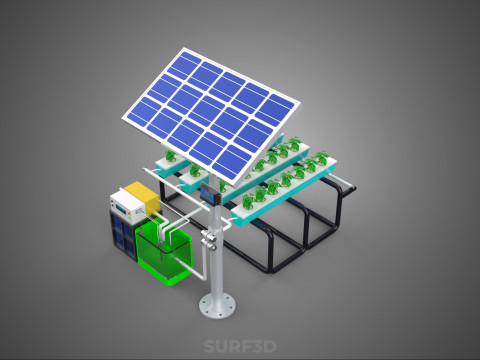

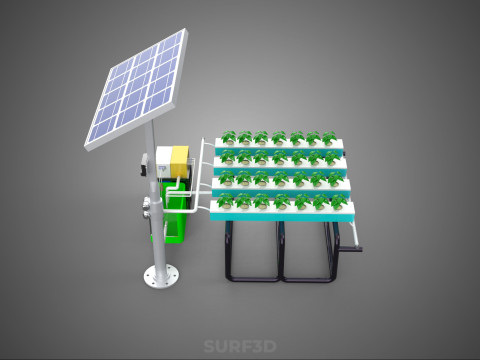

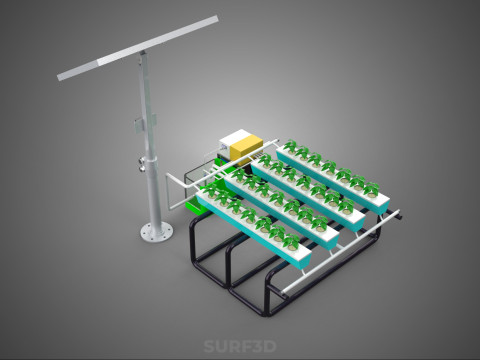

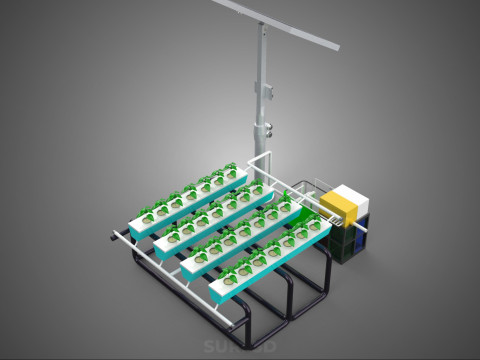

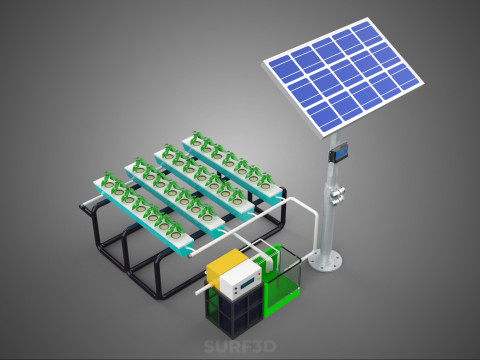

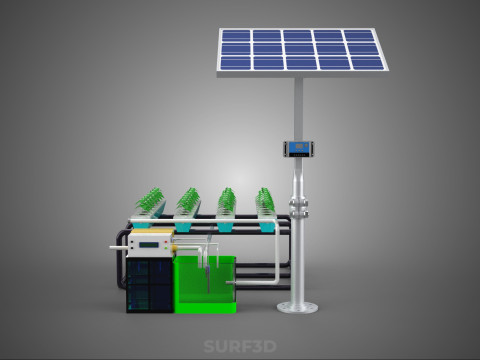

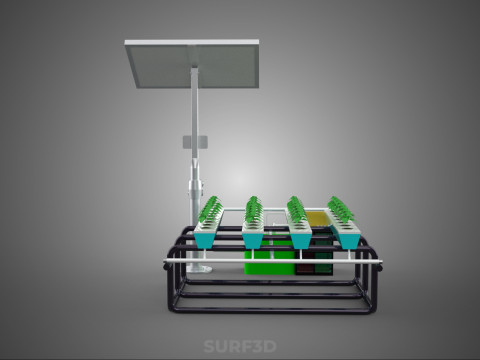

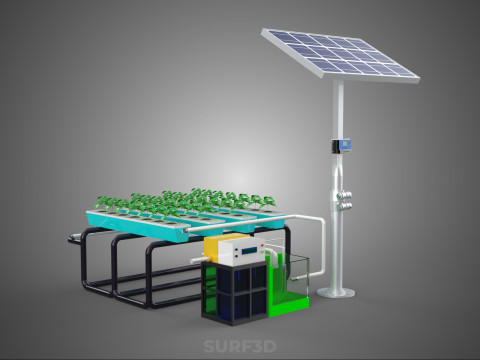

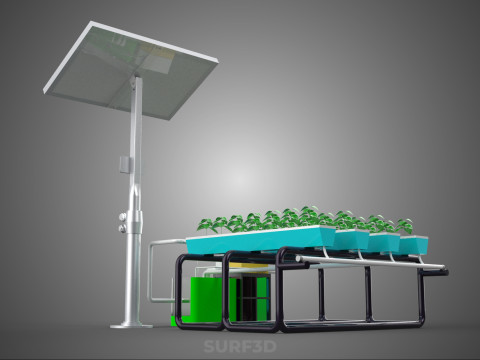

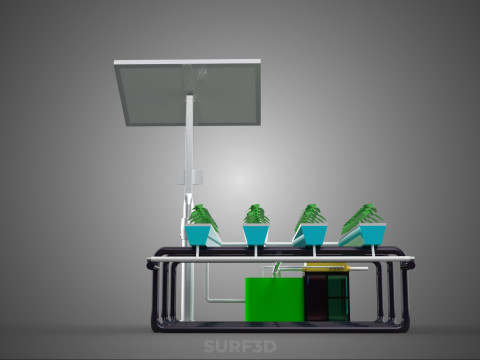

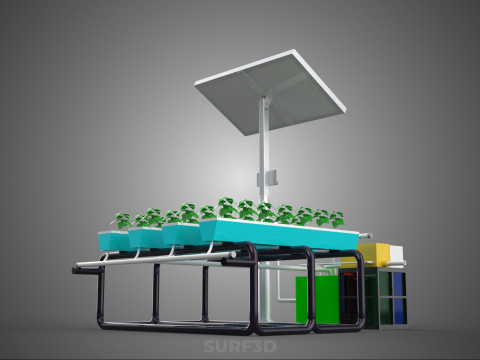

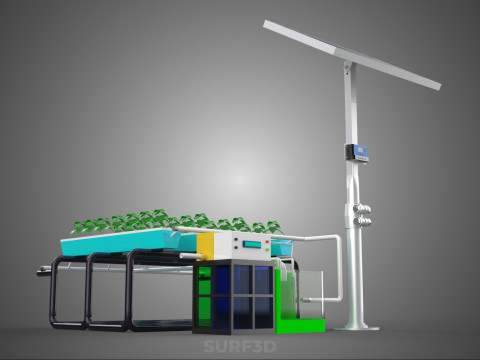

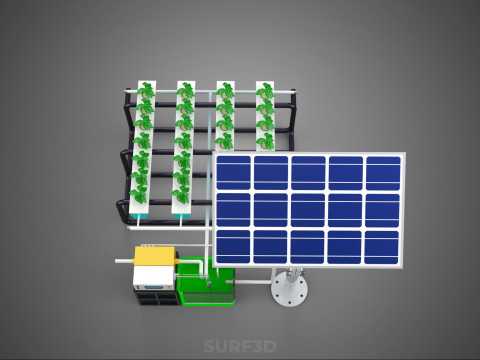

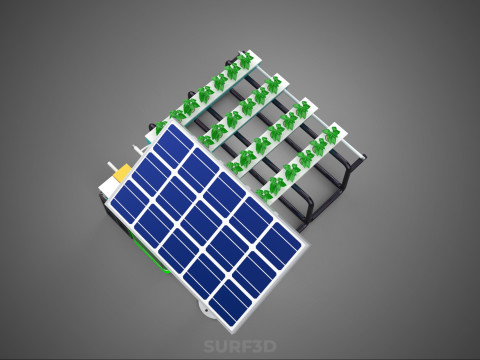

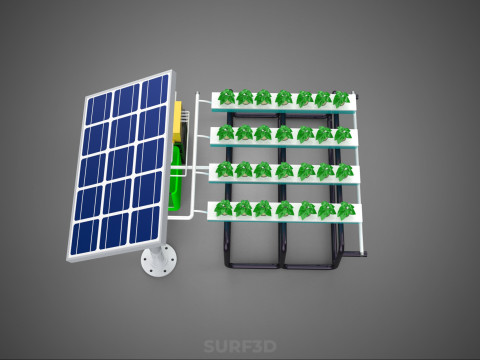

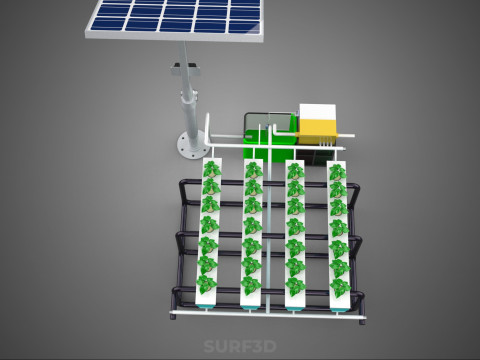

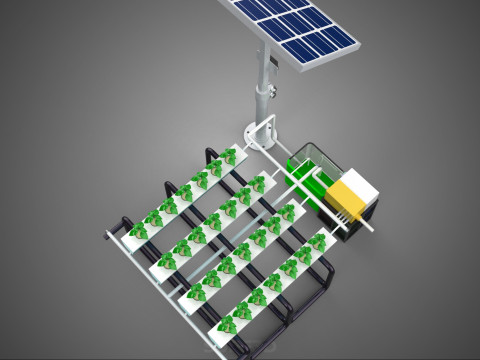

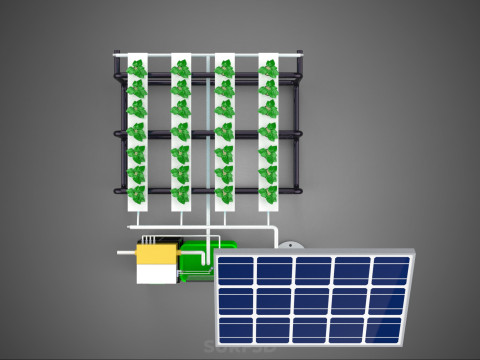

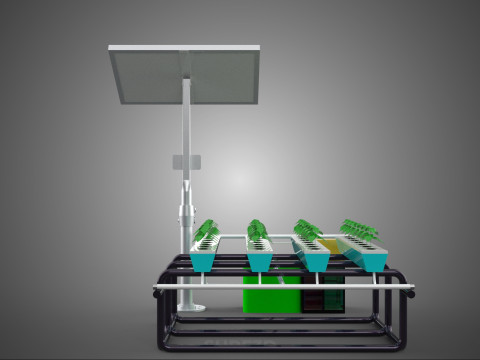

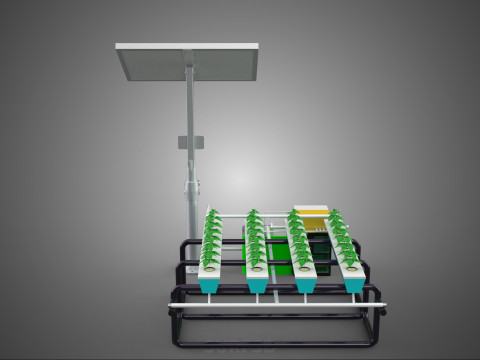

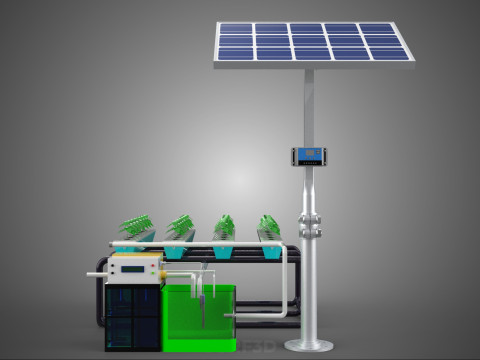

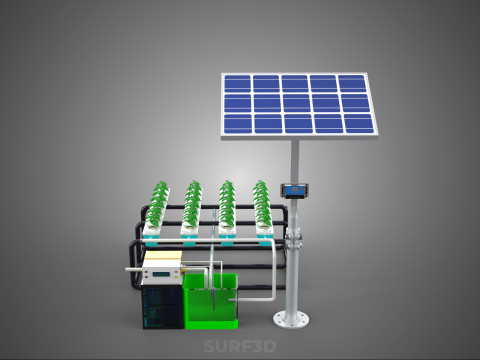

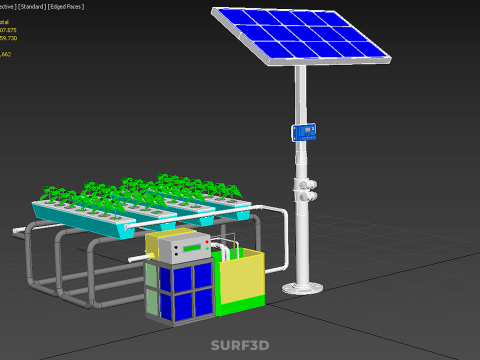

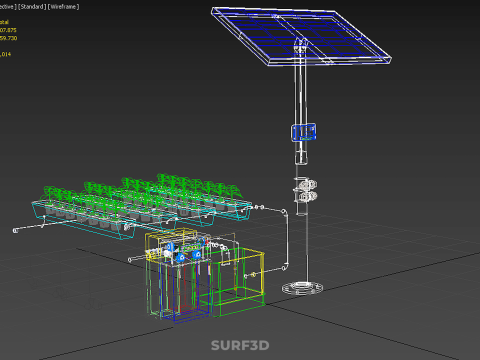

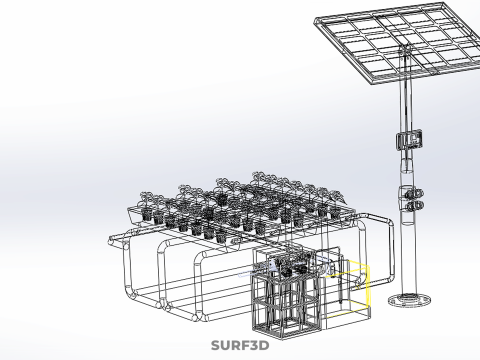

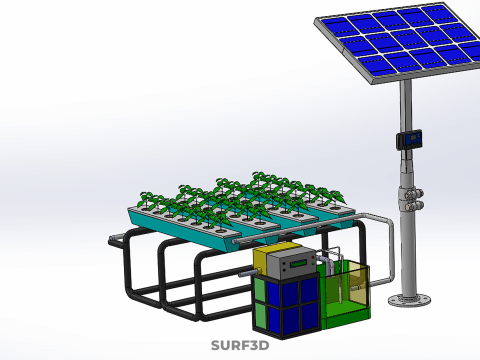

SOLAR PANEL POWER SMART IOT PH NUTRIENT CONTROL HYDROPONIC PLANT 3D Модель

- Доступні формати: STEP (.step) 3.68 MBAutodesk 3DS MAX (.max) 20.26 MBCollada (.dae) 11.09 MBIGES (.iges) 4.14 MBStereolithography (.stl) 11.06 MBGLB (.glb / .gltf) 6.20 MBSketchUp (.skp) 6.50 MBACIS(.sat) 8.45 MBAutodesk FBX (.fbx) 20.79 MBAutodesk AutoCAD (.dwg) 5.34 MBBlender3D (.blend) 12.88 MBRhinoceros (.3dm) 22.12 MB3D Studio (.3ds) 4.39 MBWavefront OBJ (.obj) 10.82 MB

- Полігони:907875

- Вершини:659730

- Анімована:No

- Текстури:No

- Скелет:No

- Матеріали:

- Лоу-полі:No

- Колекція:No

- UVW зображення:No

- Плагіни:No

- Готовність до друку:No

- 3D Скан:No

- Зміст для дорослих:No

- PBR:No

- ШІ Навчання:No

- Геометрія:Poly NURBS

- Розгорнуті UVs:Unknown

- Перегляди:81

- Дата: 2025-09-17

- ID Товару:599538

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

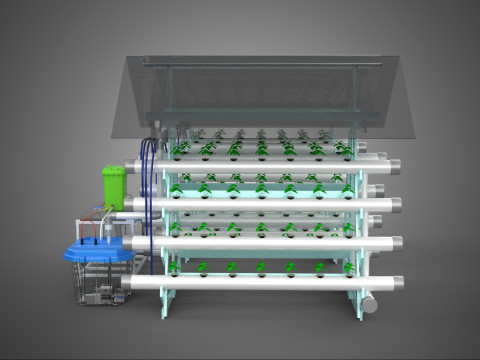

A "Smart IoT pH Nutrient Control Hydroponic Plant with Solar Panel Power" denotes an advanced agricultural system that integrates precision hydroponics with intelligent automation, real-time environmental monitoring, and sustainable energy sourcing. This system is designed for the soilless cultivation of plants, where nutrient-rich water solutions are precisely managed, and all operations are powered by photovoltaic (solar) energy, enabling remote oversight and control via the Internet of Things (IoT).

**Core Hydroponic Principles:**

The foundation of this system is hydroponics, a method of growing plants without soil, using mineral nutrient solutions dissolved in water. This approach offers several advantages, including significantly reduced water consumption due to recirculation, accelerated growth rates, higher yields per unit area, and elimination of soil-borne pests and diseases. Essential parameters for optimal plant growth in hydroponics include the pH level of the nutrient solution, its electrical conductivity (EC) which indicates nutrient concentration, and the solution's temperature.

**Smart IoT Integration:**

The "Smart IoT" component imbues the hydroponic system with intelligence and connectivity. It typically involves a network of sensors, microcontrollers, communication modules, and cloud-based platforms.

1. **Sensors:** Critical data points such as pH, EC, water temperature, water level in reservoirs, and ******t environmental factors (air temperature, humidity) are continuously monitored by specialized sensors.

2. **Microcontrollers:** A central processing unit, often a microcontroller (e.g., Arduino, ESP32) or a single-board computer (e.g., Raspberry Pi), collects data from the sensors. It processes this information, executes control algorithms, and manages actuators.

3. **Communication Modules:** Integrated Wi-Fi, Ethernet, LoRa, or cellular modules enable data transmission from the local system to a remote server or cloud platform. This allows for real-time data logging, analysis, and storage.

4. **Cloud Platform & User Interface:** Data sent to the cloud is processed and made accessible through a user-friendly interface, such as a web dashboard or mobile application. Users can monitor system status, view historical data, receive alerts, and remotely adjust parameters or trigger actions (e.g., pump activation) from anywhere with internet access. This remote capability is central to the "smart" aspect, facilitating proactive management and optimization.

**pH and Nutrient Control:**

Precise management of pH and nutrient concentration is paramount for plant health and productivity in hydroponics. This system employs a closed-loop feedback mechanism:

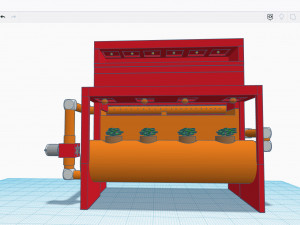

1. **pH Control:** A pH sensor continuously measures the acidity or alkalinity of the nutrient solution. If the pH deviates from the optimal range for the specific plant species, the microcontroller activates peristaltic pumps to dose precise amounts of pH-adjusting solutions (e.g., phosphoric acid to lower pH, potassium hydroxide to raise pH) into the reservoir until the desired level is restored.

2. **Nutrient Control (EC):** An EC sensor measures the total concentration of dissolved salts (nutrients) in the solution. When the EC drops below the target range (due to plant uptake), the system automatically dispenses pre-mixed stock nutrient solutions from separate reservoirs into the main nutrient tank. This ensures plants receive adequate and balanced nutrition.

3. **Automation:** This entire process is automated, minimizing manual intervention and ensuring consistent environmental conditions for plant growth, tailored to specific crop requirements.

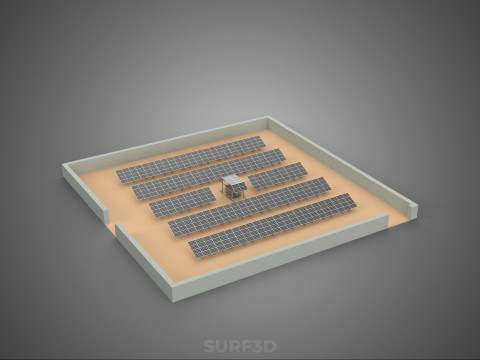

**Solar Panel Power Integration:**

The inclusion of a solar panel power system renders the hydroponic setup sustainable and capable of off-grid operation.

1. **Photovoltaic (PV) Panels:** These panels convert sunlight directly into direct current (DC) electricity.

2. **Charge Controller:** A solar charge controller regulates the voltage and current from the solar panels to efficiently charge and protect the energy storage battery, preventing overcharging or deep discharge.

3. **Battery Bank:** Deep-cycle batteries store the electrical energy generated by the solar panels, providing continuous power to all system components (sensors, microcontrollers, pumps, valves, lights if used) during periods of low sunlight or at night.

4. **Inverter (Optional):** If certain components require alternating current (AC) power, an inverter converts the DC power from the battery bank into AC power.

This sustainable power source reduces reliance on grid electricity, lowers operational costs, and minimizes the carbon footprint of the agricultural operation. It also enables deployment in remote areas lacking reliable grid infrastructure.

**Advantages and Applications:**

Such a system offers numerous benefits: enhanced resource efficiency (water, nutrients, energy), reduced labor requirements, improved yield quality and quantity, precise environmental control, and environmental sustainability. Applications include urban farming, vertical farms, research facilities, educational projects, off-grid agricultural deployments, and regions with water scarcity or limited arable land.

KEYWORDS: Smart Hydroponics, IoT Agriculture, pH Control, Nutrient Control, Solar Power, Sustainable Farming, Precision Agriculture, Automated Hydroponics, Remote Monitoring, Crop Optimization, Energy Independence, Off-grid Farming, Data-driven Farming, Water Efficiency, Soilless Cultivation, Environmental Control, Plant Growth, Microcontroller, Sensors, Actuators, Cloud Computing, Wireless Communication, Photovoltaic, Battery Storage, Peristaltic Pump, EC Sensor, Urban Farming, Vertical Farming, Resource Management.

Якщо вам потрібен інший формат, будь ласка, зробіть запит за допомогою тікета підтримки. Ми можемо конвертувати 3D моделі: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Ми не конвертуємо 3d сцени і такі формати, як .step, .iges, .stp, .sldprt тощо!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी