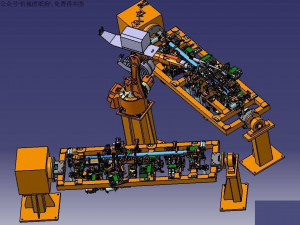

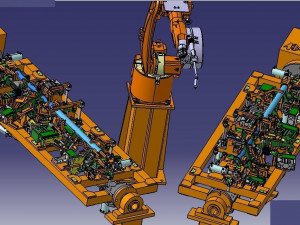

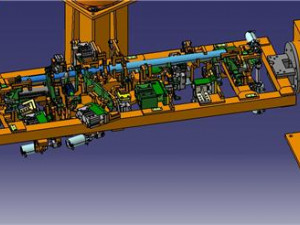

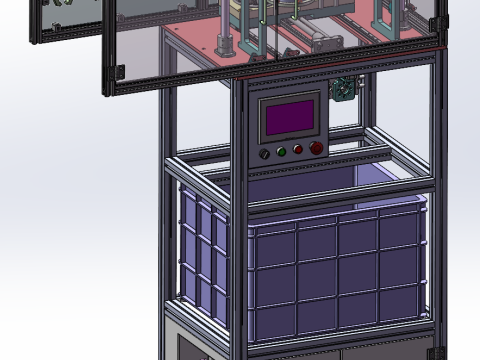

welding jig for welding of instrument frame welding beam Modèle 3D

CYBER MONDAY

SALE 50% OFF

$

8.50 USD

- Demander l'assistance produit

- Formats disponibles:

- ID de produit:314443

- Date: 2020-09-29

- Animé:No

- Textures:No

- Installé:No

- Matériaux:

- Bas-poly:No

- Collection:No

- cartographie UVW:No

- Plugins Utilisé:No

- Prêt à imprimer:No

- 3D Balayage:No

- Contenu adulte:No

- PBR:No

- Géométrie:Polygonal

- UVs non enveloppés:Unknown

- Vus:6142

Description

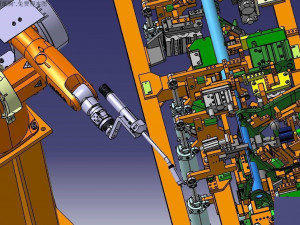

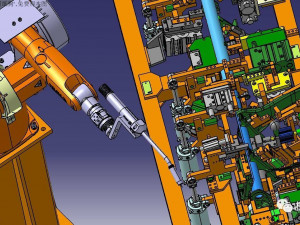

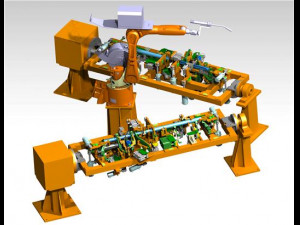

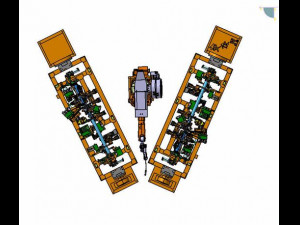

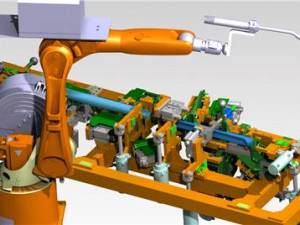

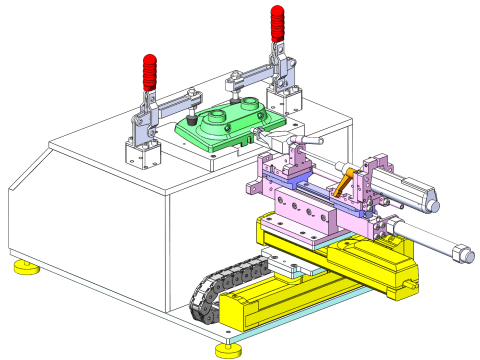

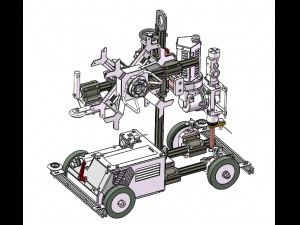

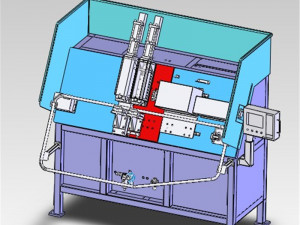

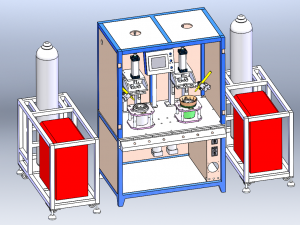

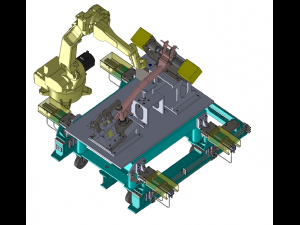

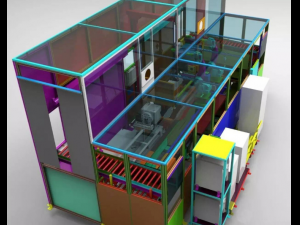

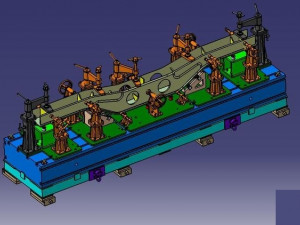

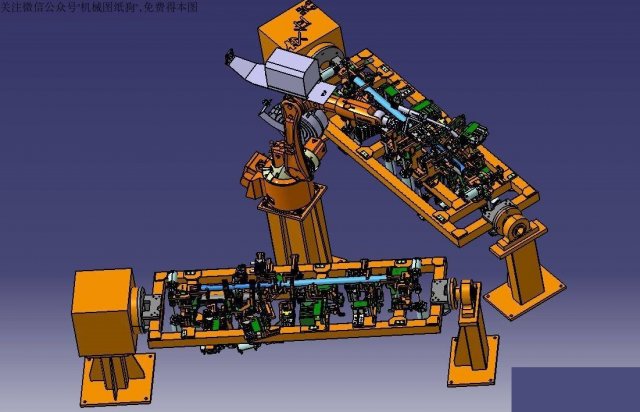

the instrument beam assembly is made of 18 kinds of small stamping parts, which is required to meet the production program of 60000 vehicles per year. the number of stamping parts of the instrument beam is large, and the thickness of the plate is many, so it is difficult to weld the assembly. according to the process analysis, the welding method is suitable for co2 gas shielded gas welding, with the length of 1420mm and the number of weld joints being 45 sections. because the welding position is in three-dimensional cross distribution and the position of each support has the requirements of assembly accuracy, the automation requirements for this station are high. manual welding can not meet the requirements in terms of welding quality, production rhythm and product stability. therefore, the final process plan determines that the assembly will be welded with co2 gas shielded welding for all welding points through welding robot workstation,determine the height of the robot and the distance from the front and rear left and right, ensure that all welding points are covered in the working range that the robot welding can reach. the most reliable method for optimizing design is to simulate the actual welding work through robot simulation software. the method is to add 3d model of station fixture, work piece and welding, and assemble and debug the workstation in virtual environment, and find out whether it is dry or not in this way, the relative size of each part can be adjusted to the best.

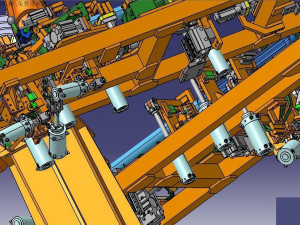

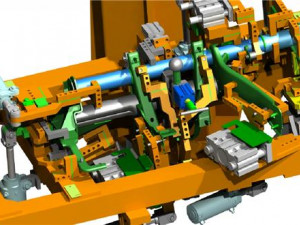

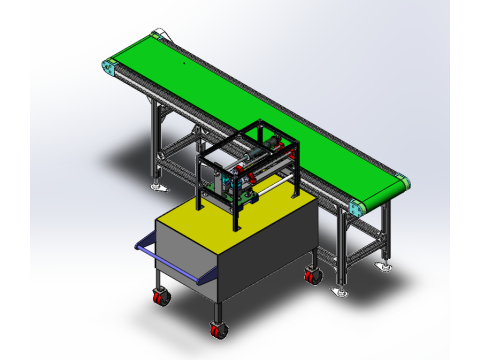

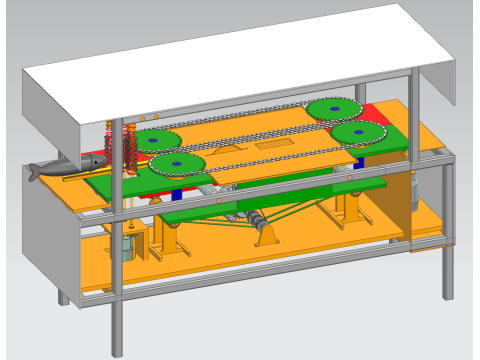

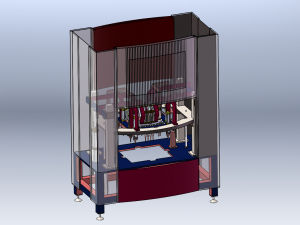

each station can be reversed around the horizontal axis of the positioner, and its posture can coordinate with the robot during welding to meet the requirements of welding process. it is mainly composed of two external axis servo motors (i.e. displacement machine) and their reducer, coordination software, converter, cable, two sets of fixture turning mechanism, servo drive system, etc. two sets of turning mechanism are driven by positioner, and the system is realized by robot control system.

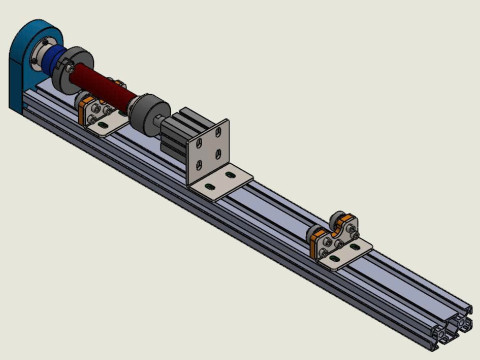

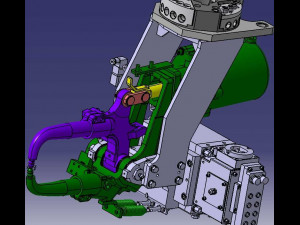

the driven shaft is connected with the connecting plate and is installed on the mounting base. the turning mechanism of welding fixture is connected with the connecting plate, and the machining error and installation of welding fixture are considered. the height of positioner and driven shaft can be adjusted. the driven shaft is universal rotary bearing, so as to avoid machining error and make installation and maintenance convenient.

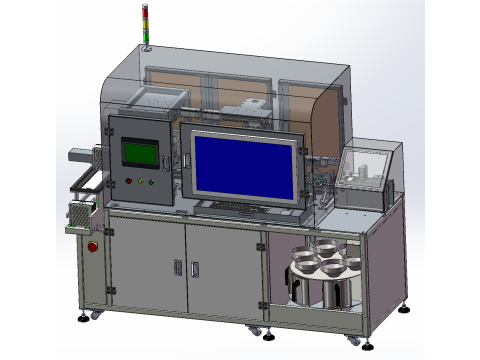

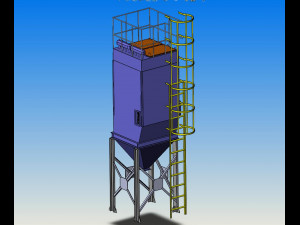

cleaning and silicone oil spraying device: a total of 1 set, consisting of cleaning mechanism, clamping mechanism and silicon oil spraying mechanism. the actions are as follows:

robot moves welding to cleaning device - cleaning device clamping welding - automatic cleaning - robot moves welding to silicon oil spraying place - spraying silicon oil - robot moves welding back to its original position.

the welding clamp is of frame structure, which is convenient for robot welding to approach the workpiece. there are 25 movable locating pins, 2 fixed locating pin sleeves and 3 fixing pins, so that the workpiece can be taken out of the fixture. the second station is the same as the first station to increase the capacity to avoid the waiting time of the robot, so that the robot does not stop working when the manual parts are put on and taken, and the working efficiency is improved. Prêt à imprimer: Non

Avez besoin de plus de formats?

Si vous avea besoin d’\autre format veuillez ouvrir un billet d’\assistance et demandez le. Nous pouvons convertir les modèles de 3D en: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Conversion de format libreNous ne convertissons pas les scènes 3D et des formats tels que .step, .iges, .stp, .sldprt.!

Informations d'utilisation

welding jig for welding of instrument frame welding beam - Vous pouvez utiliser ce modèle 3D libre de droits à des fins personnelles et commerciales, conformément à la Licence de Base ou à la Licence Étendue.La Licence de Base couvre la plupart des cas d'utilisation courants, notamment les publicités numériques, les projets de conception et de visualisation, les comptes de réseaux sociaux professionnels, les applications natives, les applications web, les jeux vidéo et les produits finis physiques ou numériques (gratuits ou payants).

La Licence Étendue inclut tous les droits accordés par la Licence de Base, sans limitation d'utilisation, et autorise l'utilisation du modèle 3D dans un nombre illimité de projets commerciaux, dans des conditions de libre de droits.

En savoir plus

Fournissez-vous garantie de remboursement?

Oui. Si vous avez acheté un produit et trouvé une erreur dans le rend ou la description, nous allons essayer de résoudre le problème le plus tôt possible. Si nous ne pouvons pas corriger l'erreur, nous allons annuler votre commande et vous récupérer votre argent dans les 24 heures de téléchargement de l'élément. Lire la suite de conditions iciMots clés

Produits incidents de cet auteur

Aucun commentaires sur ce produit.

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी