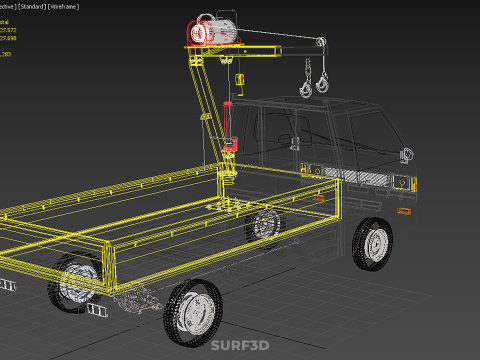

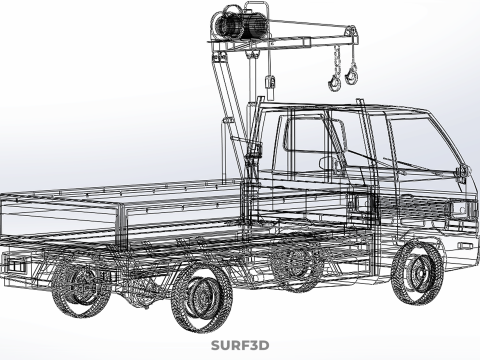

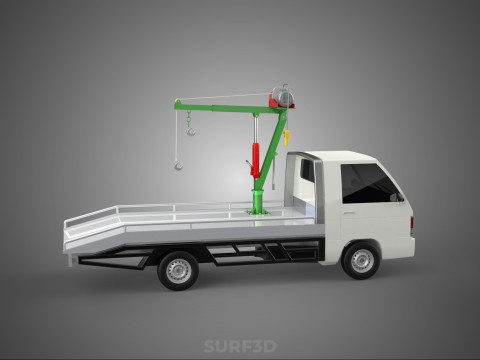

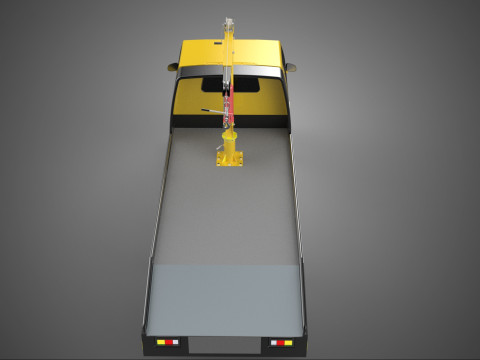

PICKUP TRUCK ELECTRIC WINCH HOIST LIFT BOOM HYDRAULIC CRANE JIB 3D Модель

- Доступні формати: SketchUp (.skp) 9.18 MBAutodesk 3DS MAX (.max) 24.32 MBRhinoceros (.3dm) 27.72 MBAutodesk FBX (.fbx) 12.72 MBACIS(.sat) 15.45 MBGLB (.glb / .gltf) 5.23 MBSTEP (.step) 7.57 MB3D Studio (.3ds) 3.91 MBBlender3D (.blend) 9.95 MBIGES (.iges) 7.19 MBCollada (.dae) 10.99 MBStereolithography (.stl) 8.18 MBWavefront OBJ (.obj) 7.67 MBAutodesk AutoCAD (.dwg) 18.80 MB

- Полігони:527572

- Вершини:427698

- Анімована:No

- Текстури:No

- Скелет:No

- Матеріали:

- Лоу-полі:No

- Колекція:No

- UVW зображення:No

- Плагіни:No

- Готовність до друку:No

- 3D Скан:No

- Зміст для дорослих:No

- PBR:No

- ШІ Навчання:No

- Геометрія:Poly NURBS

- Розгорнуті UVs:Unknown

- Перегляди:171

- Дата: 2025-08-16

- ID Товару:592834

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

A "Pickup Truck with Electric ***ch Hoist Lift Boom and Manual Hydraulic Crane Jib" designates a specialized mobile lifting system integrated onto a light-duty or medium-duty pickup truck chassis. This configuration provides versatile material handling capabilities, combining electrically powered vertical lifting with hydraulically assisted manual horizontal manipulation, suitable for a range of applications where portability and on-demand lifting are critical.

The foundational element is a robust pickup truck, selected for its inherent mobility, payload capacity, and the structural integrity of its frame, which serves as the primary mounting platform for the lifting apparatus. The choice ***ween two-wheel drive (2WD) and four-wheel drive (4WD) variants is determined by the required accessibility to diverse terrains and job site conditions. The truck's electrical system, typically 12V DC, powers the electric components of the lifting mechanism.

The integrated lifting system comprises two primary components:

1. **Electric ***ch Hoist Lift Boom:** This constitutes the main vertical lifting mechanism. It consists of a high-strength steel boom, which can be fixed, telescoping, or articulated, securely mounted to the truck's bed or chassis, often via a reinforced pedestal or mast. An electric ***ch, powered by the truck's battery, is integrated into or mounted near the boom. This ***ch utilizes a steel cable and hook assembly to provide the primary lifting and lowering force. Operations are typically managed via a wired remote pendant, offering precise control over speed and direction. Key safety features often include overload protection, thermal cut-offs to prevent motor damage, and automatic braking mechanisms that engage upon power loss or control release, ensuring the load is held securely. Lift capacities vary significantly based on the ***ch's rating, the boom's structural design, and its operational extension, typically ranging from hundreds to several thousand pounds.

2. **Manual Hydraulic Crane Jib:** Complementing the electric hoist, the manual hydraulic crane jib provides enhanced horizontal reach and fine-tuned angular positioning. This jib can be an articulated extension of the main boom or a distinct, independently mounted unit. It operates via a hand-pumped hydraulic cylinder and lever system, allo***g for precise manual extension, retraction, and sometimes sle***g (rotation) of the load within a confined radius. This manual control is particularly advantageous for delicate load placement, navigating obstructions, or achieving exact alignment, especially for lighter loads or the final stages of positioning. While offering precision, its lifting capacity is generally lower than that of the electric ***ch and boom, limited by the mechanical advantage of the hydraulic system and operator effort.

**Operational Aspects and Safety:**

The overall load capacity of the system is constrained by the weakest link, which may be the truck's gross vehicle weight rating (GVWR), the boom's structural limits at maximum extension, or the stability of the entire setup. Stability is paramount during lifting operations, often necessitating the deployment of integrated or optional outriggers or stabilizers to counteract the overturning moments generated by off-center loads. Adherence to load charts, proper weight distribution, and a thorough understanding of the center of gravity are critical for safe operation. Operators require specialized training in load securement techniques, safe operating distances, recognition of power line hazards, and the specific controls of both the electric ***ch and the manual hydraulic jib. Routine maintenance, including inspection of cables, hydraulic lines, electrical connections, and structural components, is essential for ensuring ongoing reliability and safety compliance.

**Applications:**

This versatile equipment configuration finds widespread application across various industries:

* **Field Service and Maintenance:** For lifting heavy components, generators, or tools at remote job sites.

* **Utility and Telecommunications:** Assisting with pole setting, transformer installation, or cable handling.

* **Construction:** Moving small building materials, tools, or aiding in light equipment placement.

* **Agriculture:** Lifting feed bags, engine components, or farm equipment.

* **Roadside Assistance:** Performing light recovery or assisting with tire changes for commercial vehicles.

* **Logistics and Delivery:** Facilitating the loading and unloading of items that cannot be handled manually.

* **Emergency Services:** For specialized recovery operations or aid in specific scenarios.

**Advantages and Limitations:**

The primary advantages of this integrated system include its enhanced mobility, the capability to operate independently of external power sources, its cost-effectiveness compared to larger dedicated cranes, and the versatility derived from having both a powerful vertical lift and precise manual horizontal positioning. Limitations encompass lower lift capacities relative to industrial-grade cranes, inherent reliance on the stability of the host truck, and the imperative for proficient operator skill in simultaneously managing both powered and manual systems.

KEYWORDS: Pickup truck, electric ***ch, hoist, lift boom, hydraulic crane, manual jib, material handling, mobile crane, utility vehicle, field service, construction equipment, versatile lifting, powered lift, load capacity, stability, outriggers, remote control, heavy lifting, light duty, medium duty, industrial applications, vehicle modification, equipment transport, cargo handling, emergency services, agricultural equipment, telecommunications, self-contained, portable lifting.

Якщо вам потрібен інший формат, будь ласка, зробіть запит за допомогою тікета підтримки. Ми можемо конвертувати 3D моделі: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Ми не конвертуємо 3d сцени і такі формати, як .step, .iges, .stp, .sldprt тощо!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी