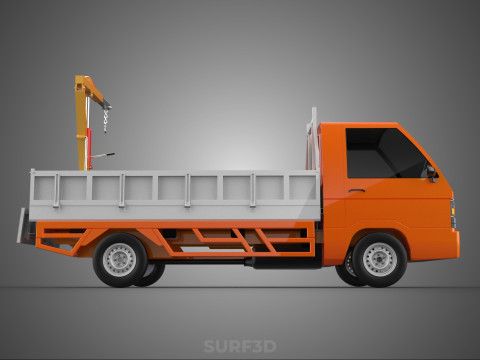

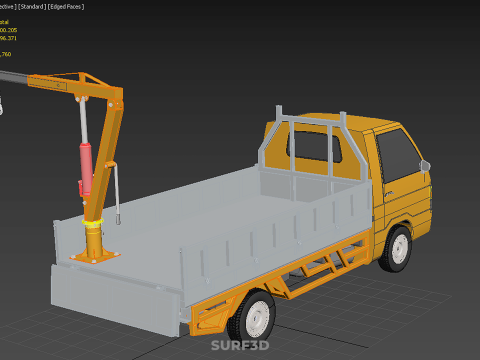

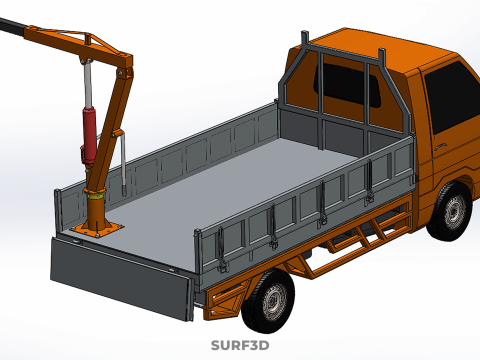

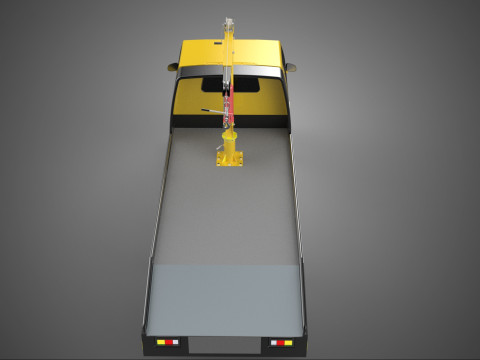

TAILGATE REAR GATE HYDRAULIC JACK LIFT HOIST CRANE PICKUP TRUCK Model 3D

- Format yang tersedia: IGES (.iges) 9.46 MBGLB (.glb / .gltf) 5.77 MBWavefront OBJ (.obj) 8.40 MBStereolithography (.stl) 8.80 MBAutodesk AutoCAD (.dwg) 21.76 MB3D Studio (.3ds) 4.40 MBAutodesk FBX (.fbx) 14.73 MBRhinoceros (.3dm) 39.10 MBSTEP (.step) 12.36 MBSketchUp (.skp) 10.93 MBAutodesk 3DS MAX (.max) 28.49 MBACIS(.sat) 19.85 MBBlender3D (.blend) 11.16 MBCollada (.dae) 11.90 MB

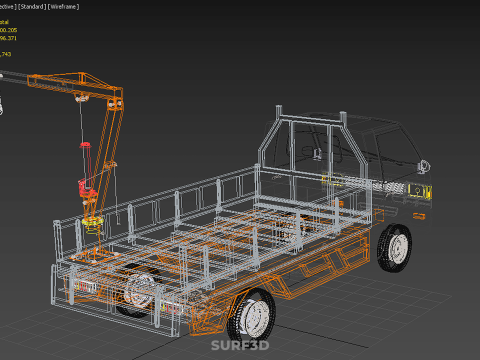

- Poligon:600205

- Sudut:496371

- Animasi:No

- Bertekstur:No

- Dimanipulasi:No

- Material:

- Low-poly:No

- Koleksi:No

- Pemetaan UVW:No

- Plugin Digunakan:No

- Siap Cetak:No

- Pindai 3D:No

- Konten Dewasa:No

- PBR:No

- AI Pelatihan:No

- Geometri:Poly NURBS

- Unwrapped UVs:Unknown

- Tampilan:177

- Tanggal: 2025-08-18

- ID Barang:593223

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

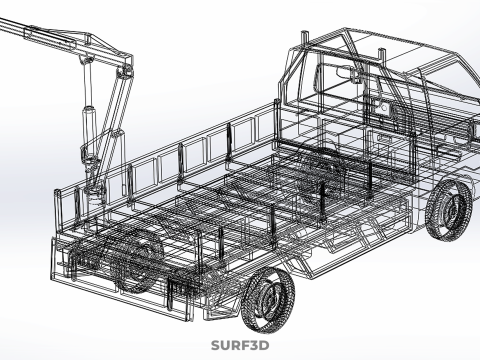

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

A **Tailgate Rear Pickup Truck with Attached Hydraulic Lifting System**, often referred to more specifically as a **tailgate-mounted hydraulic crane**, **pickup truck lift hoist**, or **tailgate gantry system**, represents a specialized modification designed to enhance the utility and material handling capabilities of conventional pickup trucks. This integrated apparatus facilitates the efficient and safe loading and unloading of heavy, bulky, or ******* items into and out of the truck bed, significantly reducing manual labor and the risk of injury.

**Nomenclature and Function:**

The descriptive title "TAILGATE REAR PICKUP TRUCK OPENED WITH GATE HYDRAULIC JACK LIFT HOIST CRANE ATTACHED" encompasses a system where a standard pickup truck's rear tailgate area is equipped with a versatile hydraulic mechanism capable of performing the functions of a jack, lift, hoist, or small crane. The phrase "opened with gate" typically refers to the necessity of having the tailgate in an open (lowered) position to allow for the full operational range and stability of the attached lifting equipment.

**Design and Components:**

The core of this system involves several key components, meticulously integrated with the truck's structure:

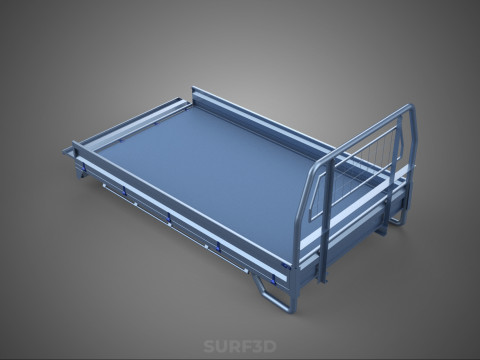

1. **Modified/Reinforced Tailgate and Mounting Platform:** The conventional tailgate, or the truck's rear frame section adjacent to it, serves as the primary mounting point for the hydraulic lifting apparatus. This area is often reinforced to withstand the substantial forces and torques generated during lifting operations. In some designs, the tailgate itself might be specifically engineered to act as a stable base or a component of the lifting structure when lowered.

2. **Hydraulic Power Unit (HPU):** This unit comprises an electric motor (powered by the truck's electrical system), a hydraulic pump, a fluid reservoir, and a system of control valves. The HPU generates the pressurized hydraulic fluid necessary to actuate the lifting cylinders.

3. **Hydraulic Cylinders:** These linear actuators convert hydraulic pressure into mechanical force, enabling the various movements of the lifting arm, such as vertical elevation, boom extension, and rotational (sle***g) motion.

4. **Lifting Arm/Boom:** This is the primary lifting component, typically a robust steel arm that can be fixed, telescopic, or articulated (******* boom). It is designed to extend over the truck bed and often features a hook, ***ch, or other specialized attachment point for securing loads. The arm is mounted on a pivot point, allo***g it to s***g or rotate to precisely position items.

5. **Control System:** Operation is managed via a wired or wireless remote control, providing the operator with precise command over all hydraulic functions from a safe distance, enhancing visibility and control.

6. **Stabilizers/Outriggers:** Depending on the lifting capacity and potential for instability, particularly when lifting heavier loads or operating on uneven terrain, some systems include deployable outriggers. These extend from the truck's frame to provide additional stability and prevent vehicle tipping during operation.

**Operational Principles:**

When in use, the truck is positioned, and the tailgate is typically lowered. The hydraulic lifting arm is then deployed from its stowed position. The operator uses the remote control to activate the hydraulic pump, which directs pressurized fluid to the appropriate cylinders. This allows the lifting arm to extend, raise, lower, and rotate, enabling the attachment and manipulation of loads. Once an item is lifted, it can be swung over the truck bed and carefully lowered into place. After operations, the arm is retracted and secured, and the tailgate can be closed.

**Applications:**

Tailgate-mounted hydraulic lifting systems are highly versatile and find widespread application across various sectors:

* **Commercial and Service Industries:** Used by plumbers, electricians, HVAC technicians, landscapers, mobile mechanics, and delivery services for loading heavy tools, equipment, supplies, or packages.

* **Construction:** Facilitates the transport and placement of building materials, small machinery, generators, and compressors.

* **Recreational Use:** Enables easier loading of ATVs, motorcycles, generators, camping gear, and other heavy recreational equipment.

* **Specialized Logistics:** Assists in the handling of ******* or fragile items that require precise placement.

**Advantages:**

* **Enhanced Utility:** Transforms a standard pickup truck into a highly capable material handling vehicle.

* **Safety and Ergonomics:** Eliminates the need for manual heavy lifting, significantly reducing the risk of musculoskeletal injuries.

* **Efficiency:** Streamlines loading and unloading processes, saving time and labor costs.

* **Self-Sufficiency:** Provides an integrated lifting solution without the need for external equipment or additional personnel.

* **Versatility:** Capable of performing multiple lifting functions (vertical lift, horizontal s***g, controlled descent).

**Disadvantages and Considerations:**

* **Cost:** The installation of such a system represents a significant investment.

* **Weight and Payload:** The added weight of the hydraulic system and crane reduces the truck's available payload capacity and can impact fuel efficiency.

* **Complexity and Maintenance:** Hydraulic systems require regular maintenance to ensure optimal performance and safety.

* **Rear Obstruction:** The stowed system may affect rear visibility or departure angle.

* **Lifting Capacity Limits:** While powerful, these systems have capacity limits that are lower than those of dedicated, larger truck-mounted cranes.

In summary, a tailgate-mounted hydraulic lifting system fundamentally augments a pickup truck's functionality, making it an invaluable tool for professional applications requiring routine handling of substantial loads.

Jika Anda membutuhkan format yang berbeda, silakan buka Tiket Dukungan baru dan minta itu. Kita dapat mengonversi model 3D menjadi: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Kami tidak mengonversi adegan 3d dan format seperti .step, .iges, .stp, .sldprt.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी