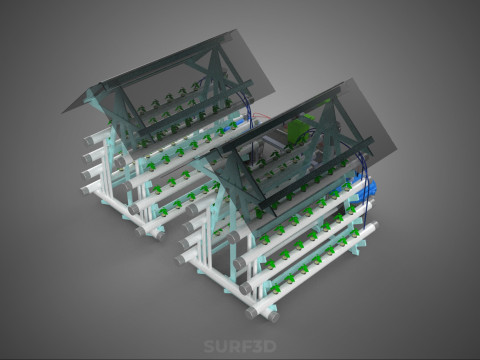

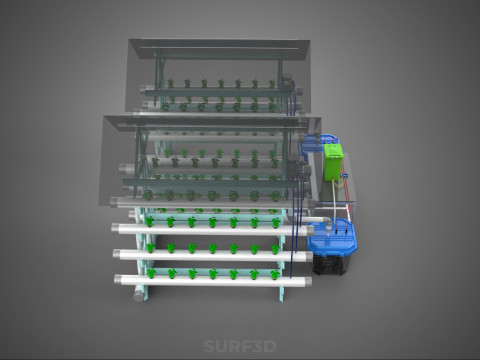

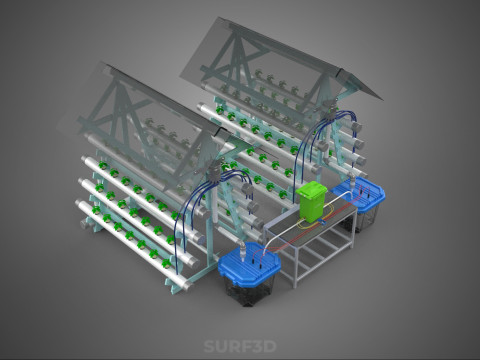

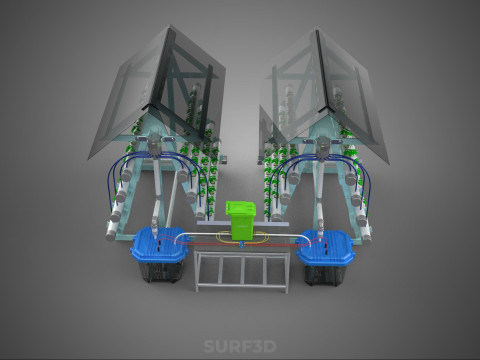

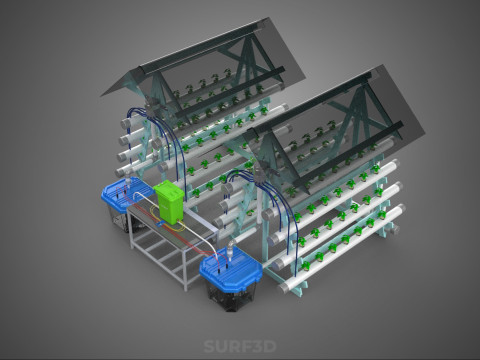

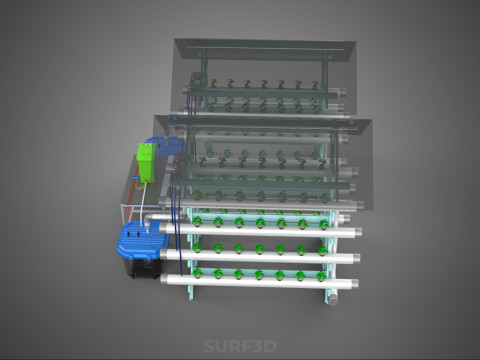

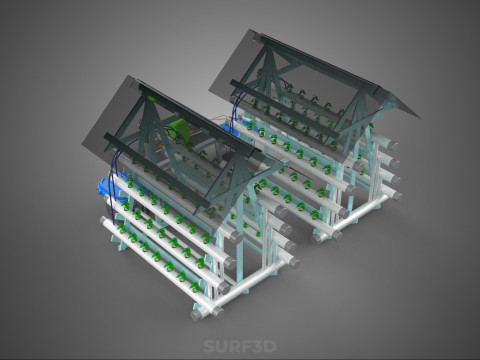

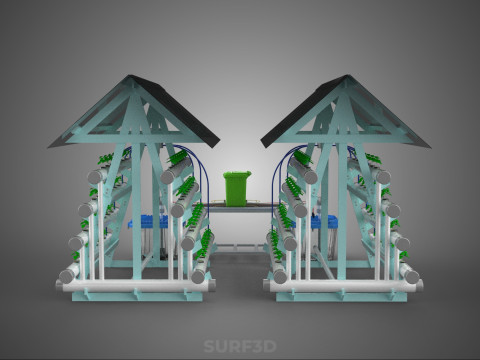

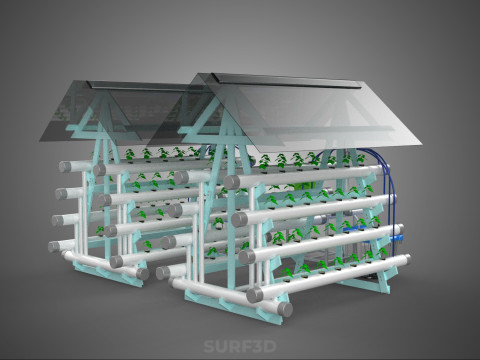

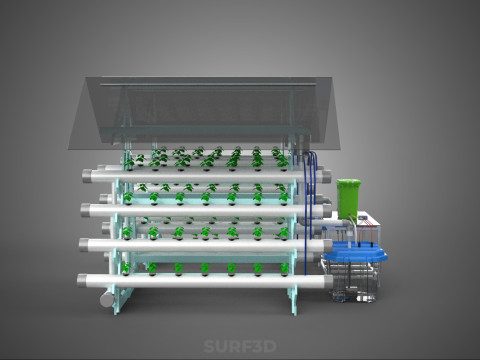

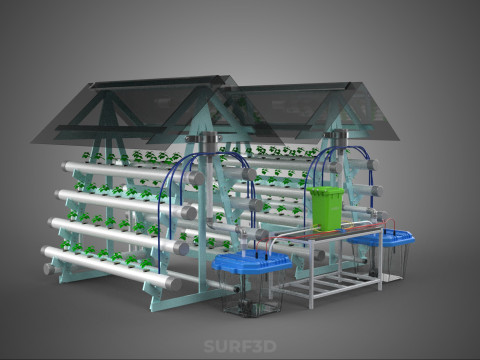

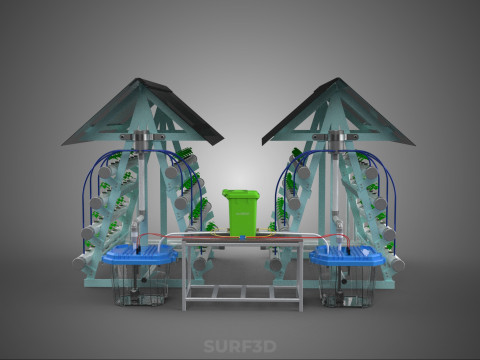

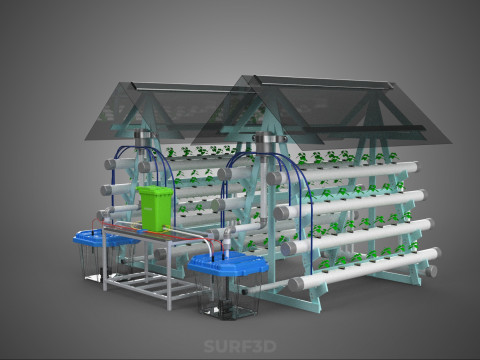

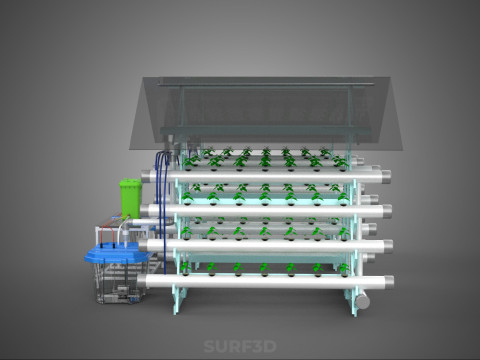

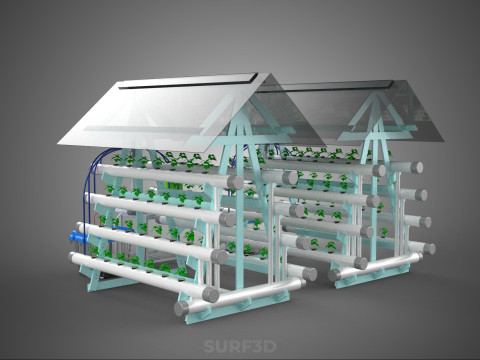

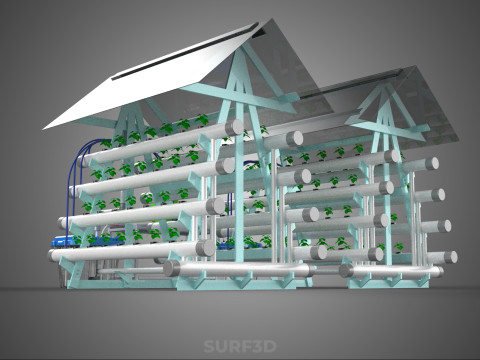

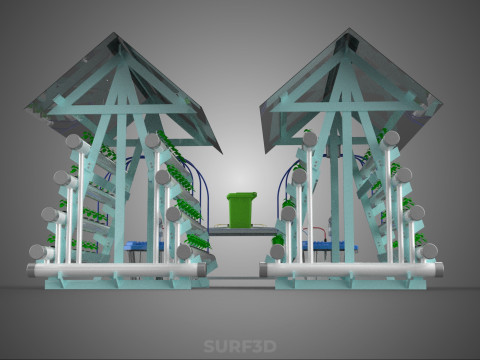

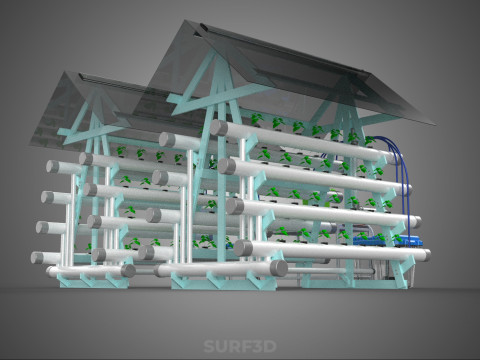

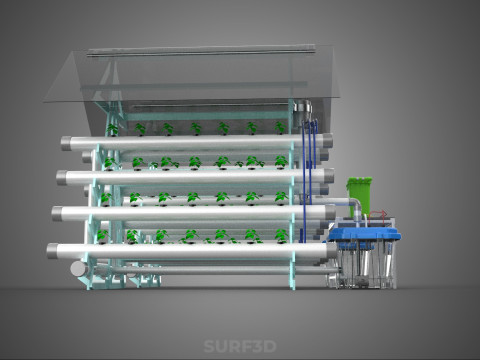

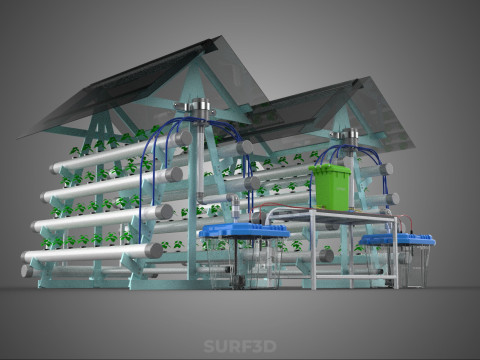

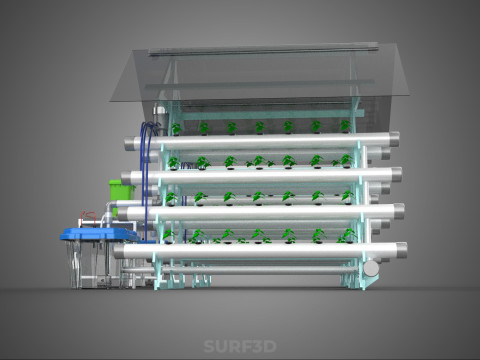

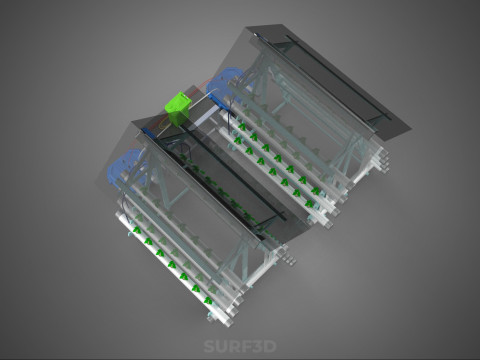

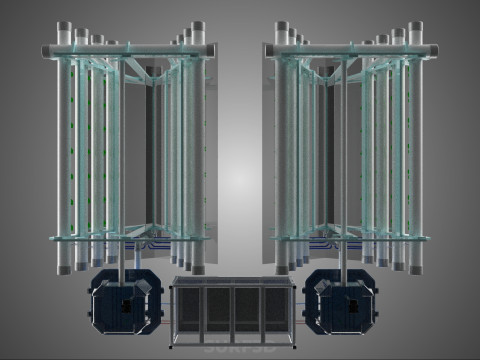

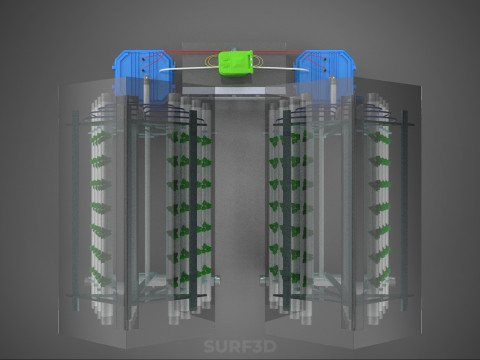

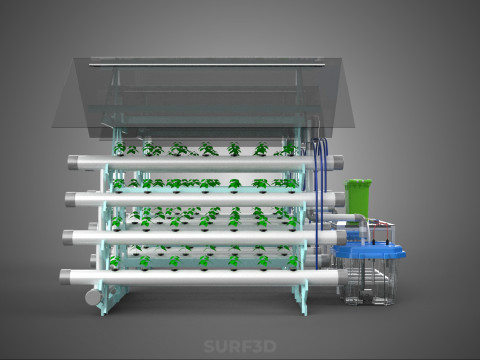

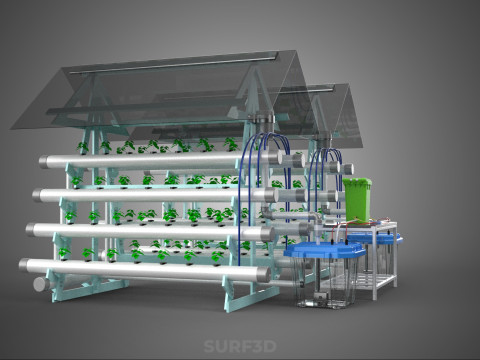

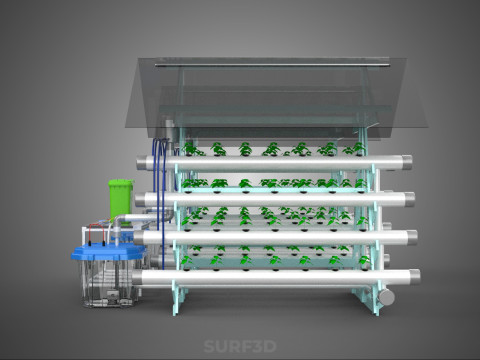

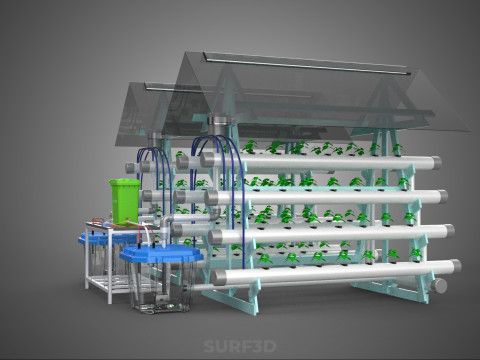

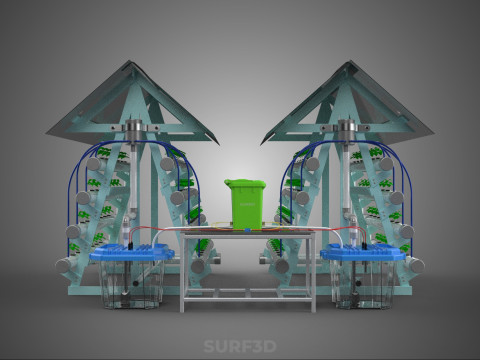

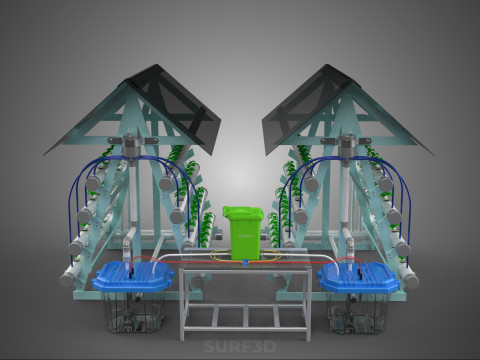

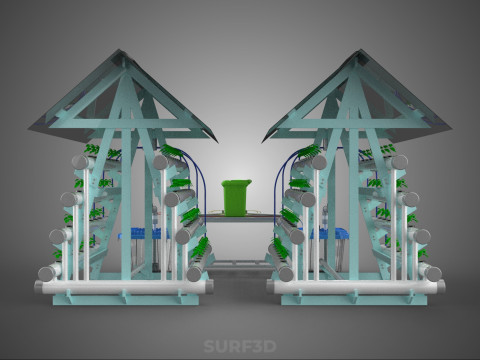

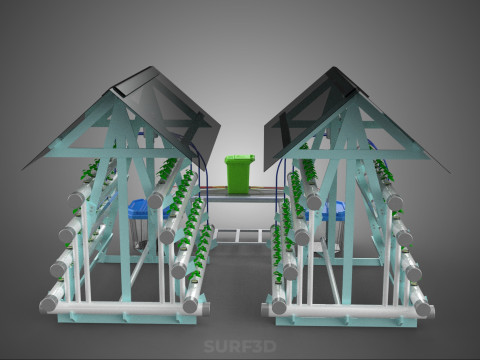

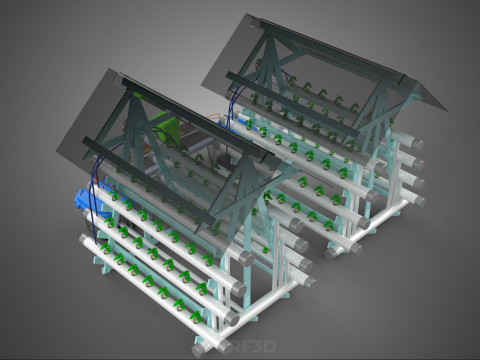

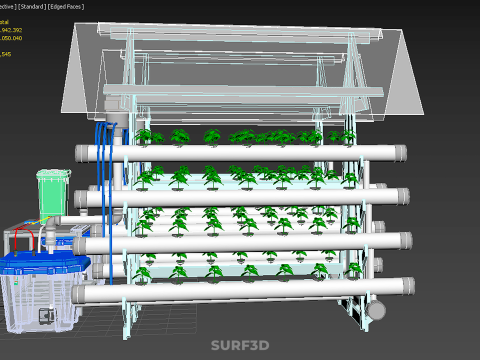

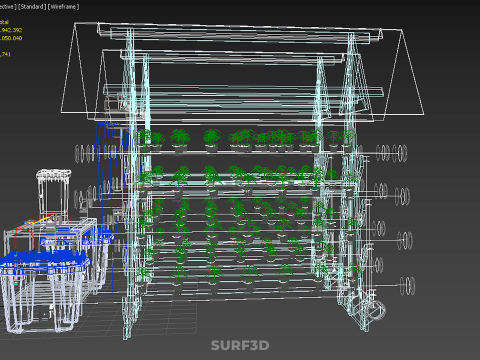

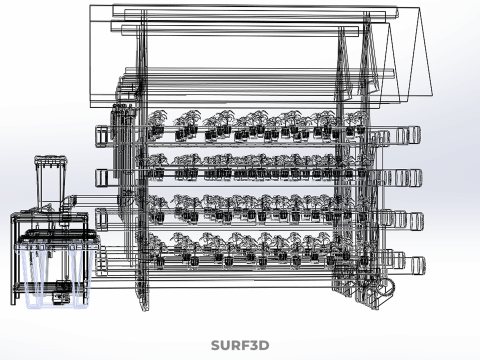

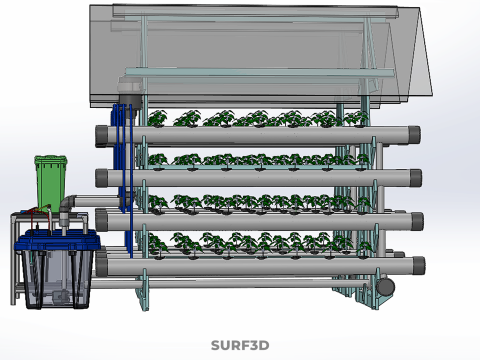

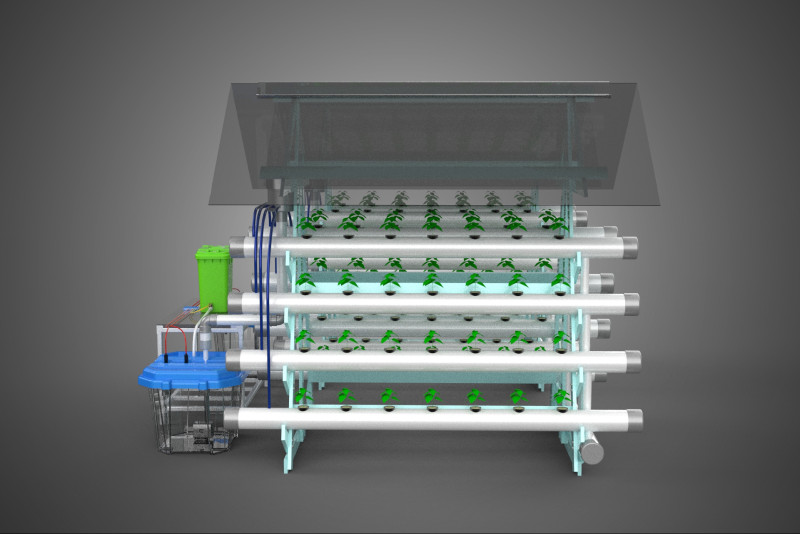

AUTO CONTROL MONITORING NUTRIENT DELIVERY HYDROPONIC PLANT FARM Modèle 3D

- Formats disponibles: STEP (.step) 15.00 MBSketchUp (.skp) 12.34 MBCollada (.dae) 36.87 MBIGES (.iges) 11.99 MBAutodesk 3DS MAX (.max) 72.42 MBRhinoceros (.3dm) 45.17 MBAutoCAD (.dwg) 28.46 MB3D Studio (.3ds) 13.90 MBAutodesk FBX (.fbx) 70.06 MBStereolithography (.stl) 36.86 MBGLB (.glb / .gltf) 17.57 MBBlender3D (.blend) 38.38 MBWavefront OBJ (.obj) 34.84 MBACIS(.sat) 34.30 MB

- Polygones:2942392

- Sommets:2050040

- Animé:No

- Textures:No

- Installé:No

- Matériaux:

- Bas-poly:No

- Collection:No

- cartographie UVW:No

- Plugins Utilisé:No

- Prêt à imprimer:No

- 3D Balayage:No

- Contenu adulte:No

- PBR:No

- IA Formation:No

- Géométrie:Poly NURBS

- UVs non enveloppés:Unknown

- Vus:27

- Date: 2025-09-06

- ID de produit:597291

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

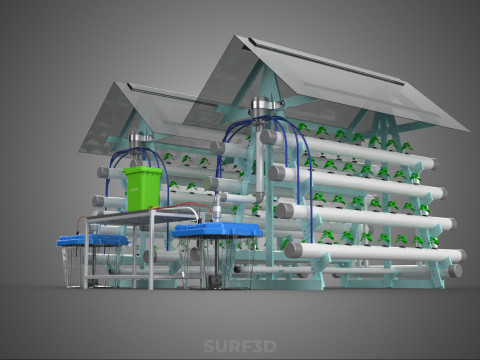

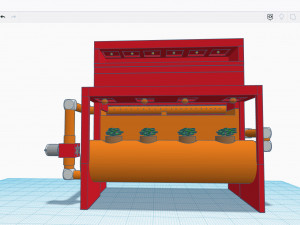

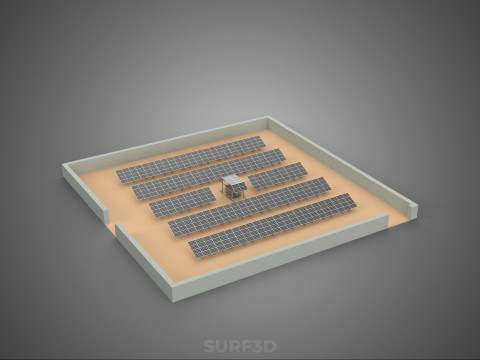

An Auto Control Monitoring Nutrient Delivery Hydroponic Plant Farm represents an advanced, highly automated system for soilless cultivation of plants, designed to optimize growth conditions, maximize yields, and conserve resources. This integrated approach combines the principles of hydroponics with sophisticated sensor technology, real-time data analysis, and automated control mechanisms to precisely manage the delivery of essential nutrients to plants. It falls under the umbrella of Controlled Environment Agriculture (CEA) and precision agriculture, leveraging technology to create an ideal growing environment independent of soil or external climatic variations.

**Fundamental Principles**

The core of this system is hydroponics, a method of growing plants in nutrient-rich water solutions instead of soil. This technique allows for direct delivery of water, oxygen, and minerals to plant roots, leading to faster growth rates and more efficient resource utilization compared to traditional soil-based farming. Common hydroponic methods integrated into such farms include Nutrient Film Technique (NFT), Deep Water Culture (DWC), Aeroponics, and Drip Systems, each offering specific advantages depending on the plant species and scale of operation.

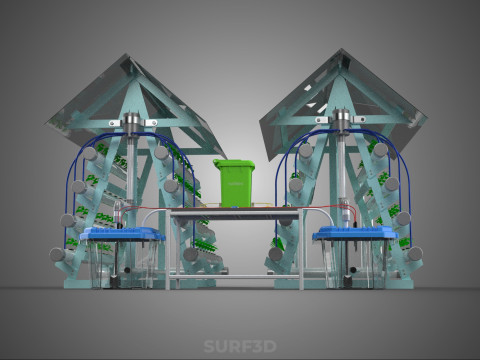

**System Architecture and Components**

The operational efficacy of an auto control monitoring nutrient delivery hydroponic plant farm relies on the seamless interaction of several subsystems:

1. **Hydroponic Growth System**: This forms the physical infrastructure where plants are cultivated. It includes channels, troughs, or containers for holding plant roots, a reservoir for the nutrient solution, and a pump for circulating the solution. The design facilitates optimal root aeration and nutrient uptake.

2. **Monitoring Subsystem**: This crucial component continuously gathers data on critical environmental and solution parameters. Key sensors typically measure:

* **Electrical Conductivity (EC) or Total Dissolved Solids (TDS)**: Indicates the concentration of dissolved mineral salts (nutrients) in the solution, directly impacting nutrient availability.

* **pH**: Measures the acidity or alkalinity of the nutrient solution, which profoundly affects nutrient solubility and plant uptake efficiency.

* **Temperature**: Monitored in both the nutrient solution and the ******t air, influencing plant metabolic rates and disease susceptibility.

* **Dissolved Oxygen (DO)**: Essential for root respiration and overall plant health.

* **Water Level**: Tracks the volume of solution in the reservoir, triggering refills or adjustments.

* **Humidity and Light Intensity**: (Optional, but common in CEA) Monitor atmospheric conditions and Photosynthetically Active Radiation (PAR) for optimal photosynthesis.

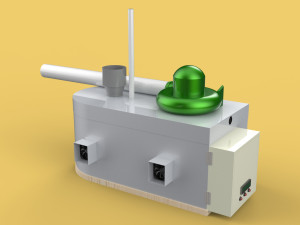

3. **Nutrient Delivery Subsystem**: This manages the precise formulation and replenishment of the nutrient solution. It typically comprises:

* **Stock Solution Reservoirs**: Separate containers holding concentrated acidic, alkaline, and specific macronutrient and micronutrient solutions (e.g., NPK, calcium, magnesium, trace elements).

* **Dosing Pumps**: Peristaltic or diaphragm pumps, often digitally controlled, that accurately inject specified volumes of stock solutions into the main reservoir or directly into the circulating system based on monitoring data.

4. **Auto Control Subsystem**: This is the intelligence of the farm, processing data from the monitoring subsystem and actuating the nutrient delivery. It typically consists of:

* **Programmable Logic Controller (PLC) or Microcontroller**: The central processing unit that executes pre-programmed algorithms.

* **Feedback Control Loop**: The controller compares real-time sensor data (e.g., current pH) with predefined optimal "setpoints" (e.g., target pH 5.8-6.2). If a deviation is detected, the controller activates appropriate dosing pumps (e.g., acid or base for pH adjustment, nutrient solutions for EC adjustment) until the setpoint is restored.

* **Data Logging and Communication**: Records historical data for analysis, trend identification, and remote monitoring/control via internet-of-things (IoT) platforms.

**Operational Flow**

The system operates in a continuous feedback loop. Sensors constantly feed data to the central controller. The controller analyzes this data against pre-programmed setpoints for parameters like pH, EC, and solution temperature, which are critical for specific plant species at different growth stages. If a parameter deviates from its setpoint, the controller activates the appropriate dosing pumps to introduce precise amounts of concentrated nutrients, pH adjusters (acid or base), or fresh water into the main nutrient reservoir. This ensures that the plant roots are consistently bathed in an optimally balanced and stable nutrient solution. Light cycles, temperature, and humidity within the growing environment can also be integrated into this automated control for a truly comprehensive CEA system.

**Advantages and Applications**

The implementation of auto control monitoring nutrient delivery systems in hydroponic farms offers numerous benefits:

* **Optimized Plant Growth**: Consistent, ideal conditions lead to faster growth, healthier plants, and higher yields.

* **Resource Efficiency**: Significant reduction in water consumption (up to 90% less than soil farming due to recirculation), minimized nutrient waste, and efficient use of space.

* **Reduced Labor**: Automation decreases the need for manual monitoring and adjustments, freeing up personnel for other tasks.

* **Pest and Disease Control**: Closed systems reduce exposure to soil-borne pathogens and pests, often minimizing pesticide use.

* **Environmental Sustainability**: Lower environmental footprint through reduced water, land, and chemical usage.

* **Consistent Quality**: Produces crops with uniform characteristics and predictable harvests.

* **Scalability**: Adaptable for small-scale urban farming to large-scale commercial operations and vertical farms.

Si vous avea besoin d’\autre format veuillez ouvrir un billet d’\assistance et demandez le. Nous pouvons convertir les modèles de 3D en: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Nous ne convertissons pas les scènes 3D et des formats tels que .step, .iges, .stp, .sldprt.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी