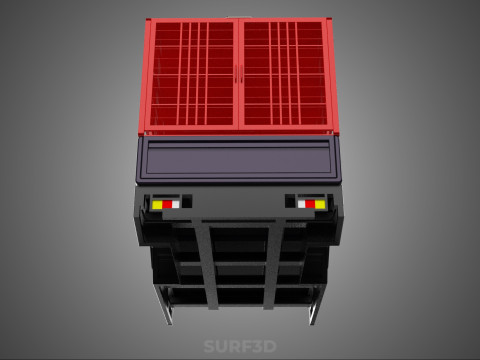

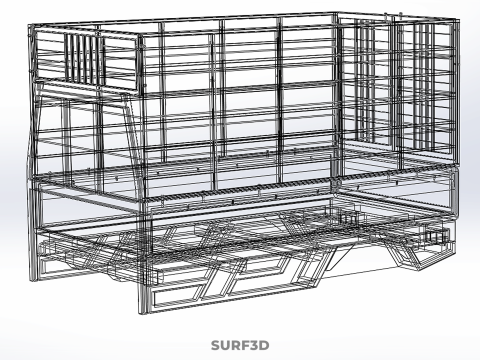

가금류 닭 캐리어 랙 울타리 케이지 화물 트럭 픽업 차량 3D 모델

- 작성자에게 제품 지원 요청

- 이용 가능한 포맷:

- 아이템 ID:589710

- 날짜: 2025-07-28

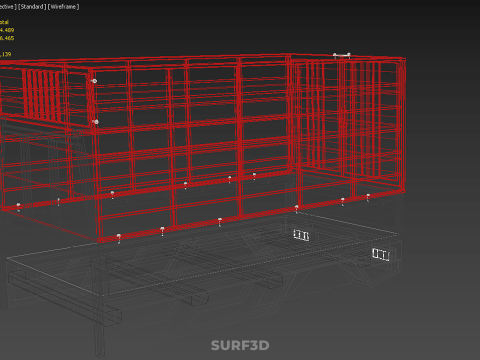

- 폴리곤:74489

- 버텍스:66465

- 애니메이티드:No

- 텍스쳐드:No

- 리그드:No

- 재료:

- 로우 폴리곤:No

- 컬렉션:No

- UVW 매핑:No

- 플러그인 사용 됨:No

- 프린트 준비:No

- 3D 스캔:No

- 성인용 콘텐츠:No

- PBR:No

- AI 훈련:No

- 지오메트리:Poly NURBS

- 언래핑 된 UVs:Unknown

- 조회:353

설명

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

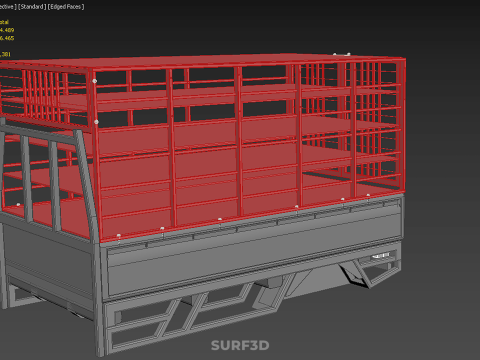

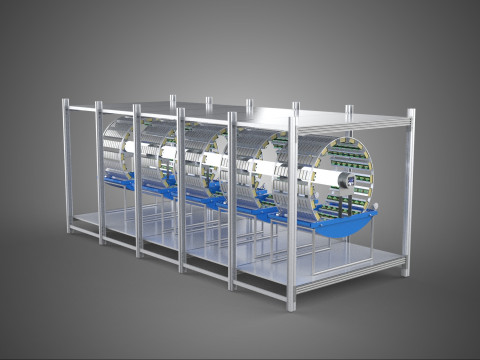

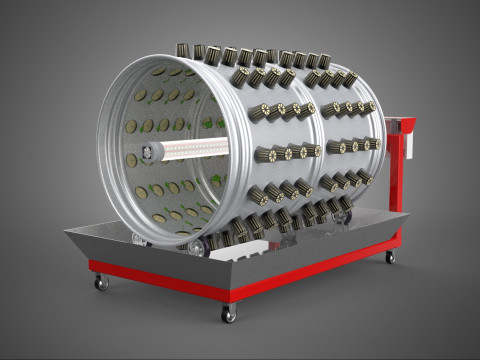

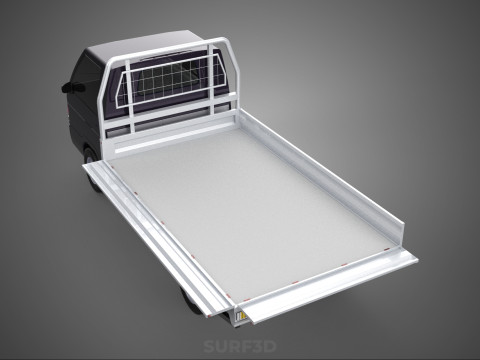

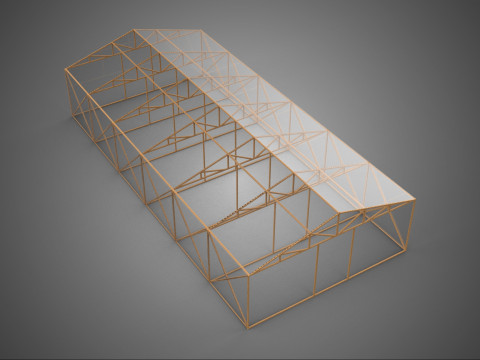

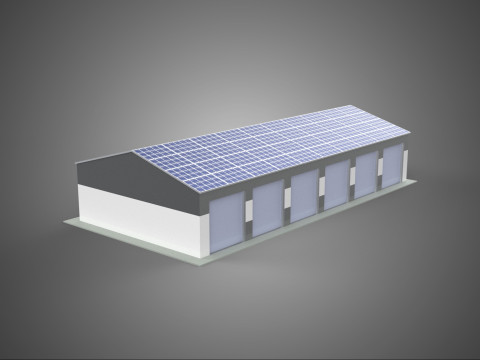

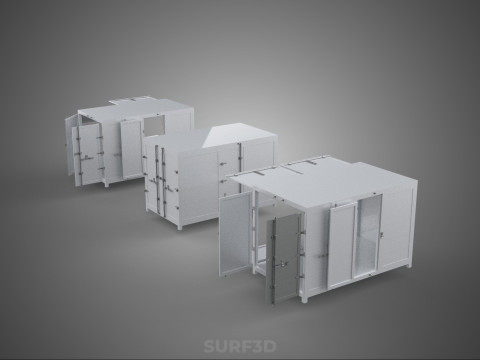

A **Poultry Chicken Carrier Rack Fence Cage Cargo System**, often referred to as a poultry transport module, live bird crate system, or chicken cargo cage, is a specialized equipment assembly designed for the safe, humane, and efficient transportation of live poultry, primarily chickens. This system typically comprises a series of robust, ventilated cages or crates securely affixed to a supporting rack, which is then mounted onto the cargo bed of commercial trucks, pickup trucks, or other utility vehicles.

**Purpose and Function:**

The primary function of such a system is to facilitate the logistical movement of live birds within the poultry industry, from breeding farms to grow-out facilities, or from farms to processing plants (abattoirs). Key objectives include minimizing stress and injury to the birds during transit, ensuring adequate ventilation and thermal regulation, and optimizing the carrying capacity of the transport vehicle. The design aims to prevent escape while allowing for hygienic conditions and ease of cleaning, thereby contributing to both operational efficiency and animal welfare standards.

**Design and Construction:**

These systems are typically constructed from durable, non-corrosive materials. Individual poultry cages are most commonly made from high-density polyethylene (HDPE) plastic, known for its resilience, ease of cleaning, and resistance to chemical degradation. These cages are engineered for stackability, often featuring interlocking designs that provide stability during transit and prevent shifting. Essential design elements include ample ventilation openings (slats or perforations) to ensure continuous airflow and regulate internal temperatures, smooth interior surfaces to prevent injury to the birds' feathers or skin, and sometimes integrated waste collection trays or slatted floors to manage droppings and maintain hygiene. Access points, usually hinged doors or sliding gates, are strategically placed to allow for efficient and low-stress loading and unloading of poultry.

The overarching rack structure, which supports multiple individual cages, is custom-fabricated from strong materials such as galvanized steel or aluminum. This frame is designed to distribute weight evenly and includes secure attachment mechanisms (e.g., bolts, clamps, or integrated locking pins) to the vehicle chassis or cargo bed, ensuring stability and safety during transport over varying terrains and distances. Some advanced systems may feature hydraulic lifting mechanisms for multi-tier loading or automated cleaning capabilities.

**Types and Variations:**

Variations exist in design and scale to accommodate different operational needs. Some systems are modular, allowing individual crates to be removed and handled separately for cleaning, loading, or storage. Others are more permanently integrated cage units within a larger fixed frame. Sizes vary based on the type and number of birds to be transported, ranging from smaller units suitable for local farm use on standard pickup trucks to large, multi-tiered systems employed on semi-trailer trucks for industrial-scale operations that can transport thousands of birds per journey. The number of compartments per crate and the overall dimensions of the rack are specified to comply with industry standards and animal welfare regulations regarding bird density and space allowances.

**Operational Considerations and Animal Welfare:**

Operational considerations for poultry transport systems include careful loading densities to prevent overcrowding, maintaining appropriate environmental conditions (temperature, humidity, air quality) throughout the journey, and minimizing journey times to reduce stress. Adherence to animal welfare regulations, which often dictate crate size, ventilation requirements, maximum transport durations, and handling protocols, is paramount. Such systems are engineered to facilitate compliance with these guidelines, ensuring the humane treatment of poultry during transportation, which also impacts meat quality and disease prevention.

**Applications:**

The primary application for poultry chicken carrier rack fence cage cargo systems is in the commercial poultry industry, serving as a critical link in the supply chain that connects breeding and grow-out farms to processing facilities. Additionally, smaller versions are utilized by independent farmers, agricultural cooperatives, poultry distributors, and for transporting birds to live poultry markets, agricultural shows, or for breeding purposes.

KEYWORDS: Poultry, Chickens, Transport, Carrier, Rack, Cage, Crate, Fence, Cargo, Truck, Pickup, Vehicle, Livestock, Animal Welfare, Farm, Abattoir, Logistics, Commercial, Agricultural, Module, Humane Transport, Ventilation, HDPE, Galvanized Steel, Stackable, Durable, Modular, Supply Chain, Poultry Industry, Live Bird.

다른 포맷이 필요하세요?

다른 포맷이 필요하시면, 새로운 지원 티켓을 열어 요청하세요. 저희는 3D 모델을 다음으로 변환할 수 있습니다: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 자유 형식 변환우리는 3D 장면을 변환하지 않습니다 .step, .iges, .stp, .sldprt와 같은 형식도 포함됩니다.!

사용 정보

가금류 닭 캐리어 랙 울타리 케이지 화물 트럭 픽업 차량 - 기본 또는 확장 라이선스에 따라 이 로열티 프리 3D 모델을 개인적 및 상업적 목적으로 사용할 수 있습니다.기본 라이선스는 디지털 광고, 디자인 및 시각화 프로젝트, 비즈니스 소셜 미디어 계정, 네이티브 앱, 웹 앱, 비디오 게임, 그리고 물리적 또는 디지털 최종 제품(무료 및 유료 모두)을 포함한 대부분의 표준 사용 사례를 포괄합니다.

확장 라이선스는 기본 라이선스에 따라 부여된 모든 권리를 포함하며 사용 제한이 없으며, 로열티 프리 조건 하에 3D 모델을 상업적 프로젝트에 무제한으로 사용할 수 있습니다.

더 보기

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी