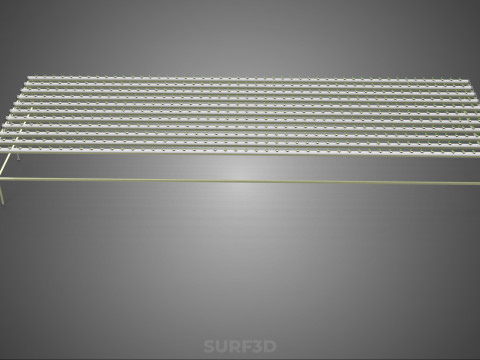

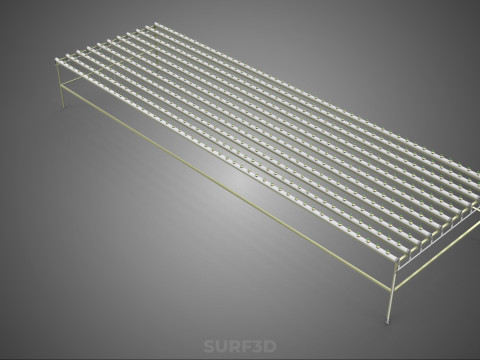

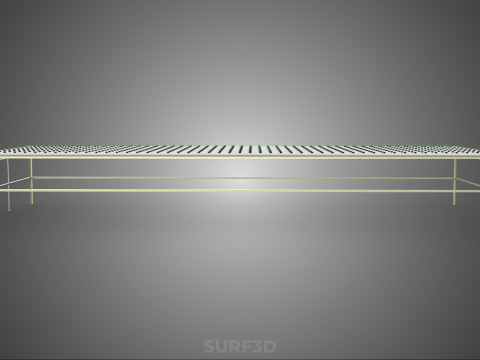

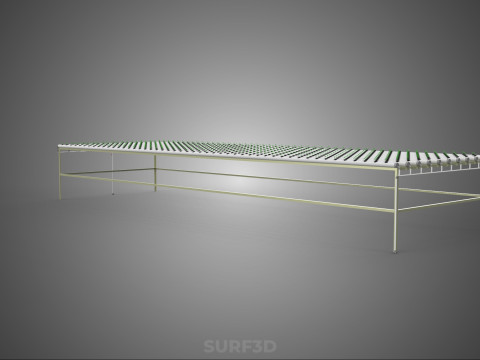

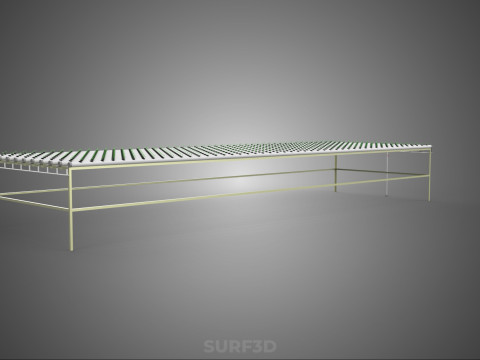

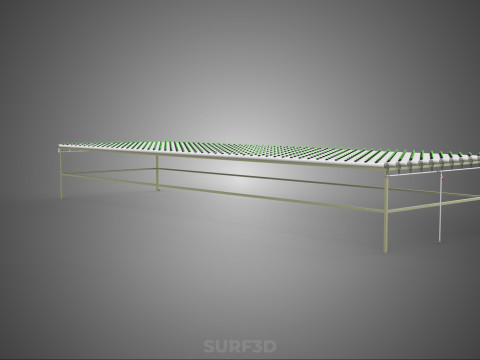

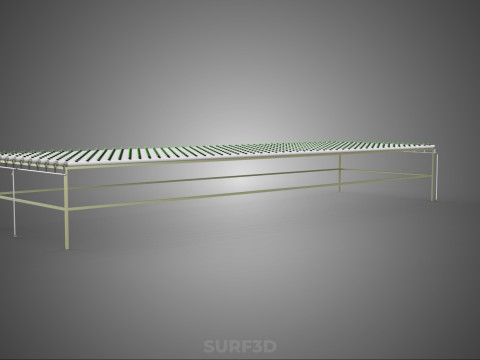

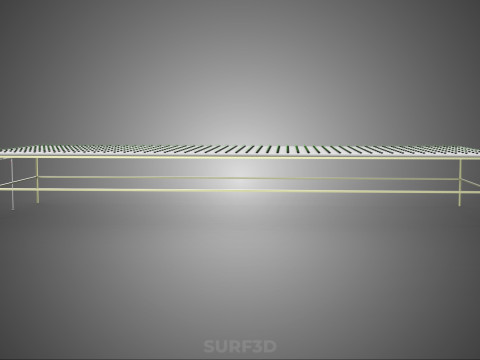

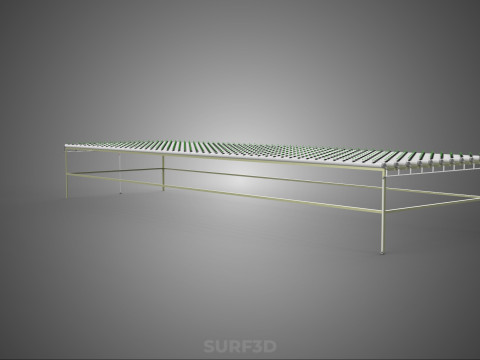

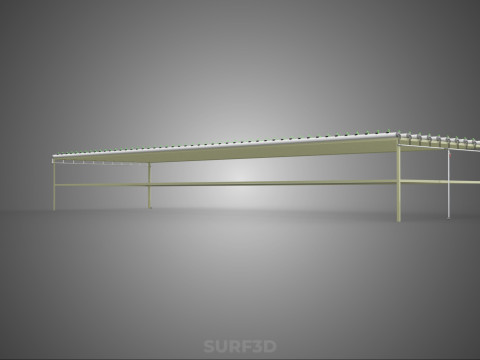

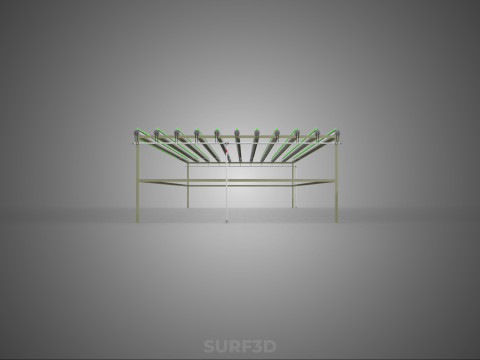

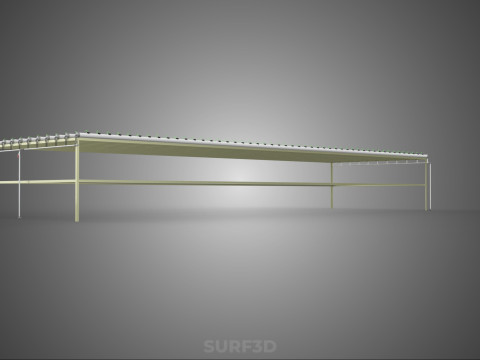

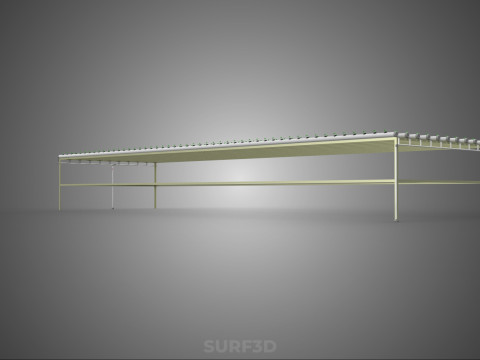

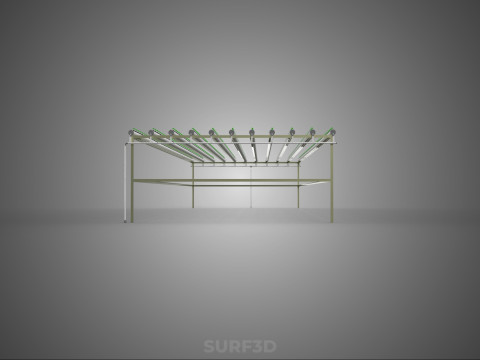

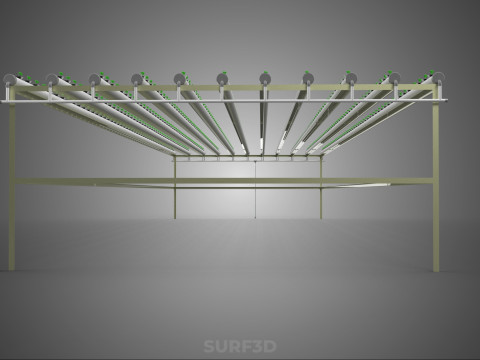

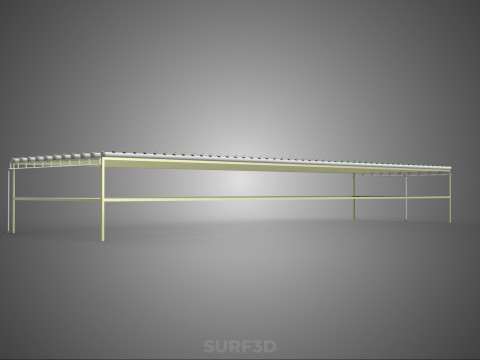

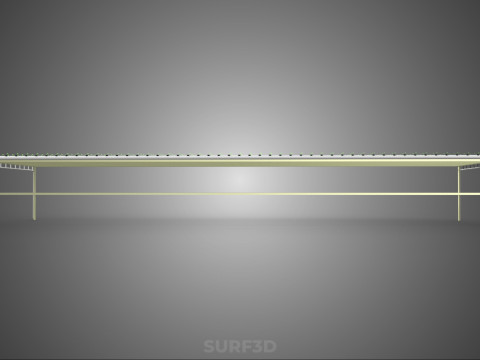

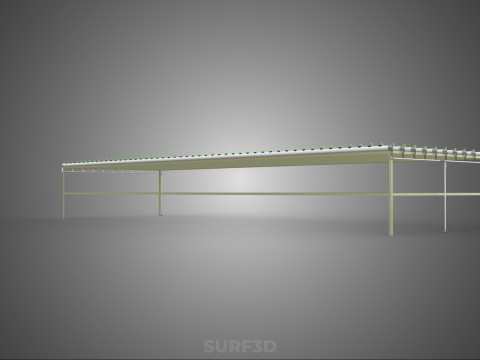

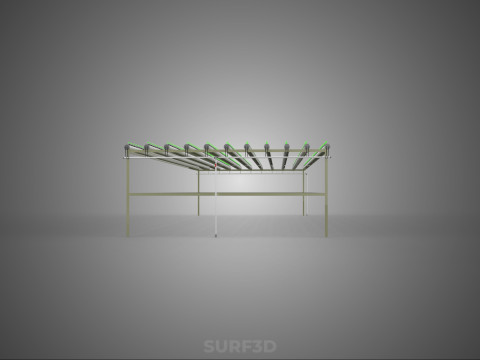

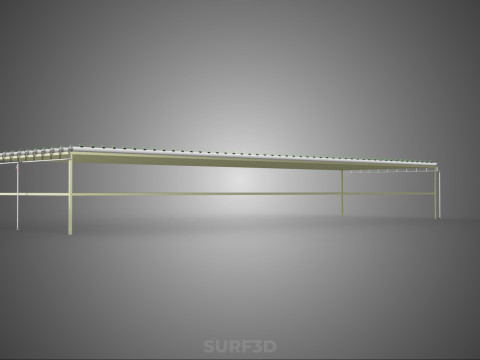

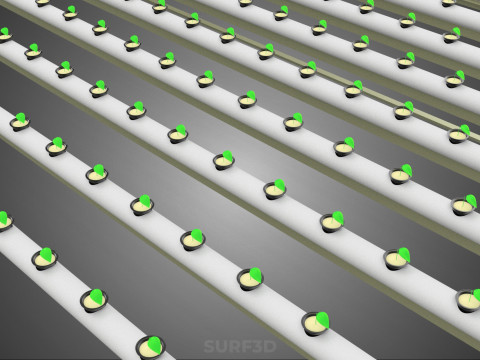

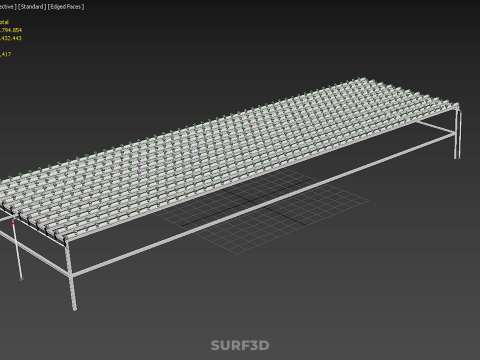

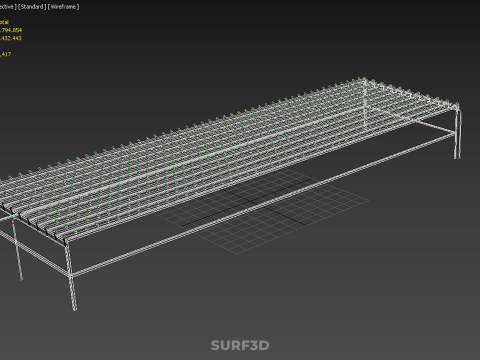

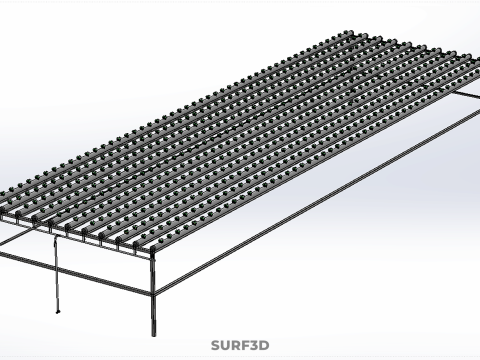

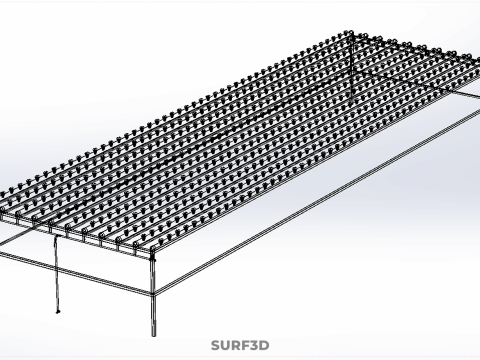

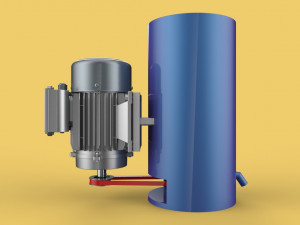

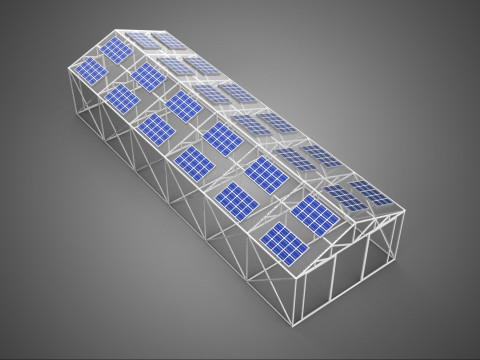

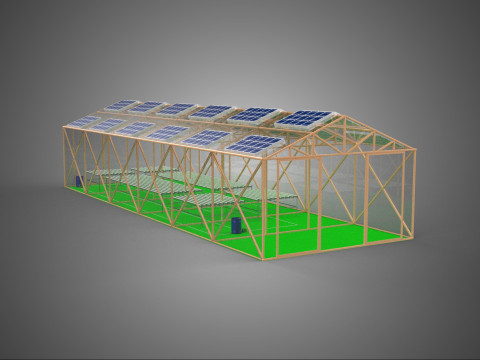

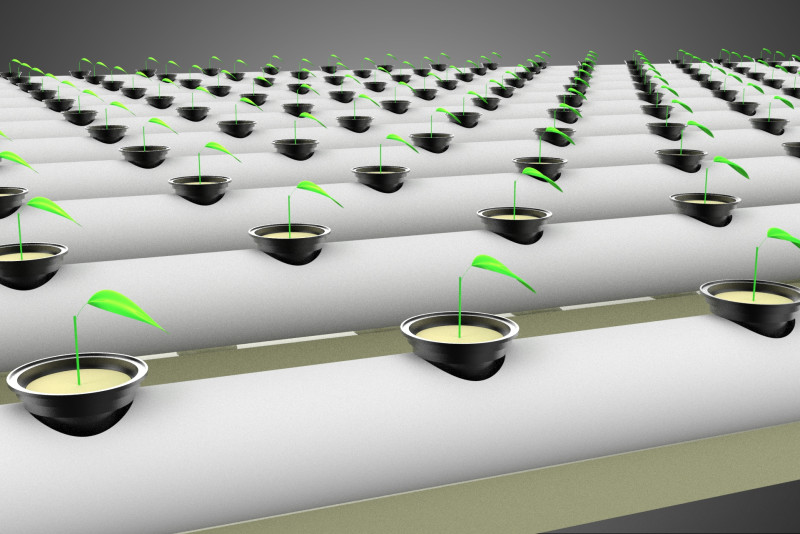

FILET DE SEMIS POT CROISSANCE SYSTÈMES DE FERME HYDROPONIQUE PARALLÈLE PVC Modèle 3D

- Formats disponibles: Rhinoceros (.3dm) 3.64 MB3D Studio (.3ds) 34.35 MBBlender3D (.blend) 99.48 MBCollada (.dae) 74.76 MBAutodesk AutoCAD (.dwg) 29.66 MBGLB (.glb / .gltf) 27.15 MBIGES (.iges) 766.69 kbAutodesk 3DS MAX (.max) 174.63 MBWavefront OBJ (.obj) 87.73 MBACIS(.sat) 94.74 MBSketchUp (.skp) 1.56 MBSTEP (.step) 902.42 kbStereolithography (.stl) 78.43 MBAutodesk FBX (.fbx) 175.98 MB

- Polygones:8794854

- Sommets:7432443

- Animé:No

- Textures:No

- Installé:No

- Matériaux:

- Bas-poly:No

- Collection:No

- cartographie UVW:No

- Plugins Utilisé:No

- Prêt à imprimer:No

- 3D Balayage:No

- Contenu adulte:No

- PBR:No

- IA Formation:No

- Géométrie:Poly NURBS

- UVs non enveloppés:Unknown

- Vus:28

- Date: 2025-10-27

- ID de produit:607719

FILET DE SEMIS POT CROISSANCE SYSTÈMES DE FERME HYDROPONIQUE PARALLÈLE PVC Modèle 3D 3dm, 3ds, blend, dae, dwg, glb, iges, max, obj, sat, skp, step, stl, fbx, De surf3d

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

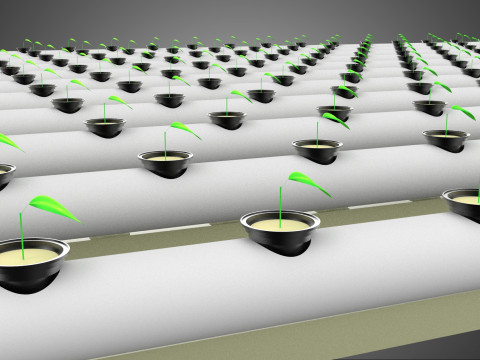

The apparatus described, "SEEDLING NET POT CUP GROWTH HYDROPONIC FARM SYSTEMS PARALLEL PVC," refers to a highly standardized, pipe-based configuration utilized in controlled environment agriculture (CEA) for high-density plant cultivation without soil (soilless culture). This system is designed for maximizing spatial efficiency, particularly during the critical establishment and vegetative growth phases of seedlings.

### Nomenclature and System Classification

This configuration typically falls under the category of recirculating hydroponics, most commonly implementing variations of the Nutrient Film Technique (NFT) or shallow Deep Water Culture (DWC). The system is defined by its reliance on Polyvinyl Chloride (PVC) channels to deliver and retrieve a precisely formulated aqueous nutrient solution. It is structurally rigid, scalable, and engineered for long-term commercial or institutional operation.

### Component Analysis

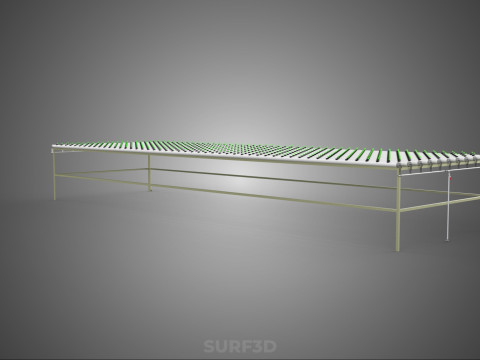

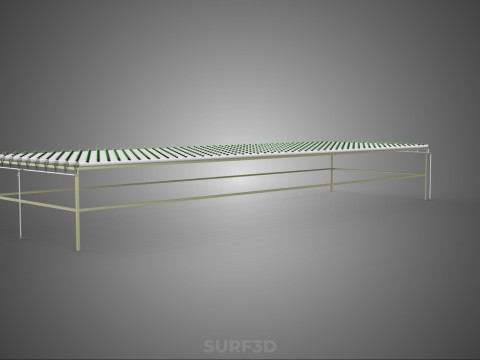

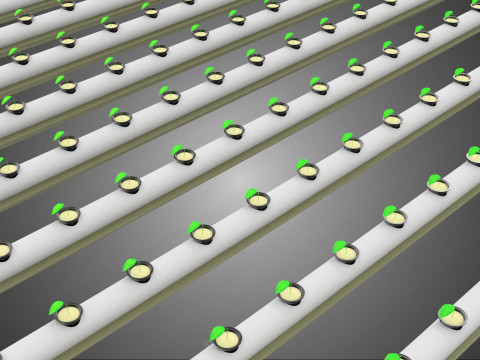

#### 1. Seedling and Growth Integration

The operation begins with the transplantation of juvenile plants (seedlings), typically germinated in an inert propagation medium such as rockwool or coco coir plugs. The system is optimized for crops with moderate root requirements and short cycles, including leafy greens (e.g., lettuce, kale), culinary herbs, and certain small vine crops. The use of net pots facilitates a seamless transition from nursery to the main grow system, minimizing transplant shock.

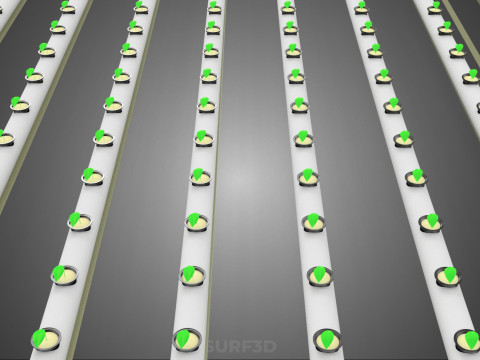

#### 2. Net Pot Cup Design

The net pot cup acts as the physical interface between the plant and the hydroponic channel. These containers are manufactured from inert, food-grade plastics, typically High-Density Polyethylene (HDPE) or Polypropylene (PP), ensuring chemical non-reactivity with the nutrient solution.

Key design features include:

* **Mesh Structure:** A lattice or mesh sidewall design allows for unrestricted root growth outside the pot and into the nutrient stream, promoting optimal oxygen exchange and nutrient absorption.

* **Support:** The lip of the net pot is designed to rest securely within pre-drilled apertures along the top surface of the PVC pipe, suspending the plant mass above the nutrient solution or within a shallow flow layer.

* **Standardization:** Net pot diameters are standardized (commonly 50mm, 70mm, or 80mm) to ensure compatibility with standardized PVC piping dimensions and hole saws.

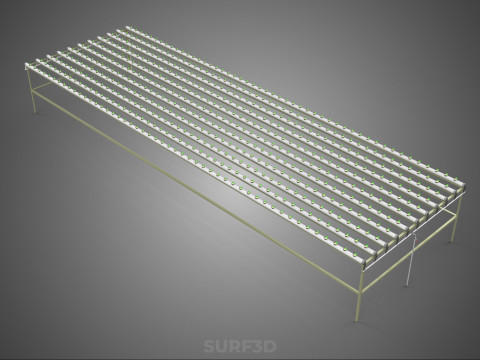

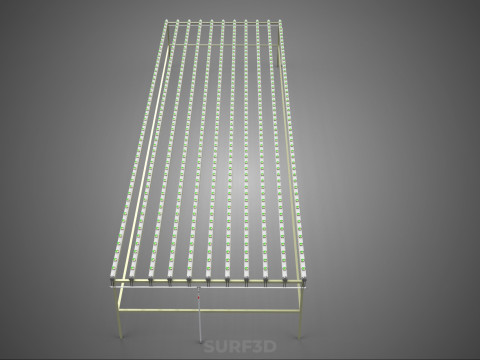

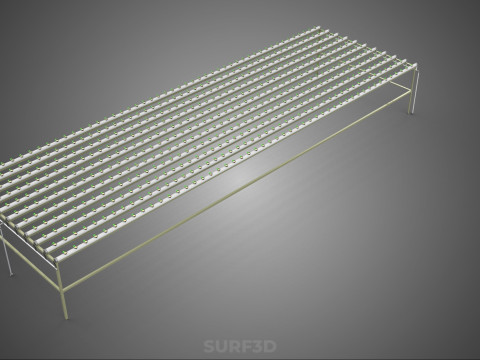

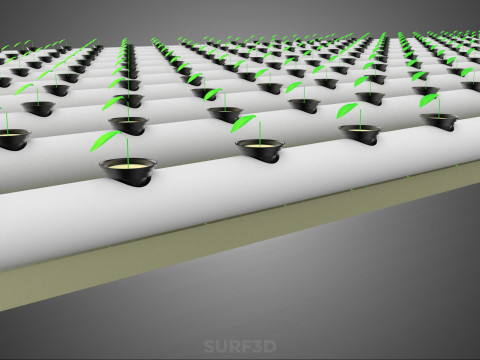

#### 3. Parallel PVC Farm Systems

The structural backbone of the system is the series of parallel PVC channels. This arrangement is foundational to large-scale efficiency and uniformity:

* **Structure and Material:** Schedule 40 or similar durable PVC piping (commonly 100mm or 150mm diameter) is employed due to its durability, low cost, corrosion resistance, and suitability for handling potable water. The white exterior color is often preferred to reflect light and mitigate thermal absorption, preventing excessive heating of the nutrient solution.

* **Parallel Configuration:** Multiple lengths of PVC pipe are aligned in a side-by-side (parallel) fashion, supported by a framework (often metal racking or specialized PVC stands). This geometry maximizes the planting density (plants per square meter) and ensures accessibility for monitoring and harvesting.

* **Flow Dynamics:** The parallel channels are installed with a slight, continuous gradient (typically 1% to 3% slope) to harness gravity, ensuring that the nutrient solution flows consistently from a primary header pipe along the array length and returns to a centralized reservoir via a collection gutter or drain pipe. This continuous circulation maintains consistent nutrient delivery (Electrical Conductivity, EC) and acidity (pH) throughout the system.

### Operational Advantages

The parallel PVC net pot system offers significant benefits in controlled agriculture:

1. **Water Efficiency:** Recirculating systems achieve extremely high water use efficiency, typically utilizing less than 10% of the water required by traditional field agriculture.

2. **Nutrient Control:** Precise control over nutrient concentration and composition is possible, leading to accelerated growth cycles and consistent crop quality.

3. **Disease Management:** The isolation of the root systems within separate pipe channels minimizes the potential for rapid spread of waterborne pathogens.

4. **Scalability:** The modular design of the parallel rows allows for straightforward vertical or horizontal expansion of the growing operation.

This setup is the dominant choice for mechanized, commercial production of high-value, fast-turnaround crops globally.

KEYWORDS: Hydroponics, NFT, Deep Water Culture, Recirculating System, Net Pot, PVC Piping, Seedling Growth, Parallel Array, Controlled Environment Agriculture, CEA, Soilless Culture, Nutrient Film Technique, Rockwool, HDPE, Polypropylene, Commercial Hydroponics, Vegetative Phase, Transplanting, Nutrient Solution, Flow Dynamics, Gravity Feed, Schedule 40, Crop Density, Water Efficiency, Modular System, Scalability, Greenhouse, Food-Grade Plastic, Root Zone.

Avez besoin de plus de formats?

Si vous avea besoin d’\autre format veuillez ouvrir un billet d’\assistance et demandez le. Nous pouvons convertir les modèles de 3D en: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Nous ne convertissons pas les scènes 3D et des formats tels que .step, .iges, .stp, .sldprt.!Informations d'utilisation

FILET DE SEMIS POT CROISSANCE SYSTÈMES DE FERME HYDROPONIQUE PARALLÈLE PVC - Vous pouvez utiliser ce modèle 3D libre de droits à des fins personnelles et commerciales, conformément à la Licence de Base ou à la Licence Étendue.La Licence de Base couvre la plupart des cas d'utilisation courants, notamment les publicités numériques, les projets de conception et de visualisation, les comptes de réseaux sociaux professionnels, les applications natives, les applications web, les jeux vidéo et les produits finis physiques ou numériques (gratuits ou payants).

La Licence Étendue inclut tous les droits accordés par la Licence de Base, sans limitation d'utilisation, et autorise l'utilisation du modèle 3D dans un nombre illimité de projets commerciaux, dans des conditions de libre de droits.

En savoir plus

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी