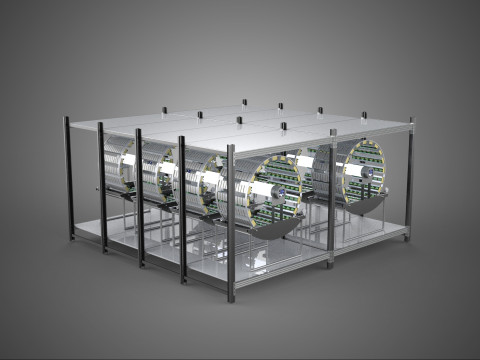

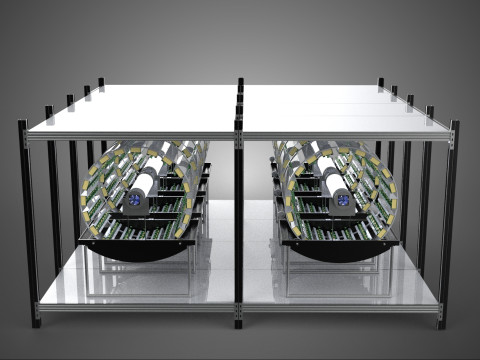

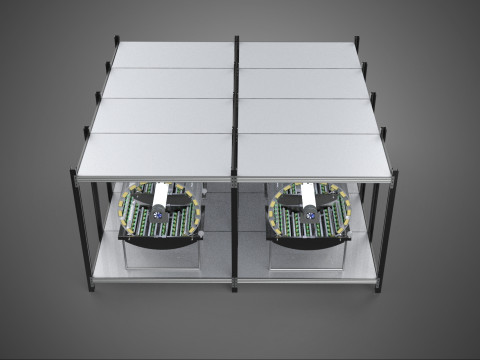

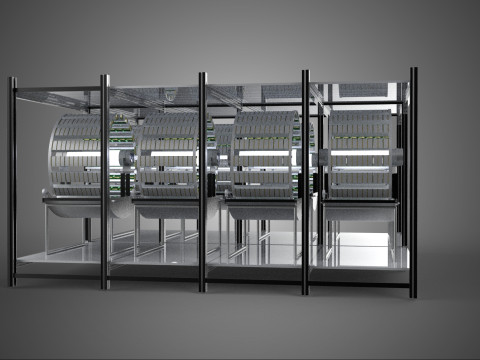

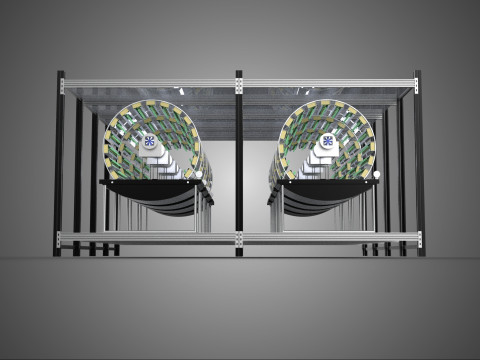

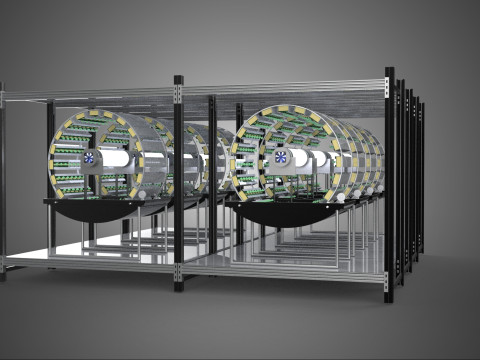

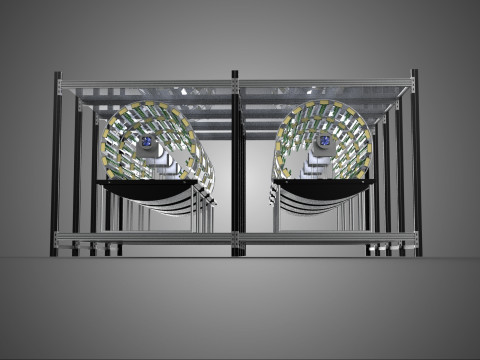

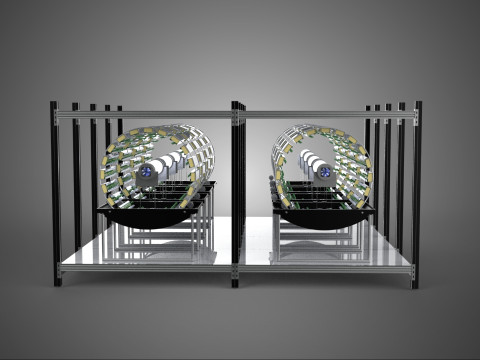

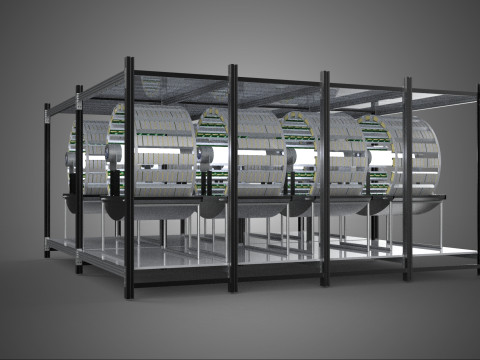

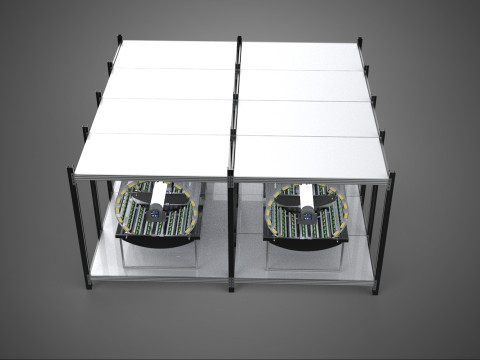

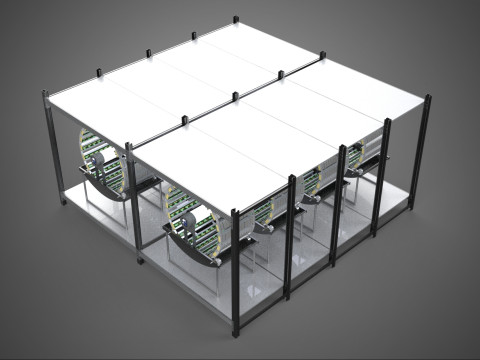

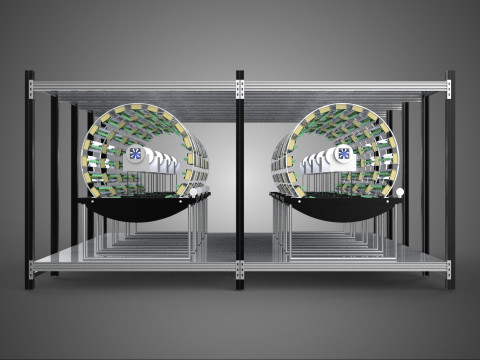

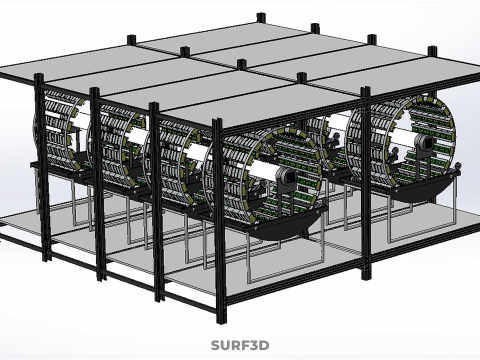

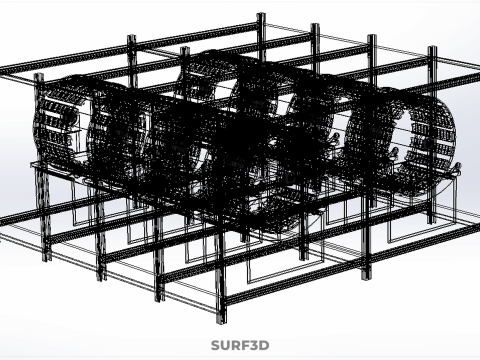

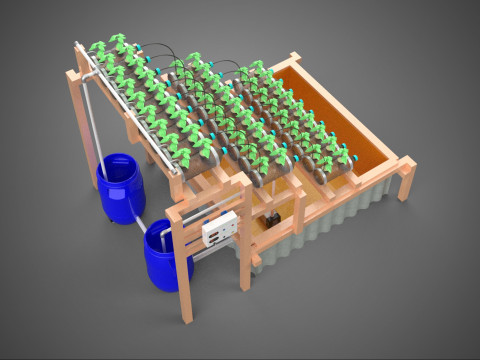

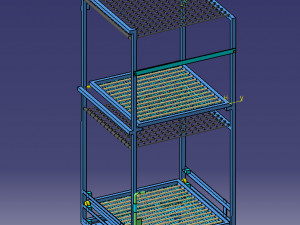

FILA DE ESTANTE INTERIOR BANDEJA DE ESTANTE PLANTA HIDROPÓNICA GIRATORIA GRANJA Modelo 3D

- Formatos disponibles:

- Conversión de formato libre

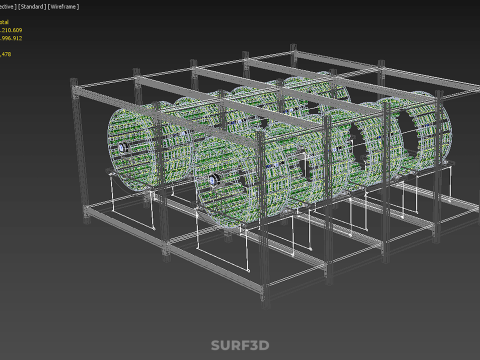

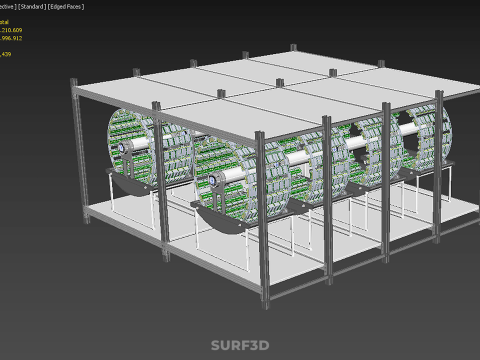

- Polígonos:5210609

- Vértices:3996912

- Animados:No

- Texturas:No

- Articulados:No

- Materiales:

- Low-poly:No

- Colección:No

- Mapas UVW:No

- Plugins Usados:No

- Listo para Imprimir:No

- 3D Scan:No

- Para adultos:No

- PBR:No

- AI Capacitación:No

- Geometría:Poly NURBS

- Desenvolver UVs:Unknown

- Vistas:196

- Fecha: 2025-10-02

- ID de artículo:602758

FILA DE ESTANTE INTERIOR BANDEJA DE ESTANTE PLANTA HIDROPÓNICA GIRATORIA GRANJA Modelo 3D De surf3d

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

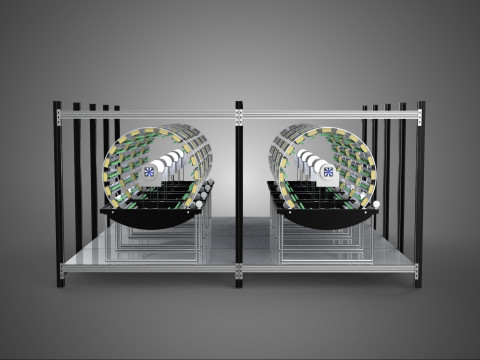

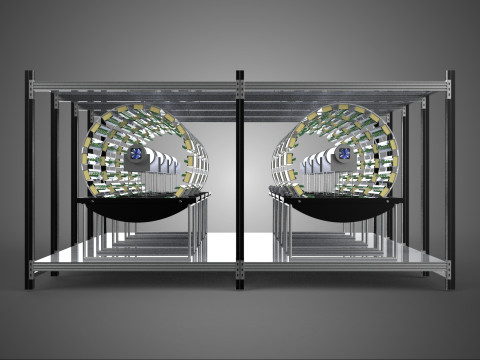

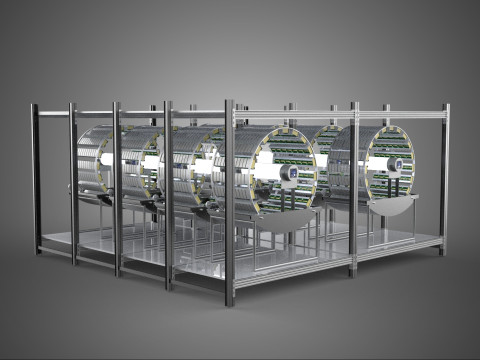

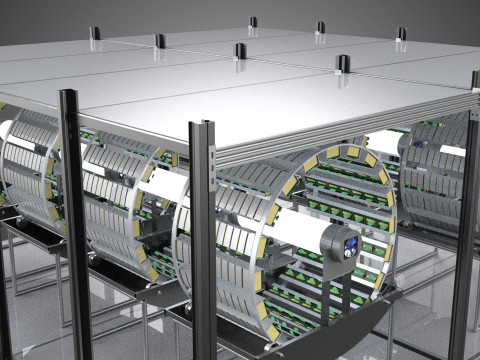

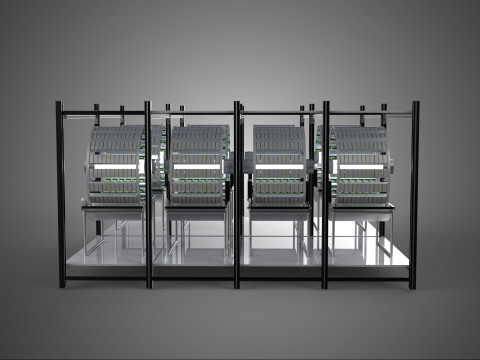

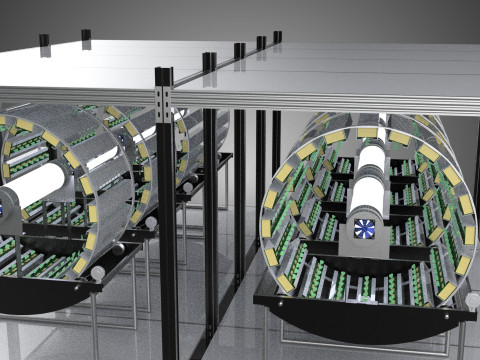

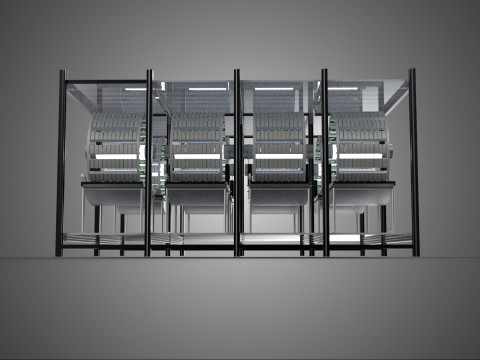

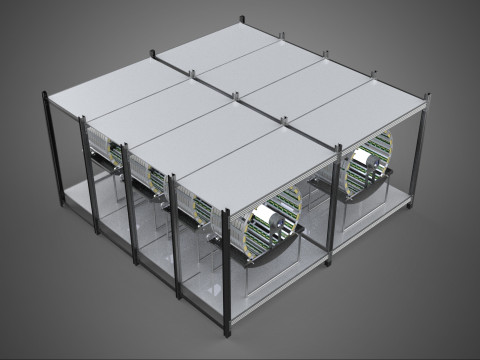

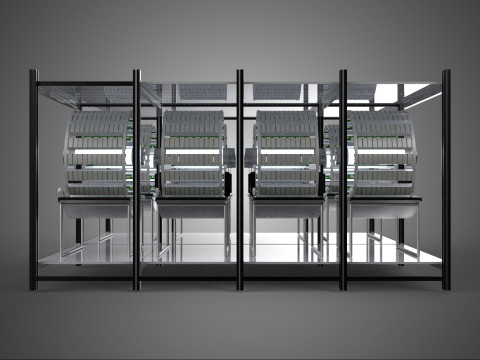

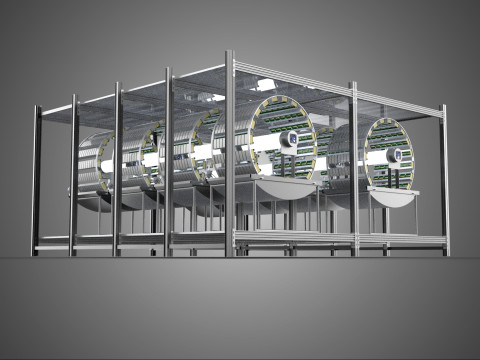

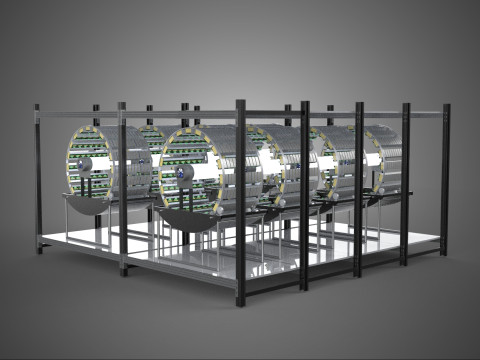

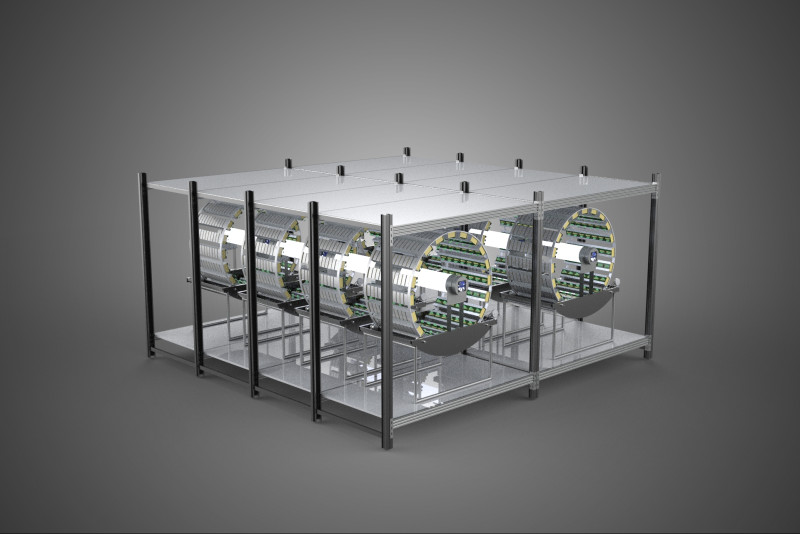

An "Indoor Array Row Shelf Rack Tray Rotary Hydroponic Plant Farm UP" designates a sophisticated, high-density, and controlled-environment agricultural (CEA) system engineered for the soilless cultivation of plants within an enclosed indoor setting. This integrated technology systematically combines vertical farming principles, a dynamic rotary mechanism, and advanced hydroponic nutrient delivery to optimize space utilization, resource efficiency, and plant yield. The descriptor "UP" inherently emphasizes its vertical orientation, often implying scalability and advanced design for elevated production.

This advanced plant cultivation system is characterized by several key integrated components:

1. **Structural Framework (Array Row Shelf Rack):** The foundation is a robust, multi-tiered vertical shelving or racking system, typically constructed from durable, corrosion-resistant materials suitable for humid environments. Plants are arranged in linear rows or systematic arrays across multiple shelves, maximizing cultivation density within a minimal footprint.

2. **Plant Trays/Modules:** Individual, inert, food-grade trays or grow modules are designed to hold plants and facilitate the delivery of nutrient solutions to their roots. These are integrated into the shelving units.

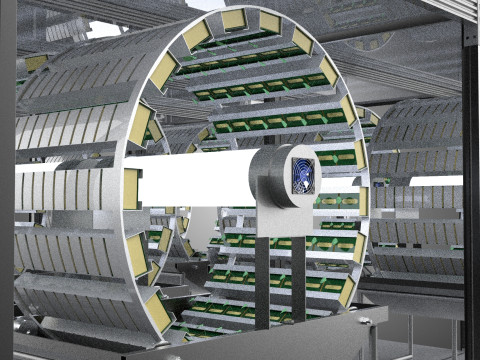

3. **Rotary Mechanism:** This is a defining and innovative feature. The rotary aspect can manifest in several configurations:

* **Rotating Shelves/Racks:** Entire sections or individual shelves slowly rotate, often around a central axis, ensuring all plants receive uniform exposure to stationary light sources and facilitating periodic access for monitoring or harvesting.

* **Rotating Drums/Cylinders:** In systems like the "rotary drum" or "carousel" hydroponics, plants are anchored to a large, slowly rotating cylinder or drum, typically with roots suspended internally. As the drum rotates, roots are either periodically misted with nutrient solution (aeroponics) or briefly dipped into a nutrient reservoir (hydroponics), promoting rapid growth and excellent root aeration. This design is highly space-efficient for light distribution.

4. **Hydroponic System:** The core cultivation method involves supplying water-dissolved mineral nutrients directly to the plant roots without soil. Common hydroponic techniques adapted for these rotary systems include Nutrient Film Technique (NFT), Deep Water Culture (DWC), drip irrigation, or aeroponics, chosen based on crop type and system design. Nutrient solutions are typically recirculated to minimize water and fertilizer waste.

5. **Lighting System:** Artificial grow lights, predominantly energy-efficient Light Emitting Diodes (LEDs), are strategically positioned. The rotary mechanism allows for fewer light fixtures to illuminate a larger plant area by constantly moving plants through the lighted zone, optimizing photon capture and promoting uniform growth across the entire crop.

6. **Environmental Control System:** A sophisticated network of sensors and automated controls continuously monitors and regulates crucial environmental parameters. These include temperature, humidity, carbon dioxide (CO2) levels, and air circulation, all maintained within optimal ranges for specific plant growth requirements.

**Operational Principles:**

Plants are typically propagated in inert starting media before being transferred to the system's trays or modules. A precisely balanced hydroponic solution, rich in essential macro- and micronutrients, is delivered to the plant roots. The rotary mechanism is fundamental to the system's efficiency, ensuring uniform light exposure for all plants by continuously moving them past fixed light sources. This dynamic movement also contributes to improved air circulation around the plants and can simplify tasks like inspection and harvesting in some designs.

**Advantages:**

This integrated system offers several significant benefits: unparalleled **space efficiency** for high crop density; substantial **resource conservation**, particularly water, through recirculation; **accelerated growth rates** and higher yields due to optimized environmental control and nutrient delivery; **year-round production** independent of external climate; enhanced **pest and disease control** in a sterile indoor environment, reducing pesticide use; and improved **crop uniformity** resulting from equitable light distribution.

**Applications:**

Such advanced hydroponic systems are predominantly utilized in commercial vertical farms, urban agriculture initiatives, research institutions, and specialized indoor cultivation facilities for high-value crops like leafy greens, herbs, strawberries, and certain specialty vegetables, contributing to local food security and sustainable production.

**Challenges:**

Implementation of an "Indoor Array Row Shelf Rack Tray Rotary Hydroponic Plant Farm UP" requires substantial initial capital investment, significant technical expertise for setup and maintenance, and considerable energy consumption for lighting and environmental controls, which represents a primary operational cost.

In conclusion, this advanced hydroponic farm configuration represents a cutting-edge approach to controlled-environment agriculture, leveraging sophisticated engineering to achieve unparalleled efficiency and productivity in indoor plant cultivation, addressing contemporary challenges in food production.

KEYWORDS: Hydroponics, Vertical Farming, Controlled Environment Agriculture (CEA), Indoor Agriculture, Rotary Hydroponics, Automated Farming, Urban Farming, Sustainable Agriculture, Plant Cultivation, Soilless Culture, Grow Lights (LED), Nutrient Film Technique (NFT), Deep Water Culture (DWC), Aeroponics, Environmental Control, Space Efficiency, Resource Conservation, Crop Yield, Multi-tiered System, Vertical Racks, Plant Trays, Automation, Precision Agriculture, Year-Round Production, Food Security, Controlled Growing, Carousel Hydroponics, Rotating Drum System, Vertical Gardens, High-Density Farming

¿Necesita más formatos?

Si precisa un formato distinto, por favor, abra una consulta de Soporte y solicítelo. Podemos convertir modelos 3D a: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Nosotros no convertimos escenas 3d y formatos como .step, .iges, .stp, .sldprt.!Información de uso

FILA DE ESTANTE INTERIOR BANDEJA DE ESTANTE PLANTA HIDROPÓNICA GIRATORIA GRANJA - Puede usar este modelo 3D libre de regalías tanto para fines personales como comerciales, de acuerdo con la Licencia Básica o Extendida.La Licencia Básica cubre la mayoría de los casos de uso estándar, incluyendo anuncios digitales, proyectos de diseño y visualización, cuentas empresariales en redes sociales, aplicaciones nativas, aplicaciones web, videojuegos y productos finales físicos o digitales (tanto gratuitos como comerciales).

La Licencia Extendida incluye todos los derechos otorgados bajo la Licencia Básica, sin limitaciones de uso, y permite que el modelo 3D se use en un número ilimitado de proyectos comerciales bajo las condiciones de la Licencia Libre de Regalías.

Leer más

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी