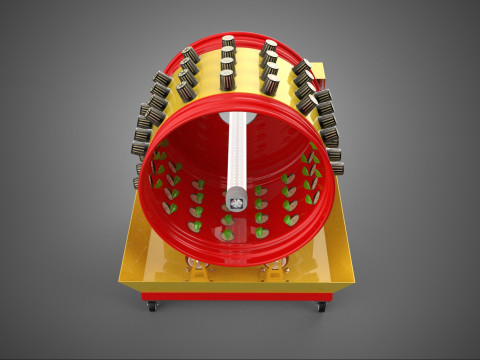

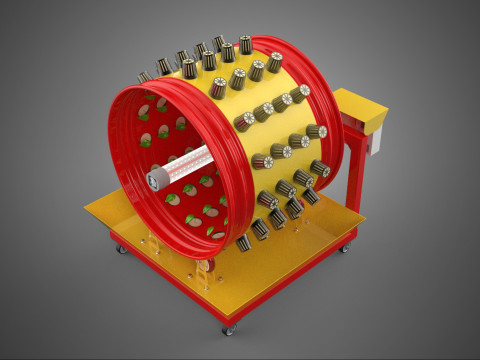

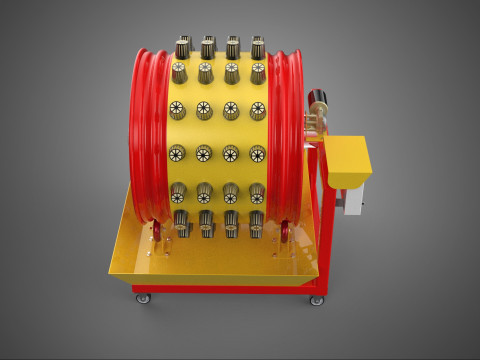

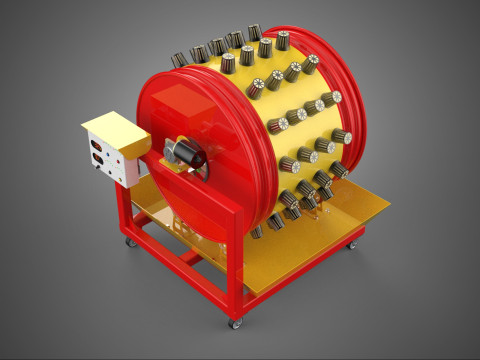

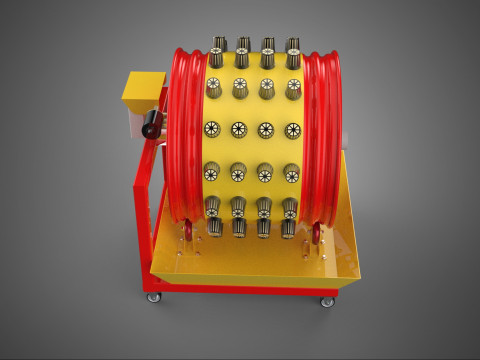

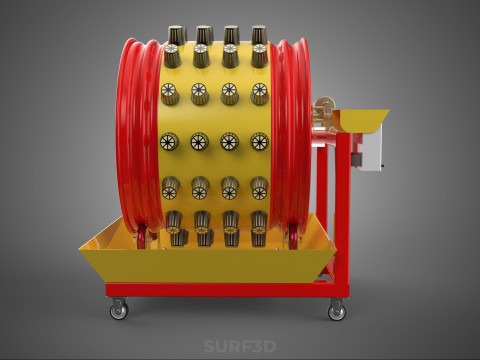

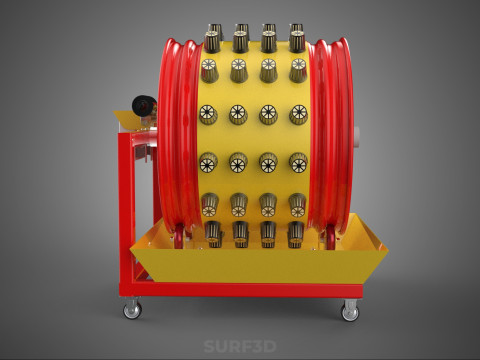

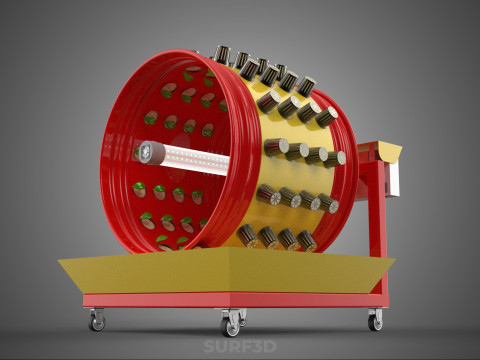

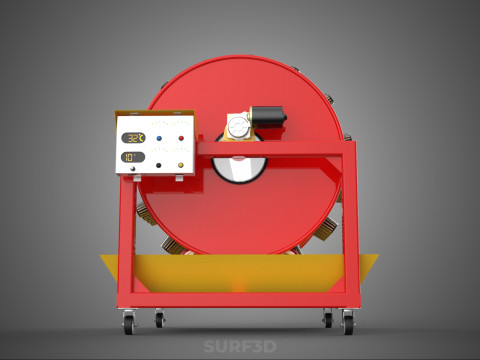

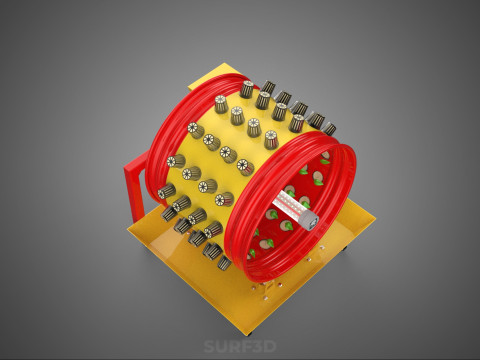

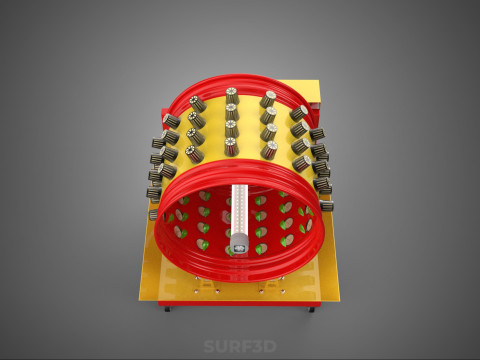

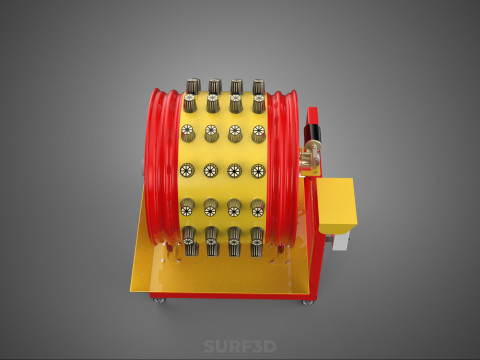

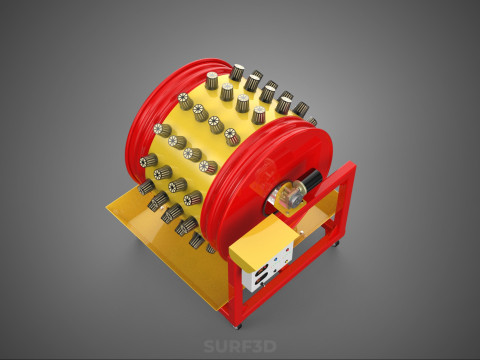

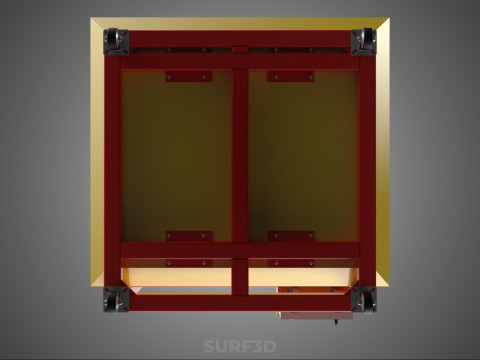

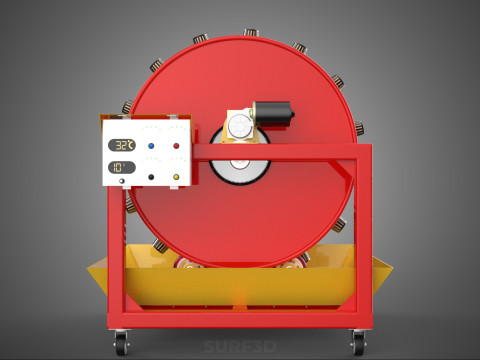

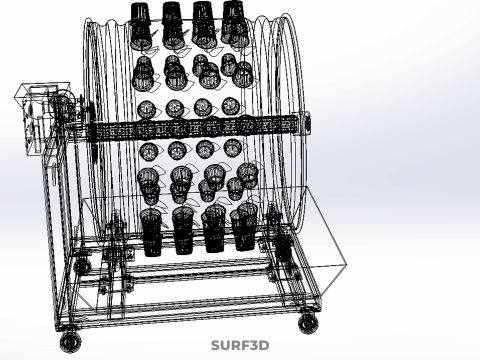

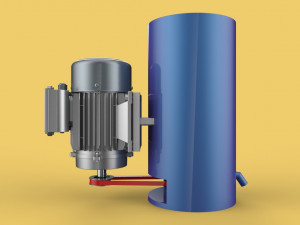

TAMBOUR EN ACIER ROTATIVE HYDROPONIQUE SPIN JARDIN PLANTE SYSTÈME DE FERME ROUE Modèle 3D

- Demander l'assistance produit

- Formats disponibles:

- ID de produit:603190

- Date: 2025-10-04

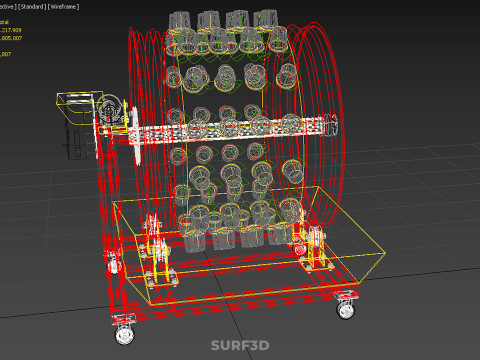

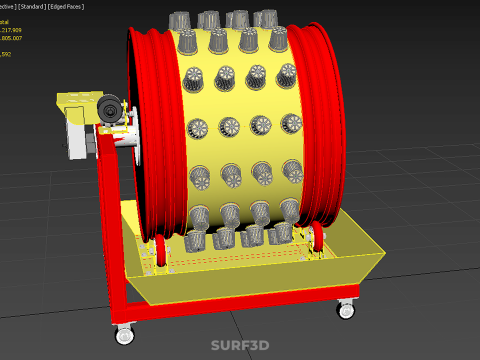

- Polygones:2217909

- Sommets:1805007

- Animé:No

- Textures:No

- Installé:No

- Matériaux:

- Bas-poly:No

- Collection:No

- cartographie UVW:No

- Plugins Utilisé:No

- Prêt à imprimer:No

- 3D Balayage:No

- Contenu adulte:No

- PBR:No

- IA Formation:No

- Géométrie:Poly NURBS

- UVs non enveloppés:Unknown

- Vus:214

Description

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

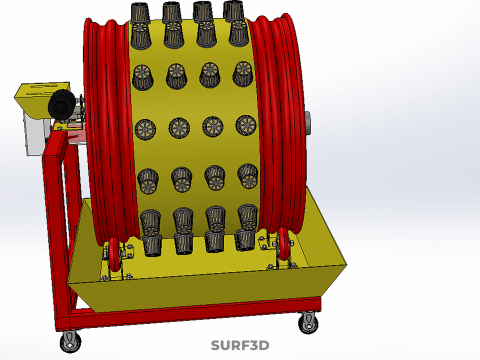

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

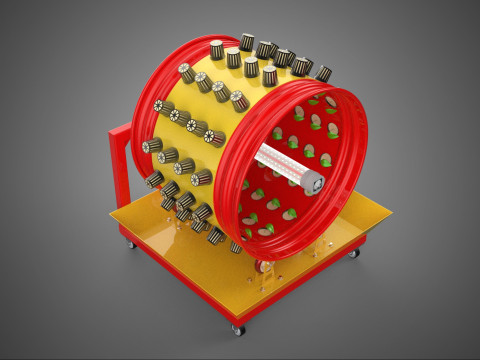

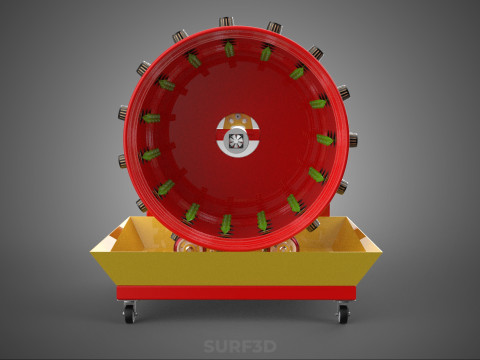

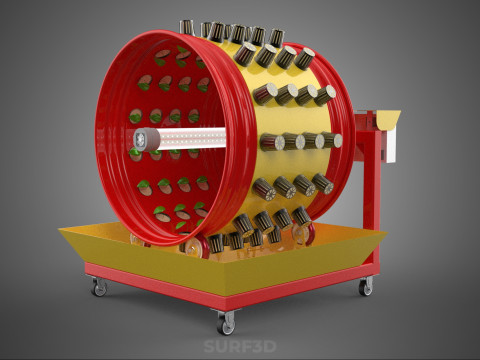

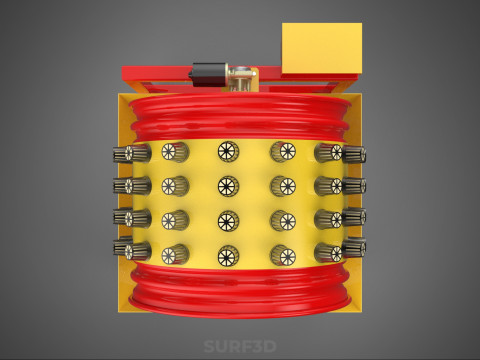

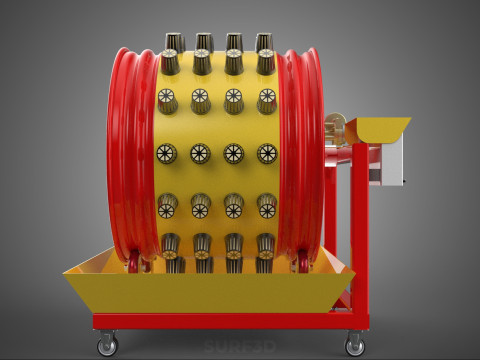

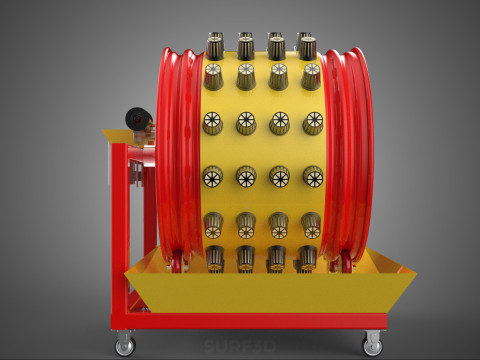

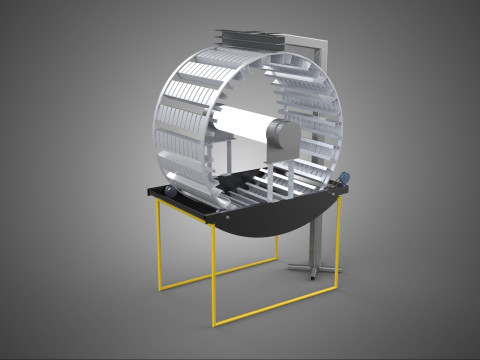

A "Steel Drum Rotary Hydroponic Spin Garden Plant Farm System Wheel" refers to a specialized, often self-contained, closed-loop hydroponic cultivation apparatus characterized by its utilization of a repurposed industrial steel drum as the primary structural and rotational component. This system is designed to maximize cultivation density and efficiency within a confined footprint by employing a rotational mechanism that optimizes light exposure and nutrient delivery to plants grown without soil.

**Nomenclature and Core Concept:**

The term combines several key elements:

* **Steel Drum:** Indicates the use of a standard industrial barrel (e.g., 55-gallon/208-liter) as the central housing, often repurposed, offering a robust and readily available structure.

* **Rotary/Spin Garden:** Highlights the system's dynamic nature, where the plant-holding component rotates around a central axis. This rotation is fundamental to its operational principle.

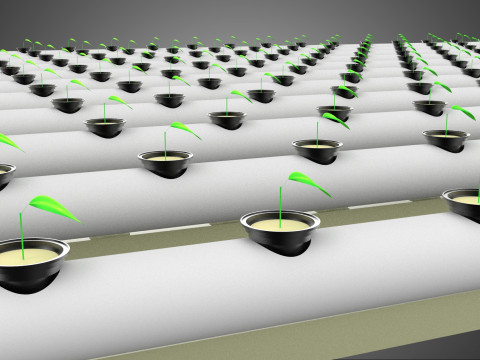

* **Hydroponic:** Specifies the soilless cultivation method, where plant roots are supplied with nutrient-rich water solution.

* **Plant Farm System Wheel:** Emphasizes its function as a controlled agricultural system designed for growing multiple plants, with "wheel" reinforcing the circular, rotating design.

**Design and Construction:**

Typically, a steel drum rotary hydroponic system consists of:

1. **The Steel Drum:** Often oriented horizontally or at a slight incline, serving as the outer shell. It is modified to house plant sites and internal mechanisms.

2. **Plant Cultivation Sites:** Holes are precisely cut into the drum's circumference, into which net pots or other plant-holding inserts are placed. The plants' roots extend into the drum's interior.

3. **Rotational Mechanism:** A motor, gearbox, and drive system (e.g., chains, belts, or direct drive) are employed to ensure slow, continuous, or intermittent rotation of the drum. This rotation speed is critical for plant health and consistent nutrient/light exposure.

4. **Central Light Source:** High-intensity discharge (HID), fluorescent, or increasingly, LED grow lights are positioned along the central axis of the drum, providing uniform illumination to all plants as they rotate past the light.

5. **Nutrient Solution Reservoir and Delivery System:** A separate reservoir holds the nutrient-rich water. A pump circulates this solution through internal plumbing within the drum, delivering it to the roots of the plants. Common methods include nutrient film technique (NFT), drip irrigation, or a recirculating deep water culture (DWC) variant where roots dip into a shallow rotating pool of solution or are constantly misted (aeroponics).

6. **Drainage and Recirculation:** Excess nutrient solution is collected and returned to the reservoir, minimizing waste and ensuring a closed-loop system.

7. **Environmental Controls:** Basic systems may rely on ambient conditions, while more advanced setups integrate sensors and controllers for temperature, humidity, pH, electrical conductivity (EC) of the nutrient solution, and lighting cycles.

**Operational Principles:**

The core principle is to provide plants with optimal and consistent access to light, water, and nutrients in a highly space-efficient manner. As the drum slowly rotates (typically one revolution every 30 minutes to a few hours), each plant receives an equal share of light from the central source. Concurrently, the hydroponic system delivers the nutrient solution to the plant roots, often through methods that ensure roots are exposed to both solution and air for oxygenation, preventing waterlogging and promoting robust growth.

**Advantages:**

* **Space Efficiency:** Maximizes plant count per unit of floor space, making it ideal for urban farming, small-scale operations, or areas with limited space.

* **Optimized Light Exposure:** Uniform rotation ensures all plants receive consistent light, potentially leading to faster and more even growth.

* **Water and Nutrient Conservation:** Closed-loop hydroponic systems significantly reduce water usage compared to traditional soil-based agriculture, often by 70-90%.

* **Reduced Pests and Diseases:** The controlled indoor environment minimizes exposure to outdoor pests and diseases, reducing the need for pesticides.

* **Accelerated Growth:** Optimized environmental conditions and direct nutrient delivery can lead to faster plant growth cycles.

**Challenges and Considerations:**

* **Complexity:** Designing and constructing such a system requires mechanical, electrical, and horticultural knowledge.

* **Energy Consumption:** The motor for rotation and the high-intensity grow lights contribute significantly to energy usage.

* **Maintenance and Access:** Accessing plants for harvesting, pruning, or inspecting roots can be more challenging than in static systems.

* **Plant Suitability:** Best suited for smaller, non-vining plants like leafy greens, herbs, and strawberries. Taller or vining plants may not be practical.

* **Initial Cost:** The specialized components (motor, lighting, plumbing, controls) can result in a higher initial investment compared to simpler hydroponic setups.

* **Potential for Failure:** Mechanical or pump failures can rapidly compromise the entire crop due to lack of water, nutrients, or light.

**Applications:**

Steel drum rotary hydroponic spin garden systems are typically employed by hobbyist growers, educational institutions, research facilities, and small-scale urban farmers seeking innovative ways to produce fresh produce in compact spaces. They represent an accessible entry point into vertical farming concepts using repurposed materials.

Avez besoin de plus de formats?

Si vous avea besoin d’\autre format veuillez ouvrir un billet d’\assistance et demandez le. Nous pouvons convertir les modèles de 3D en: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Conversion de format libreNous ne convertissons pas les scènes 3D et des formats tels que .step, .iges, .stp, .sldprt.!

Informations d'utilisation

TAMBOUR EN ACIER ROTATIVE HYDROPONIQUE SPIN JARDIN PLANTE SYSTÈME DE FERME ROUE - Vous pouvez utiliser ce modèle 3D libre de droits à des fins personnelles et commerciales, conformément à la Licence de Base ou à la Licence Étendue.La Licence de Base couvre la plupart des cas d'utilisation courants, notamment les publicités numériques, les projets de conception et de visualisation, les comptes de réseaux sociaux professionnels, les applications natives, les applications web, les jeux vidéo et les produits finis physiques ou numériques (gratuits ou payants).

La Licence Étendue inclut tous les droits accordés par la Licence de Base, sans limitation d'utilisation, et autorise l'utilisation du modèle 3D dans un nombre illimité de projets commerciaux, dans des conditions de libre de droits.

En savoir plus

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी