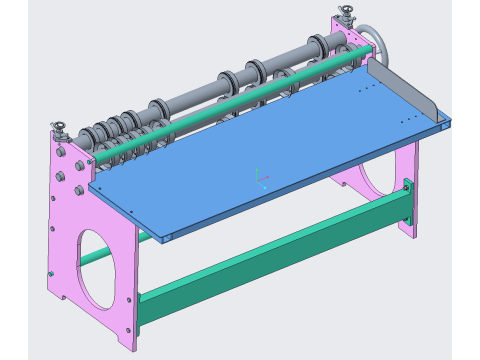

Pressure sintering furnace for cemented carbide 3D 모델

$

200.00 USD

가지고 있는 아이템 $0.00 크레딧. 크레딧 구입

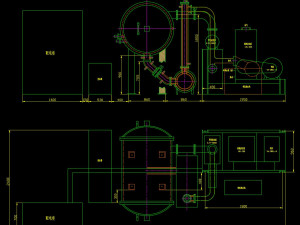

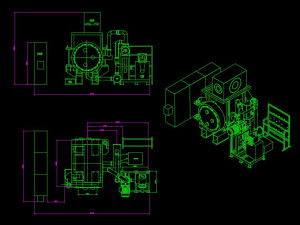

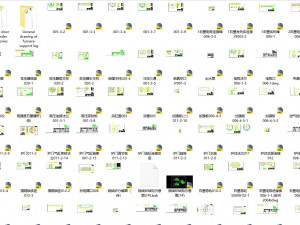

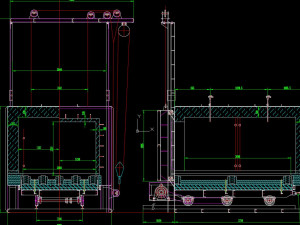

- 이용 가능한 포맷: Autodesk AutoCAD (.dwg) 9.60 MB

- 애니메이티드:No

- 텍스쳐드:No

- 리그드:No

- 재료:

- 로우 폴리곤:No

- 컬렉션:No

- UVW 매핑:No

- 플러그인 사용 됨:No

- 프린트 준비:No

- 3D 스캔:No

- 성인용 콘텐츠:No

- PBR:No

- AI 훈련:No

- 지오메트리:Polygonal

- 언래핑 된 UVs:Unknown

- 조회:3182

- 날짜: 2020-10-01

- 아이템 ID:314865

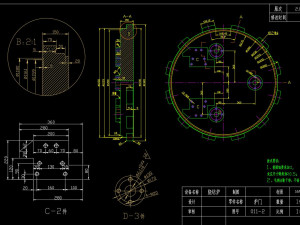

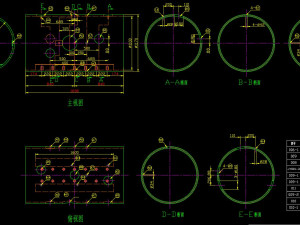

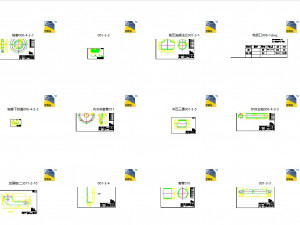

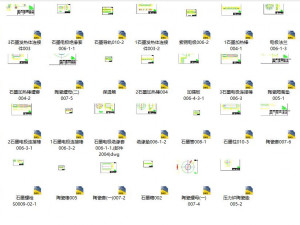

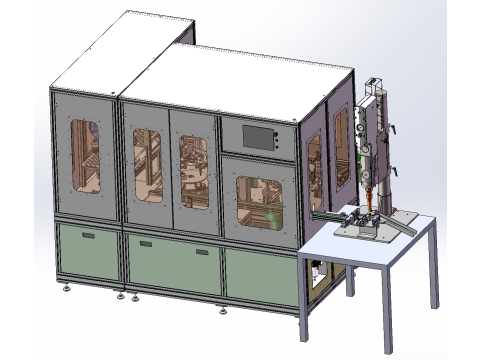

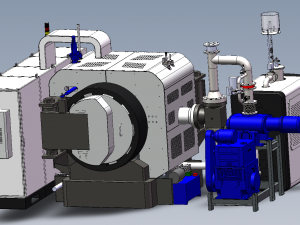

Pressure sintering furnace for cemented carbide 3D 모델 dwg, 발신 tzd

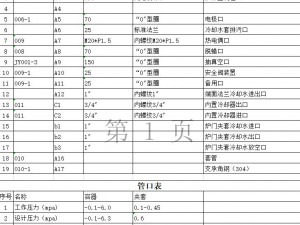

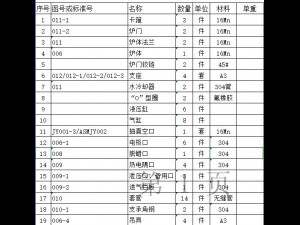

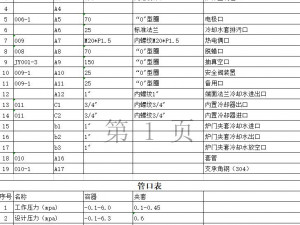

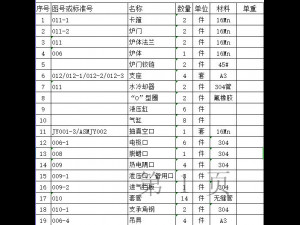

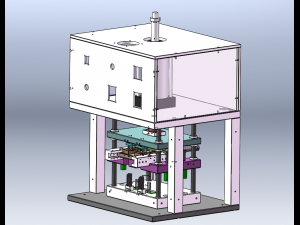

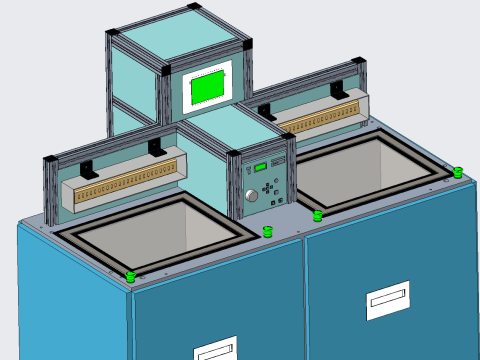

pressure sintering furnace for cemented carbidebrief description:

gas pressure sintering means that the sintering process is carried out at low pressure first, then the material is sintered under normal pressure and finally sintered at high pressure (the result is to further increase the fatigue state of the material and quickly eliminate the stress in the material), after the high temperature and high pressure sintering process, the mechanical properties (hardness, strength, toughness, etc.) of the materials are better than those of the ordinary sintering process.

1、 principle of equipment

gas pressure sintering means that the sintering process is carried out at low pressure first, then the material is sintered under normal pressure and finally sintered at high pressure (the result is to further increase the fatigue state of the material and quickly eliminate the stress in the material), after the high temperature and high pressure sintering process, the mechanical properties (hardness, strength, toughness, etc.) of the materials are better than those of the ordinary sintering process.

2、 equipment usage

this product is of periodic operation type, which is suitable for high temperature and high pressure sintering of ceramics (such as silicon carbide, zirconia, alumina, silicon nitride, etc.) and metal materials (such as cemented carbide) under the condition of high pressure protection atmosphere, which is conducive to increase the sintering density of materials and improve the mechanical properties of materials.

3、 main features of the equipment

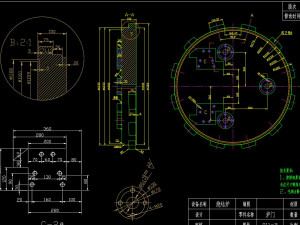

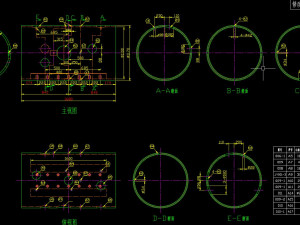

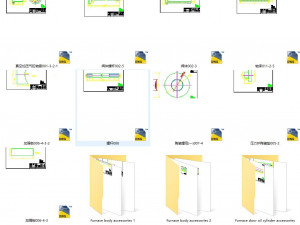

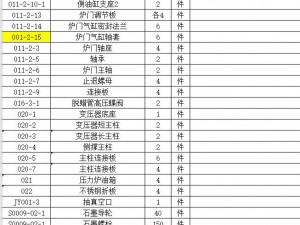

the equipment is designed and manufactured according to the requirements of class 3 pressure vessel standards.

the door lock of the furnace is bolted or tooth locked quick release flange, which is easy to operate, safe and reliable.

the heat preservation material in the furnace is carbon deposition composite hard felt, and the heating element is imported graphite.

the temperature measuring element adopts ultra-high temperature protection tube and tungsten rhenium thermocouple. the service life of thermocouple wire is as long as 6 months.

the control system is touch screen with complete functions of safety interlock protection and alarm.

high pressure valve and pipeline are selected brand or equivalent imported products, safe and reliable.

vacuum pressure sintering furnace complete set of drawings, welcome to download! vacuum sintering furnace is a kind of furnace which uses induction heating to carry out protective sintering of heated objects. it can be divided into power frequency, medium frequency, high frequency and other types, which can be classified into the subclass of vacuum sintering furnace. vacuum induction sintering furnace is a complete set of equipment for sintering cemented carbide cutter head and various metal powder compacts by using the principle of medium frequency induction heating under vacuum or protective atmosphere. it is designed for the industrial production of cemented carbide, dysprosium metal and ceramic materials. 프린트 준비: 아니오

다른 포맷이 필요하세요?

다른 포맷이 필요하시면, 새로운 지원 티켓을 열어 요청하세요. 저희는 3D 모델을 다음으로 변환할 수 있습니다: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 우리는 3D 장면을 변환하지 않습니다 .step, .iges, .stp, .sldprt와 같은 형식도 포함됩니다.!사용 정보

Pressure sintering furnace for cemented carbide - 기본 또는 확장 라이선스에 따라 이 로열티 프리 3D 모델을 개인적 및 상업적 목적으로 사용할 수 있습니다.기본 라이선스는 디지털 광고, 디자인 및 시각화 프로젝트, 비즈니스 소셜 미디어 계정, 네이티브 앱, 웹 앱, 비디오 게임, 그리고 물리적 또는 디지털 최종 제품(무료 및 유료 모두)을 포함한 대부분의 표준 사용 사례를 포괄합니다.

확장 라이선스는 기본 라이선스에 따라 부여된 모든 권리를 포함하며 사용 제한이 없으며, 로열티 프리 조건 하에 3D 모델을 상업적 프로젝트에 무제한으로 사용할 수 있습니다.

더 보기

환불이 보장되나요?

네, 환불을 보장합니다. 작품 구입 후 렌더나 설명에서 오류를 발견하시면, 저희는 최대한 빨리 해당 문제를 수정 할 것입니다. 저희가 해당 오류를 수정 할 수 없는 경우, 저희는 귀하의 주문을 취소하며 아이템 다운로드 24 시간 내에 금액을 환불해드립니다. 더 자세한 정보는 여기를 참조하세요키워드

vacuum pressure sintering이 아이템에 대한 코멘트 없음.

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी