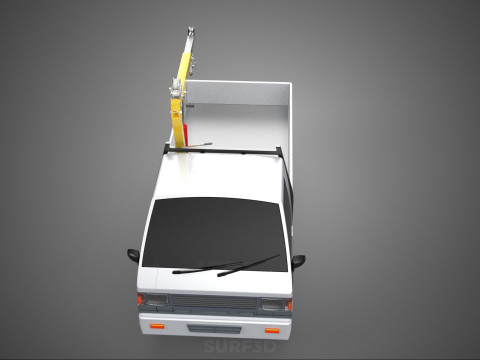

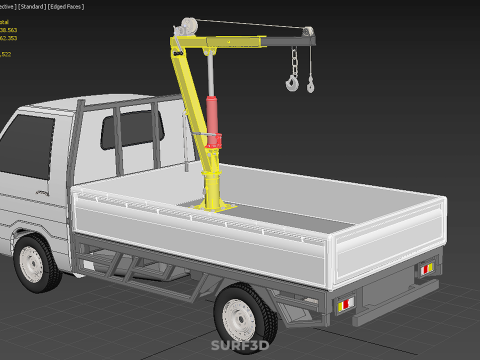

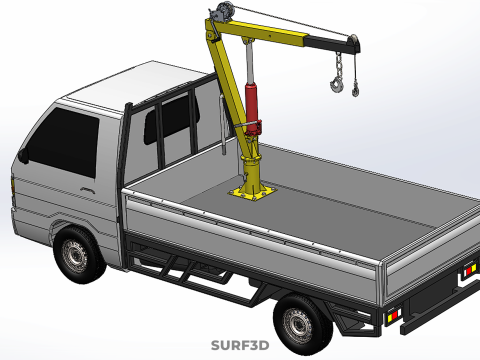

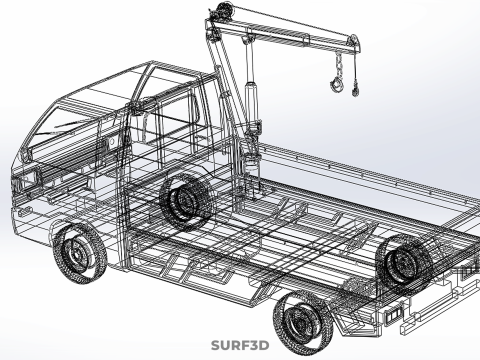

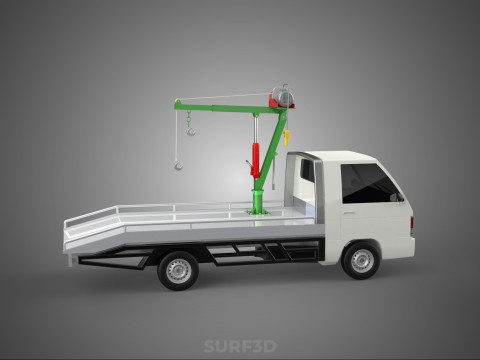

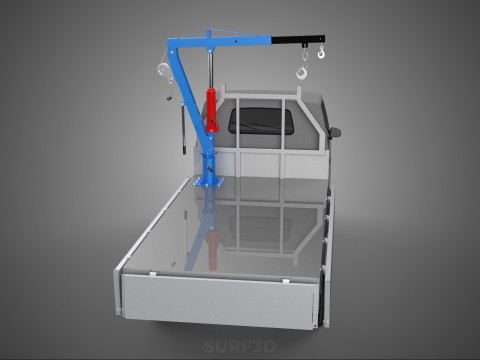

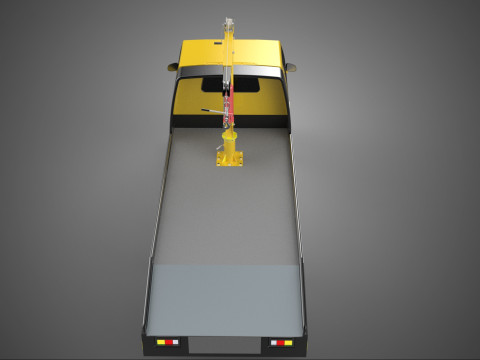

SWIVEL JIB CRANE LIFTING WINCH HOIST HOOK FLATBED TRUCK PICKUP 3D 모델

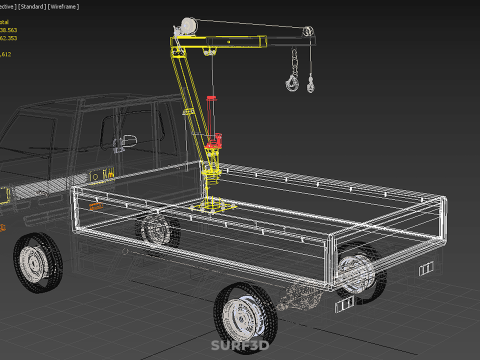

- 이용 가능한 포맷: Collada (.dae) 12.92 MBBlender3D (.blend) 12.88 MBIGES (.iges) 8.17 MBACIS(.sat) 15.86 MBStereolithography (.stl) 10.26 MBWavefront OBJ (.obj) 9.96 MBRhinoceros (.3dm) 33.03 MBGLB (.glb / .gltf) 6.38 MB3D Studio (.3ds) 4.79 MBAutodesk FBX (.fbx) 16.86 MBSTEP (.step) 7.78 MBSketchUp (.skp) 12.38 MBAutodesk 3DS MAX (.max) 27.90 MBAutodesk AutoCAD (.dwg) 18.91 MB

- 폴리곤:738563

- 버텍스:562353

- 애니메이티드:No

- 텍스쳐드:No

- 리그드:No

- 재료:

- 로우 폴리곤:No

- 컬렉션:No

- UVW 매핑:No

- 플러그인 사용 됨:No

- 프린트 준비:No

- 3D 스캔:No

- 성인용 콘텐츠:No

- PBR:No

- AI 훈련:No

- 지오메트리:Poly NURBS

- 언래핑 된 UVs:Unknown

- 조회:186

- 날짜: 2025-08-16

- 아이템 ID:592911

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and ****ed for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

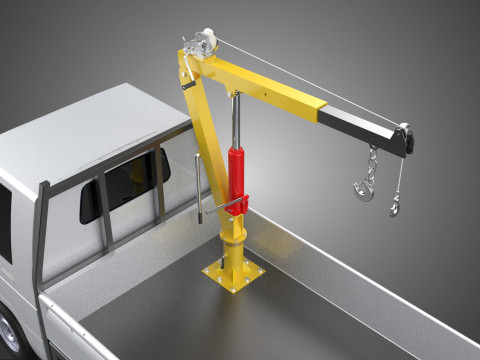

A swivel jib crane lifting system, integrated with a hand-crank ***ch hoist and hook, mounted on a flatbed truck pickup, represents a highly versatile and portable material handling solution. This assembly is engineered to facilitate the manual lifting, lowering, and lateral positioning of moderate loads in diverse operational environments, particularly where fixed lifting equipment is impractical or unavailable. Its primary utility lies in providing localized lifting capabilities combined with vehicular mobility.

**Components:**

The system comprises several inter-dependent components:

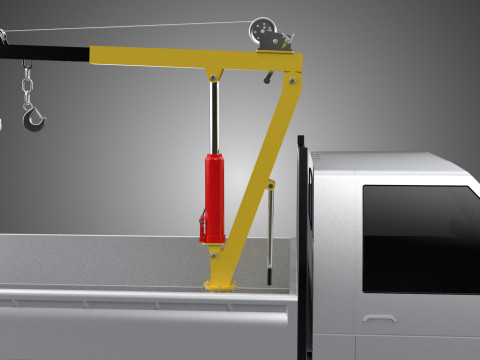

* **Swivel Jib Crane:** This is the primary structural element for lifting. It typically consists of a vertical mast or column securely anchored to the flatbed, from which a horizontal or slightly inclined boom (jib arm) extends. The crucial "swivel" or "sle***g" mechanism allows the jib arm to rotate horizontally, commonly through 180 to 360 degrees, around the mast's axis. This rotational capability enables the operator to move loads from the pick-up point to various positions within the crane's radius without repositioning the vehicle. The design often incorporates a robust base plate for secure bolt-down or weld-on installation to the truck's frame.

* **Hand Crank ***ch Hoist:** Functioning as the lifting mechanism, this component is a manually operated device designed to multiply input force through a system of gears. It typically consists of a durable steel frame, a rotating drum around which a wire rope (or synthetic cable) is spooled, a hand crank for operation, and a gearing system that provides mechanical advantage. This mechanical advantage allows a single operator to lift loads significantly heavier than they could by direct manual effort. A pawl or braking mechanism is usually integrated to prevent unintentional load descent and to hold the load securely in position. The ***ch can be mounted directly on the jib arm or on the mast, with the cable routed over a pulley at the end of the jib.

* **Hoist Hook:** Attached to the free end of the ***ch's wire rope, the hoist hook is the direct interface with the load. These hooks are typically constructed from high-strength alloy steel, designed to resist deformation under rated loads. They commonly feature a safety latch or clevis to prevent accidental disengagement of the load during lifting or transport, ensuring secure attachment.

* **Flatbed Truck Pickup:** This vehicle serves as the mobile platform for the entire lifting apparatus. A "flatbed truck pickup" implies a light-duty to medium-duty truck chassis featuring an open, flat cargo bed, typically devoid of side walls or a roof. This design provides an ideal, stable, and accessible surface for mounting the crane, offering excellent maneuverability, especially in confined spaces, and enabling the transport of the crane assembly along with the lifted materials. The truck's chassis, suspension, and frame must be adequately robust to support the crane's static weight and the dynamic forces generated during lifting operations.

**Functionality and Operation:**

Operation commences with positioning the flatbed truck so that the crane is within the effective reach of the object to be lifted. The hand crank ***ch is then manually operated to lower the hoist hook, which is subsequently secured to the load using appropriate rigging. Subsequent cranking of the ***ch handle retracts the cable, lifting the load vertically. Once lifted, the swivel mechanism of the jib crane allows the operator to manually rotate the jib arm, s***ging the suspended load horizontally to a desired location on the truck bed or an adjacent area. The load is then safely lowered by carefully reversing the ***ch operation, utilizing its integrated braking mechanism for controlled descent. The entire system is characterized by its independence from external power sources, relying solely on human effort for operation.

**Applications:**

This configuration is highly valued in scenarios requiring localized, mobile, and unpowered lifting capabilities. Common applications include:

* **Field Service & Maintenance:** Lifting and positioning heavy components (e.g., generators, pumps, tools, equipment parts) onto or off service vehicles at remote sites or construction areas.

* **Construction:** Small-scale material handling, such as moving construction materials, tools, or light equipment on job sites where larger cranes are not feasible.

* **Agriculture:** Loading and unloading feed bags, agricultural equipment parts, or small machinery on farms.

* **Utility & Municipal Work:** Handling poles, pipes, valves, or equipment for roadside repairs or installations.

* **Workshop & Garage Use:** Moving engines, transmissions, or other heavy parts within a workshop that also requires mobility ***ween bays or to transport items.

* **Salvage & Recovery:** Lifting lighter salvage items or assisting in recovery operations.

**Advantages and Limitations:**

* **Advantages:**

* **Portability:** Inherits mobility from the host vehicle, enabling rapid deployment to various locations.

* **Independence:** Operates without external power, making it ideal for remote or off-grid environments where electricity or hydraulic power is unavailable.

* **Cost-Effectiveness:** Generally less expensive to purchase and maintain compared to hydraulic or electrically powered cranes.

* **Simplicity:** Straightforward mechanical design leads to ease of operation and maintenance, requiring minimal specialized training.

* **Versatility:** Adaptable to a wide range of light-to-medium lifting tasks across multiple industries.

* **Limitations:**

* **Lifting Capacity:** Limited by the manual input force and the structural integrity of the crane, typically suited for lighter loads than powered equivalents.

* **Speed:** Lifting and lowering operations are significantly slower and more labor-intensive than powered systems.

* **Ergonomics:** Requires physical effort, which can be fatiguing for repetitive or heavy lifts, potentially leading to operator strain.

다른 포맷이 필요하시면, 새로운 지원 티켓을 열어 요청하세요. 저희는 3D 모델을 다음으로 변환할 수 있습니다: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 우리는 3D 장면을 변환하지 않습니다 .step, .iges, .stp, .sldprt와 같은 형식도 포함됩니다.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी