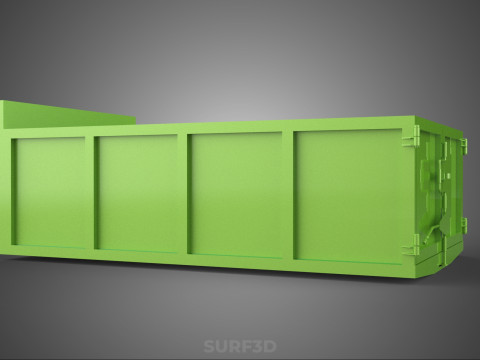

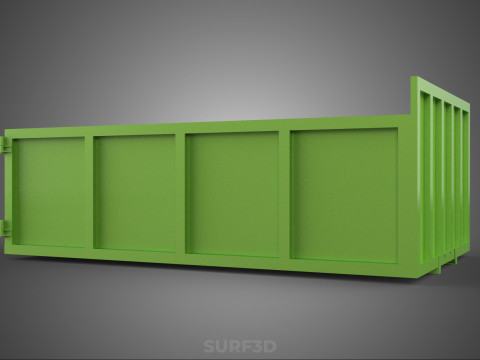

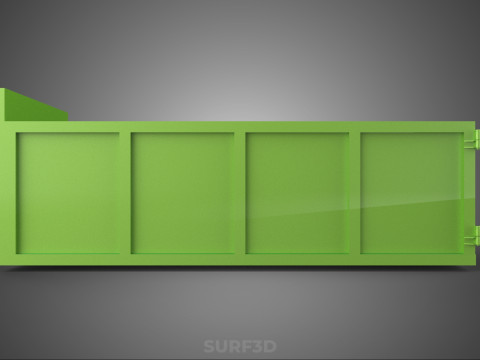

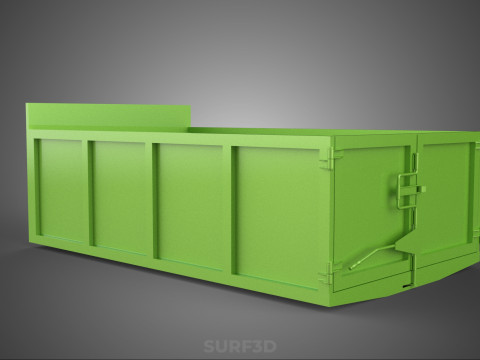

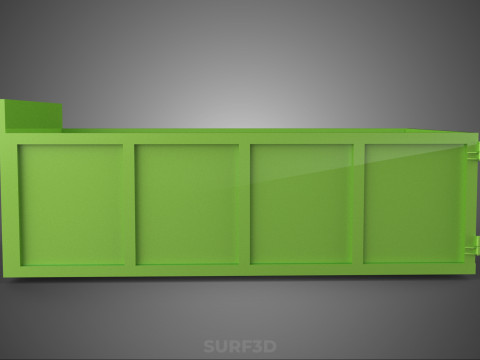

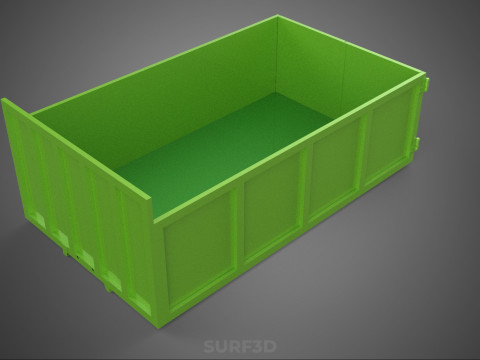

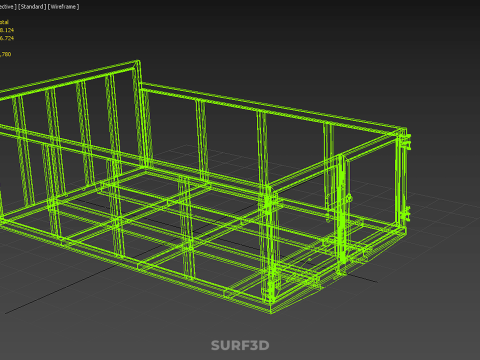

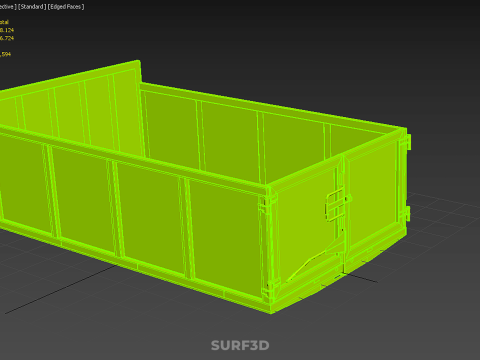

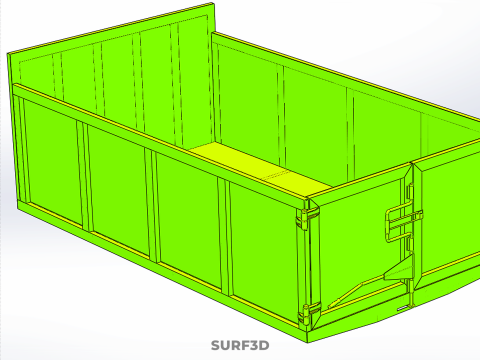

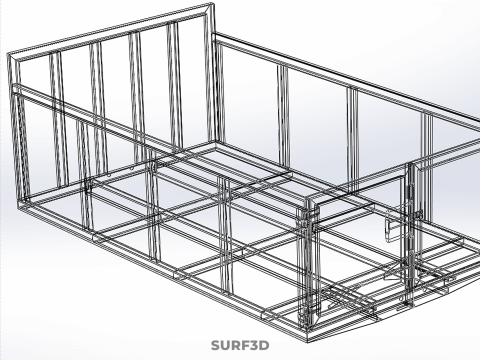

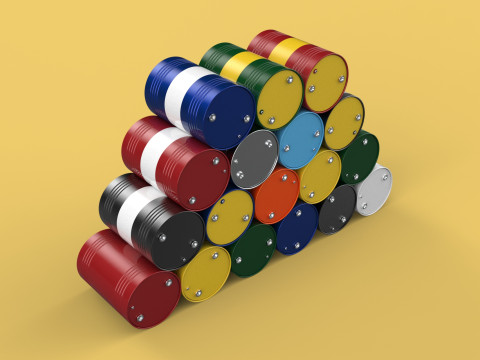

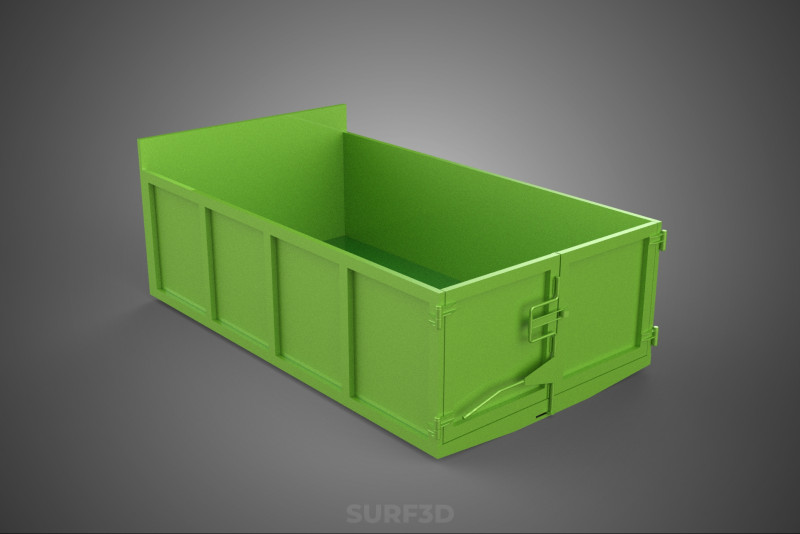

TRUCK BED DUMP BODY BOX CONTAINER BIN CARGO VEHICLE PICKUP CAR 3D 模型

- 可用的格式: Stereolithography (.stl) 482.12 kbIGES (.iges) 931.54 kbAutodesk FBX (.fbx) 1.02 MB3D Studio (.3ds) 264.56 kbRhinoceros (.3dm) 3.52 MBWavefront OBJ (.obj) 518.54 kbCollada (.dae) 589.62 kbACIS(.sat) 601.29 kbAutodesk AutoCAD (.dwg) 576.44 kbGLB (.glb / .gltf) 370.37 kbSTEP (.step) 572.74 kbBlender3D (.blend) 736.52 kbAutodesk 3DS MAX (.max) 1.58 MBSketchUp (.skp) 979.39 kb

- 多边形:38124

- 顶点:36724

- 动画:No

- 纹理:No

- 操纵:No

- 材料:

- 低聚:No

- 集合:No

- UVW 贴图:No

- 使用插件:No

- 打印准备:No

- 3D扫描:No

- 成人内容:No

- PBR:No

- 人工智能培训:No

- 几何:Poly NURBS

- 包装 UVs:Unknown

- 日期:229

- 日期: 2025-07-26

- 项目 ID:589376

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

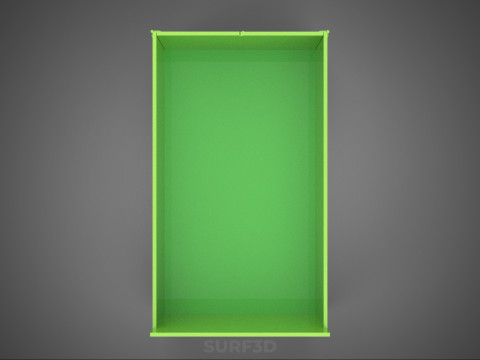

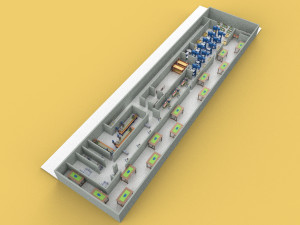

A **truck bed dump body**, often referred to as a **dump insert**, is a specialized, self-contained apparatus designed to transform the conventional open cargo area of a light-duty or medium-duty pickup truck into a hydraulically actuated dumping mechanism. The composite title "TRUCK BED DUMP BODY CONTAINER BIN CARGO FOR VEHICLE PICKUP CAR" comprehensively describes this equipment, highlighting its primary components and function as a receptacle for materials that can be mechanically discharged from a pickup truck.

**Function and Purpose:**

The fundamental purpose of a truck bed dump body is to facilitate the efficient loading, transport, and, crucially, the mechanized unloading of bulk materials. Unlike standard truck beds, which require manual shoveling or specialized equipment for discharge, a dump body allows for the rapid and controlled gravity-assisted expulsion of its contents by tilting the entire cargo bin. This significantly reduces labor, time, and effort involved in material handling tasks.

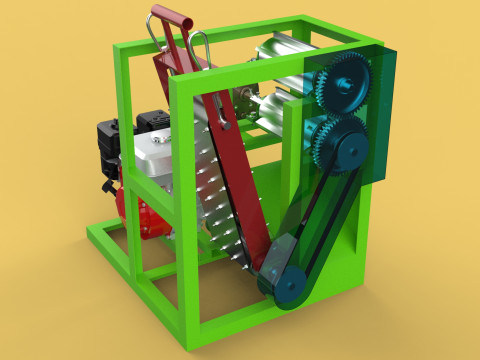

**Design and Mechanism:**

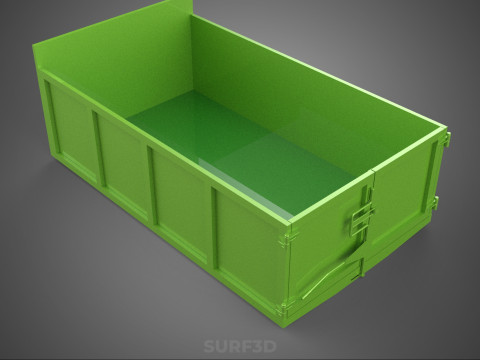

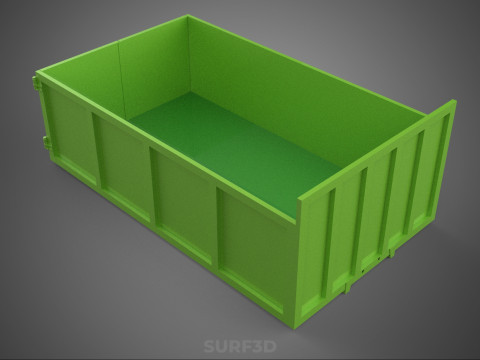

A typical truck bed dump body comprises several key components:

1. **Cargo Bin (Container/Bin):** The primary receptacle for materials, constructed from robust materials such as high-grade steel or aluminum. It is designed to withstand heavy loads and abrasive materials.

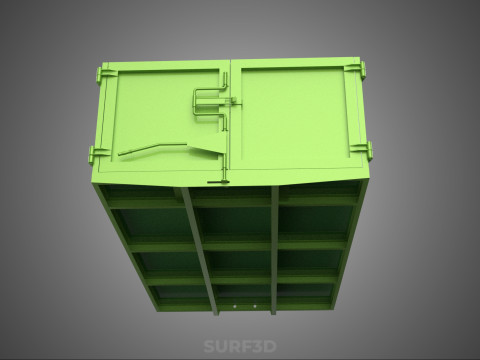

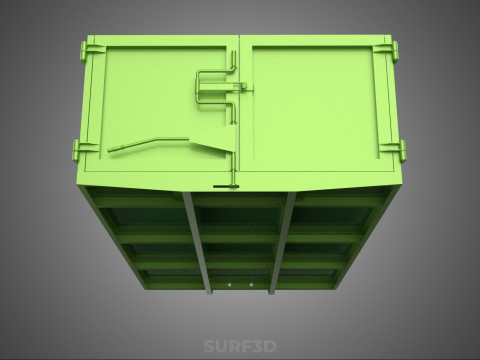

2. **Subframe:** A rigid structural frame upon which the cargo bin is mounted. This subframe is engineered to distribute the load evenly across the truck's chassis and house or support the hydraulic components.

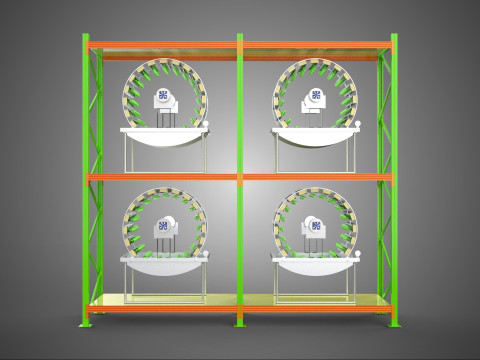

3. **Hydraulic System:** The core of the dumping mechanism. It typically includes:

* **Electric Motor:** Powers the hydraulic pump, commonly powered by the vehicle's 12V electrical system (electric-over-hydraulic systems). Some heavier-duty applications might utilize a Power Take-Off (PTO) system from the vehicle's transmission.

* **Hydraulic Pump:** Generates the high-pressure fluid required to actuate the cylinders.

* **Fluid Reservoir:** Stores the hydraulic fluid.

* **Hydraulic Cylinders:** One or more telescopic or single-stage cylinders that extend when pressurized, pushing the cargo bin upwards.

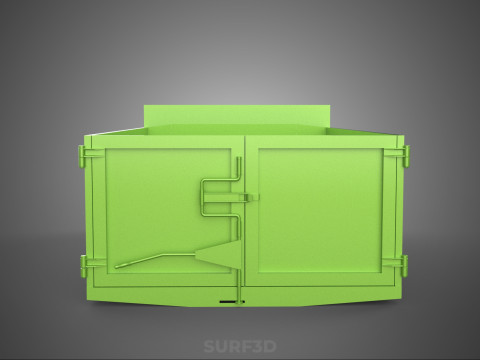

4. **Pivot Points:** Strategically located at the rear of the subframe and cargo bin, allo***g the bin to rotate upwards from its rear while the front remains relatively fixed or rises minimally.

5. **Control System:** Typically a wired or wireless remote control unit that operates the hydraulic pump to raise and lower the dump body.

6. **Tailgate Mechanism:** A s***g-out, removable, or barn-door style tailgate that allows for the unimpeded discharge of materials when the body is tilted.

Upon activation, the hydraulic system extends the cylinders, causing the cargo bin to pivot upwards, allo***g gravity to empty the contained material. The angle of tilt is critical for complete material discharge.

**Types and Configurations:**

* **Dump Inserts:** These are the most common type for pickup trucks. They are self-contained units designed to fit directly within the existing bed of a pickup truck, utilizing its sidewalls for lateral containment while providing an independent, tilting floor and often higher sidewalls. They are generally easier to install and remove.

* **Full Dump Beds (Replacement Beds):** Less common for light-duty pickups, these units completely replace the factory bed of the truck, offering a fully integrated dump body solution often with higher capacities and greater durability, sometimes requiring chassis modifications.

* **Material:** Available in heavy-duty steel for maximum durability and abrasion resistance, or aluminum for weight savings, which translates to increased payload capacity and improved fuel efficiency.

**Applications:**

Truck bed dump bodies are versatile tools widely employed across numerous sectors:

* **Landscaping:** For transporting and dumping mulch, soil, gravel, sod, and green waste.

* **Construction:** Hauling aggregates, debris, sand, cement, and tools on smaller job sites.

* **Waste Management:** Collecting and transporting refuse, recycling, or demolition debris.

* **Agriculture:** Moving feed, grain, fertilizer, or produce around farms.

* **General Utility:** For municipalities, service companies, and homeowners needing efficient bulk material handling.

**Installation and Compatibility:**

Installation typically involves securing the dump body's subframe to the pickup truck's chassis, often requiring drilling and bolting. Electrical connections are made to the vehicle's battery and charging system to power the hydraulic pump. Compatibility is crucial, considering the truck's bed length, Gross Vehicle Weight Rating (GVWR), payload capacity, and electrical system specifications.

**Advantages:**

The principal advantages of a truck bed dump body include:

* **Labor Reduction:** Eliminates the need for manual shoveling of bulk materials, saving significant time and physical effort.

* **Increased Efficiency:** Expedites loading and unloading processes, leading to faster job completion times.

* **Enhanced Versatility:** Transforms a standard pickup truck into a more capable and multifunctional vehicle, expanding its utility for various applications.

* **Cost-Effectiveness:** For many small businesses and individuals, a dump insert provides a more affordable alternative to purchasing a dedicated dump truck.

* **Safety:** Reduces strain and potential injury associated with manual material handling.

**Considerations:**

Key considerations for users include the inherent weight of the dump body itself, which reduces the vehicle's available payload capacity. The initial capital investment can also be significant, and the added weight can impact the truck's fuel economy, suspension, and tire wear over time. Proper installation and adherence to weight limits are critical for safe operation.

KEYWORDS: Dump body, Truck bed insert, Hydraulic dump, Pickup truck equipment, Material handling, Bulk transport, Cargo bin, Utility vehicle, Landscaping machinery, Construction vehicle, Waste management, Agricultural use, Load discharge, Tilting bed, Subframe, Electric-over-hydraulic, Power Take-Off (PTO), Steel dump bed, Aluminum dump bed, Payload capacity, Vehicle conversion, Light-duty truck, Commercial utility, Hauling solution, Unloading system, Tipper body, Dump box, Rear pivot, Mobile container, Expedited material removal

如果你需要一个不同的格式,请打开一个新的支持票和为此请求。我们可以转换到 3D 模型: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 我们不转换 3d 场景 以及 .step, .iges, .stp, .sldprt 等格式。!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी