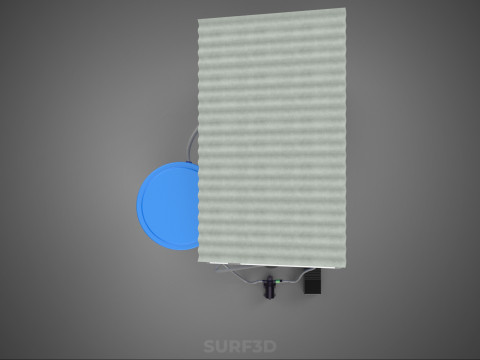

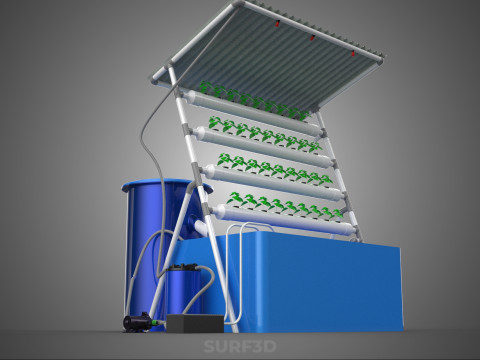

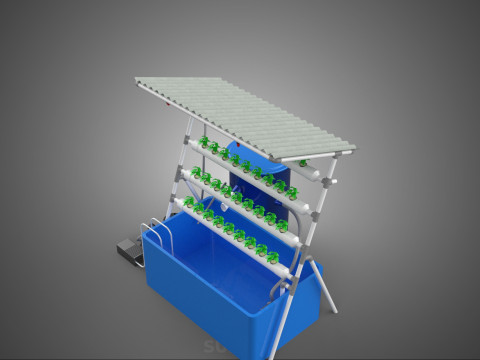

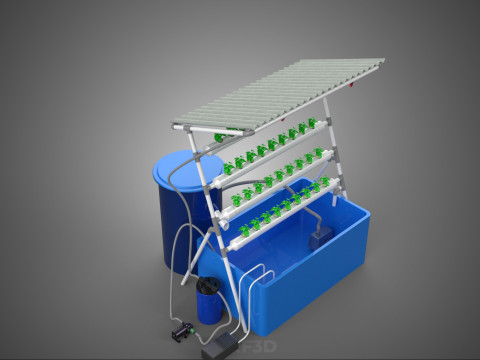

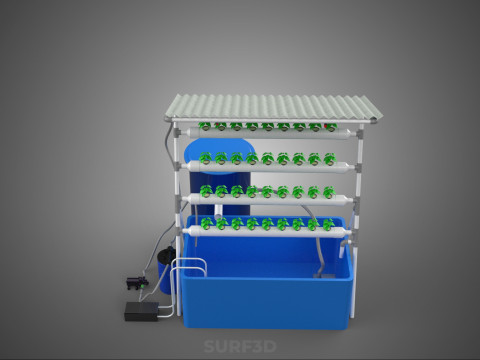

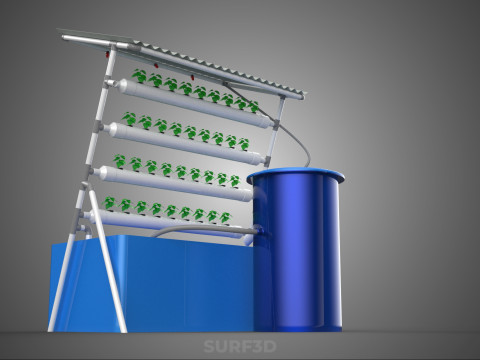

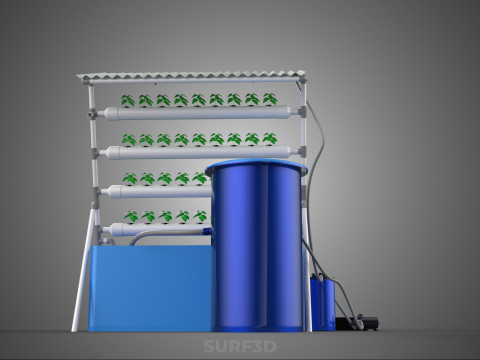

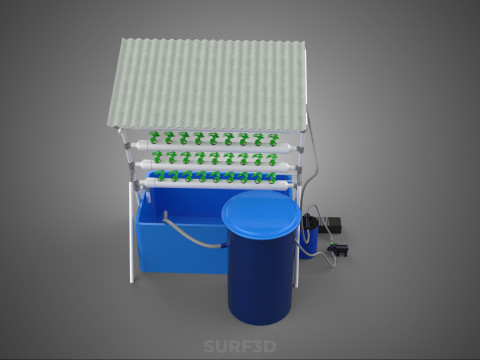

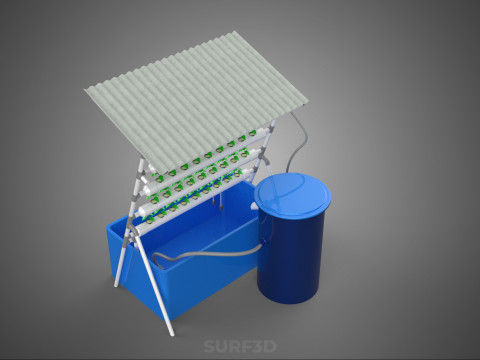

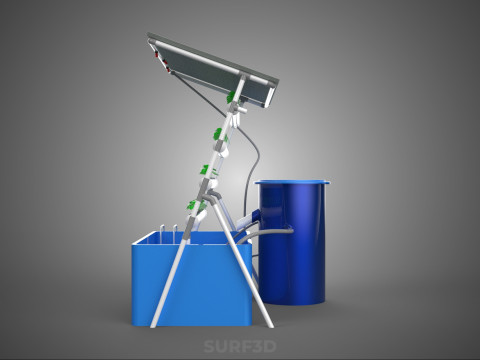

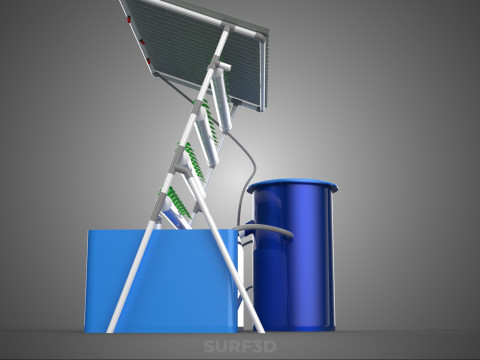

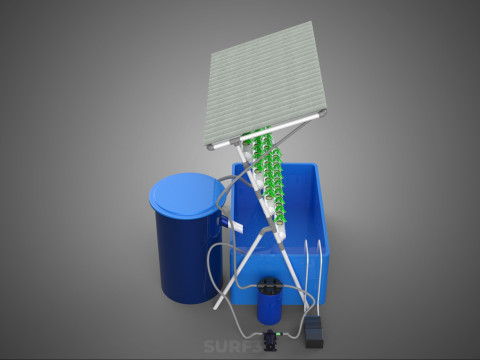

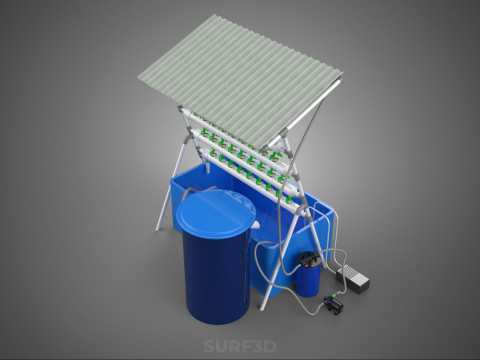

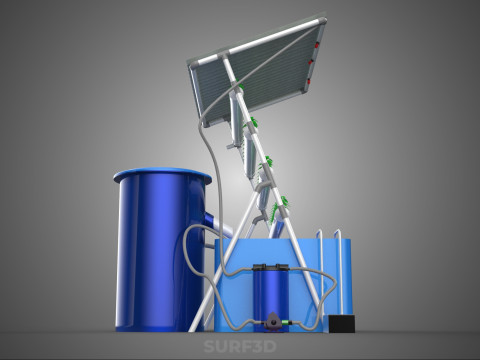

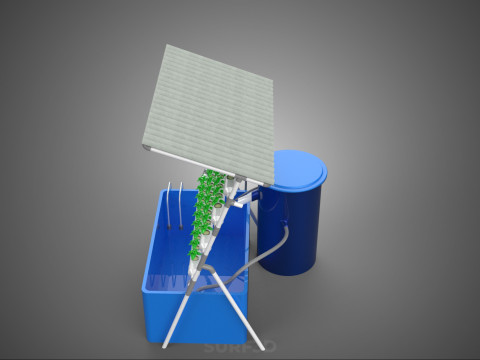

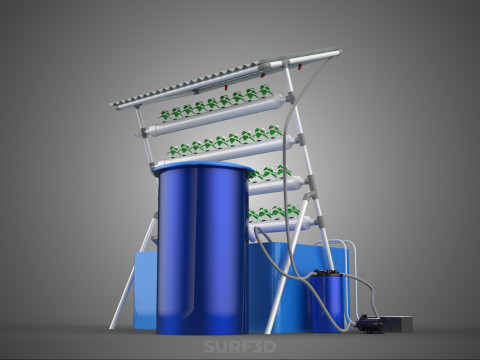

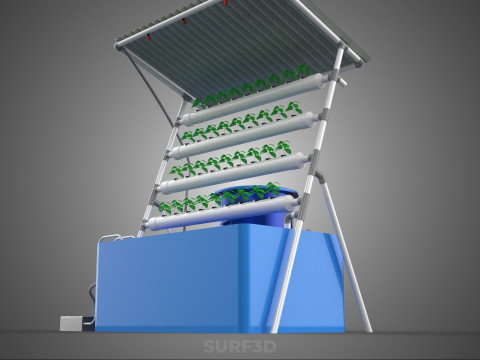

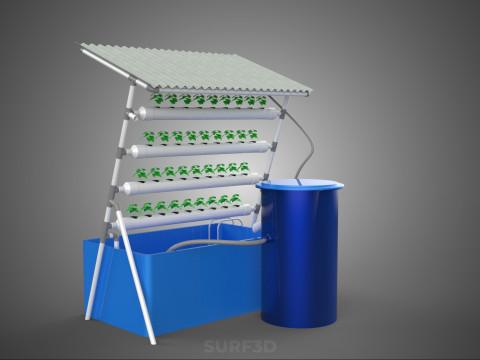

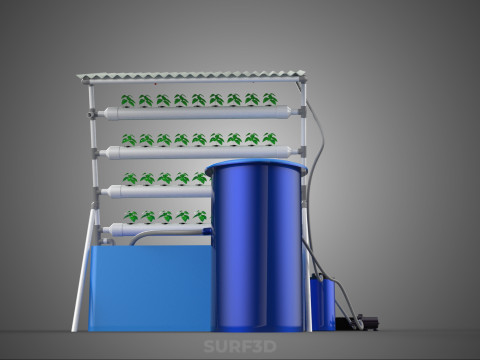

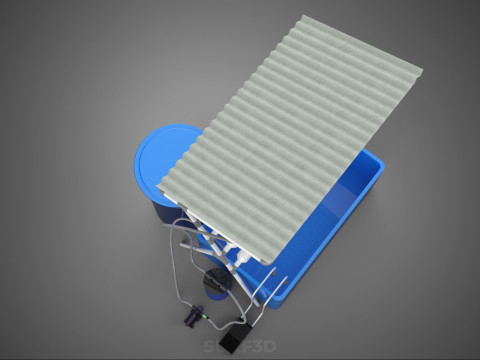

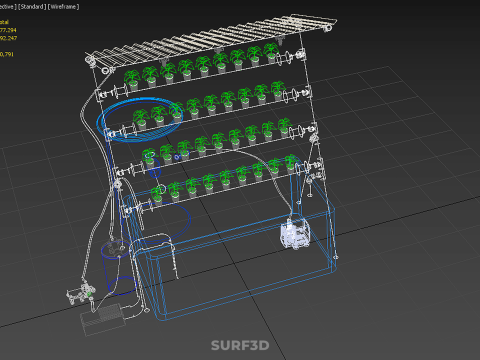

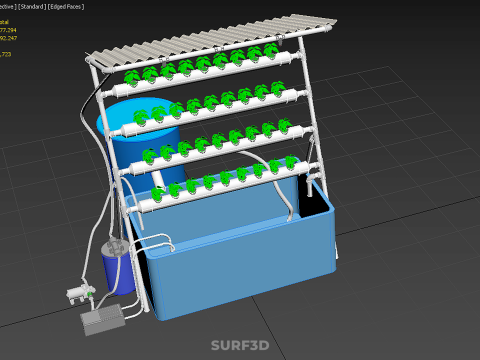

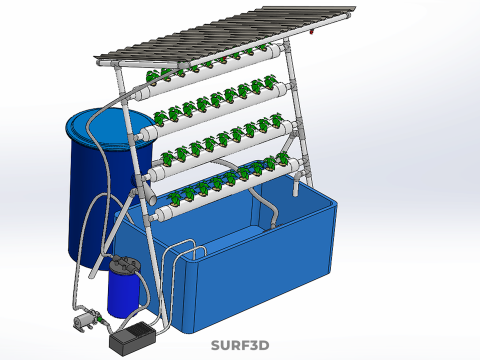

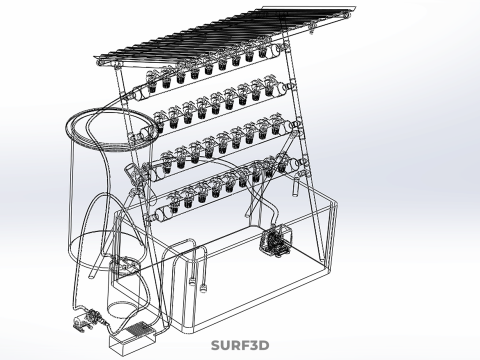

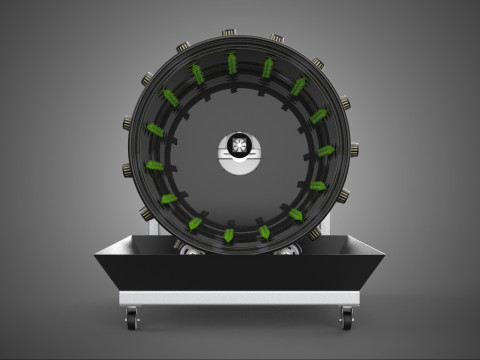

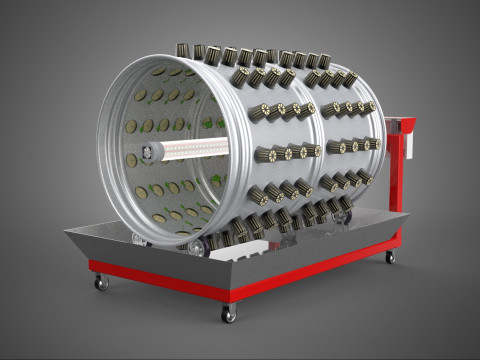

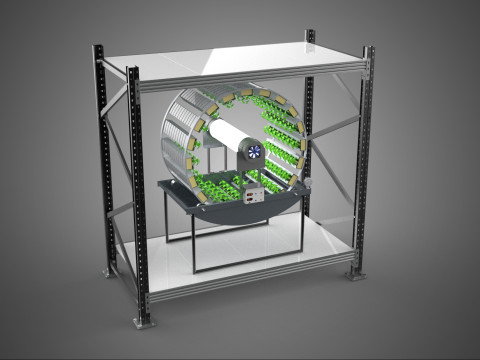

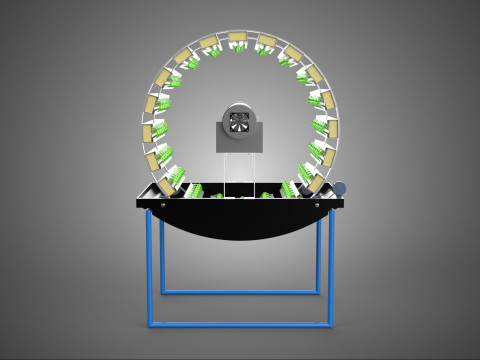

HYDROPONIC PLANT AUTO WATER CYCLE TANK PUMP NOZZLE SPRAYER FARM Model 3D

- Format yang tersedia: IGES (.iges) 3.09 MBAutodesk AutoCAD (.dwg) 5.55 MBSketchUp (.skp) 7.37 MBStereolithography (.stl) 13.03 MBACIS(.sat) 8.86 MBRhinoceros (.3dm) 25.54 MBSTEP (.step) 3.36 MBAutodesk FBX (.fbx) 20.10 MBBlender3D (.blend) 11.39 MBGLB (.glb / .gltf) 5.90 MBWavefront OBJ (.obj) 10.53 MB3D Studio (.3ds) 4.23 MBCollada (.dae) 9.36 MBAutodesk 3DS MAX (.max) 17.52 MB

- Poligon:877294

- Sudut:592247

- Animasi:No

- Bertekstur:No

- Dimanipulasi:No

- Material:

- Low-poly:No

- Koleksi:No

- Pemetaan UVW:No

- Plugin Digunakan:No

- Siap Cetak:No

- Pindai 3D:No

- Konten Dewasa:No

- PBR:No

- AI Pelatihan:No

- Geometri:Poly NURBS

- Unwrapped UVs:Unknown

- Tampilan:121

- Tanggal: 2025-09-18

- ID Barang:599831

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

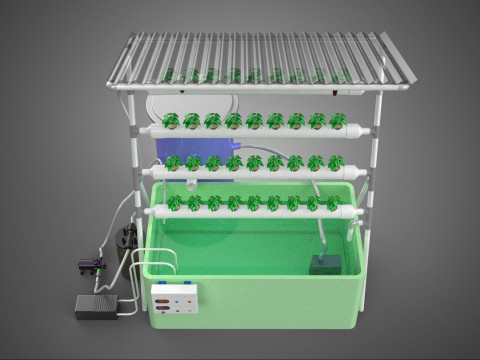

A hydroponic plant farm integrating an automated water cycle tank and an auxiliary pump nozzle sprayer system represents a sophisticated and highly efficient approach to soilless cultivation. This advanced configuration is designed to optimize plant growth by precisely delivering nutrient-rich water directly to root zones while offering supplementary application methods, thereby enhancing resource management, environmental control, and overall productivity within controlled agricultural environments.

**Hydroponic Cultivation Core**

At its foundation, the system employs hydroponics, a method of growing plants without soil, utilizing mineral nutrient solutions dissolved in water to deliver essential elements directly to the plant roots. Various hydroponic techniques can be implemented, such as Nutrient Film Technique (NFT), Deep Water Culture (DWC), ebb and flow (flood and drain), or drip systems. These are typically housed within purpose-built grow trays, channels, or vertical racks, designed to support plant structures and facilitate nutrient delivery. The primary objective is to maximize water and nutrient uptake, leading to accelerated growth rates, higher yields, and improved crop quality compared to traditional soil-based agriculture.

**Automated Water Cycle Tank (Nutrient Solution Management)**

The "Auto Water Cycle Tank" serves as the central reservoir for the nutrient solution. This tank is equipped with a submersible pump responsible for circulating the prepared solution from the reservoir to the plant root systems. An integrated automated control system, often comprising level sensors, timers, and potentially pH (potential of hydrogen) and EC (electrical conductivity) sensors, manages the precise delivery and return of the nutrient solution. The operational cycle typically involves pumping the nutrient solution to the plants, allowing it to percolate through or flow past the root zone, and then returning the spent or unused portion via gravity or a secondary pump back to the main tank. This continuous or cyclical recirculation minimizes water waste and ensures consistent nutrient availability. Automation features may include automatic water top-off to compensate for evapotranspiration and plant uptake, as well as automated nutrient dosing adjustments to maintain optimal pH and EC levels, which are critical for plant health and nutrient absorption.

**Auxiliary Pump Nozzle Sprayer System**

Complementing the primary nutrient delivery mechanism is an "additional auxiliary pump nozzle sprayer system." This subsystem typically consists of a dedicated pump, high-pressure tubing, and an array of fine-mist nozzles strategically positioned within the growing environment. Its purpose is multifaceted:

1. **Foliar Feeding:** Delivering specialized nutrient solutions directly to plant leaves, allowing for rapid absorption and addressing specific nutrient deficiencies more swiftly than root uptake alone.

2. **Environmental Control:** Misting the atmosphere to increase ******t humidity, which can be particularly beneficial for propagation, seedling development, or specific plant species requiring higher atmospheric moisture.

3. **Aeroponics Support:** In certain advanced setups, this system might act as the primary nutrient delivery for aeroponic components, where plant roots are suspended in air and periodically misted with nutrient solution.

4. **Pest and Disease Management:** Facilitating the application of organic or synthetic treatments in a finely dispersed form, ensuring thorough coverage with minimal chemical use.

5. **Root Zone Oxygenation:** Some advanced systems utilize fine misting directly onto roots to enhance oxygen availability, crucial for preventing anaerobic conditions and promoting robust root development.

The auxiliary system often operates independently or in conjunction with the main water cycle, controlled by separate timers or environmental sensors to provide precise, on-demand application based on specific crop requirements or environmental parameters.

**Operational Principles and Integration**

The seamless integration of these components creates a highly efficient and meticulously controlled agricultural environment. The automated water cycle ensures consistent and optimized nutrient delivery to the root zone, while the auxiliary sprayer provides flexible, targeted applications that cater to specific needs beyond basic root nourishment. A central control unit, often microprocessor-based or connected to a smart farming platform, orchestrates the pumps, sensors, and timers. This enables precise management of irrigation schedules, nutrient concentrations, pH levels, and environmental parameters like humidity. Such comprehensive automation significantly reduces manual labor, enhances consistency in growing conditions, and allows for data-driven adjustments to optimize plant growth cycles, maximizing both yield and quality.

**Benefits and Applications**

This sophisticated hydroponic system offers numerous advantages, including:

* **Water Efficiency:** Recirculation and precise delivery drastically reduce water consumption compared to traditional agriculture.

* **Accelerated Growth & Higher Yields:** Optimal nutrient delivery and controlled environments lead to faster growth rates and increased productivity per unit area.

* **Reduced Labor:** Automation minimizes the need for manual intervention in watering and nutrient management.

* **Space Efficiency:** Facilitates vertical farming and intensive cultivation in compact spaces, making it ideal for urban agriculture.

* **Pest and Disease Control:** The controlled environment naturally minimizes pest and disease pressure, and targeted spraying offers efficient treatment.

* **Nutrient Optimization:** Enables precise control over nutrient solution composition and delivery, tailoring it to specific crop stages.

Such integrated systems are ideal for commercial greenhouses, indoor farming operations, urban agriculture initiatives, research facilities, and any context where resource efficiency, high yield, and environmental control are paramount.

Jika Anda membutuhkan format yang berbeda, silakan buka Tiket Dukungan baru dan minta itu. Kita dapat mengonversi model 3D menjadi: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Kami tidak mengonversi adegan 3d dan format seperti .step, .iges, .stp, .sldprt.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी