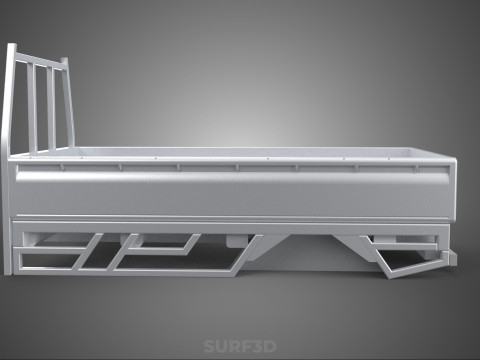

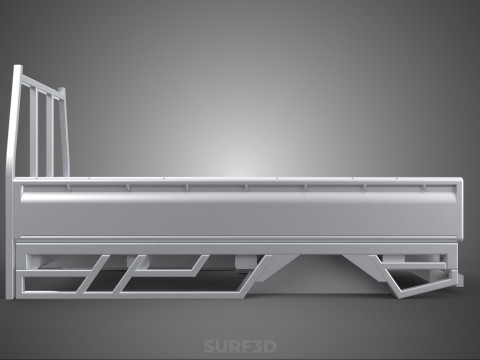

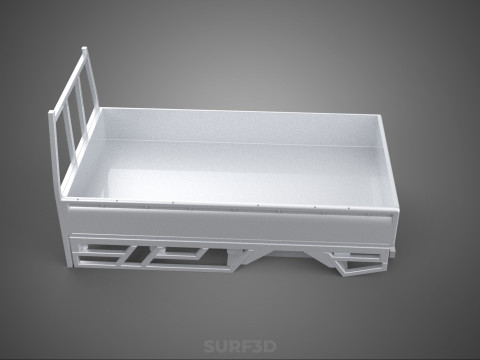

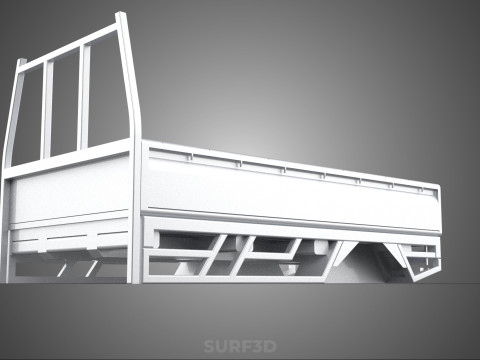

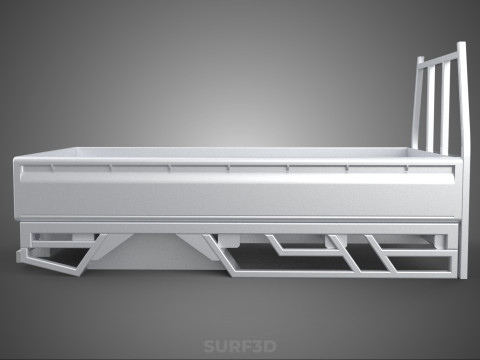

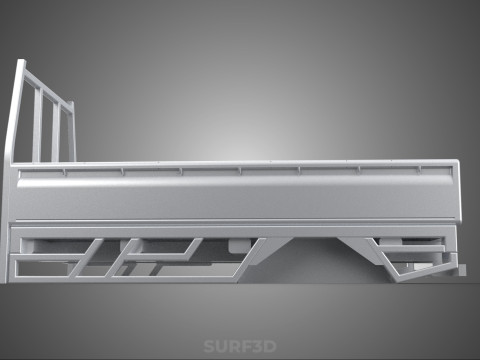

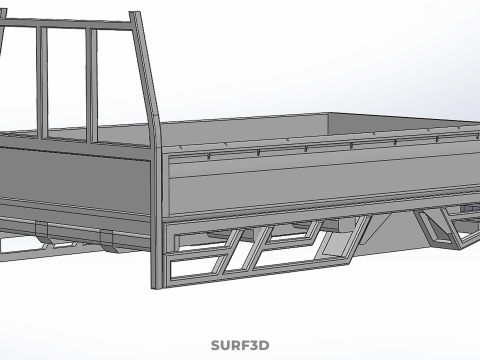

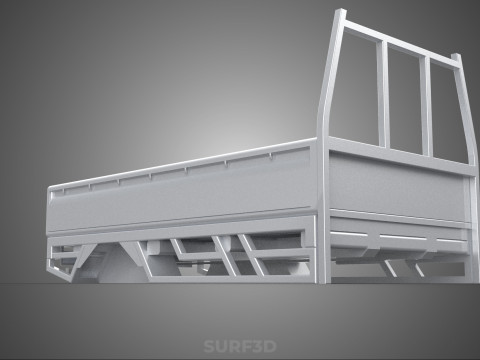

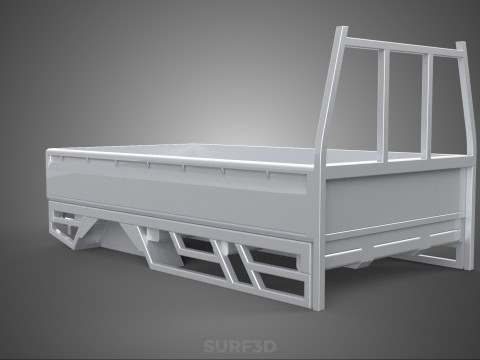

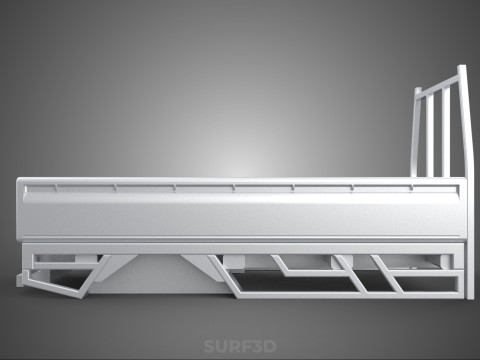

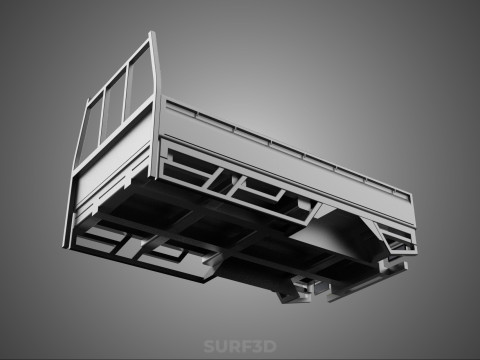

BAKKIE UTE PICKUP TRUCK FLAT BED CHASSIS BACK TRAY HEADBOARD VAN 3D Модель

- Доступні формати: Wavefront OBJ (.obj) 247.75 kbBlender3D (.blend) 462.91 kbRhinoceros (.3dm) 2.97 MBIGES (.iges) 486.01 kbAutodesk FBX (.fbx) 544.91 kbCollada (.dae) 367.34 kbACIS(.sat) 506.43 kbSTEP (.step) 436.01 kbGLB (.glb / .gltf) 205.79 kbSketchUp (.skp) 754.96 kbStereolithography (.stl) 265.87 kb3D Studio (.3ds) 145.26 kbAutodesk AutoCAD (.dwg) 645.99 kbAutodesk 3DS MAX (.max) 1.09 MB

- Полігони:18677

- Вершини:16677

- Анімована:No

- Текстури:No

- Скелет:No

- Матеріали:

- Лоу-полі:No

- Колекція:No

- UVW зображення:No

- Плагіни:No

- Готовність до друку:No

- 3D Скан:No

- Зміст для дорослих:No

- PBR:No

- ШІ Навчання:No

- Геометрія:Poly NURBS

- Розгорнуті UVs:Unknown

- Перегляди:238

- Дата: 2025-07-26

- ID Товару:589551

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and ****ed for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

A Flat Bed Chassis Back Tray with Headboard is a specialized vehicle body designed to replace the standard cargo box or load bed of light commercial vehicles, converting them into highly versatile flatbed platforms. This modular attachment consists of a robust, unenclosed load surface (the "flat bed" or "tray") mounted directly onto the vehicle's chassis frame, featuring a fixed vertical barrier (the "headboard") at its forward end. It is commonly utilized with chassis-cab configurations of pickup trucks, utilities (utes), bakkies, and certain types of vans, enhancing their capacity for diverse and irregularly shaped cargo.

**Nomenclature and Vehicle Compatibility:**

The terminology for this component varies geographically. "Flat bed" is widely understood globally, referring to an open, flat loading deck. "Chassis back tray" emphasizes its direct attachment to the vehicle's ladder frame chassis and its rearward positioning. The "headboard" serves as a protective bulkhead for the vehicle's cabin and an anchor point for loads. The specified vehicle types—"bakkie" (primarily Southern Africa), "ute" (Australia and New Zealand), "pickup truck" (North America and international), and "van" (referring specifically to chassis-cab versions of light commercial vans, not unibody panel vans)—all possess a distinct chassis frame separate from the cabin, enabling the removal of the original cargo area and the direct mounting of this specialized tray.

**Purpose and Functionality:**

The primary purpose of a flat bed chassis back tray with headboard is to significantly augment the vehicle's cargo-carrying capabilities beyond the confines of a traditional enclosed bed. By providing an uninterrupted, flat loading surface, it facilitates:

1. **Versatility:** Accommodation of oversized, long, wide, or irregularly shaped items that would not fit within a standard pickup bed.

2. **Accessibility:** Unrestricted loading and unloading from three sides (left, right, and rear) using forklifts, cranes, or manual methods, which is particularly beneficial in commercial and industrial settings.

3. **Load Distribution:** Allows for more flexible positioning of cargo to optimize weight distribution over the vehicle's axles, contributing to safer operation.

4. **Customization:** Serves as a fundamental platform for mounting specialized equipment, toolboxes, service bodies, or custom racks tailored to specific vocational requirements.

**Design and Construction:**

Flat bed chassis back trays are engineered for durability and functionality.

* **Materials:** Construction typically involves high-strength steel (e.g., mild steel, high-tensile steel, or galvanized steel for enhanced corrosion resistance) or lightweight aluminum alloys. Aluminum offers weight reduction benefits, improving fuel efficiency and payload capacity, while steel generally provides superior robustness for heavy-duty applications. The deck surface itself may be constructed from checker plate steel, smooth steel, aluminum, or sometimes incorporate timber planks for specific applications.

* **Main Frame/Subframe:** A robust subframe forms the base of the tray, designed to interface directly with the vehicle's chassis rails. This subframe includes crossmembers and long runners that distribute the load evenly and ensure structural integrity. Mounting brackets secure the tray firmly to the chassis.

* **Deck/Platform:** The flat loading surface, often reinforced with internal bracing, forms the primary cargo area. It is designed to withstand significant weight and impact. Integrated tie-down points, such as rope rails, stake pockets, or D-rings, are typically incorporated along the perimeter to facilitate secure cargo restraint.

* **Headboard:** Positioned at the front of the tray, immediately behind the vehicle's cab, the headboard is a critical safety component. It is usually constructed from the same materials as the rest of the tray and may feature a mesh design for rear visibility or solid panels for maximum protection. Its functions include:

* **Cab Protection:** Shielding the vehicle's cabin from shifting cargo, especially during sudden braking.

* **Load Retention:** Acting as a forward barrier to prevent cargo from sliding off the tray.

* **Mounting Point:** Often incorporates provisions for mounting work lights, ladder racks, spare tires, or other accessories.

* **Optional Features:** While the core definition implies an open platform, many trays are designed to accommodate optional removable drop sides (hinged panels along the sides and rear), rear tailgates, under-tray toolboxes, water tanks, and integrated lighting systems (tail lights, brake lights, indicators) that comply with road safety regulations.

**Advantages:**

* **Increased Practicality:** Superior versatility for transporting diverse cargo, especially long or wide items.

* **Enhanced Loading Efficiency:** Facilitates quicker loading and unloading processes, reducing downtime.

* **Durability and Longevity:** Constructed from robust materials, these trays are built for demanding commercial use.

* **Customization Potential:** Provides a modular base for bespoke modifications and specialized equipment integration.

* **Optimized Payload:** Lighter aluminum options can increase the vehicle's available payload capacity.

**Disadvantages and Considerations:**

* **Load Security:** Without additional features (e.g., sides, cargo nets, tarpaulins), loads are more exposed and require diligent securing.

* **Weather Protection:** Cargo is exposed to environmental elements; covers or tarpaulins are necessary for protection.

* **Aerodynamics:** A fully loaded flatbed may present increased aerodynamic drag compared to an enclosed body.

* **Installation Complexity:** Requires professional installation, including potential modifications to the vehicle's wiring for integrated lighting.

**Applications:**

Flat bed chassis back trays with headboards are indispensable across numerous industries, including:

* **Construction:** Transporting building materials, timber, scaffolding, tools.

* **Landscaping and Horticulture:** Hauling plants, soil, garden waste, machinery.

* **Agriculture:** Moving feed, equipment, fence posts, produce.

* **Utilities and Trades:** Used by electricians, plumbers, welders for tools, pipes, and equipment.

* **Logistics and Deliveries:** For oversized parcels, furniture, or equipment.

* **Recreational:** Transporting ATVs, motorbikes, or camping gear for enthusiasts.

**Regulatory Compliance:**

Installation and use must adhere to local vehicle regulations concerning dimensions (width, length, overhangs), weight limits (Gross Vehicle Mass, axle loads), lighting requirements, and load restraint standards to ensure safe road operation.

KEYWORDS: Flat bed, Chassis tray, Headboard, Pickup truck, Ute, Bakkie, Commercial vehicle, Cargo body, Vehicle platform, Load bed, Truck tray, Utility body, Chassis cab, Load capacity, Material transport, Open deck, Vehicle modification, Aluminum tray, Steel tray, Load restraint, Cab protection, Drop sides, Subframe, Customization, Work vehicle, Vocational upfit, Bulk cargo, Oversized cargo, Industrial use, Commercial transport

Якщо вам потрібен інший формат, будь ласка, зробіть запит за допомогою тікета підтримки. Ми можемо конвертувати 3D моделі: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Ми не конвертуємо 3d сцени і такі формати, як .step, .iges, .stp, .sldprt тощо!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी