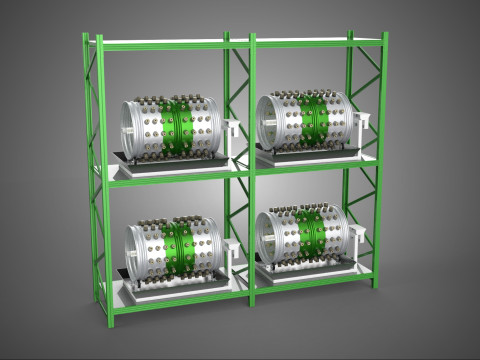

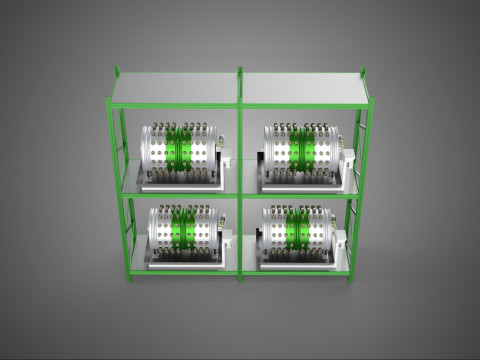

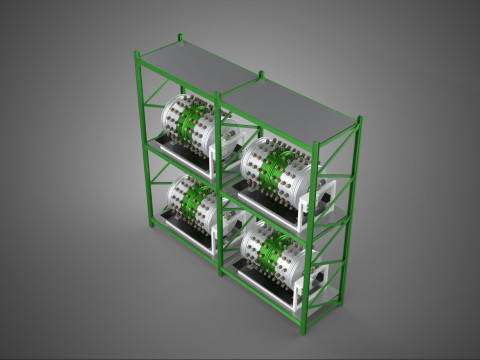

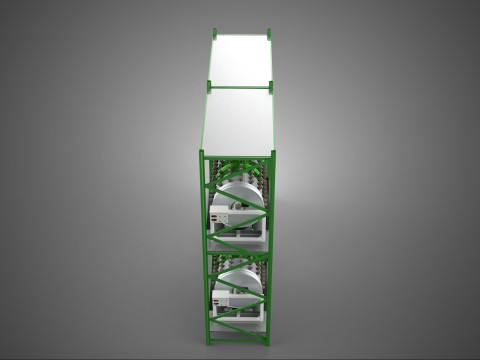

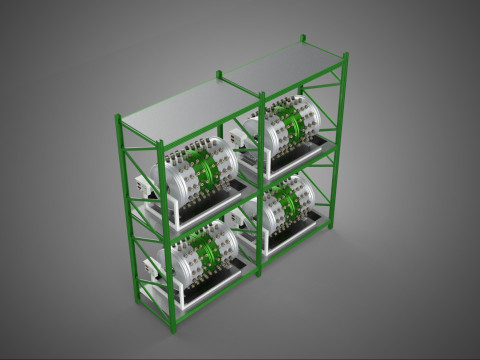

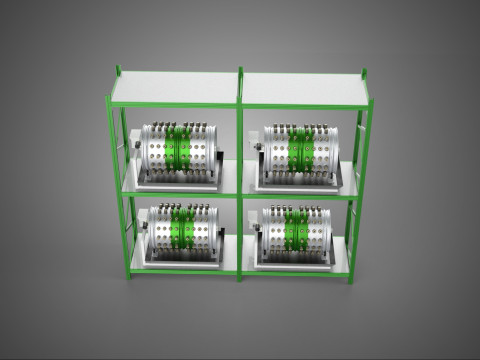

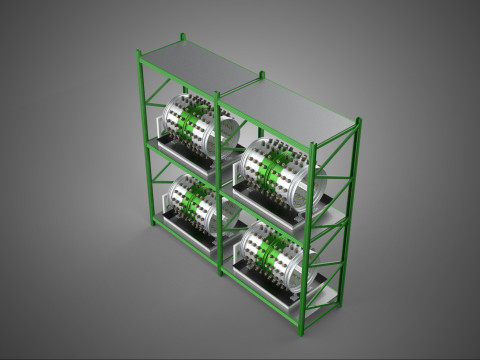

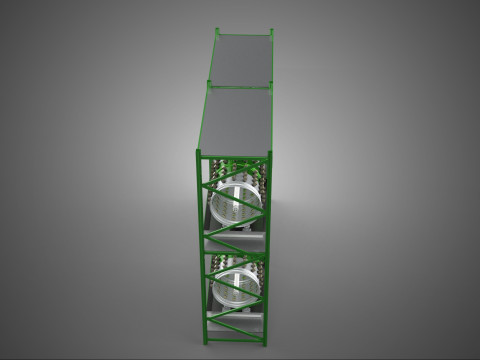

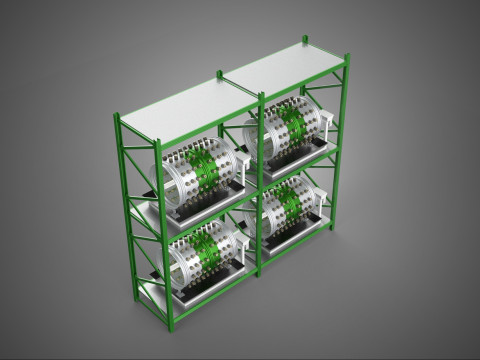

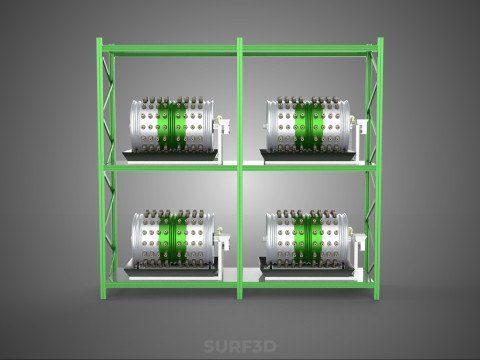

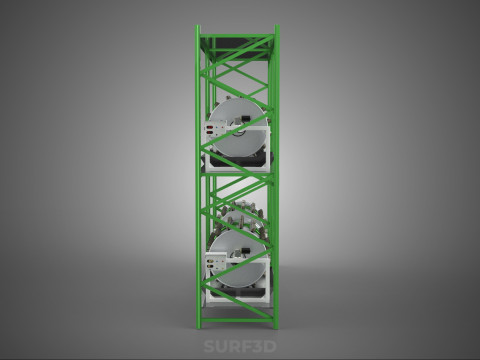

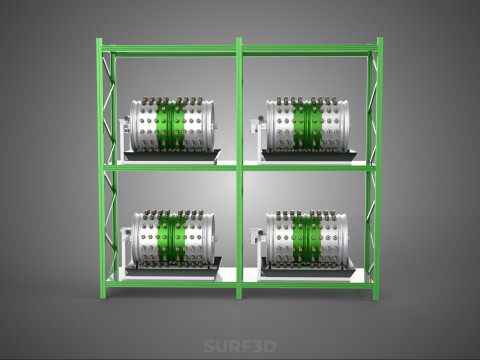

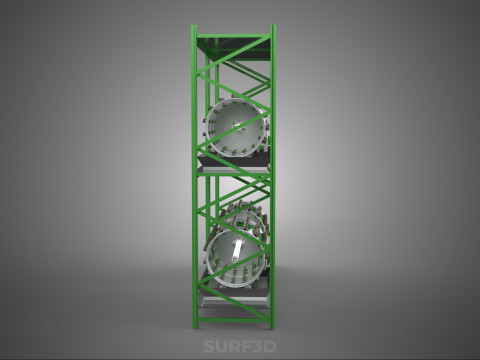

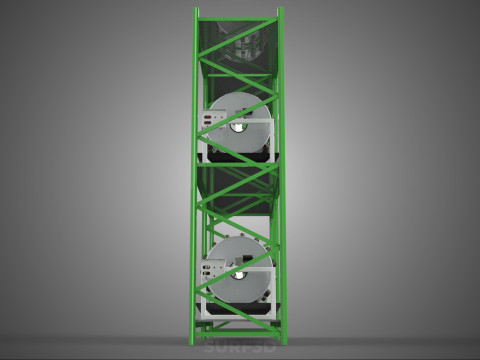

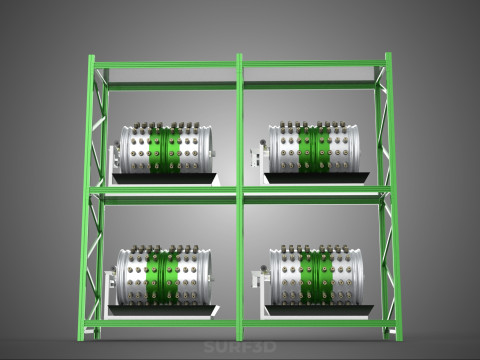

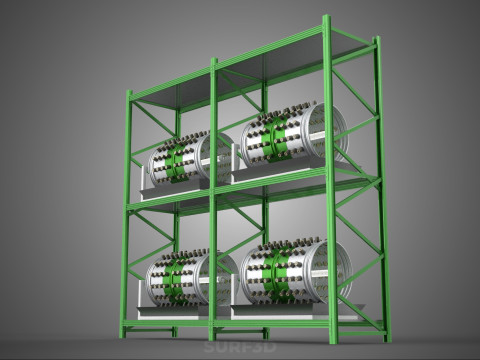

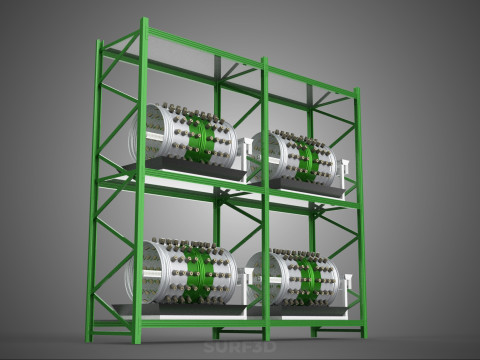

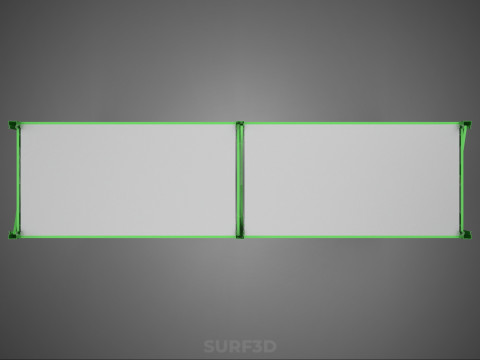

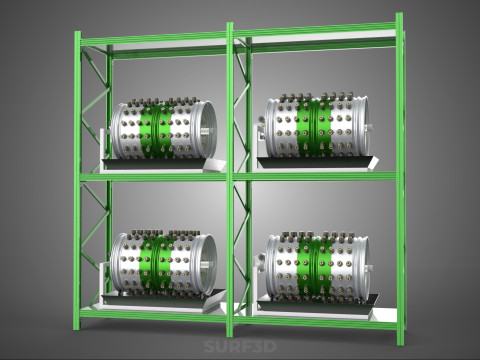

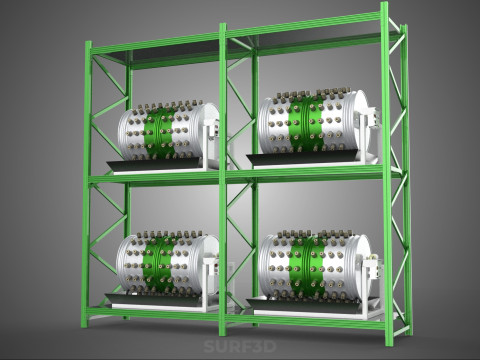

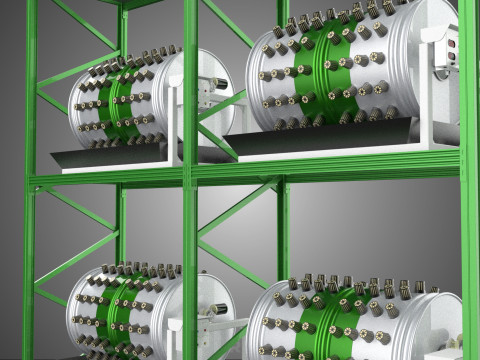

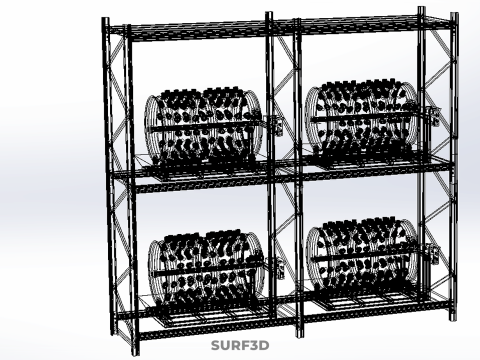

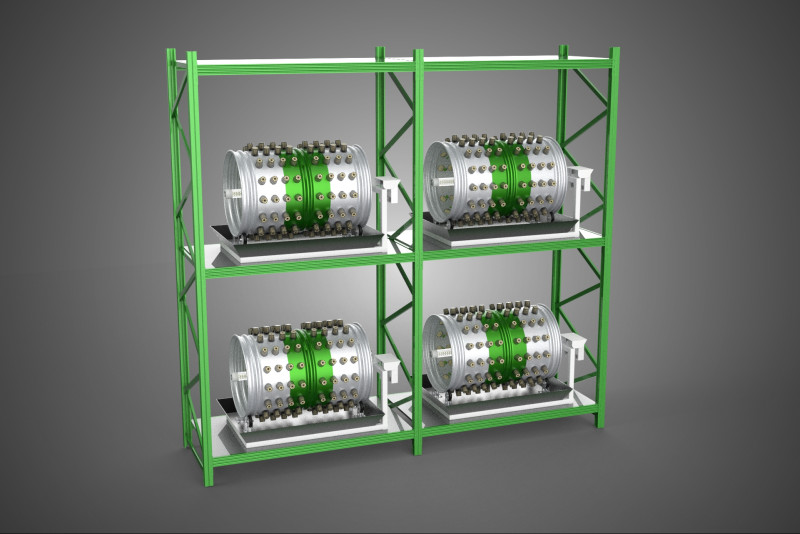

DRUM TRAY ARRAY RACK ROTARY TANAMAN HIDROPONIK TAMAN INDOOR Model 3D

- Minta dukungan produk oleh penulis

- Format yang tersedia:

- ID Barang:603958

- Tanggal: 2025-10-08

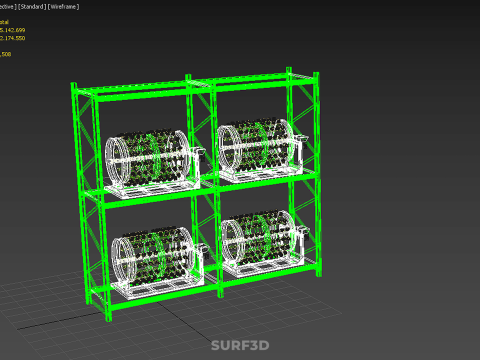

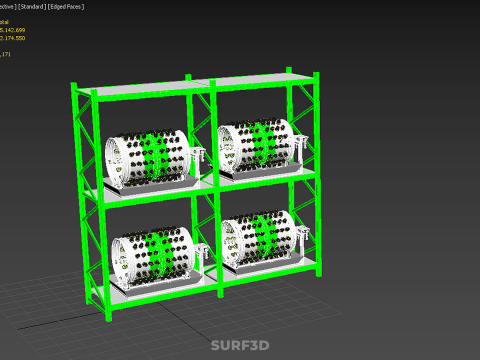

- Poligon:15142699

- Sudut:12174550

- Animasi:No

- Bertekstur:No

- Dimanipulasi:No

- Material:

- Low-poly:No

- Koleksi:No

- Pemetaan UVW:No

- Plugin Digunakan:No

- Siap Cetak:No

- Pindai 3D:No

- Konten Dewasa:No

- PBR:No

- AI Pelatihan:No

- Geometri:Poly NURBS

- Unwrapped UVs:Unknown

- Tampilan:217

Deskripsi

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

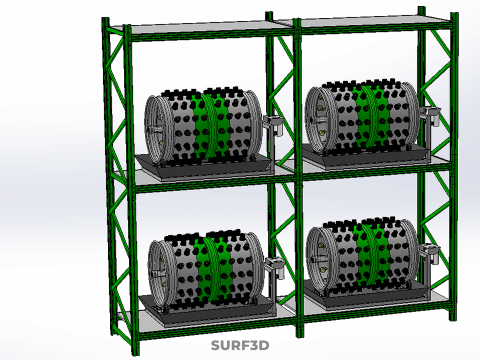

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

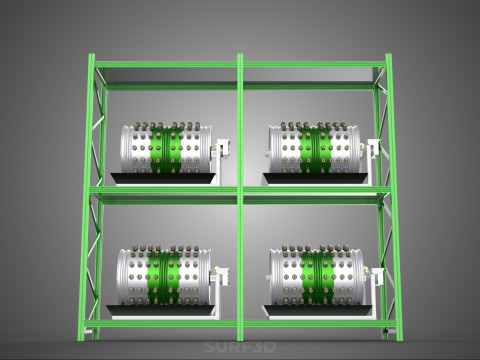

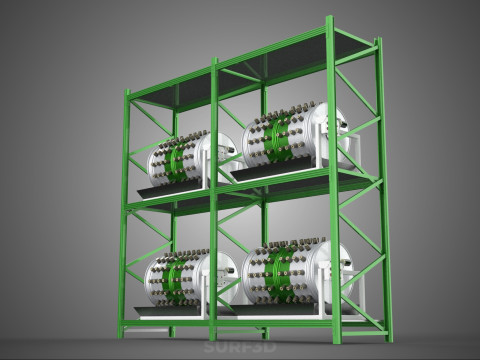

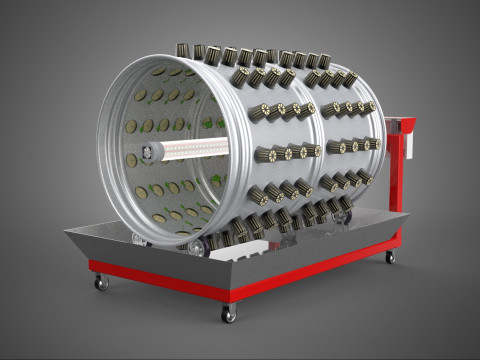

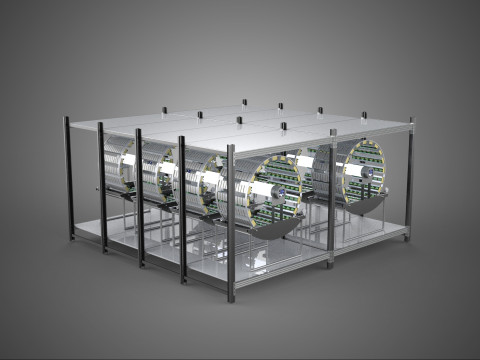

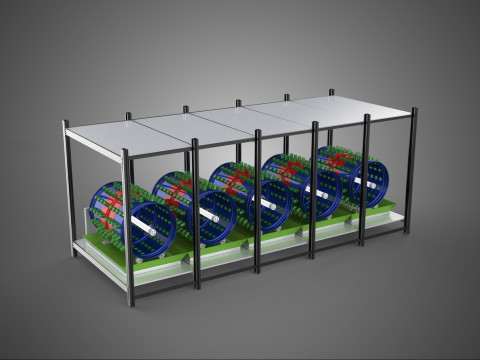

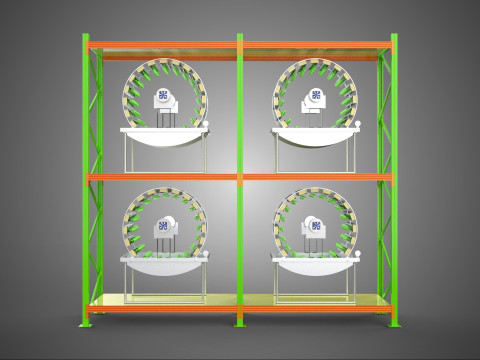

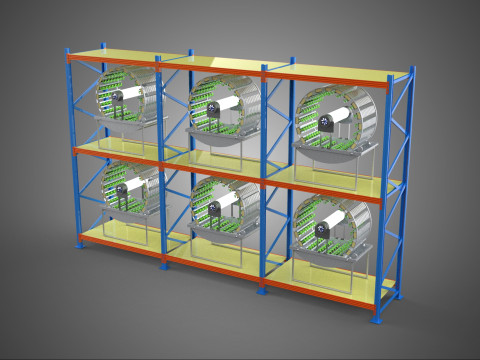

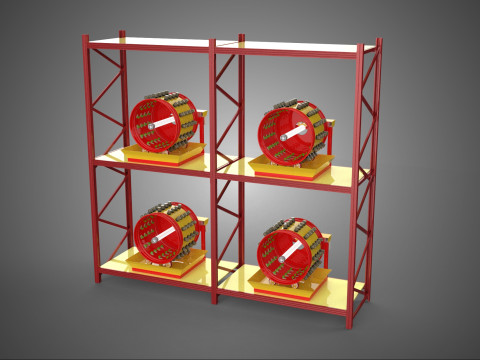

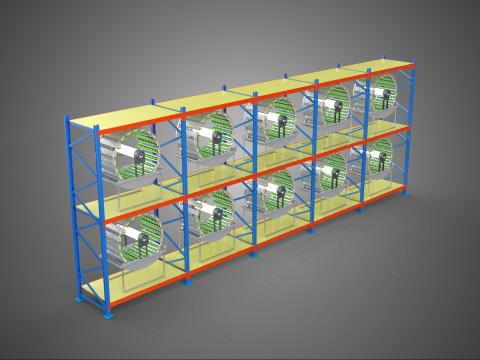

A Drum Tray Array Shelf Rack Rotary Hydroponic Plant Garden Indoor represents an advanced, highly efficient system within the domain of Controlled Environment Agriculture (CEA). This sophisticated apparatus integrates hydroponic cultivation methods with a mechanized rotary structure to optimize plant growth in confined indoor spaces, offering significant advantages in terms of space utilization, resource management, and crop yield.

**I. Definition and Core Principle**

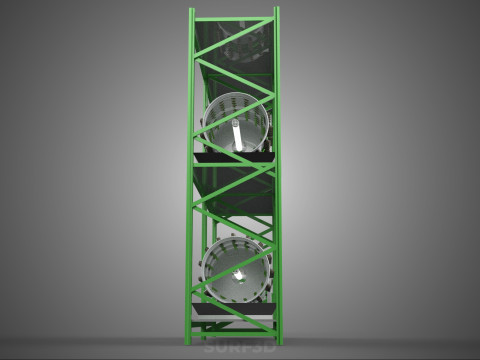

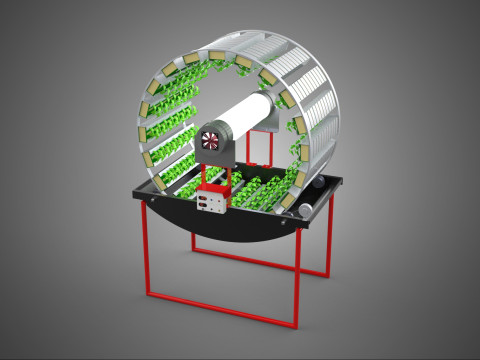

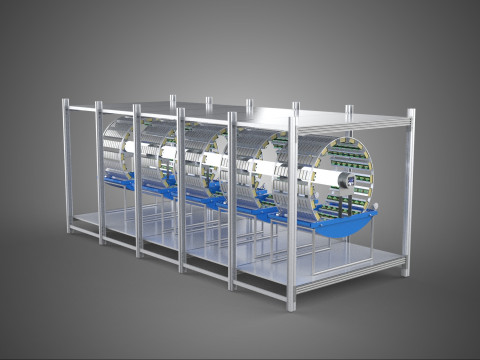

This system is fundamentally an indoor garden that cultivates plants without soil, utilizing nutrient-rich water solutions. Its defining feature is a structural shelf rack that supports an array of plant-holding trays, arranged radially or circumferentially around a central axis. This entire assembly undergoes slow, continuous, or intermittent rotation, driven by a mechanical system. The primary purpose of the rotation is to ensure uniform exposure of all plants to artificial light sources and consistent delivery of nutrient solution, mimicking natural solar cycles and optimizing growth conditions.

**II. Key Components**

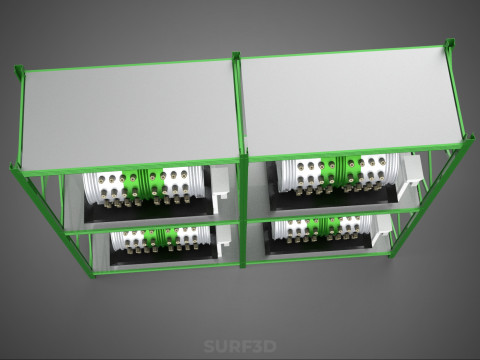

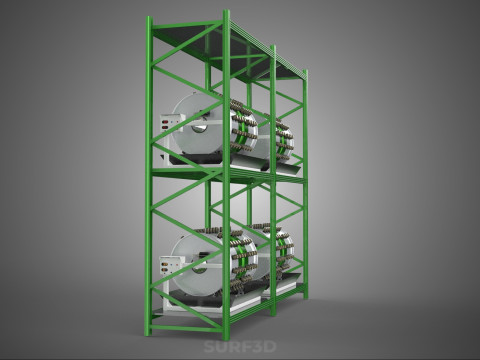

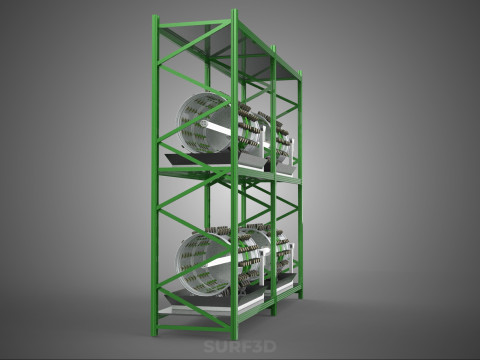

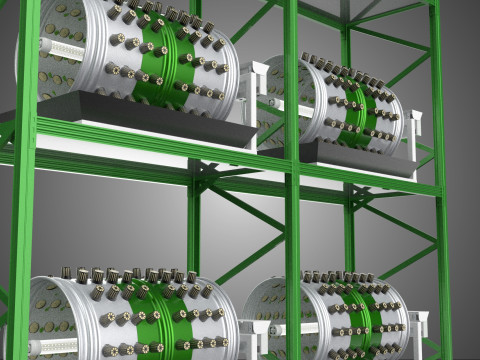

1. **Structural Shelf Rack:** The foundational element is a robust, corrosion-resistant frame, typically constructed from materials like stainless steel or reinforced aluminum. This multi-tiered rack provides the structural integrity to support the rotating drum array, hydroponic infrastructure, lighting systems, and associated control mechanisms.

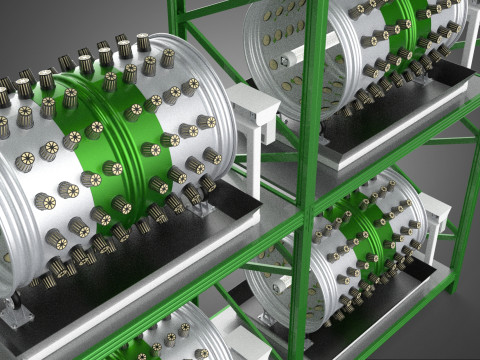

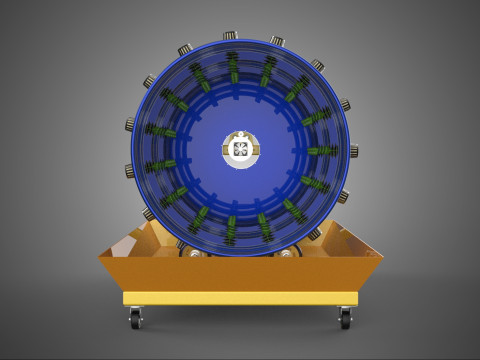

2. **Rotary Mechanism:** At the heart of the system is a precision-engineered rotary drive, usually comprising an electric motor, gears, and bearings. This mechanism facilitates the controlled rotation of the plant-holding units. Adjustable rotational speed is a common feature, allowing operators to fine-tune light exposure and nutrient distribution based on specific plant requirements and growth stages.

3. **Drum Tray Array:** This refers to the modular units that house the plants. Typically, individual trays or compartments are arranged to form a cylindrical or drum-like structure. Each compartment contains net pots or other inert growing media (e.g., rockwool, coco coir, clay pebbles) where plant roots are anchored. The "array" aspect denotes the high-density, multi-level arrangement designed to maximize the number of plants cultivated within the rotating volume.

4. **Hydroponic System:** As a soil-less cultivation method, the system incorporates a reservoir for storing a carefully balanced nutrient solution. A pump circulates this solution to the plant roots. Common hydroponic techniques employed in rotary systems include Nutrient Film Technique (NFT), where a thin film of solution flows over the roots, or drip irrigation, where solution is delivered directly to each plant site. The rotation can also facilitate even nutrient distribution.

5. **Lighting System:** Given its indoor operation, artificial light sources are indispensable. High-efficiency LED grow lights are prevalent due to their spectral tunability, energy efficiency, and low heat emission. These lights are often centrally positioned within the rotating drum or strategically arranged around its periphery, ensuring that as plants revolve, they pass through zones of optimal Photosynthetically Active Radiation (PAR).

6. **Environmental Controls:** A sophisticated suite of sensors and controllers manages the indoor growing environment. This typically includes automated timers for lighting cycles and nutrient delivery, temperature and humidity sensors linked to HVAC systems or fans, and pH/EC (electrical conductivity) monitors for real-time nutrient solution management. These controls are crucial for maintaining the precise microclimate necessary for peak plant performance.

**III. Operational Principle**

The system operates by continuously or intermittently rotating the plant-bearing drum. As the plants revolve, each individual plant is systematically exposed to the fixed artificial light source, ensuring that all foliage receives equitable photon exposure. Simultaneously, the hydroponic system delivers the nutrient solution directly to the root zone, which can also be aided by the rotational movement. This synergy of uniform light exposure and precise nutrient delivery prevents etiolation (stretching due to insufficient light), promotes robust and balanced plant development, and maximizes growth rates within a compact, vertically oriented footprint.

**IV. Advantages**

* **Space Efficiency:** Maximizes crop density per unit of floor area, making it ideal for urban agriculture, vertical farming, and environments with limited space.

* **Uniform Growth:** Ensures consistent light exposure and nutrient availability for all plants, leading to homogeneous crop development and higher quality yields.

* **Water Conservation:** Hydroponic systems recirculate water, significantly reducing water consumption compared to conventional soil-based agriculture.

* **Accelerated Growth:** Optimized environmental conditions often result in faster plant growth cycles and increased annual harvests.

* **Pest and Disease Control:** The enclosed indoor environment minimizes exposure to pests and pathogens, reducing or eliminating the need for pesticides.

* **Ergonomics:** Certain designs can improve accessibility for planting, harvesting, and routine maintenance, reducing labor intensity.

**V. Disadvantages and Challenges**

* **High Initial Investment:** The complexity of integrated mechanical, electrical, and hydroponic components leads to significant upfront costs.

* **Energy Consumption:** Requires substantial energy for lighting, the rotary motor, pumps, and environmental control systems, potentially increasing operational expenses.

* **Technical Expertise:** Successful operation demands a comprehensive understanding of horticulture, hydroponics, mechanical systems, and environmental control protocols.

* **Mechanical Reliability:** The presence of moving parts introduces potential points of mechanical failure, necessitating regular maintenance and potential component replacement.

**VI.

Perlu lebih banyak format?

Jika Anda membutuhkan format yang berbeda, silakan buka Tiket Dukungan baru dan minta itu. Kita dapat mengonversi model 3D menjadi: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Konversi Format GratisKami tidak mengonversi adegan 3d dan format seperti .step, .iges, .stp, .sldprt.!

Informasi Penggunaan

DRUM TRAY ARRAY RACK ROTARY TANAMAN HIDROPONIK TAMAN INDOOR - Anda dapat menggunakan model 3D bebas royalti ini untuk keperluan pribadi dan komersial sesuai dengan Lisensi Dasar atau Diperpanjang.Lisensi Dasar mencakup sebagian besar kasus penggunaan standar, termasuk iklan digital, proyek desain dan visualisasi, akun media sosial bisnis, aplikasi asli, aplikasi web, permainan video, dan produk akhir fisik atau digital (baik gratis maupun berbayar).

Lisensi Diperpanjang mencakup semua hak yang diberikan berdasarkan Lisensi Dasar, tanpa batasan penggunaan, dan memungkinkan model 3D untuk digunakan dalam proyek komersial tanpa batas dengan ketentuan Bebas Royalti.

Baca lebih lanjut

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी