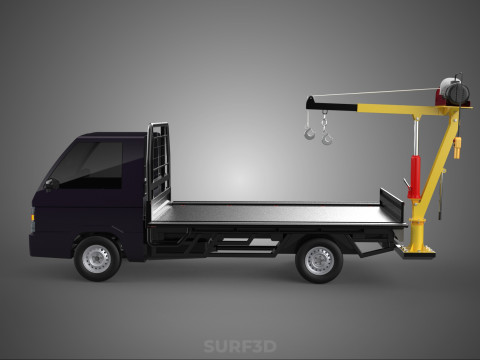

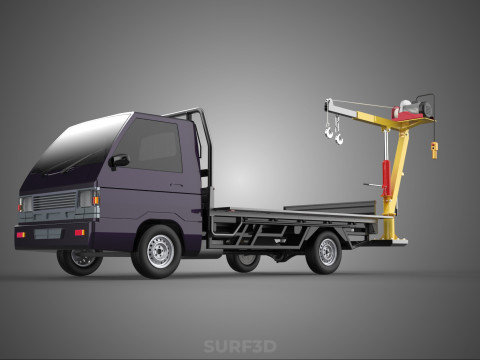

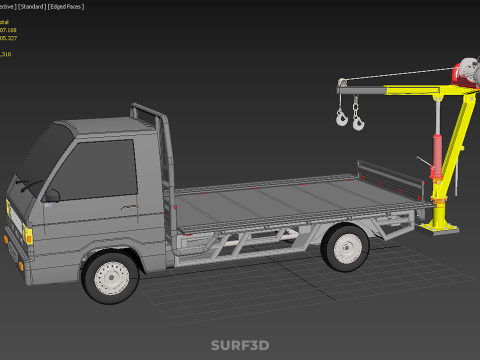

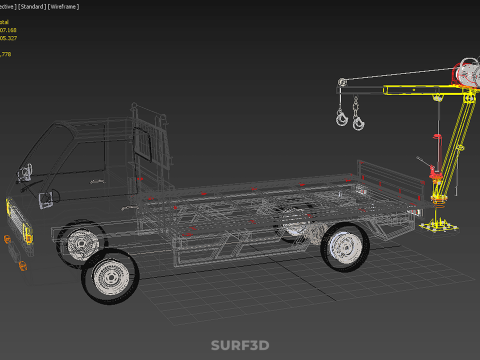

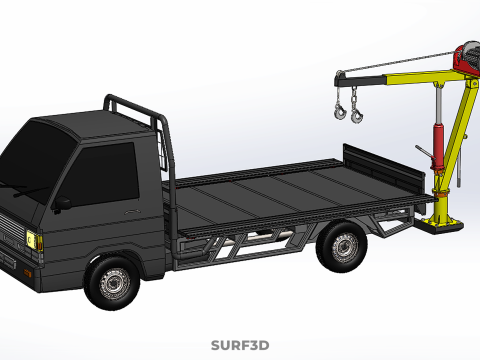

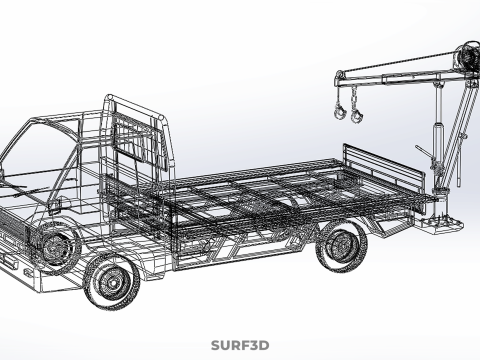

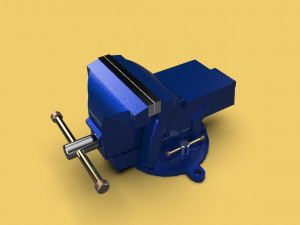

ЛЕБІДКА ПІДЙОМНИК ЗАДНЬОГО ВСТАНОВЛЕННЯ СТРІЛИ КРАНА ПІДІЙМАННЯ БЛОКТОВА ВАНТАЖКА ПІКАП 3D Модель

- Запит на підтримку продукту від автора

- Доступні формати:

- ID Товару:594494

- Дата: 2025-08-24

- Полігони:607168

- Вершини:505327

- Анімована:No

- Текстури:No

- Скелет:No

- Матеріали:

- Лоу-полі:No

- Колекція:No

- UVW зображення:No

- Плагіни:No

- Готовність до друку:No

- 3D Скан:No

- Зміст для дорослих:No

- PBR:No

- ШІ Навчання:No

- Геометрія:Poly NURBS

- Розгорнуті UVs:Unknown

- Перегляди:254

Опис

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

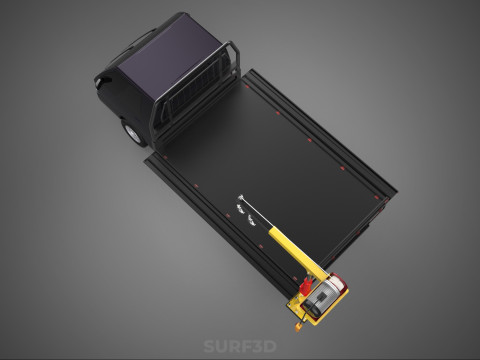

A **rear-mounted boom crane hoist winch lifting flatbed truck pickup** is a highly specialized and multi-functional commercial vehicle designed for both material handling and transportation across various industries. This descriptive designation precisely identifies a mobile lifting platform built upon a light to medium-duty truck chassis, typically derived from a heavy-duty pickup truck or a purpose-built commercial platform. It integrates a flatbed cargo area with a hydraulically-operated boom crane system and hoist winch, strategically positioned at the rear of the vehicle.

The **base vehicle** component, characterized as a "flatbed truck pickup," is fundamental to its versatility. It generally utilizes a robust automotive chassis, often retaining the familiar cab structure of a conventional pickup truck, which offers advantages in terms of driver comfort, maneuverability, and ease of operation in diverse environments. The standard pickup bed is replaced by a flat, open cargo platform – the "flatbed." This configuration provides an expansive and flexible space for transporting a wide array of materials, tools, and equipment, often featuring integrated tie-down points, stake pockets, or sideboards to secure freight. The "pickup" aspect implies a chassis that balances payload capacity with agility, making it particularly suitable for urban settings, job sites with restricted access, and general utility work where the footprint of a larger, dedicated crane truck would be impractical.

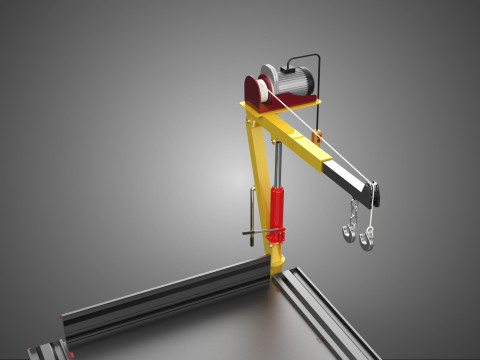

The **crane system** constitutes the core lifting apparatus. Its "rear-mounted" placement refers to its installation either immediately behind the vehicle's cab or at the extreme rear of the flatbed, a position that offers specific operational advantages regarding reach over the rear and sides of the vehicle. The "boom crane" itself is a hydraulically powered mechanism engineered for extending, retracting, and/or articulating to facilitate the precise positioning of loads. Common types include:

1. **Telescopic booms:** These extend linearly, offering simplicity, robustness, and good vertical reach.

2. **Articulating (*******) booms:** These feature multiple sections connected by hinged joints, allowing them to fold and unfold. This design provides exceptional maneuverability, the ability to reach around obstacles, and a highly compact stowed position.

The "hoist winch" is integral to the lifting function. It comprises a drum around which a high-strength steel wire rope or cable is spooled, driven by a powerful hydraulic motor. This wire rope, typically terminating in a hook block, provides the essential vertical "lifting" capability, enabling loads to be raised, lowered, and accurately placed. The entire crane mechanism is powered by the truck's engine via a Power Take-Off (PTO) unit, which drives a hydraulic pump, converting mechanical energy into hydraulic pressure to operate the system.

For safe and stable operation, especially when lifting heavy loads, these vehicles are invariably equipped with **outriggers or stabilizers**. These hydraulically-actuated support legs extend outwards and downwards from the vehicle's chassis, effectively increasing the base of support and counteracting the overturning forces generated during lifting operations. Modern systems often incorporate advanced safety features such as load moment indicators (LMIs) to prevent overloading and anti-two-block devices to prevent the hoist line from being pulled into the boom tip, safeguarding both the equipment and the operator.

The **applications** for rear-mounted boom crane flatbed truck pickups are extensive and diverse across numerous industries. They are widely utilized in:

* **Utility Services:** For installing and maintaining power poles, transformers, streetlights, and conducting general line work.

* **Construction:** Handling lighter building materials, tools, small pre-fabricated components, and moving equipment on job sites.

* **Landscaping:** Precisely placing large trees, boulders, or irrigation components.

* **HVAC and Mechanical Trades:** Lifting and positioning heavy air conditioning units, generators, or various industrial equipment.

* **General Material Handling and Logistics:** Loading and unloading freight, delivering bulky items, and assisting with various field service tasks where on-site lifting is required in conjunction with transport.

**Advantages** of this integrated vehicle type include its unparalleled mobility and relatively compact footprint compared to larger, dedicated cranes, allowing access to confined spaces; its dual capability for both lifting and transporting materials, which often reduces the need for multiple specialized vehicles; and its cost-effectiveness for light-to-medium duty lifting tasks, with capacities typically ranging from a few hundred pounds to several tons. **Operational safety** is paramount, demanding comprehensive operator training, strict adherence to load charts, regular maintenance, and diligent use of all safety features and stabilization systems to prevent accidents and ensure efficient and reliable performance.

KEYWORDS: Commercial Vehicle, Mobile Crane, Flatbed Truck, Pickup Truck, Rear Mounted, Boom Crane, Hydraulic Crane, Hoist Winch, Lifting Equipment, Material Handling, Utility Truck, Service Truck, ******* Boom, Telescopic Boom, Outriggers, Stabilizers, PTO, Power Take-Off, Hydraulic System, Load Moment Indicator, Anti-Two-Block, Construction Equipment, Landscaping Equipment, Field Service, Transportation, Versatile Vehicle, Light Duty Crane, Medium Duty Crane, Cargo Platform, Vehicle Mounted Crane

Потрібно більше форматів?

Якщо вам потрібен інший формат, будь ласка, зробіть запит за допомогою тікета підтримки. Ми можемо конвертувати 3D моделі: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Безкоштовна КонвертаціяМи не конвертуємо 3d сцени і такі формати, як .step, .iges, .stp, .sldprt тощо!

Інформація про використання

ЛЕБІДКА ПІДЙОМНИК ЗАДНЬОГО ВСТАНОВЛЕННЯ СТРІЛИ КРАНА ПІДІЙМАННЯ БЛОКТОВА ВАНТАЖКА ПІКАП - Ви можете використовувати цю безкоштовну 3D модель як для особистих, так і для комерційних цілей відповідно до Базової або Розширеної ліцензії.Базова ліцензія охоплює більшість стандартних випадків використання, включаючи цифрову рекламу, проекти дизайну та візуалізації, бізнес-акаунти в соціальних мережах, нативні додатки, веб-додатки, відеоігри та фізичні або цифрові кінцеві продукти (як безкоштовні, так і продавані).

Розширена ліцензія включає всі права, надані за Базовою ліцензією, без обмежень використання, та дозволяє використовувати 3D модель у необмеженій кількості комерційних проектів на умовах безкоштовних роялті.

Детальніше

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी