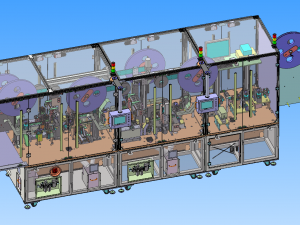

इंजेक्शन मोल्डेड भाग जांच पहचान सॉलिडवर्क्स संपादन योग्य 3D मॉडल

- लेखक द्वारा उत्पाद समर्थन का अनुरोध करें

- उपलब्ध फ़ॉर्मेट्स:

- आइटम ID:615384

- तिथि: 2025-12-03

- एनिमेटेड:No

- टेक्सचर:No

- रिग्ड:No

- सामग्रियां:

- लो-पॉली:No

- कलेक्शन:No

- UVW मैपिंग:No

- इस्तेमाल किए गए प्लगइन्स:No

- प्रिंट के लिए तैयार:No

- 3D स्कैन:No

- एडल्ट कंटेन्ट:No

- PBR:No

- एआई प्रशिक्षण:No

- ज्यामिति:Polygonal

- खुला हुआ UVs:Unknown

- व्यूस:140

विवरण

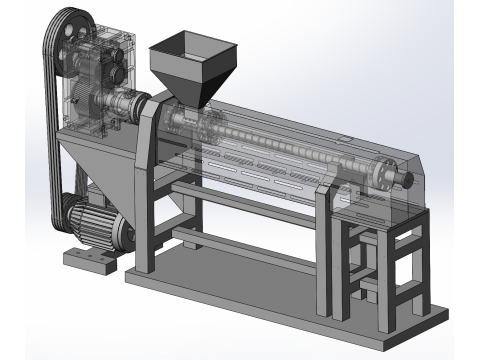

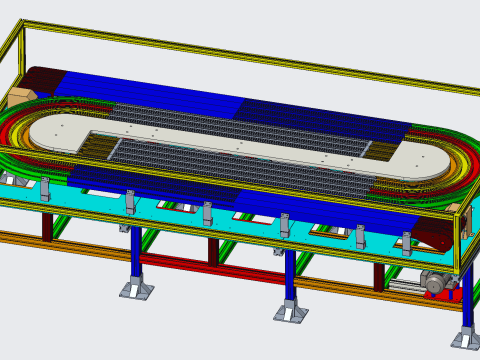

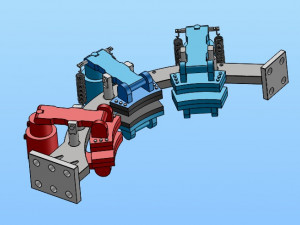

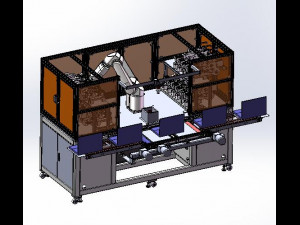

Injection molded part probe detection SolidWorks editable

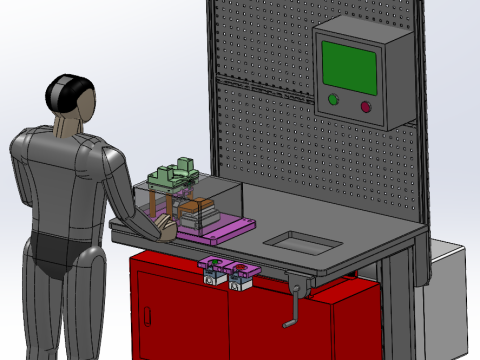

1、 Equipment preparation and feeding

The operator places the workpiece to be inspected steadily on the positioning fixture.

The sensor installed at the bottom of the tire detects the workpiece and confirms the completion of feeding.

2、 Automatic detection process

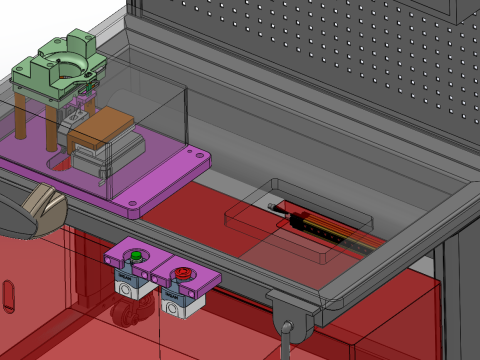

The operator presses the start button, and the system performs the following actions in sequence:

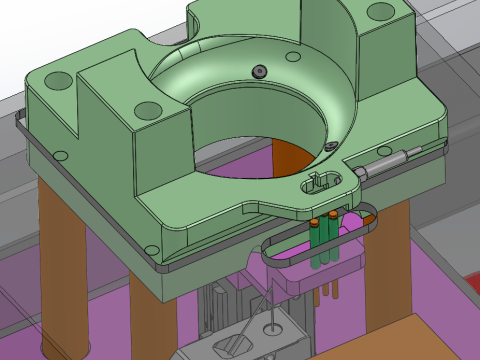

The vacuum suction cup inside the positioning fixture is activated to firmly adhere and fix the workpiece.

The pneumatic slide table rises and drives the three height positioning pins to move synchronously, making their top contact with the top of the probe and the bottom of the hole on the workpiece.

The electric slide table drives the laser ranging sensor to move sequentially to three positioning pin positions, and measures their distance values separately.

The system automatically calculates the height dimension tolerance of the probe based on three ranging values.

3、 Result display and judgment

The detection results are displayed in real-time on the touch screen or display screen.

The system performs automatic judgment:

Size qualified: The green indicator light is on.

Unqualified size: The red indicator light lights up and records the unqualified information.

4、 Cutting and handling of non-conforming products

The operator releases the vacuum suction and removes the workpiece from the positioning fixture.

Disposal of judgment results:

Qualified parts: transferred to the next process.

Unqualified parts: must be put into the designated waste bin.

5、 Security and error prevention locking

A grating detection device is installed at the entrance of the waste bin to confirm whether non-conforming products have been put into use.

If the system determines that it is unqualified, but the grating does not detect the feeding action, then:

The device is automatically locked and cannot start the next detection.

Trigger the sound and light alarm to remind the operator to handle it.

Only after confirming the input of non-conforming products can the equipment be reset and allowed to resume operation.

प्रिंट के लिए तैयार: नहींक्या आपको और फ़ॉर्मेट्स चाहिए?

अगर आपको किसी अलग फ़ॉर्मेट की जरूरत है, तो कृपया हमें कन्वर्शन अनुरोध भेजें। हम 3D मॉडल को इसमें कन्वर्ट कर सकते हैं: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. फ्री फ़ॉर्मेट कन्वर्शनहम 3D दृश्यों को कन्वर्ट नहीं करते हैं और .step, .uges, .stp, .sldprt जैसे प्रारूप।!

Usage Information

इंजेक्शन मोल्डेड भाग जांच पहचान सॉलिडवर्क्स संपादन योग्य - You can use this royalty-free 3D model for both personal and commercial purposes in accordance with the Basic or Extended License.The Basic License covers most standard use cases, including digital advertisements, design and visualization projects, business social media accounts, native apps, web apps, video games, and physical or digital end products (both free and sold).

The Extended License includes all rights granted under the Basic License, with no usage limitations, and allows the 3D model to be used in unlimited commercial projects under Royalty-Free terms.

और पढ़ें

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी