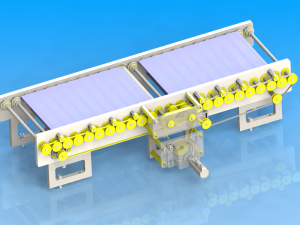

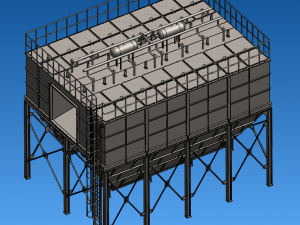

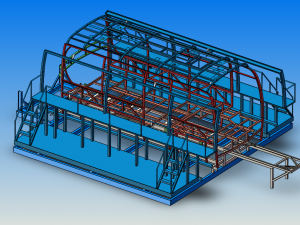

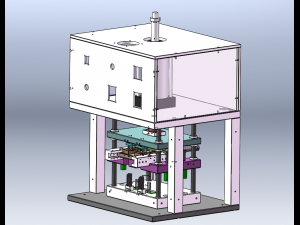

Pressure sintering furnace for cemented carbide Model 3D

$

200.00

Anda punya $0.00 Kredit. Beli Kredit

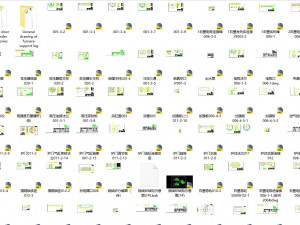

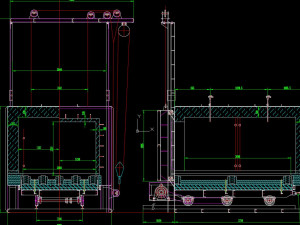

- Format yang tersedia: Autodesk AutoCAD (.dwg) 9.60 MB

- Animasi:No

- Bertekstur:No

- Dimanipulasi:No

- Material:

- Low-poly:No

- Koleksi:No

- Pemetaan UVW:No

- Plugin Digunakan:No

- Siap Cetak:No

- Pindai 3D:No

- Konten Dewasa:No

- PBR:No

- AI Pelatihan:No

- Geometri:Polygonal

- Unwrapped UVs:Unknown

- Tampilan:3094

- Tanggal: 2020-10-01

- ID Barang:314865

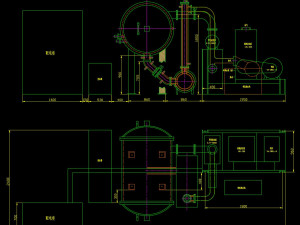

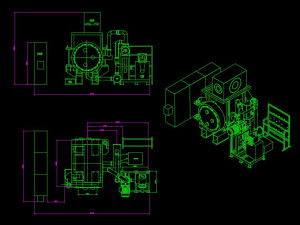

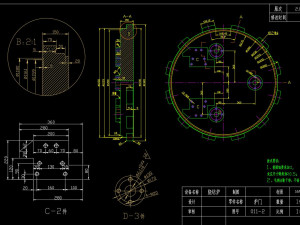

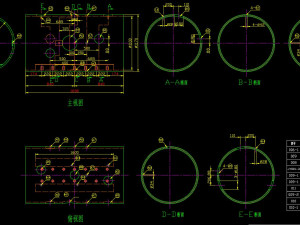

pressure sintering furnace for cemented carbide

brief description:

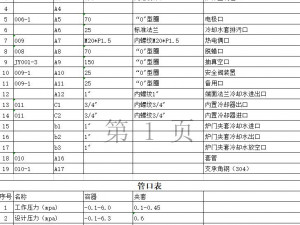

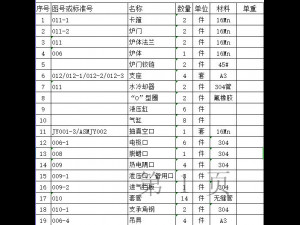

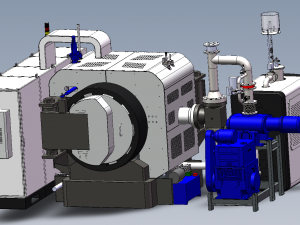

gas pressure sintering means that the sintering process is carried out at low pressure first, then the material is sintered under normal pressure and finally sintered at high pressure (the result is to further increase the fatigue state of the material and quickly eliminate the stress in the material), after the high temperature and high pressure sintering process, the mechanical properties (hardness, strength, toughness, etc.) of the materials are ***ter than those of the ordinary sintering process.

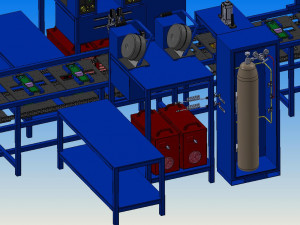

1、 principle of equipment

gas pressure sintering means that the sintering process is carried out at low pressure first, then the material is sintered under normal pressure and finally sintered at high pressure (the result is to further increase the fatigue state of the material and quickly eliminate the stress in the material), after the high temperature and high pressure sintering process, the mechanical properties (hardness, strength, toughness, etc.) of the materials are ***ter than those of the ordinary sintering process.

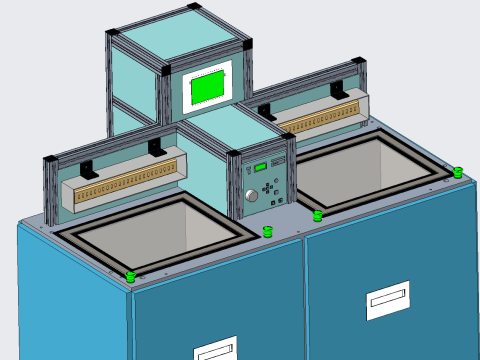

2、 equipment usage

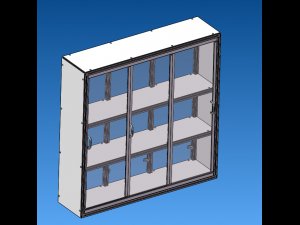

this product is of periodic operation type, which is suitable for high temperature and high pressure sintering of ceramics (such as silicon carbide, zirconia, alumina, silicon nitride, etc.) and metal materials (such as cemented carbide) under the condition of high pressure protection atmosphere, which is conducive to increase the sintering density of materials and improve the mechanical properties of materials.

3、 main features of the equipment

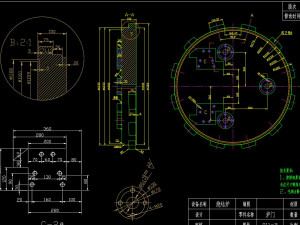

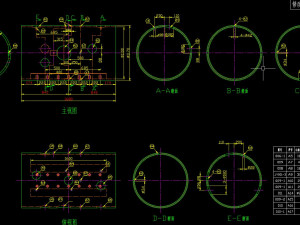

the equipment is designed and manufactured according to the requirements of class 3 pressure vessel standards.

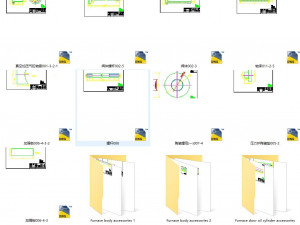

the door lock of the furnace is bolted or tooth locked quick release flange, which is easy to operate, safe and reliable.

the heat preservation material in the furnace is carbon deposition composite hard felt, and the heating element is imported graphite.

the temperature measuring element adopts ultra-high temperature protection tube and tungsten rhenium thermocouple. the service life of thermocouple wire is as long as 6 months.

the control system is touch screen with complete functions of safety interlock protection and alarm.

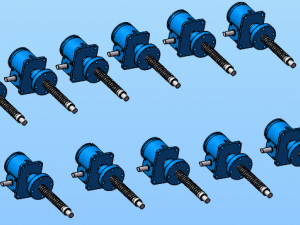

high pressure valve and pipeline are selected brand or equivalent imported products, safe and reliable.

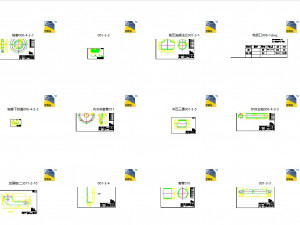

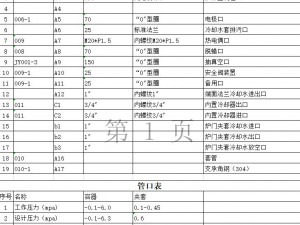

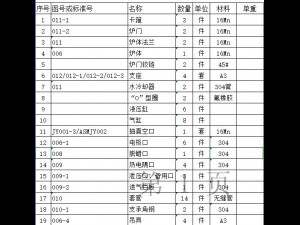

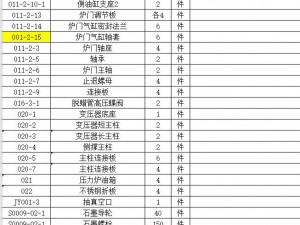

vacuum pressure sintering furnace complete set of dra***gs, welcome to download! vacuum sintering furnace is a kind of furnace which uses induction heating to carry out protective sintering of heated objects. it can be divided into power frequency, medium frequency, high frequency and other types, which can be classified into the subclass of vacuum sintering furnace. vacuum induction sintering furnace is a complete set of equipment for sintering cemented carbide cutter head and various metal powder compacts by using the principle of medium frequency induction heating under vacuum or protective atmosphere. it is designed for the industrial production of cemented carbide, dysprosium metal and ceramic materials. Siap Cetak: Tidak

Baca lebih lanjutbrief description:

gas pressure sintering means that the sintering process is carried out at low pressure first, then the material is sintered under normal pressure and finally sintered at high pressure (the result is to further increase the fatigue state of the material and quickly eliminate the stress in the material), after the high temperature and high pressure sintering process, the mechanical properties (hardness, strength, toughness, etc.) of the materials are ***ter than those of the ordinary sintering process.

1、 principle of equipment

gas pressure sintering means that the sintering process is carried out at low pressure first, then the material is sintered under normal pressure and finally sintered at high pressure (the result is to further increase the fatigue state of the material and quickly eliminate the stress in the material), after the high temperature and high pressure sintering process, the mechanical properties (hardness, strength, toughness, etc.) of the materials are ***ter than those of the ordinary sintering process.

2、 equipment usage

this product is of periodic operation type, which is suitable for high temperature and high pressure sintering of ceramics (such as silicon carbide, zirconia, alumina, silicon nitride, etc.) and metal materials (such as cemented carbide) under the condition of high pressure protection atmosphere, which is conducive to increase the sintering density of materials and improve the mechanical properties of materials.

3、 main features of the equipment

the equipment is designed and manufactured according to the requirements of class 3 pressure vessel standards.

the door lock of the furnace is bolted or tooth locked quick release flange, which is easy to operate, safe and reliable.

the heat preservation material in the furnace is carbon deposition composite hard felt, and the heating element is imported graphite.

the temperature measuring element adopts ultra-high temperature protection tube and tungsten rhenium thermocouple. the service life of thermocouple wire is as long as 6 months.

the control system is touch screen with complete functions of safety interlock protection and alarm.

high pressure valve and pipeline are selected brand or equivalent imported products, safe and reliable.

vacuum pressure sintering furnace complete set of dra***gs, welcome to download! vacuum sintering furnace is a kind of furnace which uses induction heating to carry out protective sintering of heated objects. it can be divided into power frequency, medium frequency, high frequency and other types, which can be classified into the subclass of vacuum sintering furnace. vacuum induction sintering furnace is a complete set of equipment for sintering cemented carbide cutter head and various metal powder compacts by using the principle of medium frequency induction heating under vacuum or protective atmosphere. it is designed for the industrial production of cemented carbide, dysprosium metal and ceramic materials. Siap Cetak: Tidak

Perlu lebih banyak format?

Jika Anda membutuhkan format yang berbeda, silakan buka Tiket Dukungan baru dan minta itu. Kita dapat mengonversi model 3D menjadi: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Kami tidak mengonversi adegan 3d dan format seperti .step, .iges, .stp, .sldprt.!

Jika Anda membutuhkan format yang berbeda, silakan buka Tiket Dukungan baru dan minta itu. Kita dapat mengonversi model 3D menjadi: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Kami tidak mengonversi adegan 3d dan format seperti .step, .iges, .stp, .sldprt.!

Pressure sintering furnace for cemented carbide Model 3D dwg, Dari tzd

vacuum pressure sinteringTidak ada komentar untuk item ini.

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी