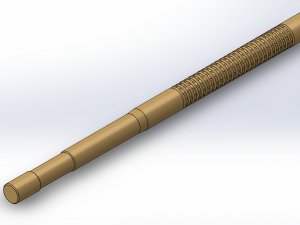

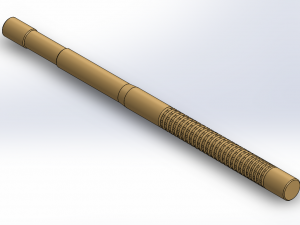

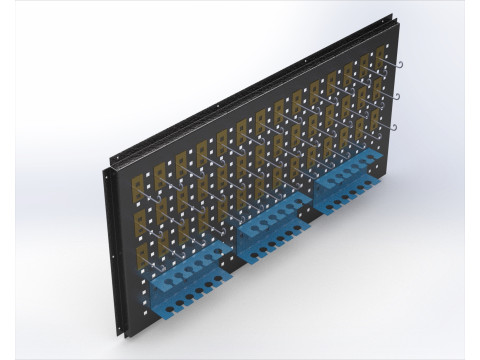

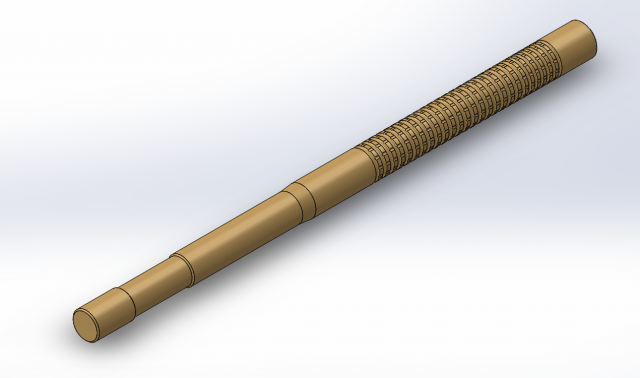

Broaching tool 3D 모델

BLACK FRIDAY

BIGGEST SALE 70% OFF

$

25.00 USD

- 작성자에게 제품 지원 요청

- 이용 가능한 포맷:

- 아이템 ID:407284

- 날짜: 2022-07-19

- 애니메이티드:No

- 텍스쳐드:No

- 리그드:No

- 재료:

- 로우 폴리곤:No

- 컬렉션:No

- UVW 매핑:No

- 플러그인 사용 됨:No

- 프린트 준비:No

- 3D 스캔:No

- 성인용 콘텐츠:No

- PBR:No

- 지오메트리:Polygonal

- 언래핑 된 UVs:Unknown

- 조회:2538

설명

Manufacture precision machining components with a high-quality broach tool. Broaching tools come in a range of styles and applications to provide innovative machining solutions. Most broaching tools use multi-tooth designs to create successive cuts at high speeds. Learn more about the variety of broaching tools available and how you can use one to create custom parts.broaching tools

Basic Types of Broaching Tools

You can separate most broach tools into two basic categories: push broach and pull broach. Alternatively, you can also divide broaches into internal or external broaching machines.

Both push and pull broach tools use similar strategies to machine materials. A push broach tool must be short enough to withstand extreme pressure without breaking or buckling. A pull broach can be used horizontally or vertically and creates accurate cuts as a workpiece is pulled across its teeth.

Internal broaches create keyways or other internal holes for a number of industries and applications. An internal broach is an excellent way to create simple or complicated components at high speeds.

External broaches, also known as internal broaches, are used to create exterior contouring or defined edges. Create built-up designs for inserts, sections and indexable tool bits with this dynamic broaching design.

Broach Tool Components

Your broach tooling is made of a laundry list of precision parts. A quality broach manufacturer or repair service must understand every part in detail in order to create, service or repair your broach. Here are some of the common broach components and nomenclature your service provider should be familiar with:

Front pilot

Length

Rear pilot

Cutting teeth

Tooth land, pitch and gullet

Chip load

Chipbreakers

Shear angle

Side relief

Because of the high-speed, high-volume nature of broaching, your broaching tool teeth can quickly become damaged or dull. Be sure you have a routine maintenance schedule in place to service these and other high-demand areas of your broaching machine. Enjoy high-volume production year-round thanks to quality repair services.

Depending on the type of broach tool you’re using, you’ll enjoy a range of precision machining in soft and hard materials. Broaching is similar to reaming, shaping, milling and boring and is competitive with each of these processes. For high-production applications, broaching can be a superior option.

Unlike typical machining processes, broaching combines all three levels of cutting teeth into one tool or a string of similar tools: rough, semi-finish and finish cutting. Each of these machining steps is achieved in quick succession, making broaching a popular option for bulk machining of precision components.

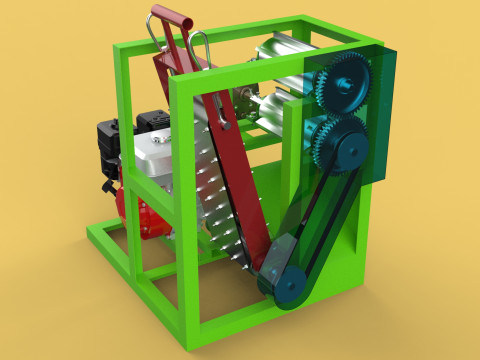

The ideal broaching tool needs a reliable broaching machine. Choose a vertical, horizontal, chain or turn broaching machine depending on the materials you’re using, the type of broaching you’re looking to achieve and your budget.

Typical Broaching Application

A broach tool and machine can be used for a wide range of industries. Automotive parts, fasteners components and industrial manufacturing applications all commonly use broaching. It’s important to work with a leading broaching company that understands your industry standards and can provide comprehensive servicing for all your broaching needs.

Thanks to the dynamic nature of broaching, there are many ways to specialize your broaching service. Whether you need to broach plastic soft metal or hard metal workpieces, customize your broaching machine to fit your exact industry specifications.

Quality Broaching Services

At Miller Broach, we specialize in broach tool services that include sharpening, reconditioning, replacing and grinding your broaching tools. From minor sharpening services to comprehensive machine rebuilds, work with us to enjoy industry-leading broaching tools and high-speed machining. Contact us to discover how we can help you compete in your industry and meet your demanding quality control levels with durable, reliable broaching tools 프린트 준비: 아니오

다른 포맷이 필요하세요?

다른 포맷이 필요하시면, 새로운 지원 티켓을 열어 요청하세요. 저희는 3D 모델을 다음으로 변환할 수 있습니다: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 자유 형식 변환우리는 3D 장면을 변환하지 않습니다 .step, .iges, .stp, .sldprt와 같은 형식도 포함됩니다.!

사용 정보

Broaching tool - 기본 또는 확장 라이선스에 따라 이 로열티 프리 3D 모델을 개인적 및 상업적 목적으로 사용할 수 있습니다.기본 라이선스는 디지털 광고, 디자인 및 시각화 프로젝트, 비즈니스 소셜 미디어 계정, 네이티브 앱, 웹 앱, 비디오 게임, 그리고 물리적 또는 디지털 최종 제품(무료 및 유료 모두)을 포함한 대부분의 표준 사용 사례를 포괄합니다.

확장 라이선스는 기본 라이선스에 따라 부여된 모든 권리를 포함하며 사용 제한이 없으며, 로열티 프리 조건 하에 3D 모델을 상업적 프로젝트에 무제한으로 사용할 수 있습니다.

더 보기

환불이 보장되나요?

네, 환불을 보장합니다. 작품 구입 후 렌더나 설명에서 오류를 발견하시면, 저희는 최대한 빨리 해당 문제를 수정 할 것입니다. 저희가 해당 오류를 수정 할 수 없는 경우, 저희는 귀하의 주문을 취소하며 아이템 다운로드 24 시간 내에 금액을 환불해드립니다. 더 자세한 정보는 여기를 참조하세요키워드

이 저작자의 랜덤 아이템

이 아이템에 대한 코멘트 없음.

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी