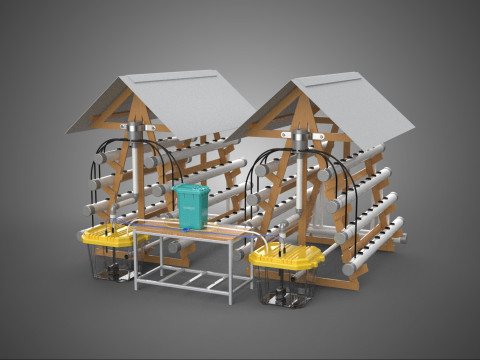

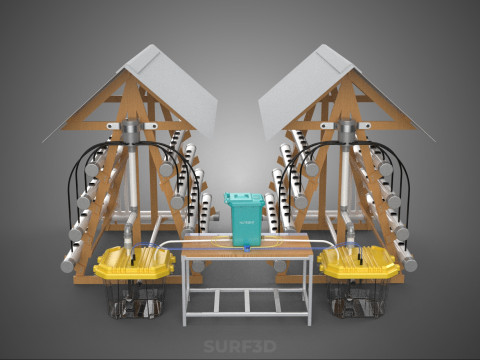

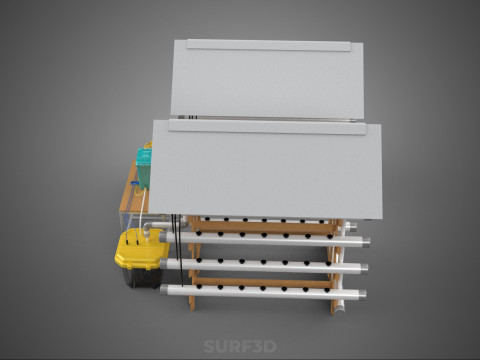

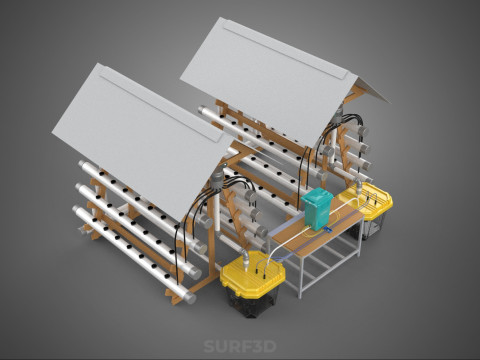

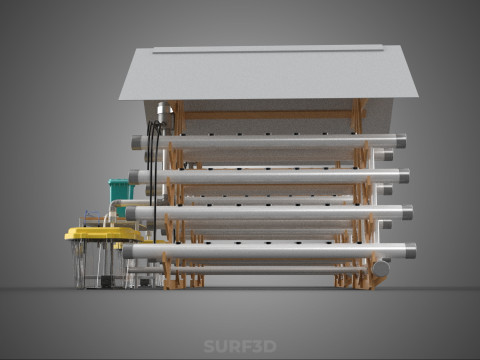

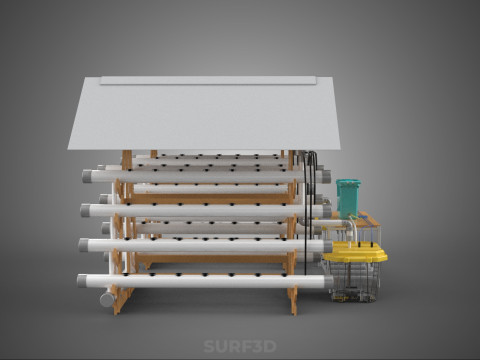

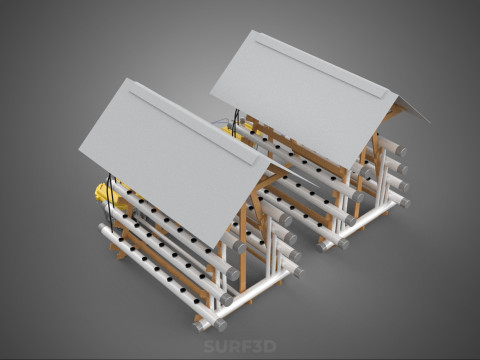

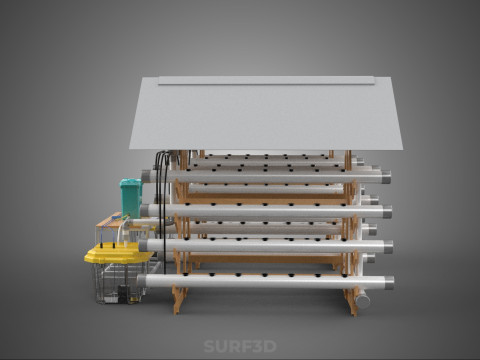

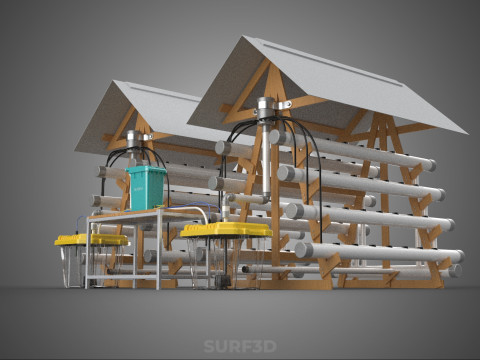

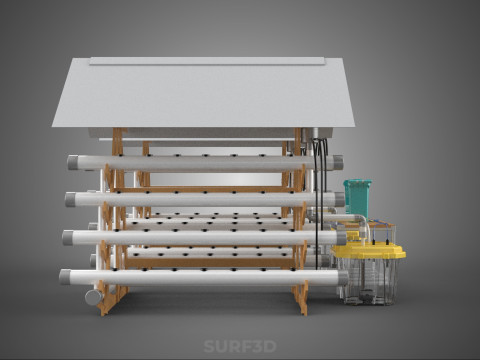

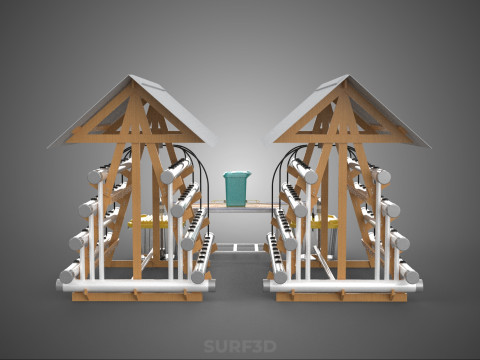

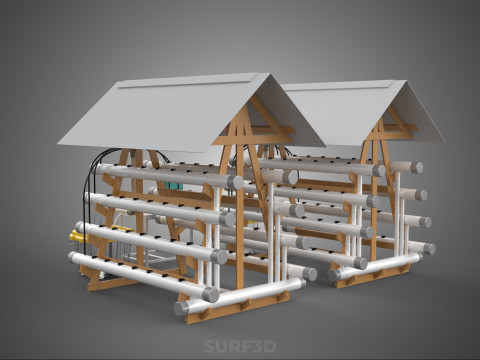

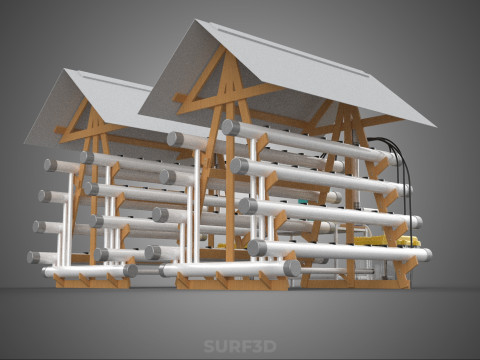

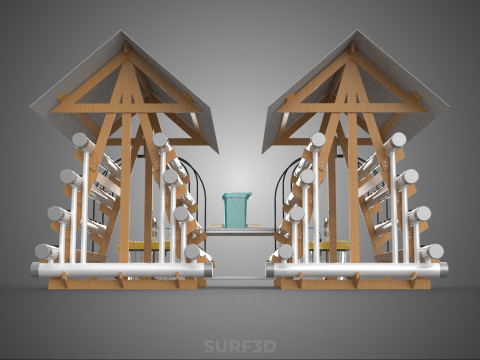

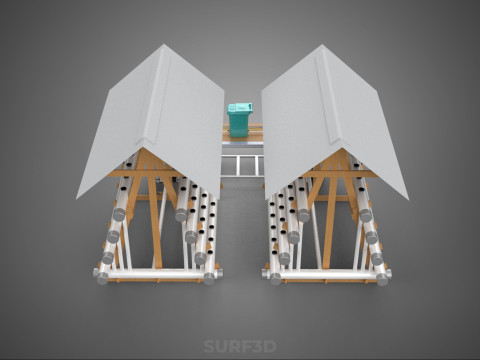

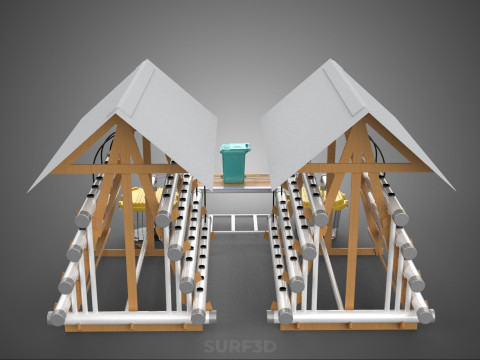

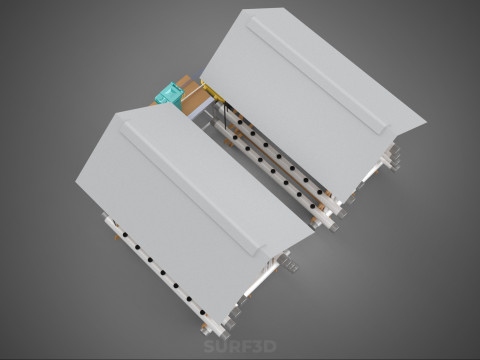

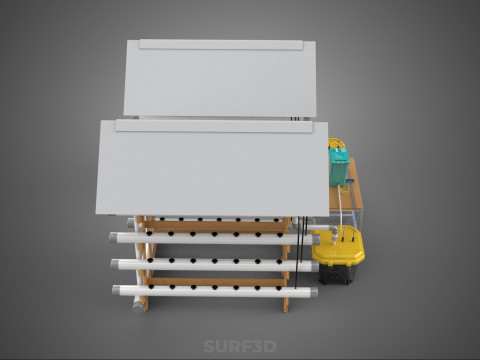

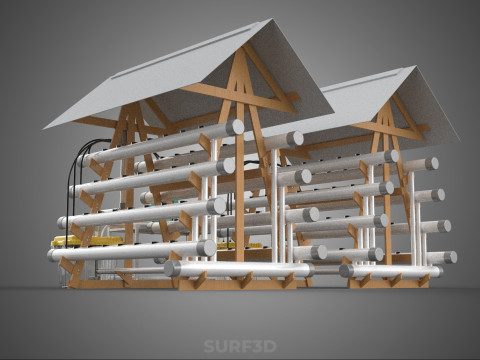

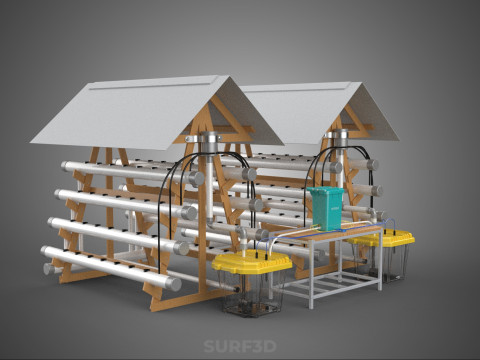

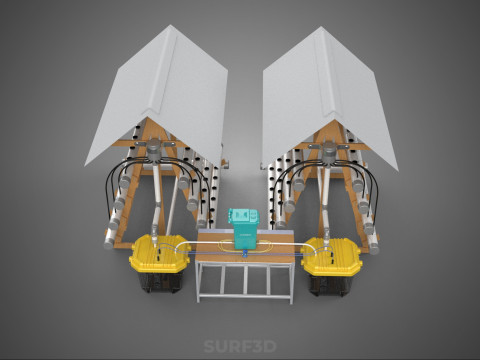

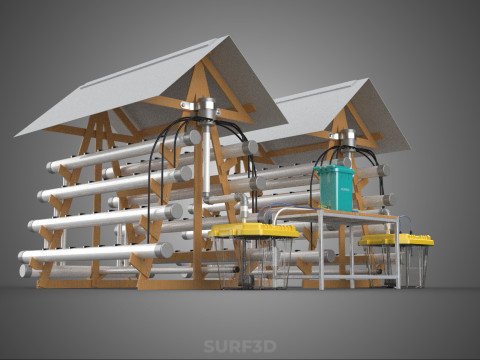

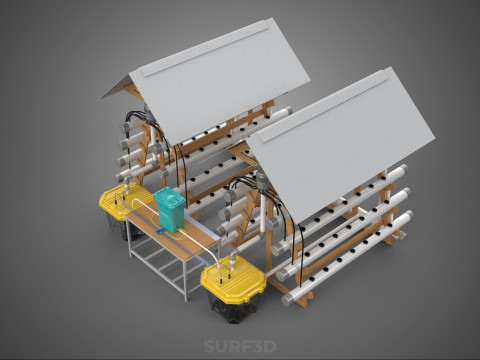

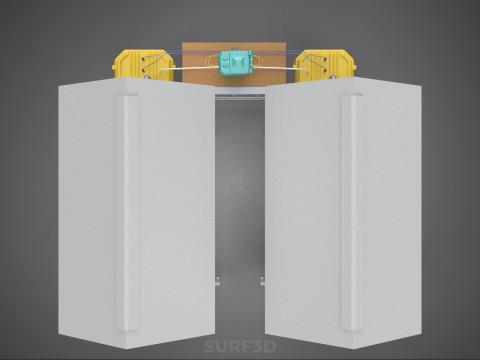

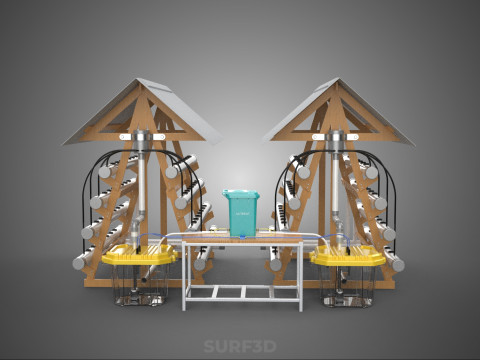

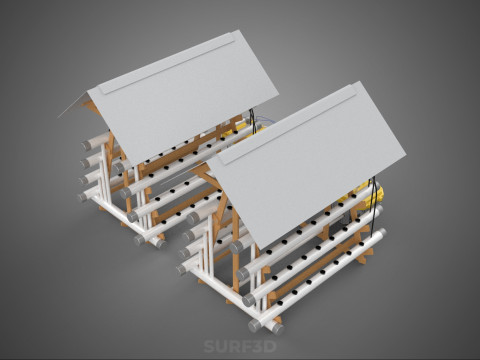

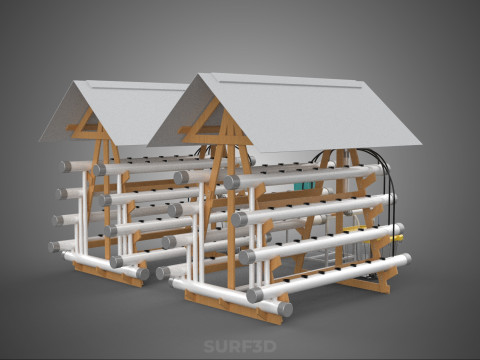

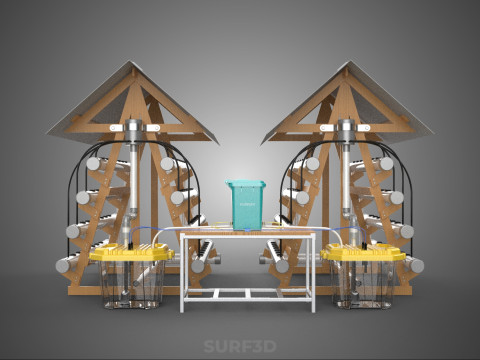

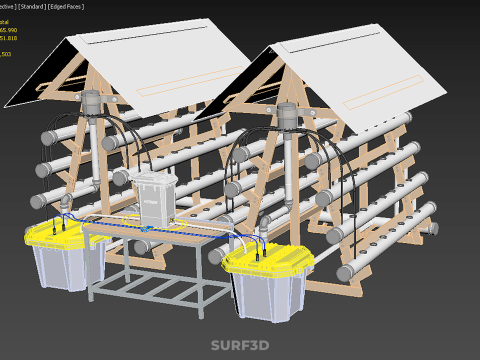

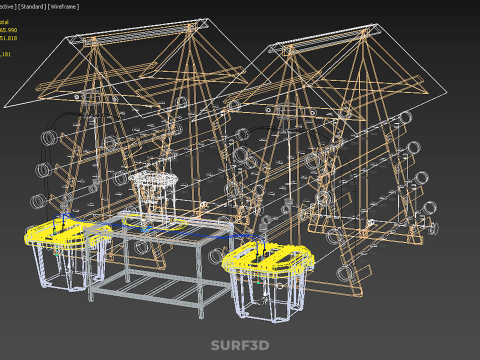

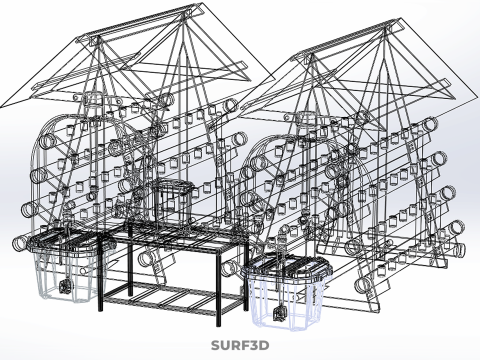

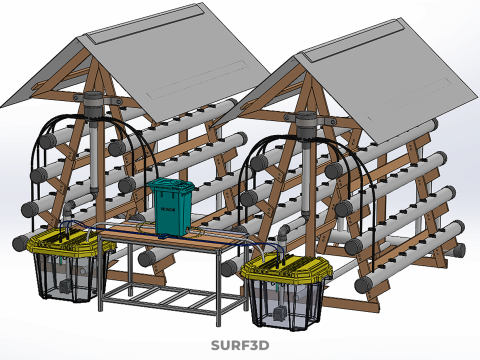

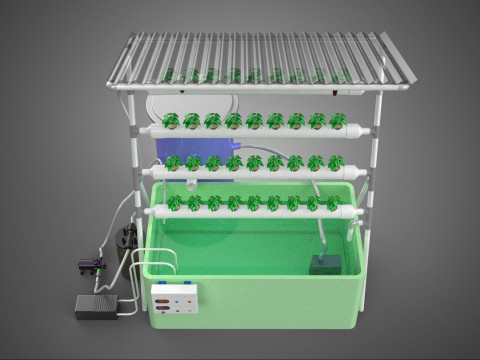

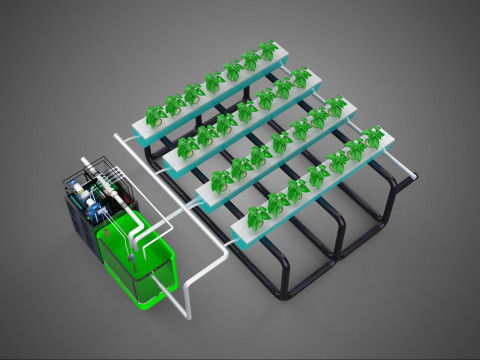

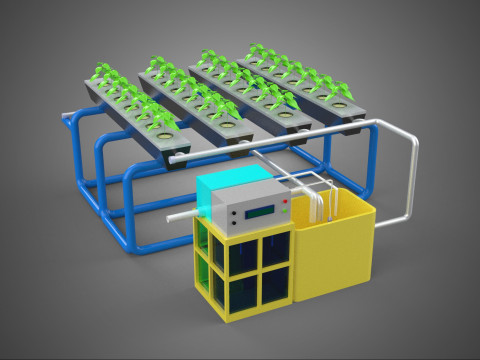

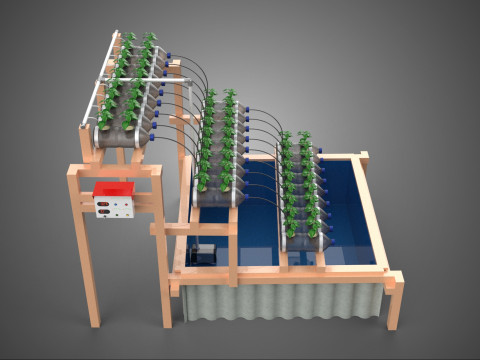

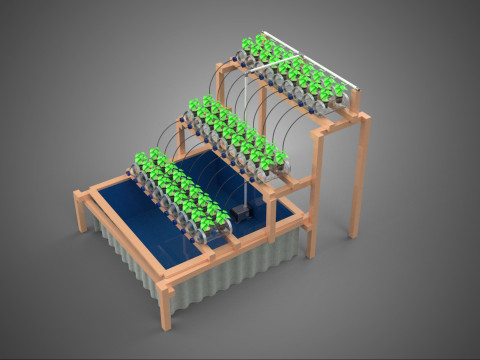

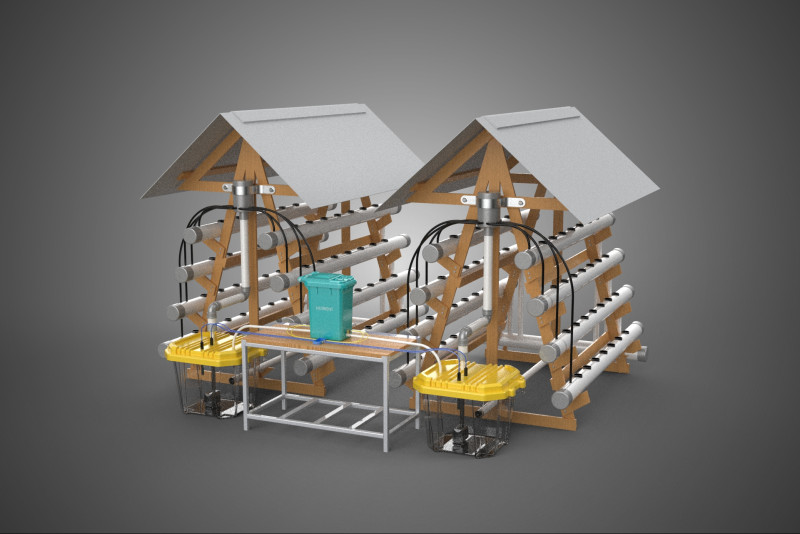

SMART IOT AUTO CONTROL NUTRIENT HYDROPONIC PLANT FARM MONITORING Model 3D

- Format yang tersedia: Autodesk FBX (.fbx) 18.69 MBBlender3D (.blend) 12.53 MBWavefront OBJ (.obj) 9.69 MBSTEP (.step) 14.72 MBCollada (.dae) 13.28 MBStereolithography (.stl) 9.99 MBSketchUp (.skp) 10.16 MB3D Studio (.3ds) 5.24 MBRhinoceros (.3dm) 44.37 MBGLB (.glb / .gltf) 5.94 MBACIS(.sat) 21.94 MBIGES (.iges) 11.80 MBAutodesk 3DS MAX (.max) 38.61 MBAutodesk AutoCAD (.dwg) 22.95 MB

- Poligon:765990

- Sudut:651818

- Animasi:No

- Bertekstur:No

- Dimanipulasi:No

- Material:

- Low-poly:No

- Koleksi:No

- Pemetaan UVW:No

- Plugin Digunakan:No

- Siap Cetak:No

- Pindai 3D:No

- Konten Dewasa:No

- PBR:No

- AI Pelatihan:No

- Geometri:Poly NURBS

- Unwrapped UVs:Unknown

- Tampilan:105

- Tanggal: 2025-09-05

- ID Barang:597115

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

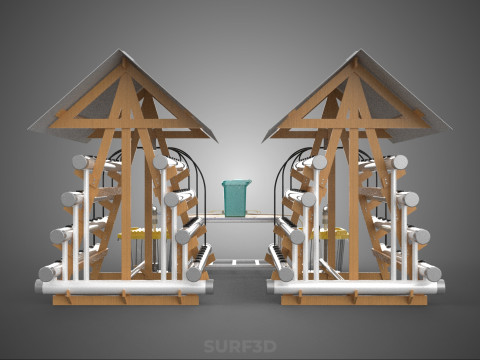

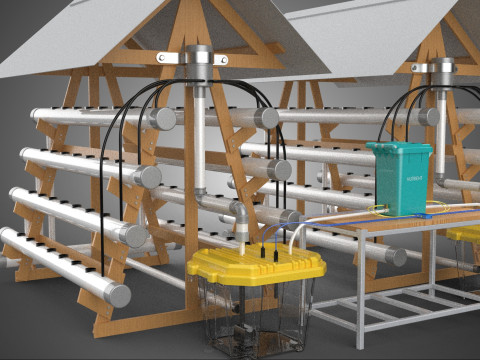

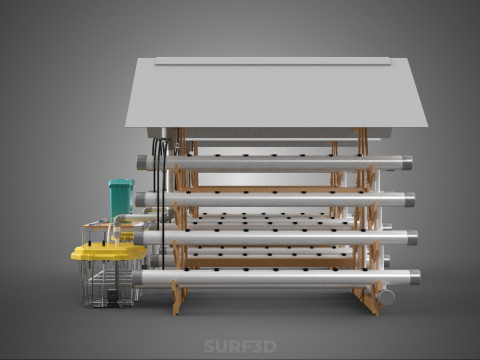

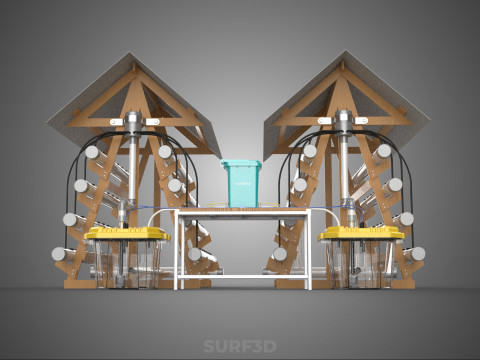

A Smart IoT Auto Control Nutrient Hydroponic Plant Farm Monitoring system represents an advanced agricultural technology integrating the Internet of Things (IoT), automation, and precision farming principles to optimize the cultivation of plants in soilless, water-based environments. This sophisticated framework is designed for the continuous observation, data-driven analysis, and automated regulation of critical environmental and nutrient parameters essential for plant growth within hydroponic systems. Its primary objective is to maximize crop yield, enhance resource efficiency, and ensure consistent plant quality through intelligent, real-time management.

At its core, the system builds upon the fundamental principles of hydroponics, a method of growing plants using mineral nutrient solutions dissolved in water, without soil. The "Smart" aspect refers to the incorporation of artificial intelligence (AI), machine learning (ML), and data analytics to interpret collected data, predict plant needs, and make proactive adjustments. The "IoT" integration signifies the network of interconnected physical devices, sensors, and actuators that collect data from the farm environment and execute control commands remotely or autonomously. "Auto Control" denotes the system's capacity for self-regulation, automatically adjusting parameters based on predefined setpoints and real-time feedback. "Nutrient Hydroponic" specifically highlights the focus on precise management of the dissolved nutrient solution, which is the sole source of sustenance for the plants. Finally, "Plant Farm Monitoring" encomp***** the continuous surveillance of all relevant growth factors and system health across an entire cultivation facility.

**Key Components and Functionality:**

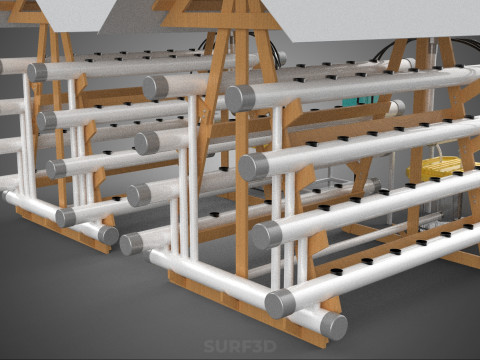

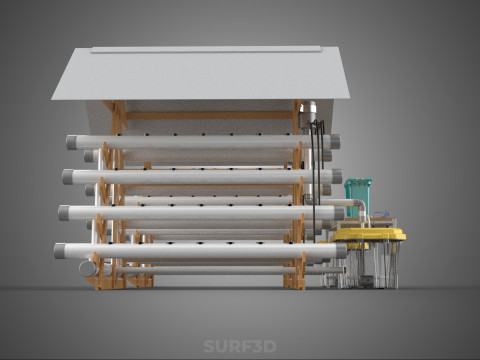

1. **Sensor Networks:** A crucial element, these networks comprise various interconnected sensors strategically placed throughout the hydroponic farm. Common sensors include:

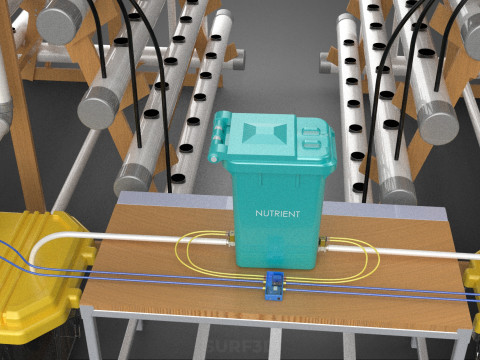

* **pH Sensors:** Monitor the acidity or alkalinity of the nutrient solution, critical for nutrient availability.

* **Electrical Conductivity (EC) Sensors:** Measure the concentration of dissolved nutrient salts in the water.

* **Temperature Sensors:** Track nutrient solution temperature and ******t air temperature.

* **Humidity Sensors:** Monitor relative humidity levels in the growing environment.

* **Light Sensors:** Measure light intensity (e.g., Photosynthetically Active Radiation - PAR) and duration.

* **Water Level Sensors:** Ensure adequate water supply in reservoirs and growing trays.

* **Dissolved Oxygen (DO) Sensors:** *****s oxygen levels in the nutrient solution, vital for root health.

* **CO2 Sensors:** Monitor carbon dioxide levels, essential for photosynthesis.

2. **Data Acquisition and Transmission:** Sensor data is collected by microcontrollers (e.g., Arduino, Raspberry Pi) or specialized IoT gateways. This data is then transmitted via various communication protocols (e.g., Wi-Fi, LoRaWAN, Cellular, Ethernet) to a central server or cloud-based platform for storage and processing.

3. **Cloud Platform and Data Analytics:** The collected data is stored, analyzed, and visualized on a secure cloud platform. This platform often integrates advanced algorithms, including machine learning, to identify trends, predict potential issues (e.g., nutrient deficiencies, disease outbreaks), and provide actionable insights. Dashboards and mobile applications offer real-time monitoring and remote control capabilities to farm operators.

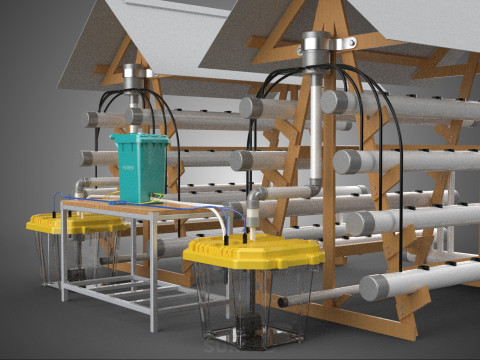

4. **Automated Control Systems (Actuators):** Based on the analyzed data and predefined optimal parameters, the system automatically triggers actuators to maintain desired conditions. These actuators include:

* **Dosing Pumps:** Precisely inject concentrated nutrient solutions (e.g., A, B, C solutions) and pH adjusters (acid/base) into the main reservoir.

* **Water Pumps:** Circulate nutrient solution to plants and manage water levels.

* **Solenoid Valves:** Control water flow for irrigation or drainage cycles.

* **Heaters and Chillers:** Regulate nutrient solution and air temperature.

* **Grow Lights:** Adjust light intensity, spectrum, and photoperiod.

* **Fans and Ventilation Systems:** Control airflow, temperature, and humidity.

* **CO2 Generators/Regulators:** Maintain optimal carbon dioxide levels.

5. **Feedback Loops and Optimization:** The system operates on a continuous feedback loop. Sensors provide input, the central system processes it and determines necessary adjustments, actuators execute these adjustments, and sensors then verify the outcome. This iterative process ensures dynamic optimization of the growing environment.

**Benefits and Advantages:**

* **Resource Efficiency:** Significantly reduces water consumption (up to 90% less than traditional farming) through recirculation and minimizes nutrient waste. Energy usage is optimized through smart control of lighting and climate.

* **Increased Yield and Quality:** Precisely controlled conditions lead to faster growth rates, higher yields, and improved crop quality and consistency.

* **Reduced Labor Costs:** Automates routine tasks such as nutrient mixing, pH balancing, and environmental control, freeing human operators for more strategic roles.

* **Pest and Disease Management:** Controlled environments reduce the incidence of soil-borne pests and diseases, minimizing the need for pesticides. Early detection through monitoring can prevent widespread outbreaks.

* **Scalability and Consistency:** Enables consistent production across large-scale facilities and different locations, irrespective of external climate conditions.

* **Data-Driven Decision Making:** Provides valuable insights into plant health and system performance, allowing for continuous improvement and optimized growing recipes.

* **Remote Management:** Operators can monitor and control the farm from anywhere, receiving alerts for critical deviations.

Jika Anda membutuhkan format yang berbeda, silakan buka Tiket Dukungan baru dan minta itu. Kita dapat mengonversi model 3D menjadi: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Kami tidak mengonversi adegan 3d dan format seperti .step, .iges, .stp, .sldprt.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी