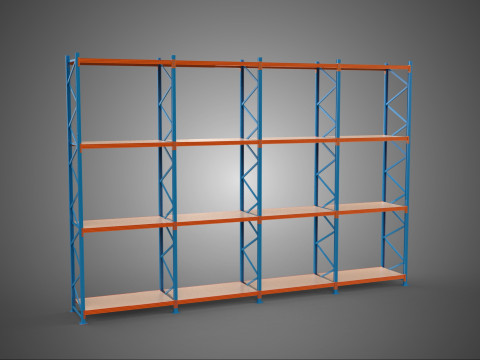

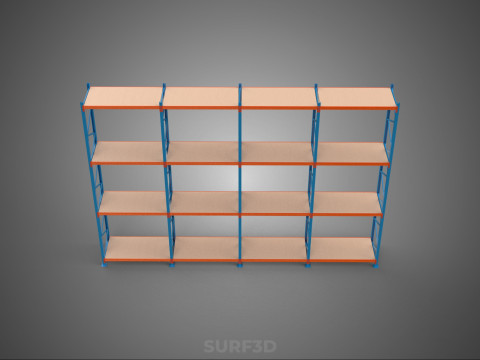

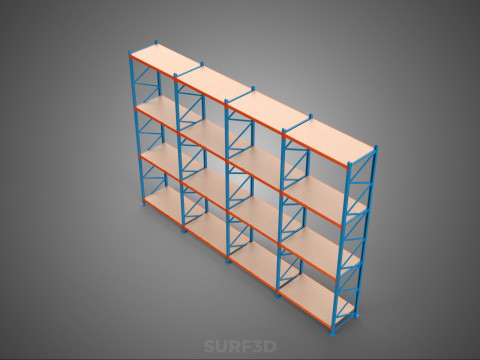

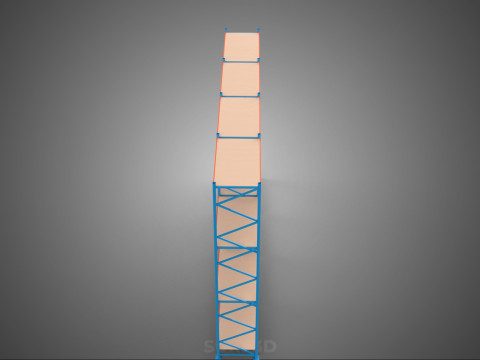

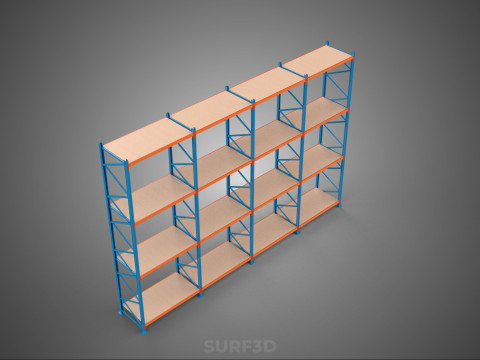

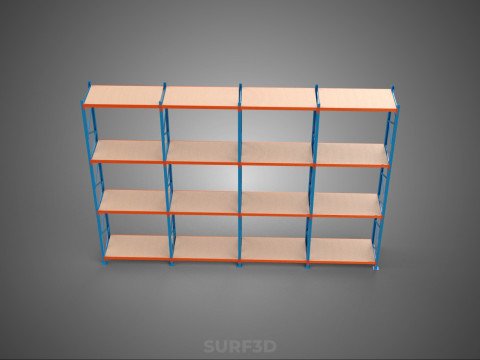

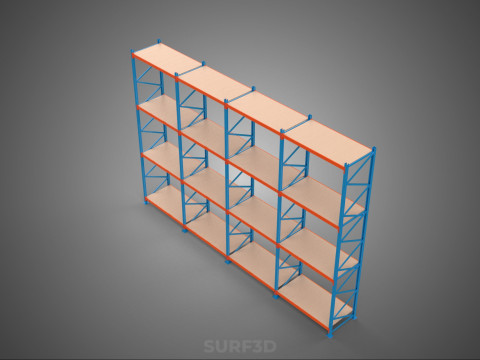

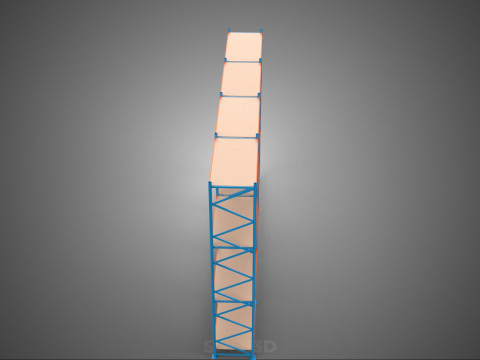

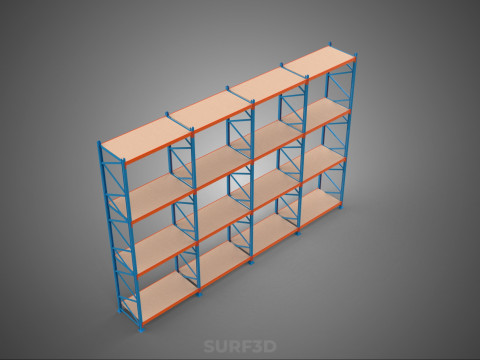

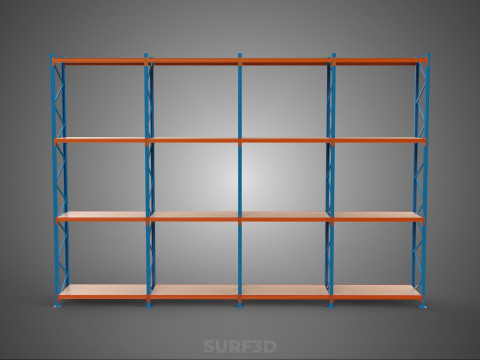

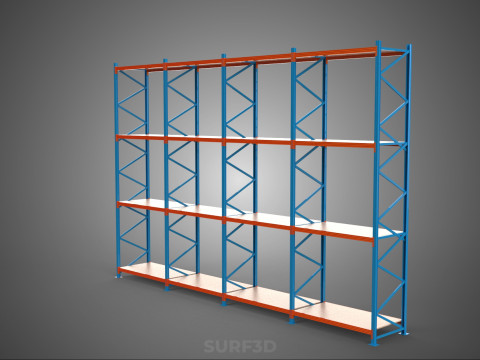

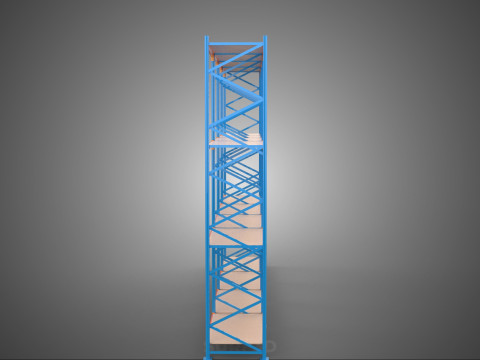

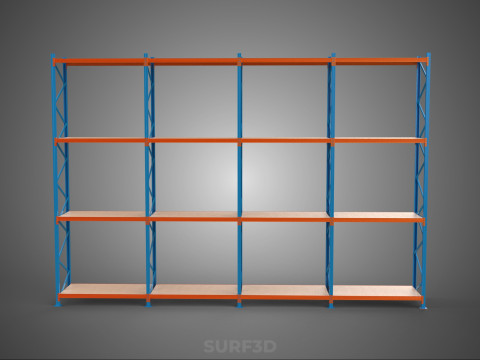

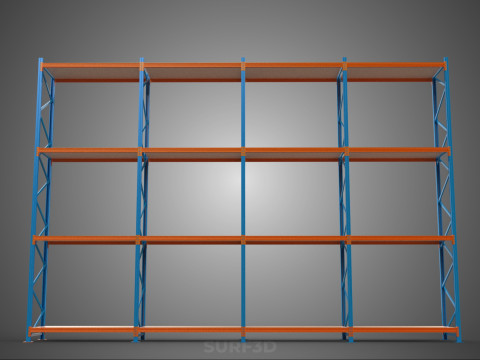

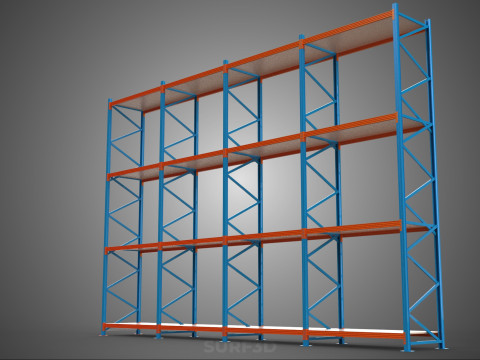

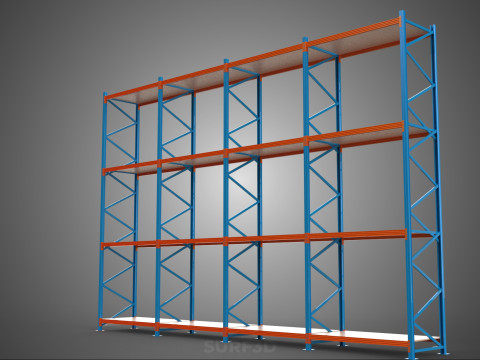

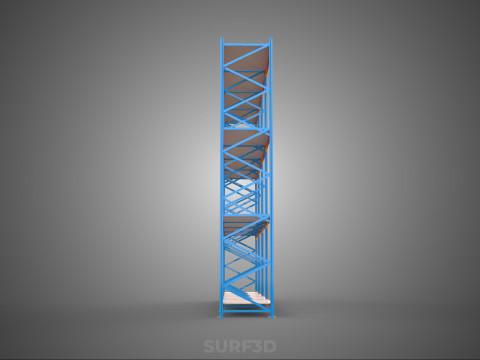

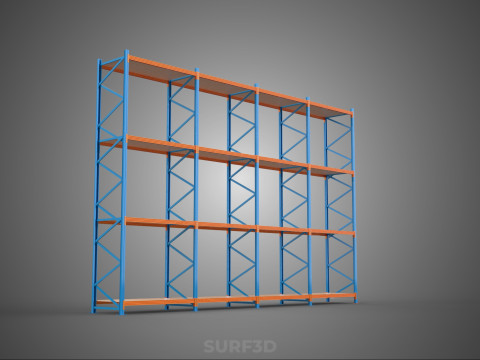

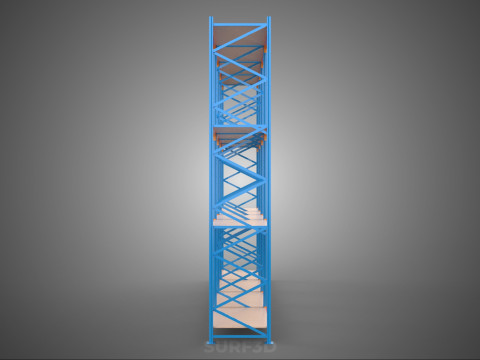

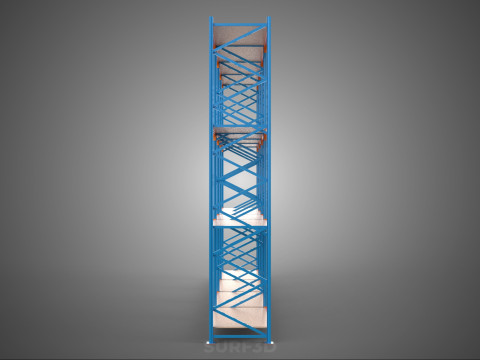

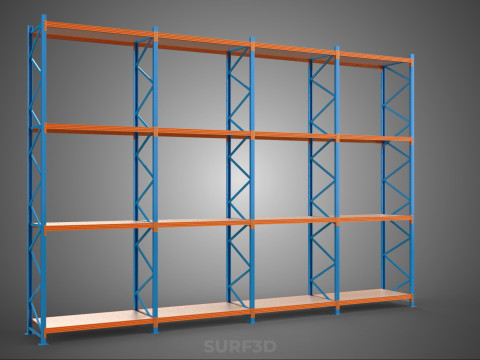

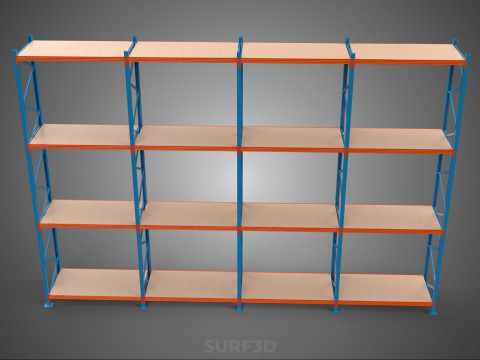

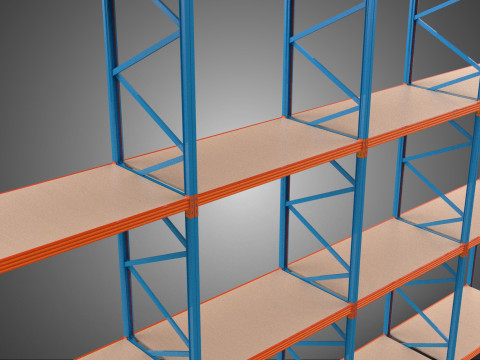

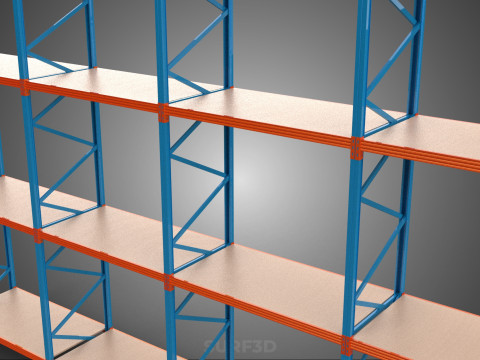

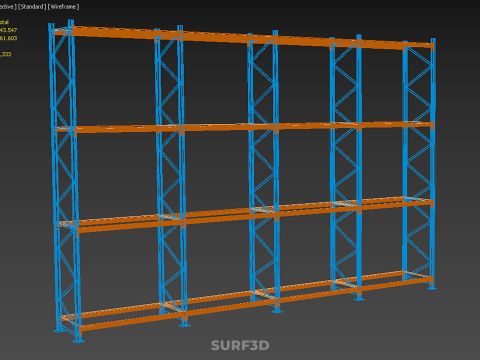

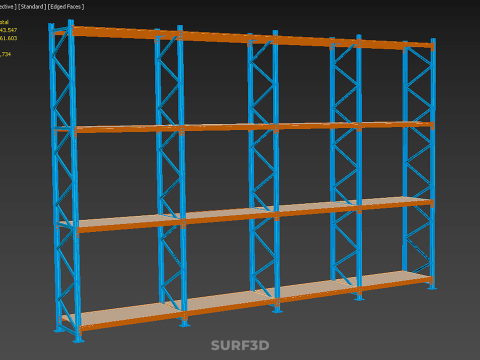

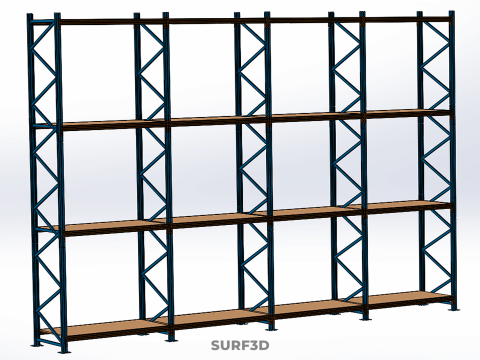

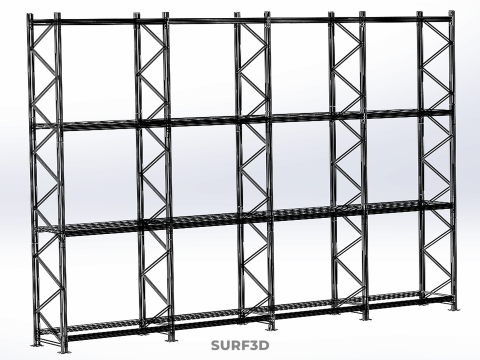

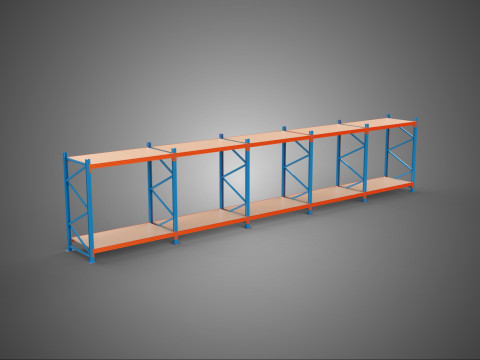

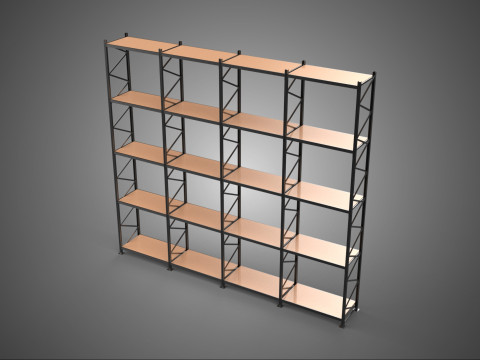

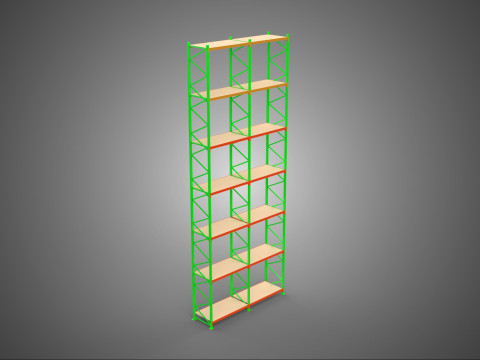

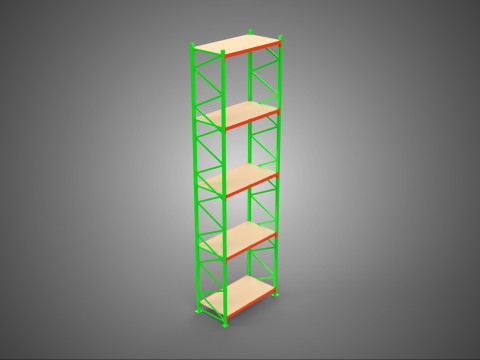

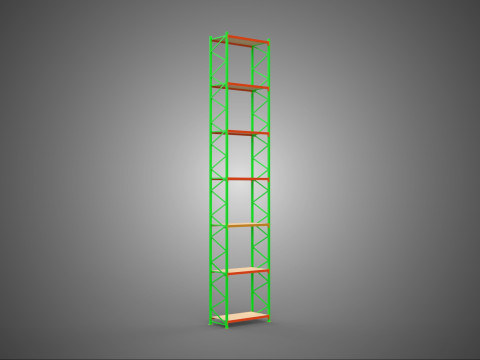

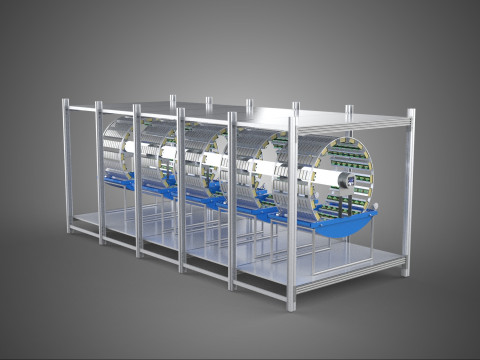

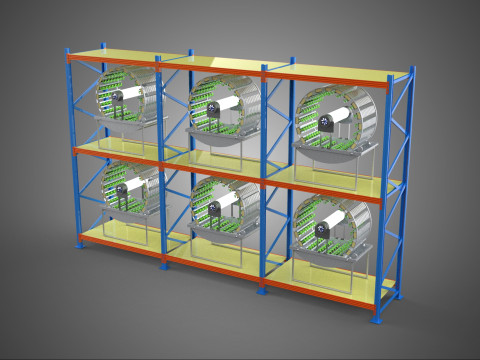

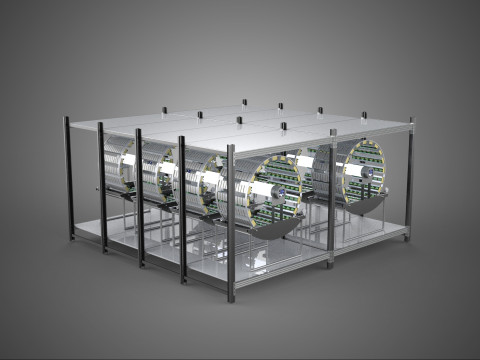

WOOD STEEL WAREHOUSE METAL SHELVING ORGANIZE STORAGE RACK SHELF 3D Model

- Hazır formatlar: Rhinoceros (.3dm) 6.55 MB3D Studio (.3ds) 670.46 kbBlender3D (.blend) 1.92 MBCollada (.dae) 1.35 MBAutodesk AutoCAD (.dwg) 2.56 MBAutodesk FBX (.fbx) 3.20 MBGLB (.glb / .gltf) 842.46 kbIGES (.iges) 4.54 MBAutodesk 3DS MAX (.max) 5.70 MBWavefront OBJ (.obj) 1.45 MBACIS(.sat) 2.65 MBSketchUp (.skp) 1.66 MBSTEP (.step) 5.01 MBStereolithography (.stl) 1.06 MB

- Poligonlar:143547

- Noktalar:161603

- Animasyon:No

- Dokulu:No

- Rigged:No

- Malzemeler:

- Low-poly:No

- Koleksiyon:No

- UVW mapping:No

- Kullanılan Eklentiler:No

- Baskıya Hazır:No

- 3D Tarama:No

- Yetişkin(+18) içerik:No

- PBR:No

- AI Eğitim:No

- Geometri:Poly NURBS

- Unwrapped UVs:Unknown

- Görüntülemeler:32

- Tarih: 2025-10-10

- Ürün ID:604314

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

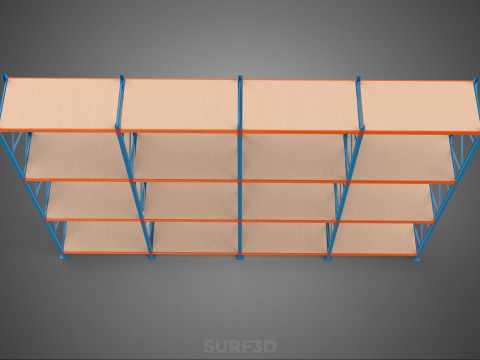

A "Wood Steel Warehouse Metal Shelving Organize Storage Rack Shelf" system refers to a category of robust, modular storage infrastructure predominantly designed for industrial, commercial, and institutional environments. This descriptive composite title highlights the fundamental characteristics of such a system: its primary construction materials (steel often integrated with wood components), its typical application setting (warehouses and similar large-scale storage facilities), and its core function (to organize, store, and manage goods efficiently). These systems are engineered to maximize vertical storage space, facilitate inventory control, and ensure safe, accessible storage for a diverse range of items, from boxed goods and components to bulk materials.

**Nomenclature and Typology:**

While "shelving" is a general term for horizontal storage surfaces, and "racking" often denotes heavier-duty systems for palletized loads (e.g., pallet racking), the specific descriptor in question typically refers to systems categorized as *long-span shelving*, *industrial shelving*, or *heavy-duty storage racks*. These are distinguished by their substantial load-bearing capacities for non-palletized items and their highly adjustable shelf levels. They represent a significant upgrade in durability and capacity compared to light-duty residential or office shelving units, utilizing thicker material gauges, reinforced beam profiles, and robust connection mechanisms.

**Construction and Materials:**

The "Wood Steel" designation underscores a hybrid construction approach that capitalizes on the specific strengths of each material:

* **Steel (Metal Shelving/Rack/Shelf Components):** This forms the primary structural framework and is central to the system's load-bearing capabilities. High-grade cold-rolled steel, engineered for strength and rigidity, constitutes the upright posts, horizontal beams, and often includes cross-bracing and back panels. Steel components are selected for their exceptional strength, durability, resistance to impact, and often feature protective finishes such as powder coating, galvanization, or enamel to enhance resistance to corrosion and wear. The design of steel beams (e.g., Z-beam, step beam) is crucial for distributing loads effectively and providing secure attachment points for shelf decking.

* **Wood (Decking/Shelving Elements):** Wood or wood-composite materials, commonly particle board, medium-density fiberboard (MDF), or plywood, are widely employed for the shelf decking or horizontal storage surfaces. These materials offer a cost-effective and lighter alternative to solid steel shelf panels, reducing overall system weight and material costs while providing a stable, flat surface for stored goods. They are typically cut to fit securely within the steel beam framework. While less common for the primary structural elements in heavy-duty warehouse applications, solid wood might be used for specialized applications or aesthetic purposes.

**Design and Configuration:**

These storage systems are inherently modular and highly configurable to adapt to specific storage requirements. Key components typically include:

* **Uprights/Posts:** Vertical steel columns that bear the entire vertical load. They feature strategically placed perforations or slots for secure beam attachment and shelf height adjustment.

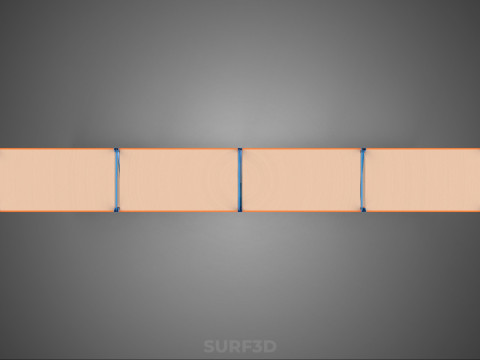

* **Horizontal Beams/Load Bearers:** Steel members that span between uprights, forming the perimeter of each shelf level. These beams directly support the shelf decking and the stored items.

* **Shelf Decking:** The horizontal surface (often wood-based) that rests upon the beams, providing the actual storage platform.

* **Fasteners/Connectors:** Systems can be categorized as "boltless" (utilizing rivets, clips, or interlocking mechanisms for rapid assembly and easy reconfiguration) or "bolted" (requiring nuts and bolts for maximum rigidity, often chosen for permanent or extremely heavy-duty installations).

* **Bracing:** Diagonal or horizontal steel elements that are sometimes incorporated into the structure to enhance lateral stability and prevent sway.

* **Footplates:** Base plates attached to the bottom of uprights to distribute the load evenly across the floor and provide points for anchoring the unit, which is critical for safety and stability.

**Operational Advantages and Applications:**

The integrated design of wood and steel in these storage systems offers compelling advantages:

* **High Load Capacity:** The robust steel framework ensures the system can safely support significant weights, accommodating heavy industrial goods.

* **Versatility and Adjustability:** Modular design permits easy adjustment of shelf heights, accommodating items of varying dimensions and adapting to evolving inventory needs.

* **Cost-Effectiveness:** The use of wood or wood-composite decking often provides a more economical solution compared to entirely steel-decked shelving, reducing initial material costs.

* **Space Optimization:** By efficiently utilizing vertical space, these systems substantially improve storage density and overall operational efficiency within warehouses and storage areas.

* **Durability:** The sturdy steel construction guarantees a long operational lifespan, even under demanding industrial conditions.

* **Organization and Access:** Clear, organized storage facilitates faster item retrieval, minimizes product damage, and enhances overall inventory management and control.

Common applications extend broadly across various sectors:

* **Warehouses and Distribution Centers:** For general storage of bulk goods, components, and finished products.

* **Retail Backrooms:** For organized storage of excess inventory and seasonal stock.

* **Archiving Facilities:** For efficient, high-density storage of documents and records.

* **Automotive Parts Departments:** For systematic storage of vehicle components.

* **Manufacturing and Assembly Plants:** For organizing raw materials, work-in-progress, and tools.

* **Workshops and Garages:** For heavy-duty storage of equipment, tools, and supplies.

Farklı bir formata ihtiyaç duyuyorsanız lütfen destek ekibimize bir talep açarak ihtiyacınızı belirtiniz. 3D modelleri şu formatlara dönüştürebiliriz: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 3d sahneleri dönüştürmüyoruz ve .step, .iges, .stp, .sldprt gibi formatlar.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी