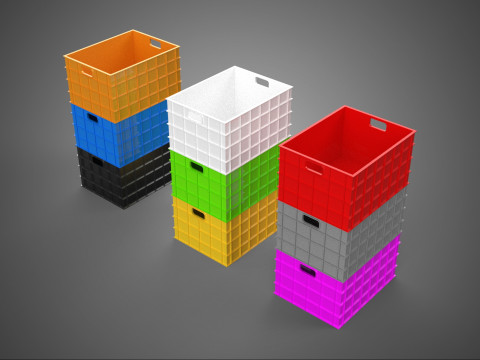

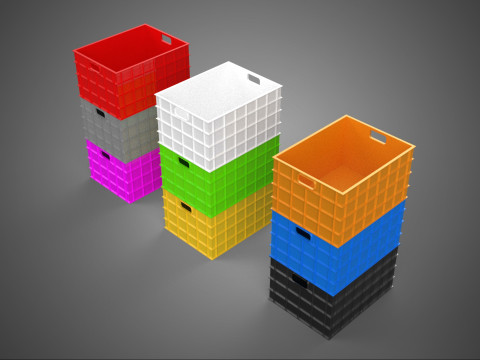

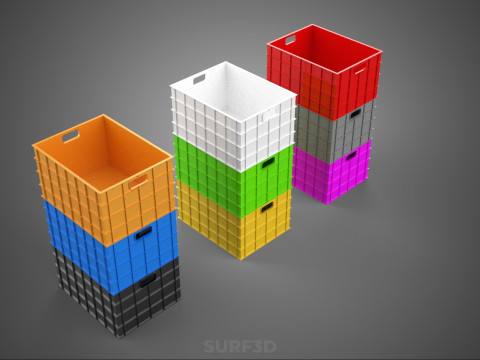

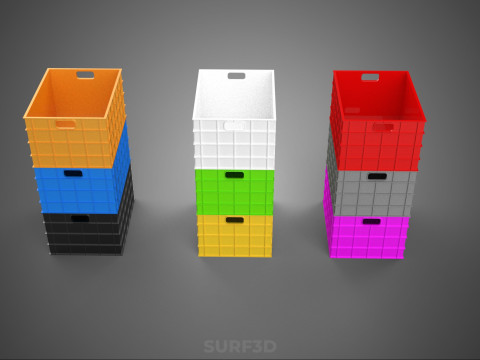

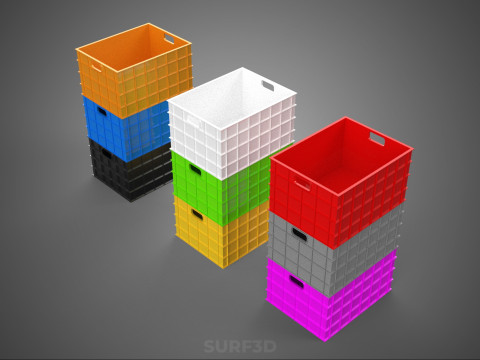

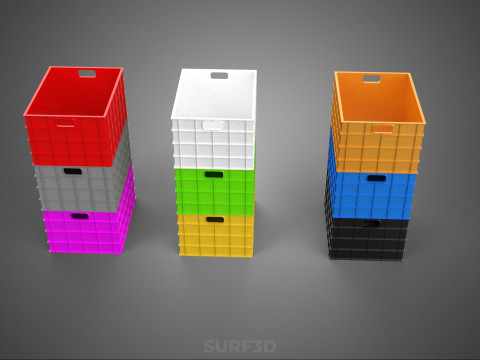

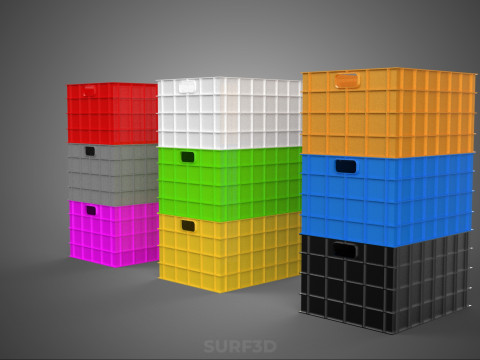

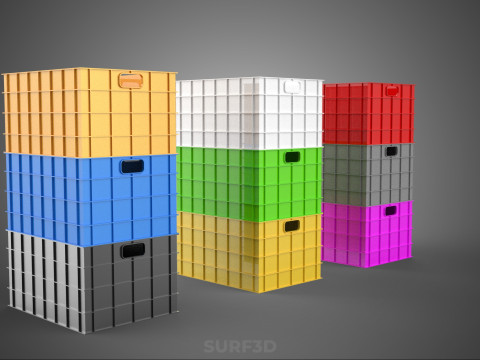

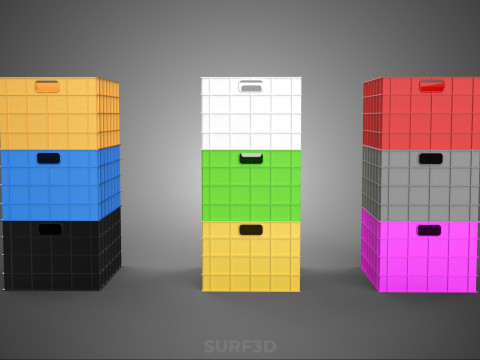

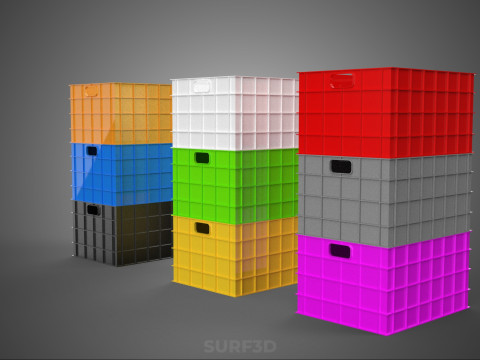

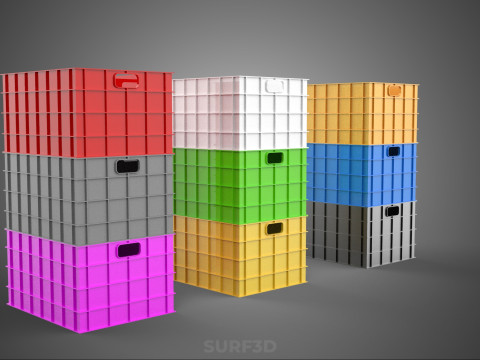

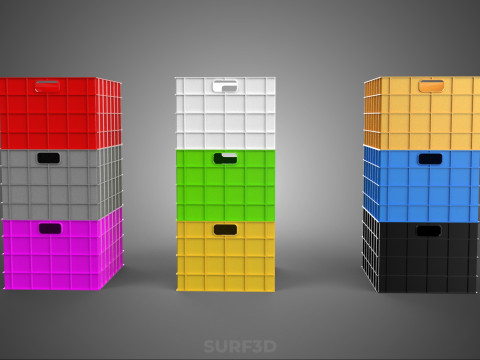

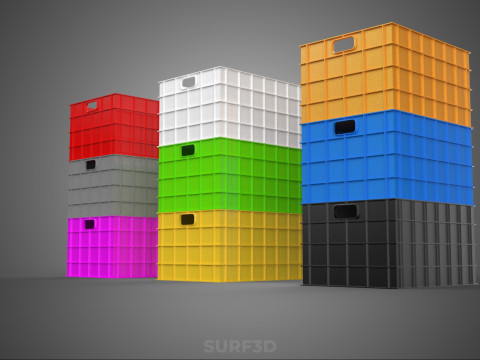

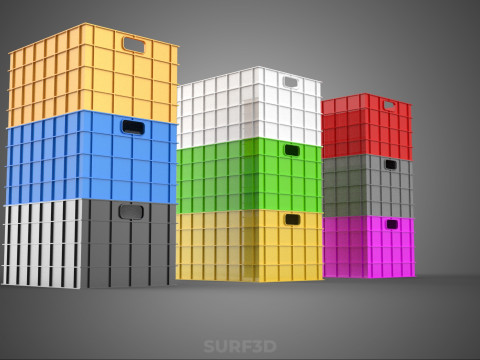

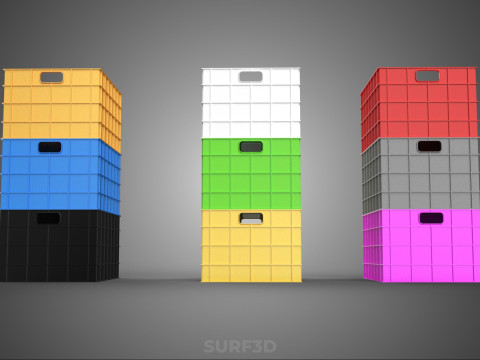

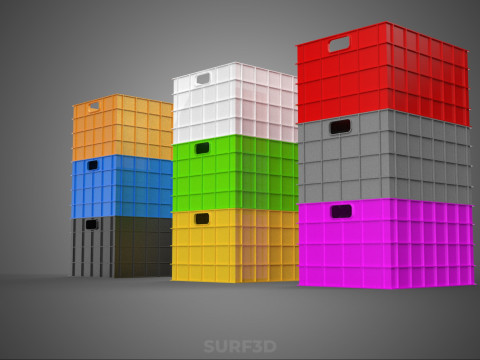

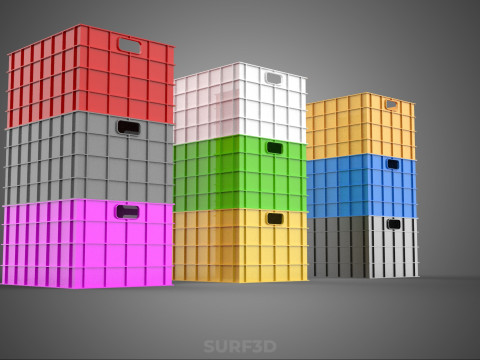

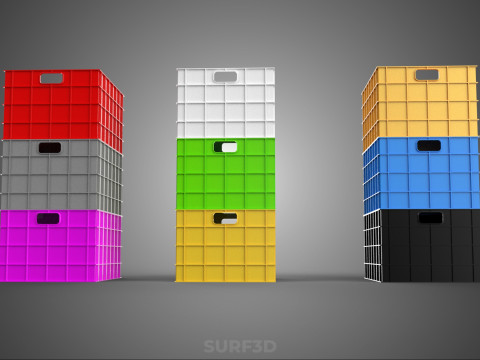

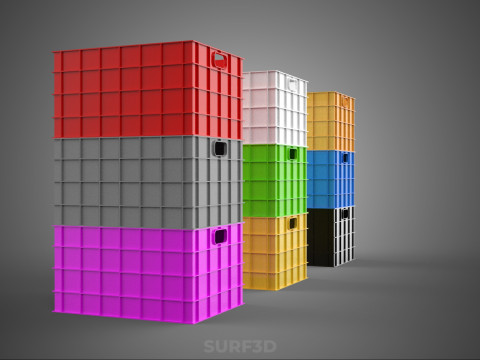

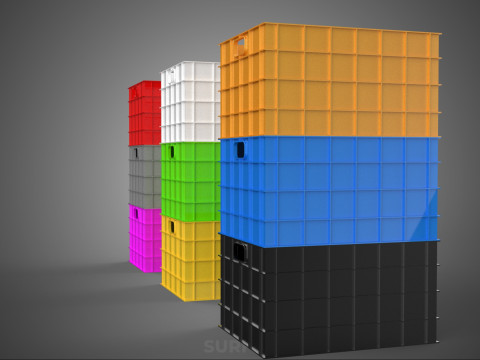

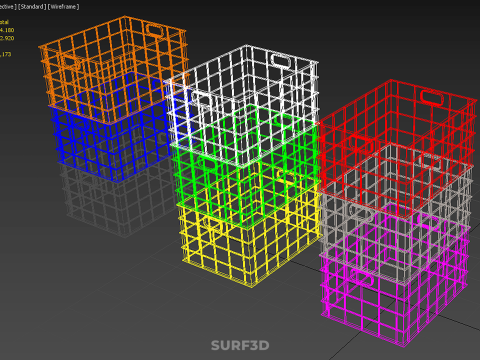

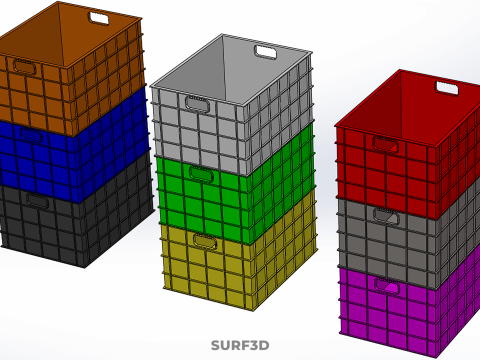

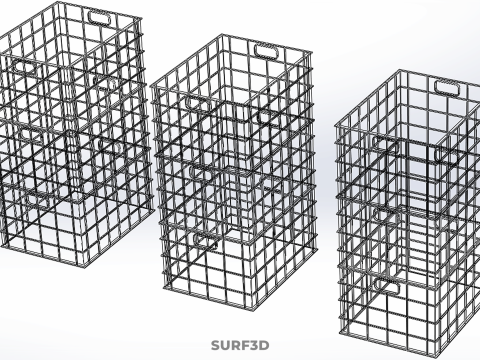

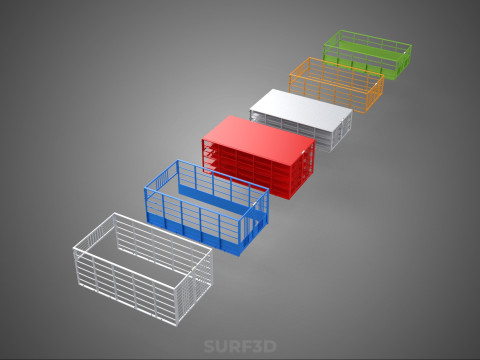

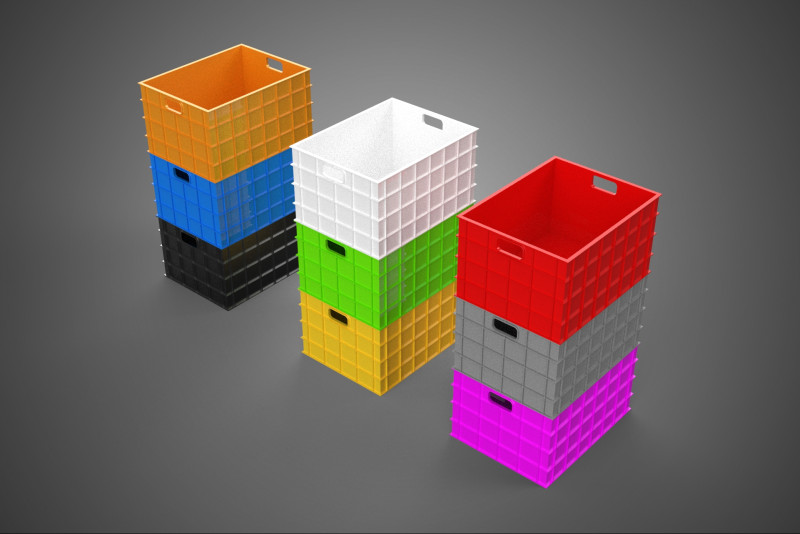

스택 쌓임형 쌓을 수 있는 플라스틱 상자 상자 컨테이너 보관함 3D 모델

- 작성자에게 제품 지원 요청

- 이용 가능한 포맷:

- 아이템 ID:613458

- 날짜: 2025-11-23

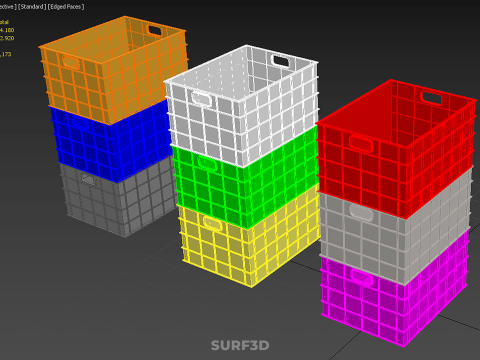

- 폴리곤:54180

- 버텍스:52920

- 애니메이티드:No

- 텍스쳐드:No

- 리그드:No

- 재료:

- 로우 폴리곤:No

- 컬렉션:No

- UVW 매핑:No

- 플러그인 사용 됨:No

- 프린트 준비:No

- 3D 스캔:No

- 성인용 콘텐츠:No

- PBR:No

- AI 훈련:No

- 지오메트리:Poly NURBS

- 언래핑 된 UVs:Unknown

- 조회:50

설명

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

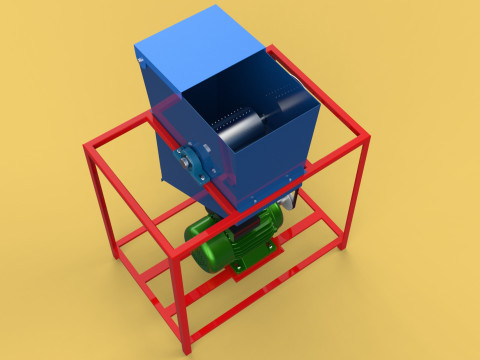

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

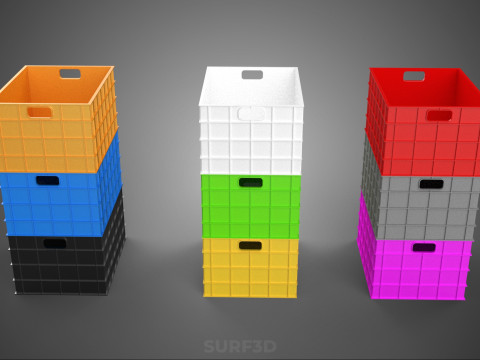

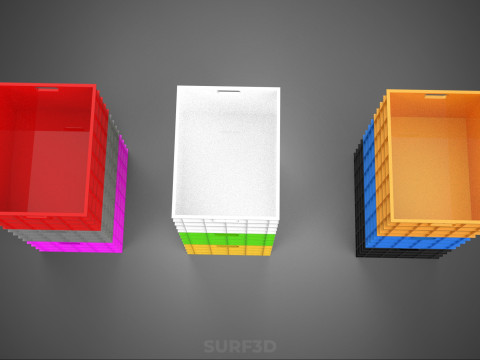

**Modular Interlocking Polymer Storage Units (Stackable Crates)**

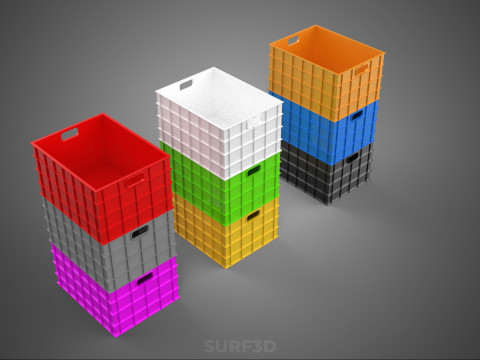

A stackable plastic crate, box, or container—formally known as a Modular Interlocking Polymer Storage Unit, or commonly referred to in logistics as a tote box, industrial bin, or Euro container—is a rigid receptacle specifically engineered for optimized storage density and integrated material handling within the supply chain. These units are defined by their capacity for high-density vertical aggregation ("stacking") and their robust design enabling systematic linear organization ("row" formation).

### I. Definition and Typology

These containers are typically constructed from high-durability thermoplastic polymers, primarily High-Density Polyethylene (HDPE) or Polypropylene (PP), selected for their resistance to impact, chemical solvents, moisture, and extreme temperature fluctuations. Their defining characteristic is the geometric design which allows multiple identical units to be placed one atop the other without compressing the contents of the lower unit, maintaining a stable, unified column (a "stack").

Typologically, stackable plastic containers fall into several categories:

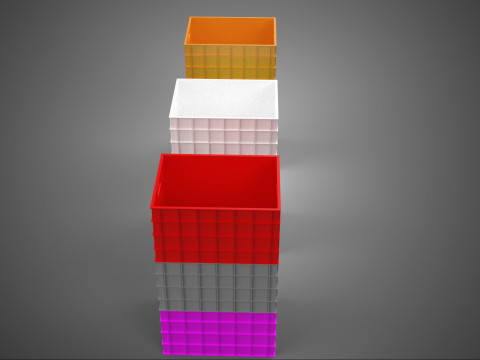

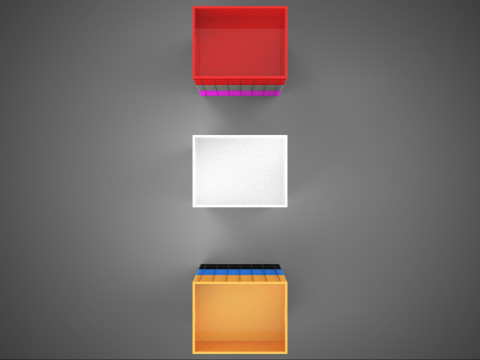

1. **Straight-Wall Containers (Stack-Only):** Designed with perpendicular internal walls to maximize internal cubic capacity. These utilize reinforced rims and load-bearing corner columns to achieve stability in high stacks.

2. **Nestable Containers (Tapered):** Featuring tapered walls, these units allow for "nesting" (one fitting inside the other) when empty, significantly reducing the volume required for storage or return logistics. They often require specialized rotating or lugged rims to facilitate stacking when full.

3. **Collapsible Containers:** Units designed with hinged sidewalls that fold flat when empty. They offer the density benefits of nesting while maintaining the straight-wall structure when deployed.

### II. Engineering and Design Characteristics

The sophisticated engineering of these crates ensures safety, longevity, and efficiency in automated and manual handling environments:

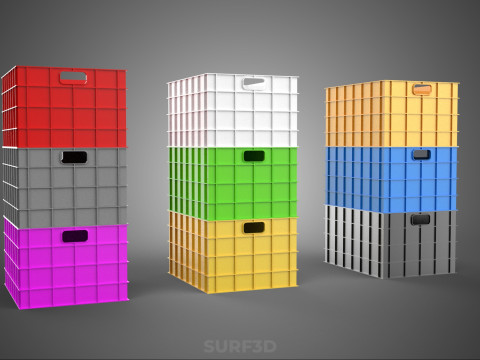

* **Interlocking Mechanisms:** The rims or base structures often incorporate positive-locking features (e.g., recessed grooves, molded lugs, or specialized lips) that prevent lateral shifting or slipping between adjacent units in a vertical stack or a dense horizontal row. This stability is critical for seismic safety and high-bay warehouse operations.

* **Dimensional Standardization:** Many industrial containers adhere to the **Euro Container Standard (Euro Norm)**, where the base footprint is a modular divisor of the 1200x800mm or 1200x1000mm standard pallet size (e.g., 600x400mm, 400x300mm). This standardization optimizes cubic utilization on standard transportation pallets and minimizes void space in shipping containers and truck trailers.

* **Load Bearing:** The base and walls are often ribbed or cross-braced to distribute heavy internal loads and resist deflection, ensuring the container remains compatible with automated conveyor systems and racking interfaces.

* **Ergonomics and Hygiene:** Integrated handles facilitate manual lifting, and the polymer construction allows for easy sterilization, making them suitable for sensitive industries like food processing (meeting FDA standards) and pharmaceuticals.

### III. Applications and Logistical Integration

Stackable plastic crates are foundational to modern closed-loop distribution and supply chain management. They are used extensively across various sectors:

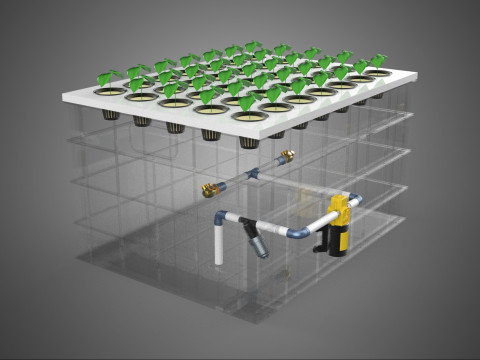

* **Warehousing and Distribution:** Used for efficient inventory buffering, sequencing, and optimizing rack space. The ability to form stable, high stacks allows for maximum utilization of vertical storage capacity.

* **Manufacturing (WIP):** Essential for organizing and transporting Work-In-Progress (WIP) components between production stages, often integrated directly with automated guided vehicles (AGVs) or robotic pick-and-place systems.

* **Retail and E-commerce:** Utilized for back-stock storage, store-to-store transfer, and organizing fulfillment centers, often incorporating features for rapid identification such as label holders or embedded RFID tags.

The capacity to form stacks and linear rows defines their operational benefit: **Stackability** maximizes cubic density, while the uniform base dimensions facilitate dense **Row** formation within automated storage and retrieval systems (AS/RS), ensuring seamless machine interface and inventory flow.

KEYWORDS: Polymer, Stackability, HDPE, Polypropylene, Logistics, Warehousing, Euro Container, Modular, Interlocking, Tote Box, Storage Crate, Industrial Bin, Standardization, Palletization, Inventory Control, Material Handling, Supply Chain, Nesting, Collapsible, Unit Load, Distribution, AS/RS, Automated Systems, Vertical Storage, Dimensional Stability, Crating, Reinforced, Transport, Closed-Loop, Ergonomics.

다른 포맷이 필요하세요?

다른 포맷이 필요하시면, 새로운 지원 티켓을 열어 요청하세요. 저희는 3D 모델을 다음으로 변환할 수 있습니다: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 자유 형식 변환우리는 3D 장면을 변환하지 않습니다 .step, .iges, .stp, .sldprt와 같은 형식도 포함됩니다.!

사용 정보

스택 쌓임형 쌓을 수 있는 플라스틱 상자 상자 컨테이너 보관함 - 기본 또는 확장 라이선스에 따라 이 로열티 프리 3D 모델을 개인적 및 상업적 목적으로 사용할 수 있습니다.기본 라이선스는 디지털 광고, 디자인 및 시각화 프로젝트, 비즈니스 소셜 미디어 계정, 네이티브 앱, 웹 앱, 비디오 게임, 그리고 물리적 또는 디지털 최종 제품(무료 및 유료 모두)을 포함한 대부분의 표준 사용 사례를 포괄합니다.

확장 라이선스는 기본 라이선스에 따라 부여된 모든 권리를 포함하며 사용 제한이 없으며, 로열티 프리 조건 하에 3D 모델을 상업적 프로젝트에 무제한으로 사용할 수 있습니다.

더 보기

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी