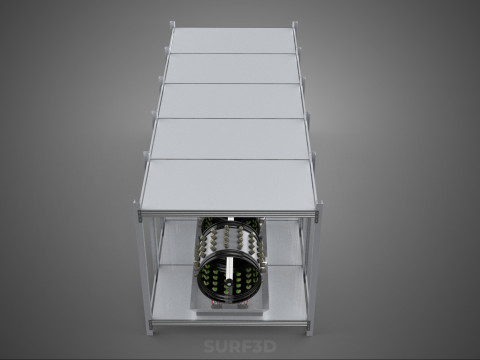

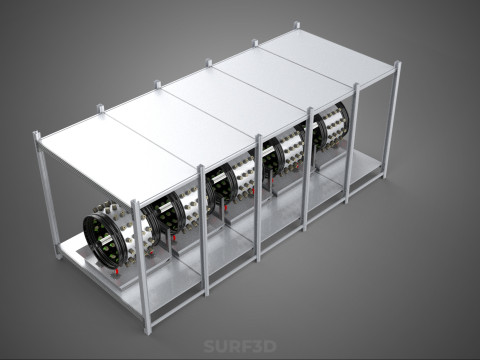

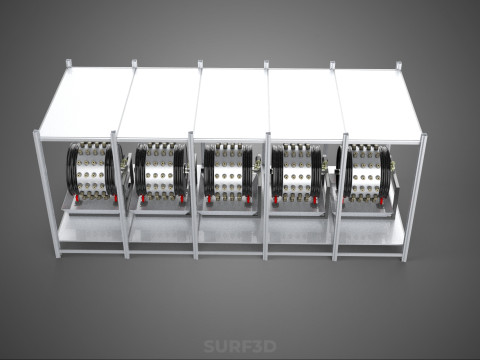

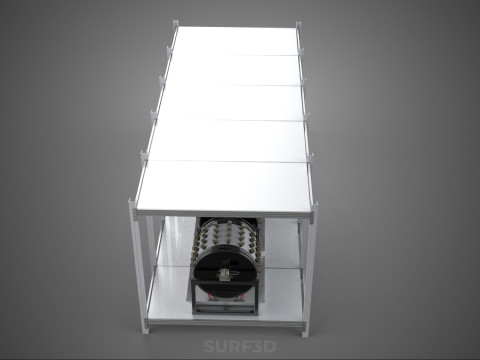

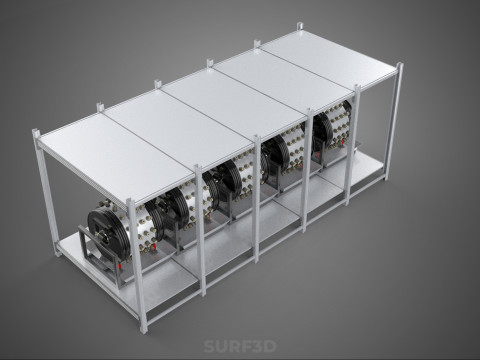

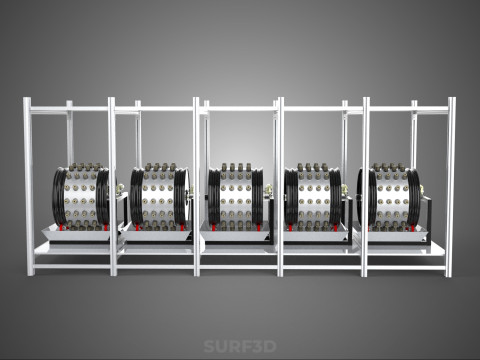

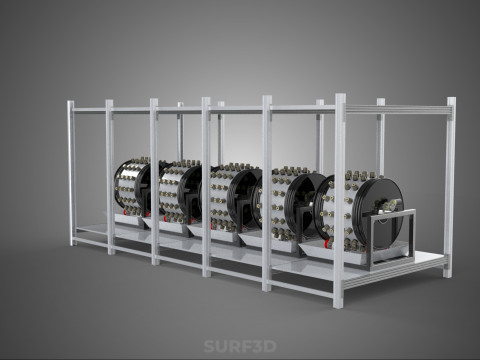

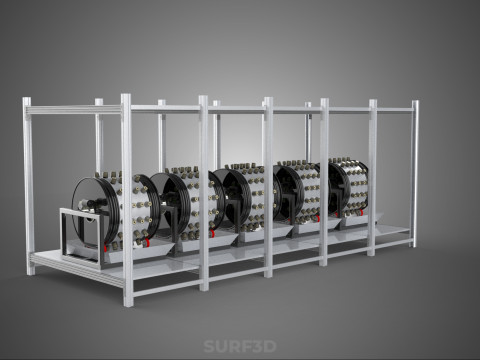

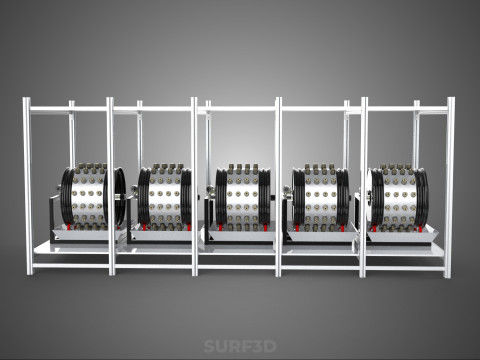

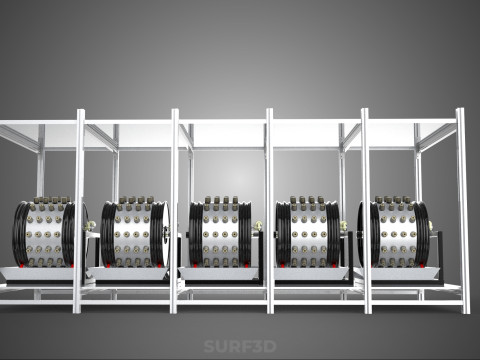

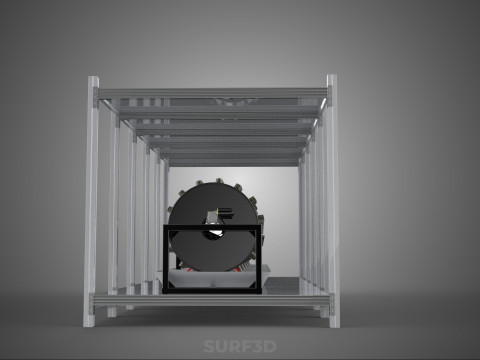

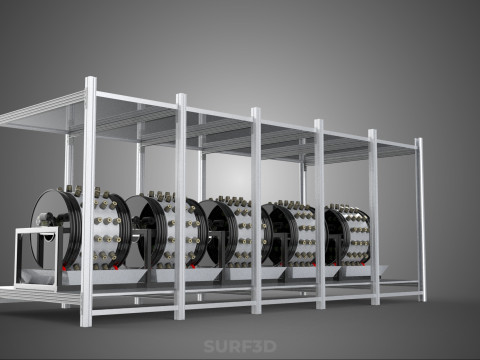

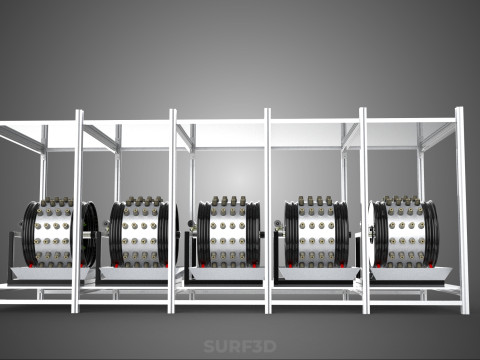

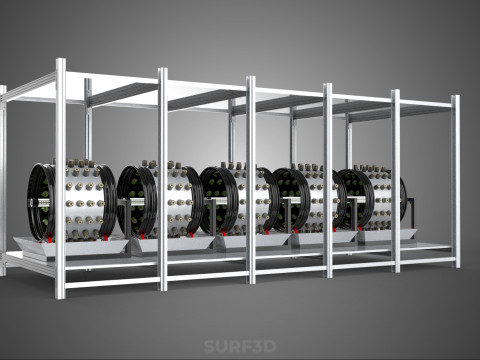

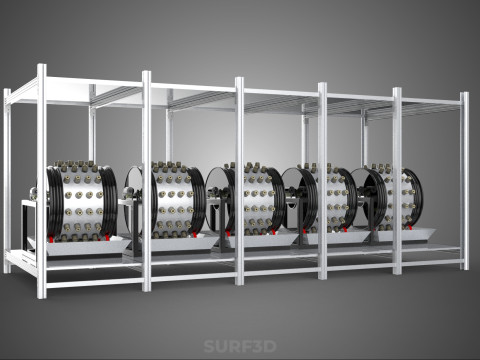

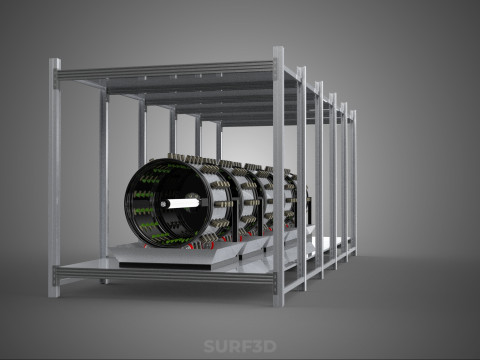

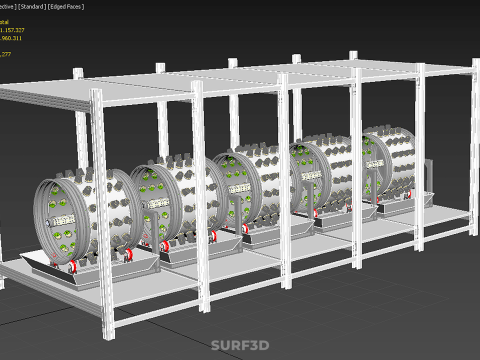

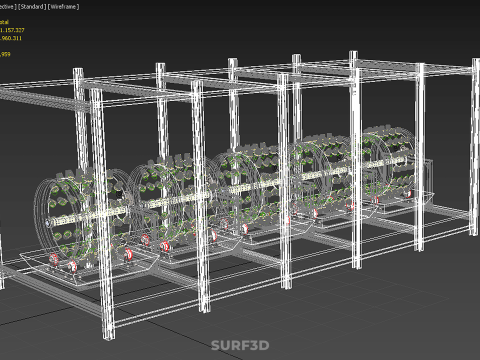

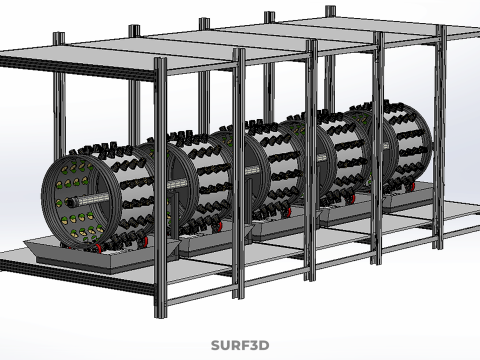

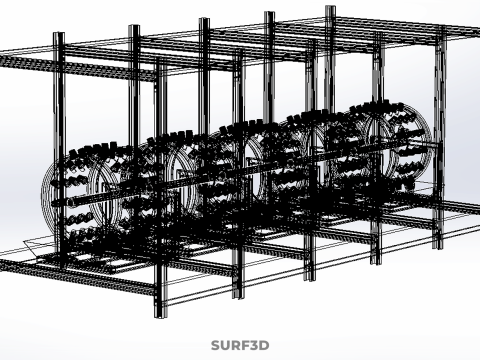

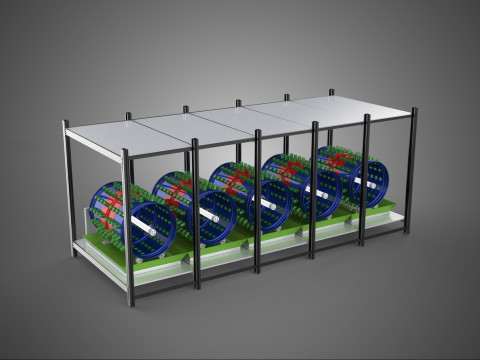

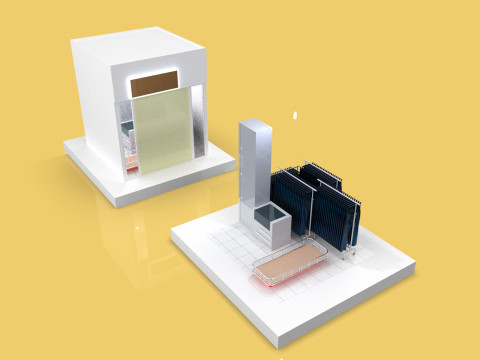

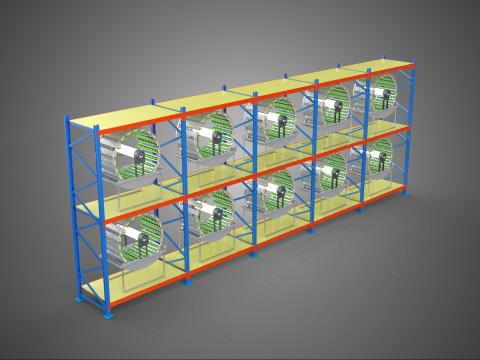

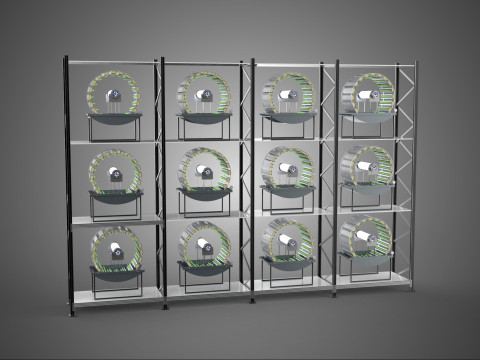

RACK FRAME ARRAY ROW SHELF TRAY ROTARY HIDROPONIK LED TANAMAN PERTANIAN Model 3D

- Minta dukungan produk oleh penulis

- Format yang tersedia:

- ID Barang:603459

- Tanggal: 2025-10-05

- Poligon:11157327

- Sudut:8960311

- Animasi:No

- Bertekstur:No

- Dimanipulasi:No

- Material:

- Low-poly:No

- Koleksi:No

- Pemetaan UVW:No

- Plugin Digunakan:No

- Siap Cetak:No

- Pindai 3D:No

- Konten Dewasa:No

- PBR:No

- AI Pelatihan:No

- Geometri:Poly NURBS

- Unwrapped UVs:Unknown

- Tampilan:254

Deskripsi

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

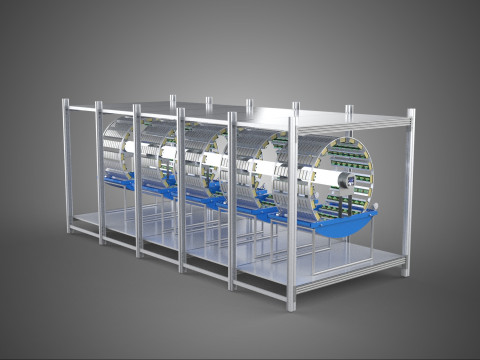

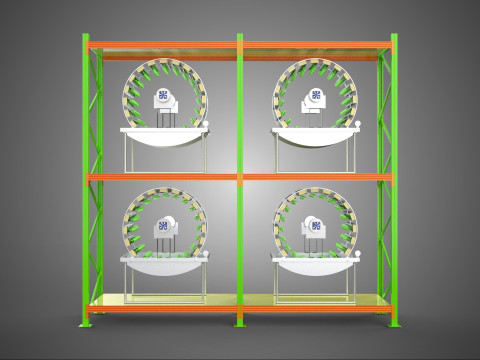

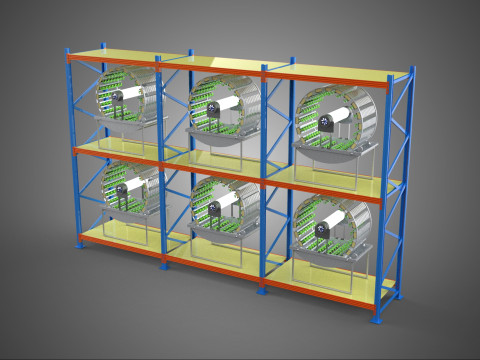

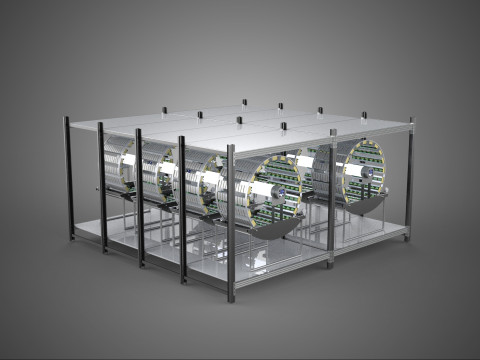

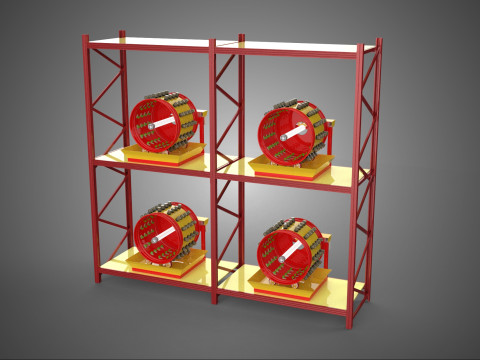

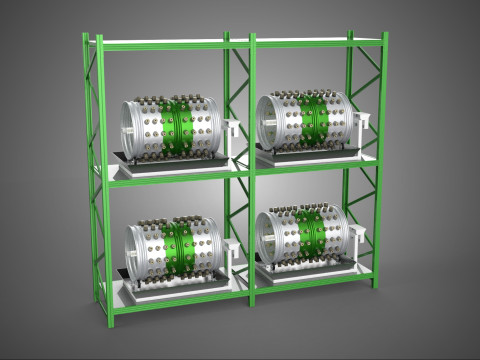

A Rotary Hydroponic LED Plant Farm represents an advanced, integrated system within the domain of Controlled Environment Agriculture (CEA), designed for highly efficient and intensive cultivation of plants. This sophisticated approach leverages a combination of structural engineering, soilless cultivation techniques, artificial illumination, and dynamic spatial management to optimize growth conditions and maximize yield within a compact footprint.

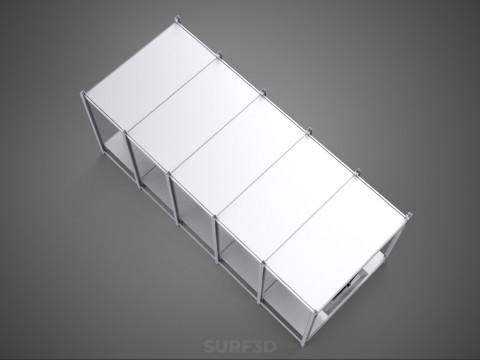

The foundational structure is composed of a robust **rack frame**, typically constructed from durable, corrosion-resistant materials such as powder-coated steel or aluminum. This frame provides the primary skeletal support for the entire system, accommodating multiple tiers of cultivation. Within this framework, plants are systematically organized into a **shelf tray array**, wherein numerous individual growing **trays** are arranged in ordered **rows** across multiple **shelves**. These trays are specifically engineered to interface with the hydroponic nutrient delivery system, securely holding plant roots while facilitating optimal access to nutrients and aeration. This multi-tiered, vertical configuration is central to achieving high planting densities and maximizing the utilization of vertical space.

A defining characteristic of this system is its **rotary** mechanism. This typically involves a mechanical system, such as a vertical carousel or a horizontal conveyor, which continuously or intermittently rotates the shelves or individual plant trays. The primary functions of this rotation are multifaceted: to ensure uniform exposure of all plants to the artificial light sources, thereby promoting consistent growth; to facilitate easier access for human or robotic intervention during planting, monitoring, and harvesting operations; and to potentially optimize the distribution of environmental parameters like airflow and temperature across the entire growing area. This dynamic movement significantly enhances the utility of the internal volume and light energy.

The cultivation methodology employed is **hydroponics**, a form of soilless agriculture where plants are grown with their roots directly immersed in or irrigated by nutrient-rich water solutions. Common hydroponic techniques integrated into such systems include Nutrient Film Technique (NFT), Deep Water Culture (DWC), or drip irrigation, chosen based on the specific crop requirements and system design. The nutrient solution is precisely formulated, recirculated, and continuously monitored for critical parameters such as pH, electrical conductivity (EC), and dissolved oxygen levels to ensure optimal nutrient uptake and plant health. This closed-loop system dramatically reduces water consumption compared to traditional agriculture.

Illumination is provided by specialized **LED** (Light Emitting Diode) grow lights. LEDs are selected for their high energy efficiency, long operational lifespan, and the ability to emit specific light spectra precisely tailored to different physiological stages of plant growth (e.g., blue light for vegetative development, red light for flowering). This targeted spectral output optimizes photosynthetic efficiency, reduces unwanted heat generation, and lowers energy consumption, contributing to reduced operational costs and enhanced environmental control within the sealed environment of the plant farm.

The entire system is often integrated with advanced environmental control units and sophisticated automation technologies. An array of sensors continuously monitors critical environmental factors such as temperature, relative humidity, carbon dioxide (CO2) concentrations, nutrient solution parameters, and light intensity. These data inputs are processed by a central control system that automates nutrient delivery, light cycles, environmental conditioning (HVAC), and the operation of the rotary mechanism. This level of automation minimizes manual labor, ensures consistent and optimal growing conditions, and enables predictive analytics for crop management.

Rotary Hydroponic LED Plant Farms offer numerous advantages. They significantly increase crop yield per unit area, enable year-round cultivation irrespective of external climatic conditions, drastically reduce water consumption (up to 90% through recirculation), eliminate the need for chemical pesticides and herbicides, and facilitate localized food production in urban or peri-urban environments. Applications span commercial-scale production of leafy greens, herbs, and small fruits, as well as research and development facilities, contributing substantially to sustainable agriculture, food security, and resource efficiency.

In summary, this integrated system represents a cutting-edge approach in controlled environment agriculture, synthesizing advanced engineering, precise horticultural science, and automation to create highly productive, resource-efficient, and sustainable platforms for plant cultivation.

KEYWORDS: Vertical Farming, Controlled Environment Agriculture, Hydroponics, LED Grow Lights, Urban Farming, Soilless Cultivation, Plant Factory, Indoor Agriculture, Automated Farming, Rotary System, Carousel Hydroponics, Nutrient Film Technique, Deep Water Culture, Aeroponics, Sustainable Agriculture, Food Security, High-Density Cultivation, Crop Optimization, Environmental Control, Precision Agriculture, CEA, Vertical Farm, Rack System, Shelf System, Tray System, Plant Cultivation, Resource Efficiency, Year-Round Production, Artificial Lighting, Nutrient Management.

Perlu lebih banyak format?

Jika Anda membutuhkan format yang berbeda, silakan buka Tiket Dukungan baru dan minta itu. Kita dapat mengonversi model 3D menjadi: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Konversi Format GratisKami tidak mengonversi adegan 3d dan format seperti .step, .iges, .stp, .sldprt.!

Informasi Penggunaan

RACK FRAME ARRAY ROW SHELF TRAY ROTARY HIDROPONIK LED TANAMAN PERTANIAN - Anda dapat menggunakan model 3D bebas royalti ini untuk keperluan pribadi dan komersial sesuai dengan Lisensi Dasar atau Diperpanjang.Lisensi Dasar mencakup sebagian besar kasus penggunaan standar, termasuk iklan digital, proyek desain dan visualisasi, akun media sosial bisnis, aplikasi asli, aplikasi web, permainan video, dan produk akhir fisik atau digital (baik gratis maupun berbayar).

Lisensi Diperpanjang mencakup semua hak yang diberikan berdasarkan Lisensi Dasar, tanpa batasan penggunaan, dan memungkinkan model 3D untuk digunakan dalam proyek komersial tanpa batas dengan ketentuan Bebas Royalti.

Baca lebih lanjut

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी