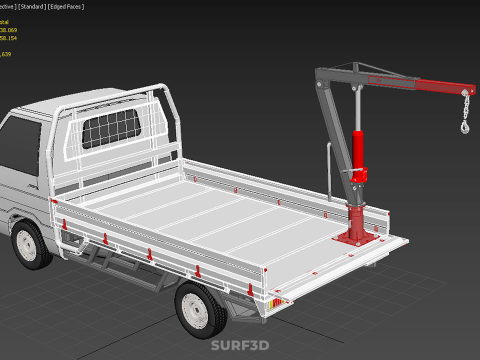

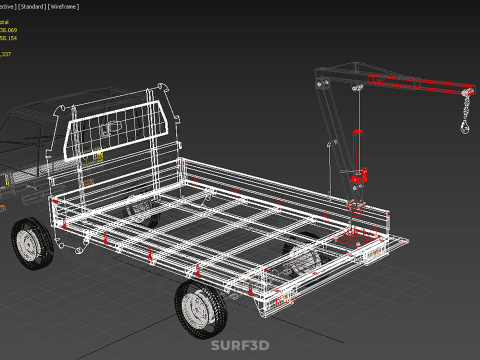

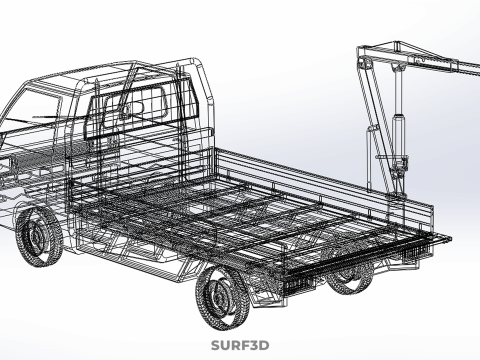

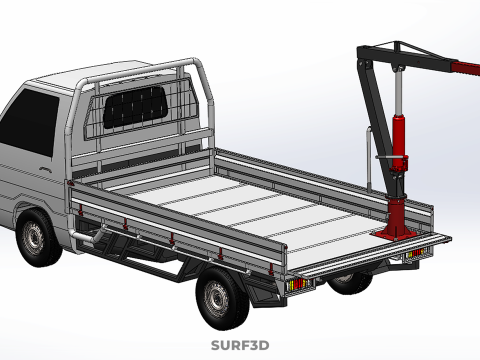

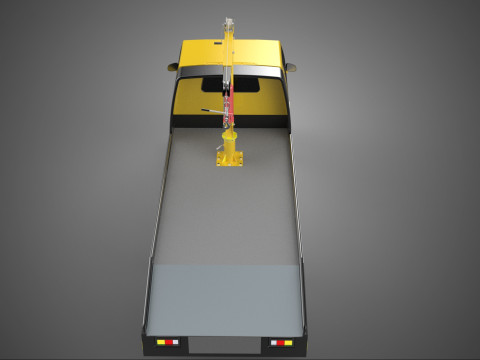

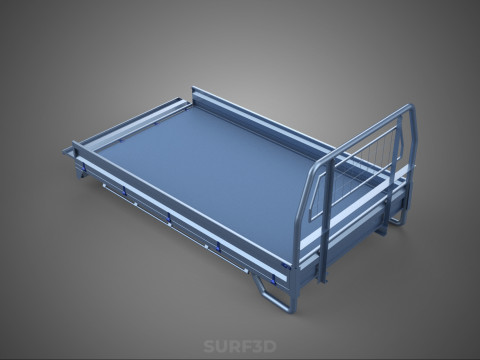

PICKUP TRUCK TAILGATE REAR GATE HYDRAULIC JACK LIFT HOIST CRANE 3D 모델

- 이용 가능한 포맷: STEP (.step) 7.49 MBBlender3D (.blend) 10.20 MBAutodesk FBX (.fbx) 13.02 MBACIS(.sat) 15.66 MBGLB (.glb / .gltf) 5.37 MBIGES (.iges) 7.41 MBSketchUp (.skp) 7.92 MBCollada (.dae) 10.54 MBAutodesk 3DS MAX (.max) 24.87 MBWavefront OBJ (.obj) 7.68 MBCollada (.dae) 10.54 MBAutodesk AutoCAD (.dwg) 18.52 MBStereolithography (.stl) 7.94 MB3D Studio (.3ds) 4.02 MBRhinoceros (.3dm) 26.48 MB

- 폴리곤:538069

- 버텍스:458154

- 애니메이티드:No

- 텍스쳐드:No

- 리그드:No

- 재료:

- 로우 폴리곤:No

- 컬렉션:No

- UVW 매핑:No

- 플러그인 사용 됨:No

- 프린트 준비:No

- 3D 스캔:No

- 성인용 콘텐츠:No

- PBR:No

- AI 훈련:No

- 지오메트리:Poly NURBS

- 언래핑 된 UVs:Unknown

- 조회:203

- 날짜: 2025-08-22

- 아이템 ID:594084

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

A "Pickup Truck with Tailgate Rear Gate Hydraulic Jack Lift Hoist Crane" describes a specialized and highly functional commercial vehicle configuration designed to integrate advanced material handling capabilities with the inherent versatility of a standard pickup truck. This system transforms a conventional utility vehicle into a mobile work platform capable of both ground-level loading and overhead lifting, significantly enhancing efficiency and safety in various professional applications.

The core of this configuration lies in the strategic integration of several hydraulic components:

1. **Pickup Truck Base:** The foundation is a robust light-duty or medium-duty pickup truck, chosen for its durability, open cargo bed, maneuverability, and existing payload capacity. The chassis and suspension are often reinforced to accommodate the additional weight and dynamic stresses imposed by the hydraulic equipment and heavy loads.

2. **Hydraulic Liftgate (Tailgate/Rear Gate):** This critical component replaces or significantly augments the traditional rear tailgate. A hydraulic liftgate consists of a sturdy platform, powered by one or more hydraulic cylinders, that can be smoothly lowered from the truck bed level to the ground and subsequently raised back up. This mechanism facilitates the safe and efficient loading and unloading of heavy, bulky, or fragile items, such as palletized goods, appliances, equipment, or machinery, without requiring ramps or manual lifting. Control is typically achieved via a wired handheld remote, foot controls, or integrated buttons, prioritizing operational ease and operator safety. Its primary function is to bridge the vertical gap ***ween the truck bed and the ground, dramatically reducing physical strain and improving logistics.

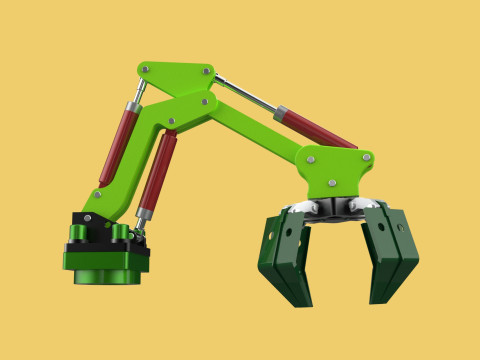

3. **Hydraulic Crane/Hoist:** Integrated into the pickup truck's cargo bed, usually mounted behind the cab or near the tailgate, is a hydraulic crane or hoist. These devices are purpose-built for lifting and positioning heavy loads that cannot be easily managed by the liftgate alone or require manipulation above the truck bed.

* **Mechanism:** Powered by hydraulic cylinders, the crane typically features a base, a mast, and a boom assembly. The boom can be equipped with a ***ch, hook, or specialized attachments for various lifting tasks.

* **Types:** Common configurations include **telescopic cranes**, which feature a boom that extends and retracts, offering considerable reach, and **articulated cranes** (or ******* boom cranes), which have multiple joints, providing greater flexibility and maneuverability in confined spaces.

* **Operation:** Cranes are controlled via wired or wireless remote controls, or integrated joystick panels. To ensure stability during lifting operations, especially with heavier loads or extended booms, most cranes require the deployment of **outriggers** or stabilizers. These hydraulic or manual extensions widen the truck's base, preventing tipping.

* **Lifting Capacity:** Varies widely based on the crane model, boom length, and truck stability, ranging from several hundred pounds to several thousand pounds.

4. **Shared Hydraulic System ("Hydraulic Jack"):** The underlying technology enabling both the liftgate and the crane is a centralized hydraulic system. The term "hydraulic jack" refers to the fundamental principle of using pressurized fluid to generate linear force.

* **Components:** This system comprises an electric or engine-driven hydraulic pump, a fluid reservoir (containing hydraulic oil), control valves, high-pressure hoses, and the hydraulic cylinders that power the liftgate and crane's movements.

* **Power Source:** The system draws power from the truck's electrical system, often augmented by heavy-duty alternators, auxiliary batteries, or a power take-off (PTO) unit if the truck's engine is utilized, to handle the significant energy demands.

* **Safety Features:** Critical safety mechanisms are integrated, including pressure relief valves to prevent overloading, emergency stop buttons, flow control valves for smooth and predictable operation, and interlocks that prevent crane deployment or operation unless stability conditions (e.g., outriggers deployed) are met.

**Operational Aspects:**

Operation of these integrated systems is designed for user-friendliness while adhering to strict safety protocols. Controls are typically intuitive, with clear labeling for various functions (lift, lower, extend, retract, s***g). Proper training is essential for operators to understand load limits, center of gravity, stability requirements, and safe operating procedures, particularly when utilizing the crane.

**Applications and Utility:**

This specialized pickup truck configuration finds extensive utility across numerous industries due to its combined capabilities:

* **Construction and Contracting:** Lifting tools, materials, and small machinery onto job sites, often in urban or less accessible areas.

* **Landscaping and Arboriculture:** Moving trees, large rocks, fencing materials, and heavy landscaping equipment.

* **Utility Services:** Handling transformers, poles, cable reels, and other equipment for electrical, telecommunications, water, or plumbing crews.

* **Delivery and Logistics:** Facilitating the delivery of heavy appliances, industrial components, specialized cargo, and large parcels directly to customer sites.

* **Field Service and Maintenance:** Equipping mobile workshops with the ability to lift and position heavy components during on-site repairs of machinery or infrastructure.

* **Emergency Services:** Used by fire departments, rescue teams, or disaster relief organizations for lifting equipment or assisting in recovery operations.

**Advantages:**

* **Increased Efficiency:** Significantly speeds up loading, unloading, and material positioning tasks.

* **Enhanced Safety:** Reduces the risk of manual lifting injuries, provides more controlled handling of heavy objects, and minimizes potential damage to cargo.

다른 포맷이 필요하시면, 새로운 지원 티켓을 열어 요청하세요. 저희는 3D 모델을 다음으로 변환할 수 있습니다: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 우리는 3D 장면을 변환하지 않습니다 .step, .iges, .stp, .sldprt와 같은 형식도 포함됩니다.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी