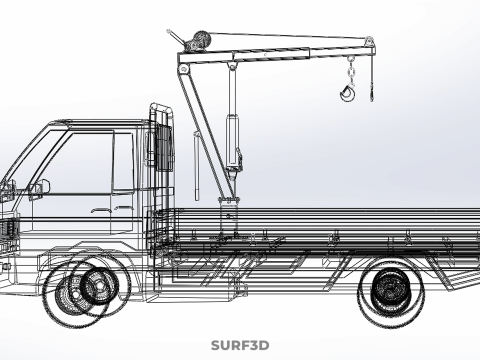

ARM FOLDING HYDRAULIC JIB CRANE MANUAL HAND WINCH TRUCK PICKUP 3D 모델

- 이용 가능한 포맷: GLB (.glb / .gltf) 6.85 MBCollada (.dae) 13.66 MBBlender3D (.blend) 14.04 MBStereolithography (.stl) 11.39 MBWavefront OBJ (.obj) 10.78 MBACIS(.sat) 16.89 MBAutodesk 3DS MAX (.max) 29.94 MBAutodesk FBX (.fbx) 18.40 MBRhinoceros (.3dm) 33.71 MBAutodesk AutoCAD (.dwg) 19.30 MBSTEP (.step) 8.33 MBIGES (.iges) 8.73 MB3D Studio (.3ds) 5.17 MBSketchUp (.skp) 12.77 MB

- 폴리곤:807019

- 버텍스:628970

- 애니메이티드:No

- 텍스쳐드:No

- 리그드:No

- 재료:

- 로우 폴리곤:No

- 컬렉션:No

- UVW 매핑:No

- 플러그인 사용 됨:No

- 프린트 준비:No

- 3D 스캔:No

- 성인용 콘텐츠:No

- PBR:No

- AI 훈련:No

- 지오메트리:Poly NURBS

- 언래핑 된 UVs:Unknown

- 조회:148

- 날짜: 2025-08-22

- 아이템 ID:594080

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

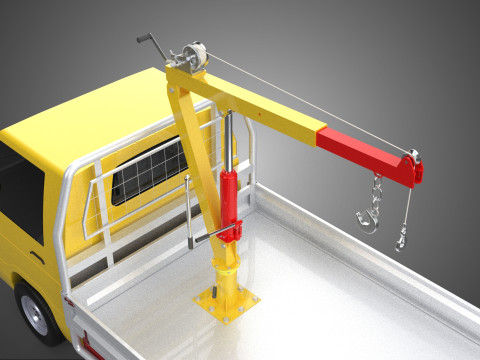

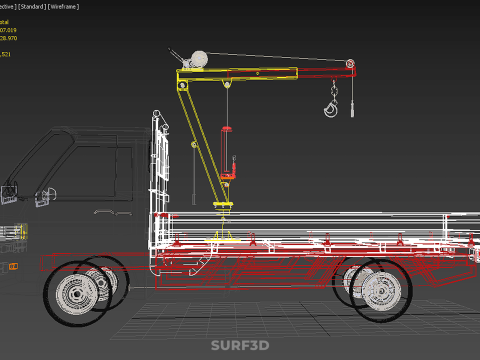

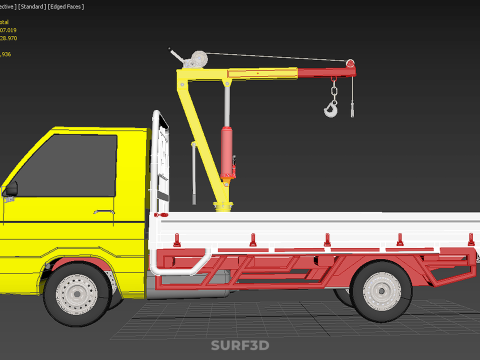

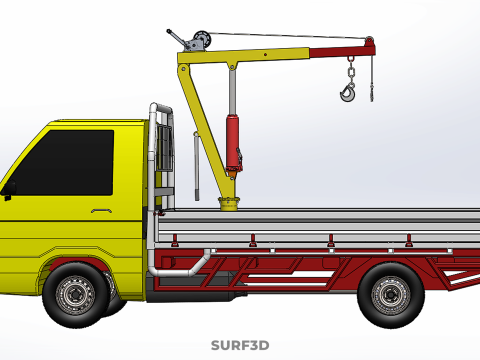

An "ARM FOLDING HYDRAULIC JIB CRANE MANUAL HAND WINCH TRUCK PICKUP" describes a specialized, mobile lifting apparatus designed for versatility and portability, specifically engineered for installation onto the chassis or bed of a pickup truck. This nomenclature precisely outlines the key functional and structural characteristics that define its operational capabilities and typical applications.

At its core, this equipment functions as a **jib crane**, a type of crane characterized by a horizontal or luffing boom (the jib) attached to a vertical mast or column. This particular variant incorporates an **arm folding** design, often referred to as an articulated or ******* boom. This multi-jointed boom allows the jib to fold into a compact configuration when not in use, significantly reducing its spatial footprint for storage, transit, and maneuvering in environments with limited space. The articulation typically involves one or more hinged sections, enabling precise positioning and a greater range of motion compared to a fixed-length jib.

The term **hydraulic** specifically refers to the power system responsible for articulating, slewing (rotating), extending, retracting, and generally positioning the crane arm. This system utilizes hydraulic fluid under pressure, generated by a pump typically powered by an electric motor (often drawing power from the truck's electrical system or a dedicated battery pack) or directly from the truck's power take-off (PTO). This hydraulic force enables smooth, controlled, and efficient deployment and repositioning of the boom sections. It is critical to note that while the arm's *movement and positioning* are hydraulically powered, the *lifting* of the load is not.

The lifting mechanism on this specific crane is a **manual hand winch**. This implies that the hoist function—raising and lowering the load—is performed by direct human effort. An operator turns a crank or handle, which rotates a drum, thereby winding or unwinding a cable or rope to manipulate the attached hook. This system is chosen for its inherent simplicity, robust reliability, independence from external power sources for the actual lift, and lower manufacturing cost. However, it intrinsically limits the maximum lifting capacity to weights manageable by a human operator and results in slower lifting speeds compared to electrically or hydraulically powered winches.

Integrated onto a **truck pickup**, this crane achieves exceptional mobility. The pickup truck serves as the stable, mobile platform, enabling the crane to be transported directly to diverse job sites, remote locations, or areas potentially inaccessible to larger, dedicated crane vehicles. Mounting typically involves securely bolting the crane's base directly to the truck's frame or bed, often with reinforcing plates to adequately distribute dynamic and static loads and ensure stability during lifting operations. To prevent tipping, particularly when the boom is extended and under load, stabilizing outriggers are frequently deployed to broaden the truck's base of support.

**Operational Principles and Applications:**

Operation commences by positioning the truck and deploying any stabilizing outriggers. The hydraulic system is then activated to unfold and articulate the jib arm, positioning it precisely over the intended lifting area. Once the load is securely attached to the manual hand winch's hook, the operator manually actuates the winch to lift or lower the item. Upon completion of the task, the hydraulic system retracts and folds the arm back into its compact, stowed position, ready for transport.

This type of crane is particularly well-suited for tasks demanding occasional lifting of moderate loads, requiring precise load placement, and benefiting from high mobility. Common applications include:

* **Utility and Field Service:** Lifting tools, equipment, or components for repairs and maintenance at various sites.

* **Light Construction:** Moving smaller building materials, tools, or light machinery on job sites.

* **Agriculture:** Handling feed bags, small equipment, or other farm necessities in remote areas.

* **Workshops and Garages:** Facilitating the loading and unloading of engines, transmissions, or other heavy parts from vehicles.

* **General Material Handling:** Any scenario where a highly portable, self-contained lifting solution for lighter goods is needed, especially where power for a motorized hoist is unavailable or unnecessary.

**Advantages include:**

* **Exceptional Portability and Mobility:** Easily transported to a wide range of locations.

* **Compact Storage:** The folding arm design minimizes space requirements when the crane is stowed for transit or storage.

* **Cost-Effectiveness:** Generally less expensive to purchase and maintain compared to fully hydraulic or electric hoist cranes.

* **Operational Independence:** The manual winch operation does not require external power for lifting, making it ideal for remote or off-grid sites.

* **Precision Control:** Manual winches can offer very fine and controlled manipulation of lifting and lowering speeds.

**Limitations include:**

* **Limited Lifting Capacity:** Inherently constrained by human strength required for the manual winch.

* **Slower Operation:** Manual winching is significantly slower than powered alternatives, impacting efficiency for frequent or high-volume lifts.

* **Operator Fatigue:** Prolonged or heavy lifting operations can be physically demanding for the operator.

* **Critical Stability Requirements:** Proper setup with outriggers and strict adherence to load charts are paramount to prevent truck instability and potential tipping.

**Safety and Maintenance:**

Safe operation mandates strict adherence to the manufacturer's load charts, proper stabilization of the truck, a thorough understanding of hydraulic controls, and regular inspection of the winch cable, hooks, and hydraulic system for any signs of wear, damage, or malfunction. Routine maintenance ensures the longevity, reliability, and safe functionality of both the hydraulic components and the manual winch.

다른 포맷이 필요하시면, 새로운 지원 티켓을 열어 요청하세요. 저희는 3D 모델을 다음으로 변환할 수 있습니다: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 우리는 3D 장면을 변환하지 않습니다 .step, .iges, .stp, .sldprt와 같은 형식도 포함됩니다.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी