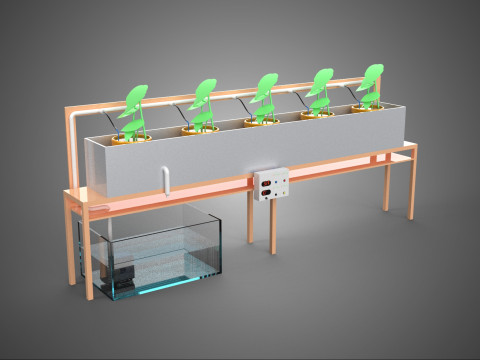

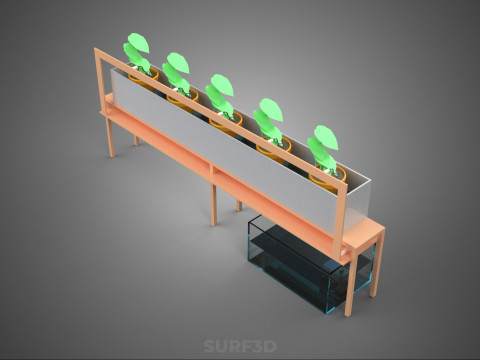

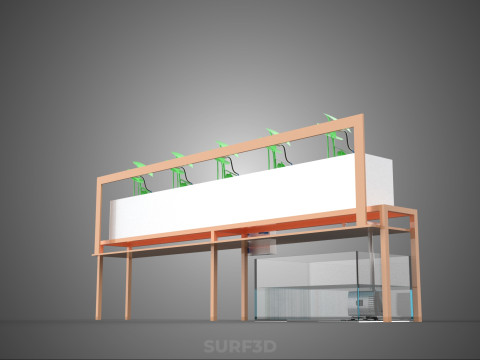

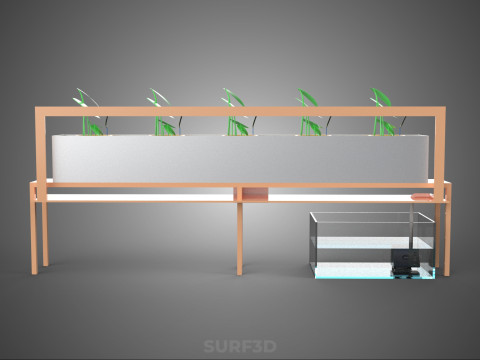

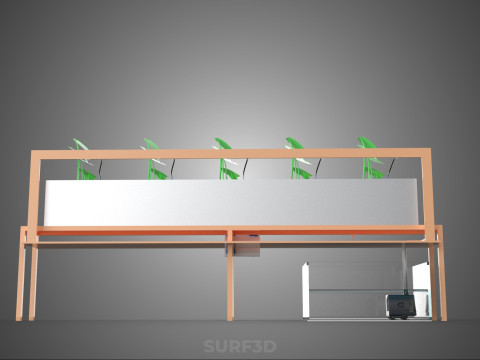

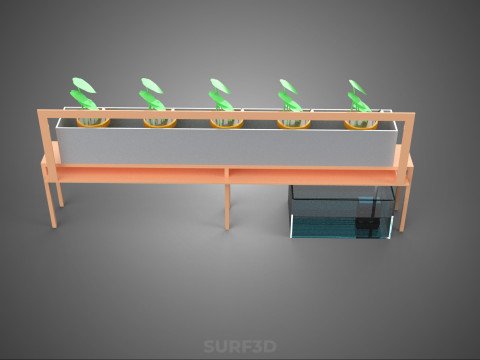

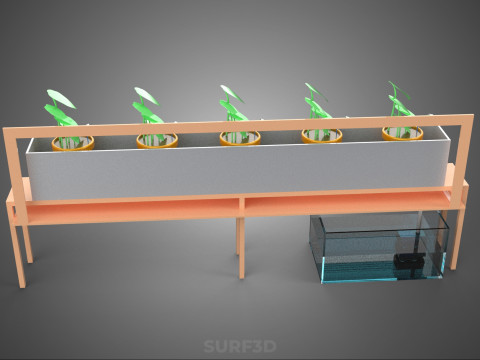

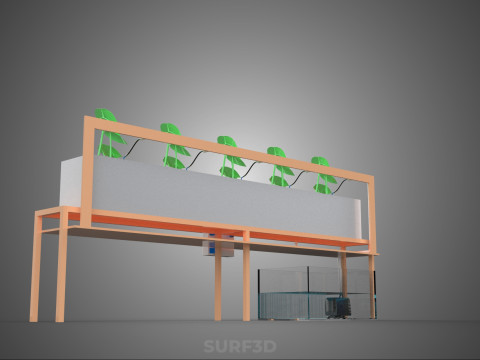

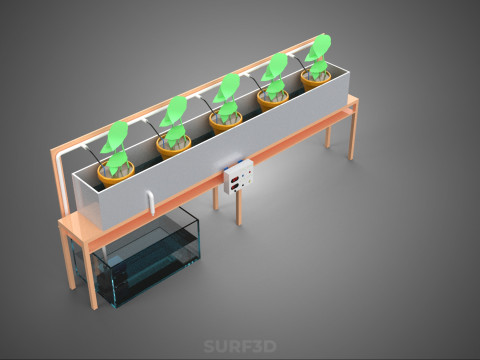

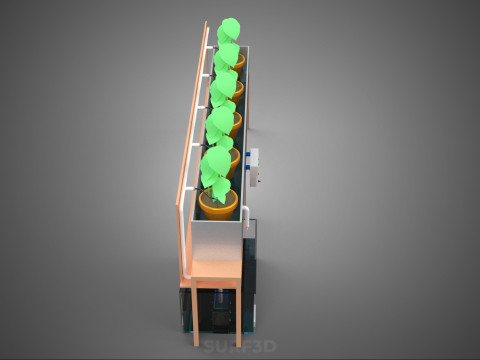

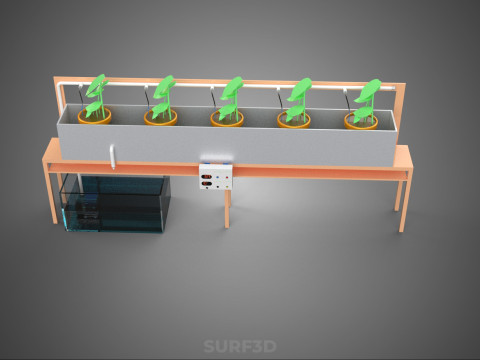

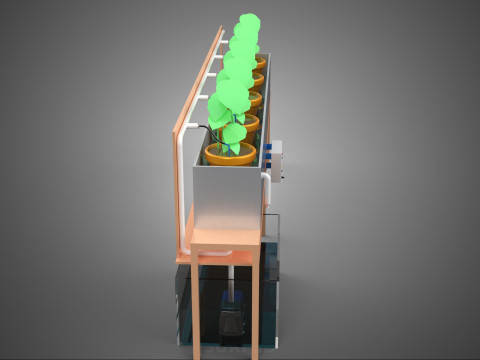

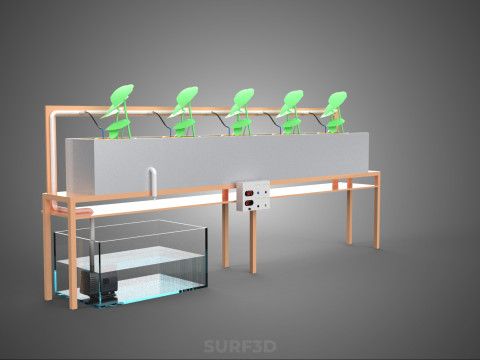

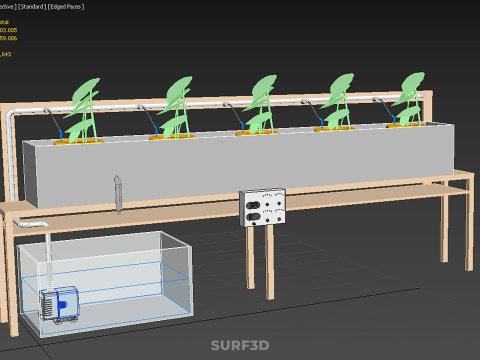

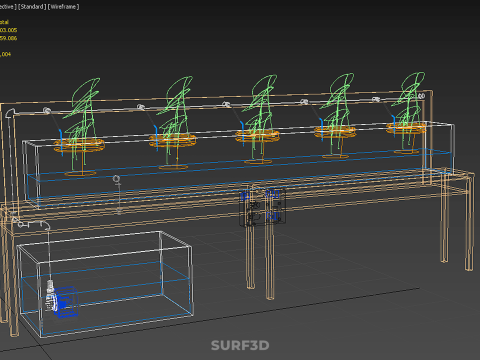

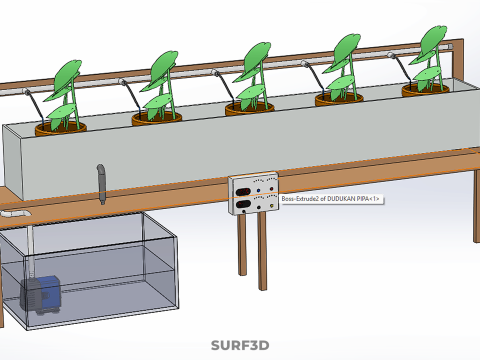

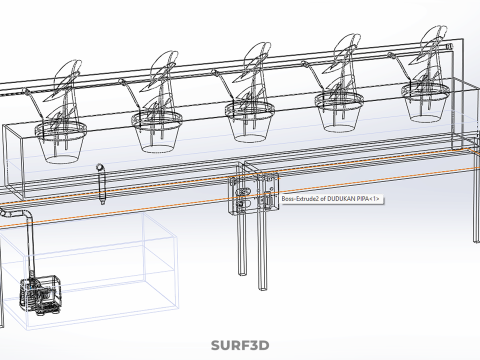

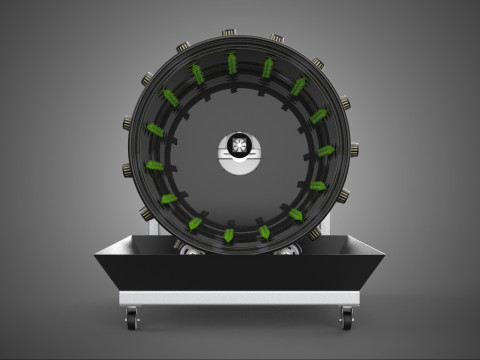

IOT HYDROPONIC PLANT AUTO CONTROL WATER DRIP IRRIGATION SYSTEM 3D Модель

- Доступні формати: Collada (.dae) 3.21 MBAutodesk 3DS MAX (.max) 7.15 MBSTEP (.step) 2.06 MB3D Studio (.3ds) 1.29 MBBlender3D (.blend) 3.52 MBSketchUp (.skp) 3.30 MBAutodesk AutoCAD (.dwg) 3.26 MBIGES (.iges) 2.11 MBRhinoceros (.3dm) 10.94 MBStereolithography (.stl) 2.75 MBGLB (.glb / .gltf) 1.66 MBAutodesk FBX (.fbx) 4.88 MBWavefront OBJ (.obj) 2.42 MBACIS(.sat) 3.84 MB

- Полігони:203005

- Вершини:159086

- Анімована:No

- Текстури:No

- Скелет:No

- Матеріали:

- Лоу-полі:No

- Колекція:No

- UVW зображення:No

- Плагіни:No

- Готовність до друку:No

- 3D Скан:No

- Зміст для дорослих:No

- PBR:No

- ШІ Навчання:No

- Геометрія:Poly NURBS

- Розгорнуті UVs:Unknown

- Перегляди:93

- Дата: 2025-09-27

- ID Товару:601870

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

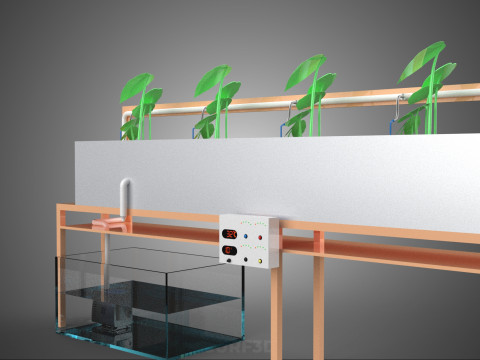

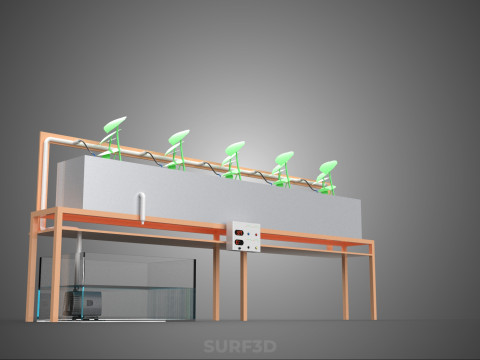

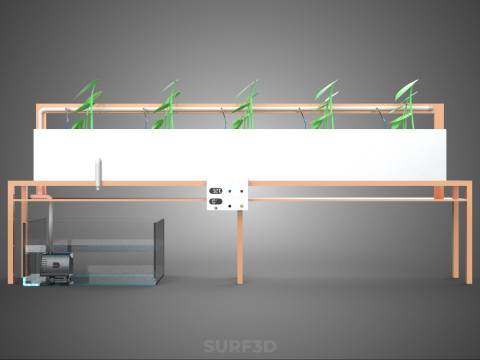

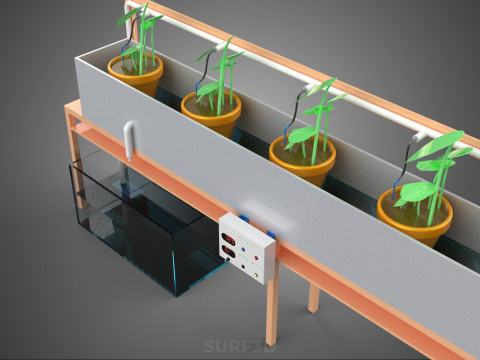

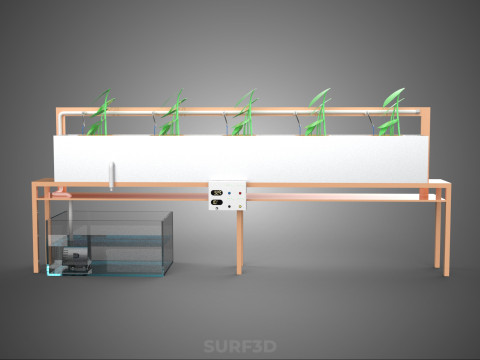

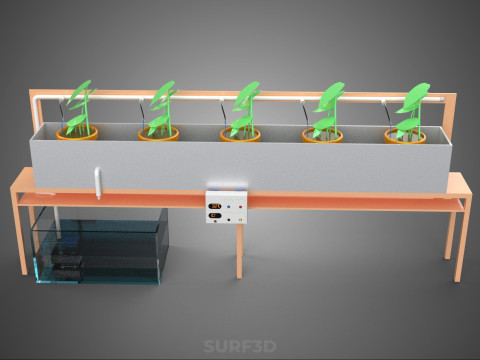

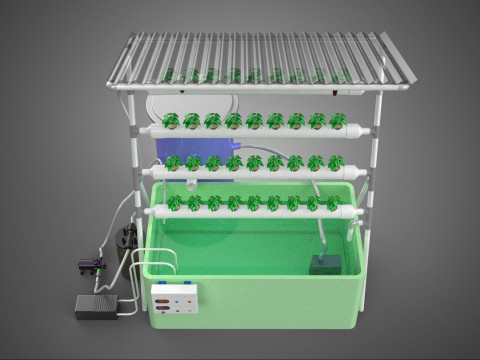

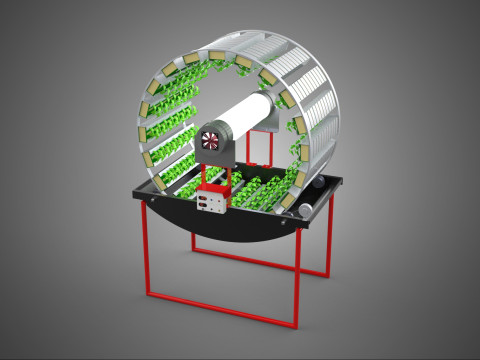

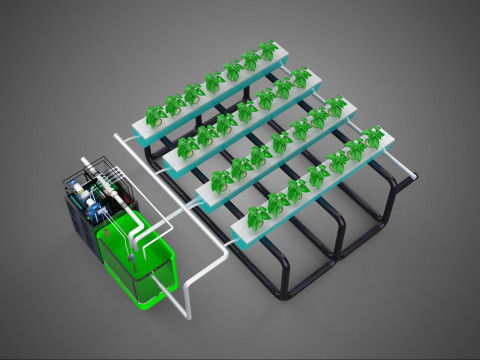

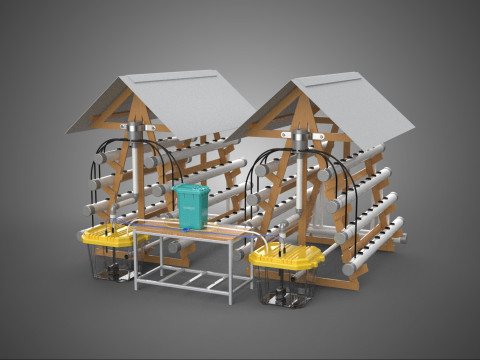

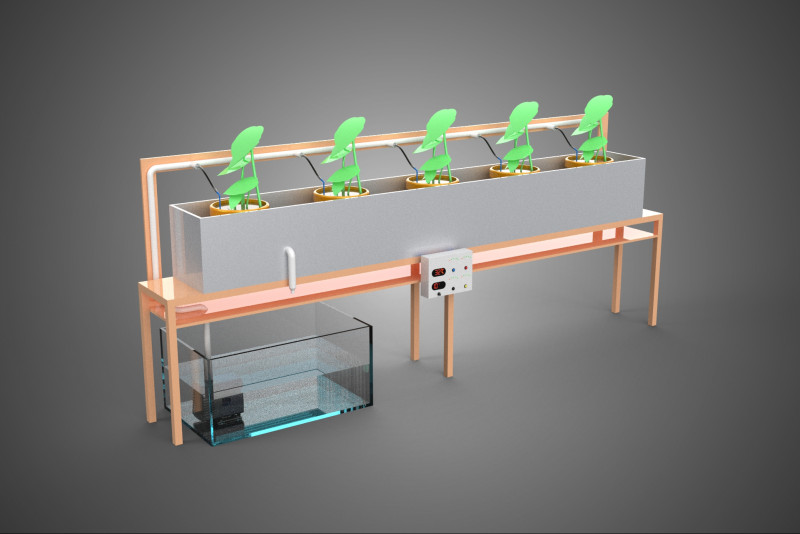

An IoT Hydroponic Plant Auto Control Water Drip Irrigation System represents an advanced agricultural technology that integrates Internet of Things (IoT) principles with soilless cultivation (hydroponics) and precision irrigation. This sophisticated system is designed to autonomously monitor, regulate, and optimize environmental parameters and nutrient delivery for plant growth, thereby significantly enhancing resource efficiency, yield, and crop quality.

**Core Components:**

At its foundation, the system comprises several integrated modules:

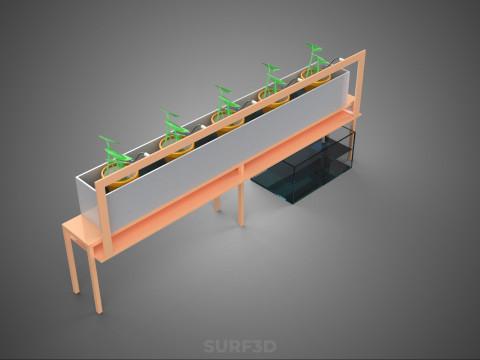

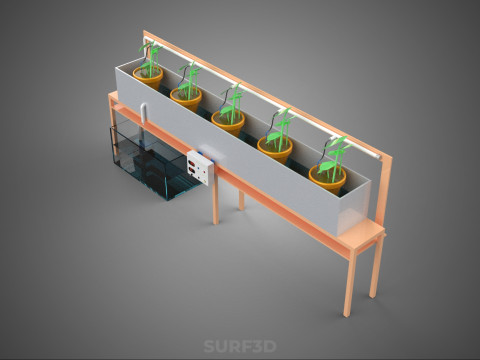

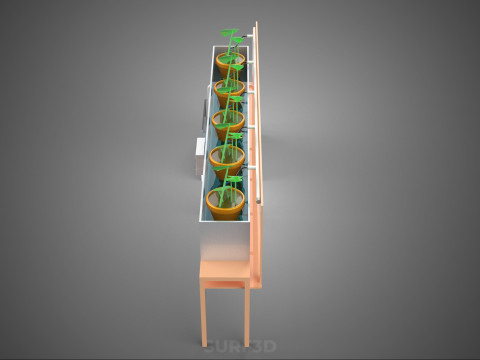

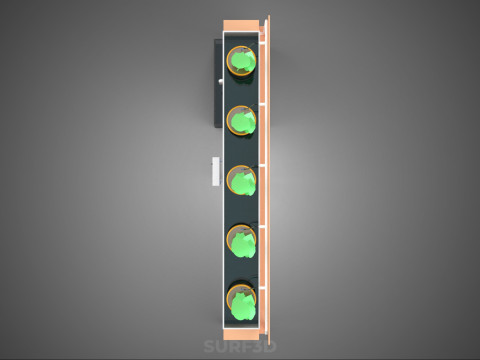

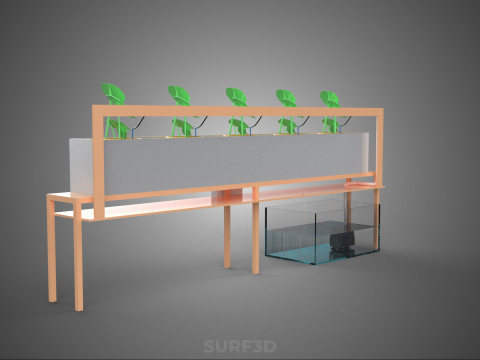

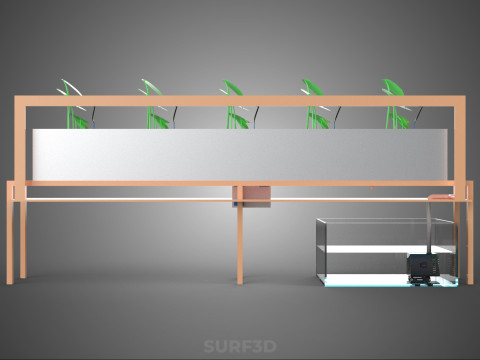

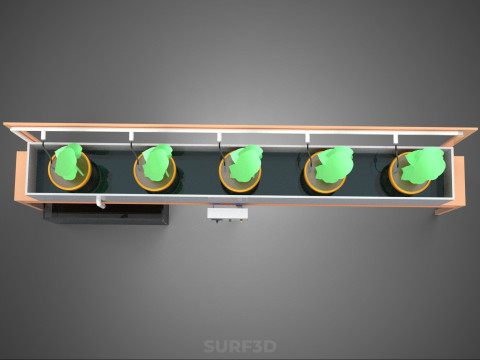

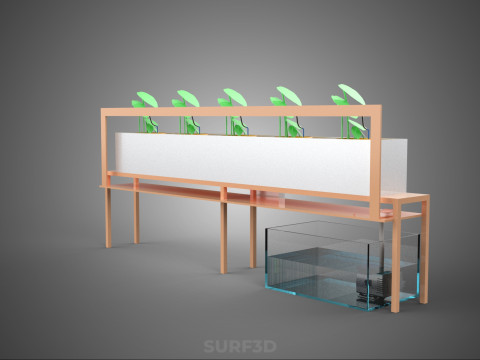

1. **Hydroponic Setup:** This fundamental component includes a grow tray or channels, inert growing media (e.g., rockwool, coco coir, perlite) for physical plant support, and a reservoir containing a precisely balanced aqueous nutrient solution. While various hydroponic techniques exist, this system specifically incorporates drip irrigation for nutrient delivery.

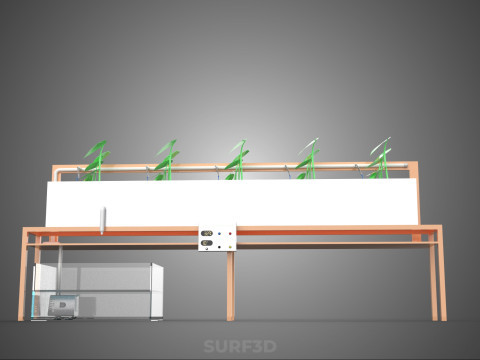

2. **Drip Irrigation Subsystem:** Central to efficient nutrient delivery, this subsystem typically consists of a submersible pump within the nutrient reservoir, a network of distribution tubing, and individual drippers or emitters positioned near the base of each plant. This method ensures targeted, consistent, and localized delivery of the nutrient solution directly to the root zone, minimizing waste through evaporation or runoff.

3. **Sensor Array:** A crucial element for real-time data acquisition, the system incorporates various environmental and solution-specific sensors. These typically include:

* **pH Sensor:** Measures the acidity or alkalinity of the nutrient solution, critical for optimal nutrient uptake by plants.

* **Electrical Conductivity (EC) / Total Dissolved Solids (TDS) Sensor:** Quantifies the concentration of dissolved mineral salts (nutrients) in the solution, indicating nutrient strength.

* **Temperature Sensors (Air & Water):** Monitors both ******t air and nutrient solution temperatures, which profoundly impact plant metabolism and dissolved oxygen levels.

* **Humidity Sensor:** Measures atmospheric moisture, vital for transpiration regulation and preventing fungal diseases.

* **Water Level Sensor:** Monitors the volume of nutrient solution in the reservoir, triggering refills as needed.

* **Light Intensity Sensor (PAR/LUX):** Measures the quantity of light available for photosynthesis, informing grow light operation.

4. **Control Unit (Microcontroller/Microprocessor):** Often a single-board computer (e.g., Raspberry Pi, Arduino) or a dedicated Programmable Logic Controller (PLC), this unit serves as the system's brain. It continuously receives, processes, and analyzes sensor data against predefined optimal parameters for specific plant types, executing logical commands.

5. **IoT Connectivity Module:** This module facilitates communication between the local control unit and a remote server or cloud platform. Utilizing wireless technologies such as Wi-Fi, Zigbee, LoRa, or cellular networks, it enables real-time data transmission, remote monitoring, and control commands from an external interface.

6. **Actuators:** These are the devices that execute physical changes in the system based on the control unit's commands. Common actuators include:

* **Peristaltic or Dosing Pumps:** Precisely dispense pH-adjusting solutions (acid/base) and concentrated nutrient blends to maintain optimal solution parameters.

* **Water Pumps:** Circulate the nutrient solution for irrigation and potentially for aeration within the reservoir.

* **Solenoid Valves:** Control the flow of water or nutrient solutions to different grow zones or for reservoir top-ups.

* **Grow Lights:** Regulate photoperiod and light intensity based on plant requirements.

* **Fans/Ventilation Systems:** Manage air circulation, temperature, and humidity within the growing environment.

**Operational Mechanism:**

The system operates on a continuous feedback loop. Sensors perpetually collect data from the hydroponic environment, transmitting it to the control unit. The control unit compares this real-time data with programmed optimal ranges for the specific crop being cultivated. If deviations are detected (e.g., pH too high, EC too low, water level below threshold, temperature outside range), the control unit activates the appropriate actuators. For instance, if pH is high, a dosing pump dispenses pH-down solution; if EC is low, nutrient concentrates are added; if water level is low, the reservoir is refilled; if air temperature is high, fans are activated. All sensor readings, system statuses, and operational logs are wirelessly transmitted via the IoT module to a cloud-based server. Users can access this data and remotely manage system parameters through a dedicated web interface or mobile application, receiving real-time alerts for critical events or abnormal conditions.

**Key Benefits and Advantages:**

The deployment of such a system offers significant advantages in modern agriculture:

* **Resource Efficiency:** Precise water and nutrient delivery drastically reduces consumption, often by up to 90% compared to traditional soil-based methods, minimizing waste and environmental impact.

* **Optimized Plant Growth:** Maintaining ideal conditions (pH, EC, temperature, humidity, light) around the clock maximizes plant health, accelerates growth rates, and ultimately enhances yields and crop quality.

* **Reduced Labor and Automation:** Automated monitoring and control significantly reduce manual intervention for routine tasks such as watering, fertilizing, and environmental adjustments, freeing up human resources.

* **Data-Driven Insights:** Continuous data collection provides valuable insights into plant responses and system performance, enabling data-driven adjustments and optimization strategies for improved efficiency and yield over time.

* **Pest and Disease Control:** Controlled Environment Agriculture (CEA) inherently reduces exposure to soil-borne pathogens and pests, simplifying pest management.

Якщо вам потрібен інший формат, будь ласка, зробіть запит за допомогою тікета підтримки. Ми можемо конвертувати 3D моделі: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Ми не конвертуємо 3d сцени і такі формати, як .step, .iges, .stp, .sldprt тощо!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी