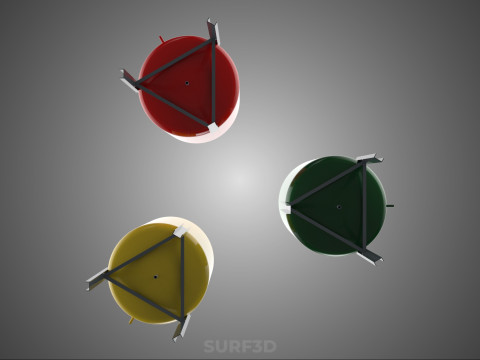

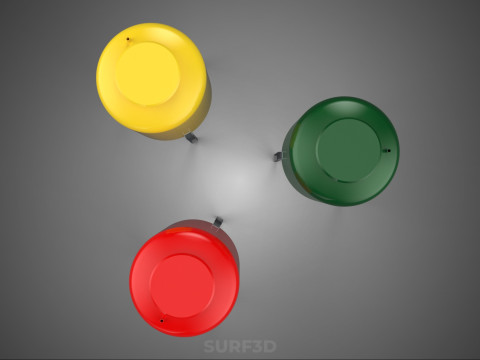

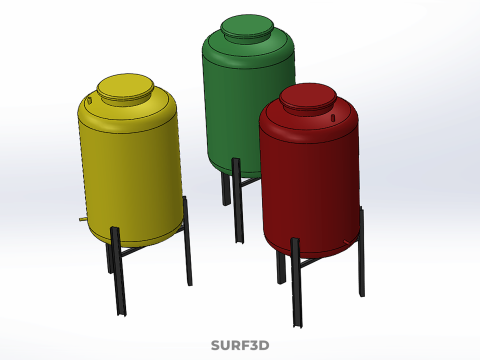

TANQUE DE CONTENEDOR DE ALMACENAMIENTO DE QUÍMICOS LÍQUIDOS INDUSTRIAL ESTÁNDAR Modelo 3D

- Solicitar soporte de producto

- Formatos disponibles:

- ID de artículo:594684

- Fecha: 2025-08-25

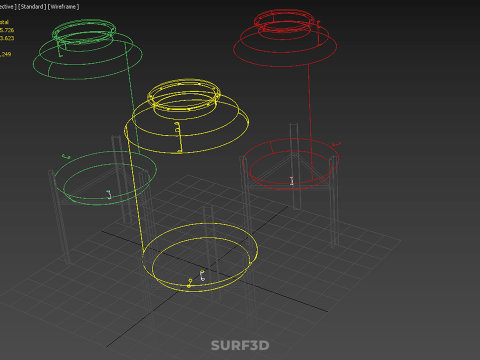

- Polígonos:15726

- Vértices:13623

- Animados:No

- Texturas:No

- Articulados:No

- Materiales:

- Low-poly:No

- Colección:No

- Mapas UVW:No

- Plugins Usados:No

- Listo para Imprimir:No

- 3D Scan:No

- Para adultos:No

- PBR:No

- AI Capacitación:No

- Geometría:Poly NURBS

- Desenvolver UVs:Unknown

- Vistas:261

Descripción

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

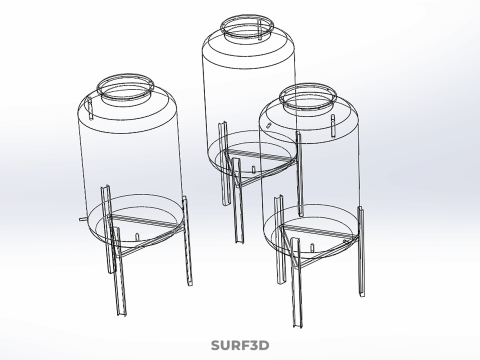

A **Standard Industrial Elevated Fluid Liquid Chemical Storage Container Tank with Stand Frame** is a specialized engineering solution designed for the safe, efficient, and controlled storage of various fluid and liquid chemicals within industrial environments. Characterized by its raised position, achieved through an integrated stand frame, this type of tank facilitates gravity-fed dispensing, improves accessibility for maintenance, and enhances overall operational safety and efficiency in chemical handling processes.

**Nomenclature and Classification:**

* **Standard:** Implies adherence to established industry norms, specifications, and safety codes, ensuring interoperability, quality control, and predictable performance. This can include compliance with national and international standards for design, fabrication, and materials.

* **Industrial:** Denotes its primary application within manufacturing, processing, utility, and other large-scale commercial and production facilities, contrasting with residential or small-scale laboratory uses. These environments typically involve larger volumes, higher throughputs, and more stringent safety requirements.

* **Elevated:** Refers to the tank's position above ground level, a critical design feature enabled by the stand frame. This elevation primarily serves to utilize gravity for fluid discharge, reducing or eliminating the need for continuous pumping in certain operations, and providing crucial clearance for ancillary equipment, secondary containment, or personnel access.

* **Fluid Liquid Chemical:** Specifies the nature of the stored medium. While "fluid" broadly encompasses liquids and gases, it is here qualified by "Liquid Chemical," denoting substances in a liquid state that are often corrosive, flammable, toxic, reactive, or otherwise hazardous, requiring specialized containment protocols and material selection.

* **Storage Container Tank:** These terms are largely synonymous in this context, describing a robust vessel engineered for holding substances over extended periods. "Tank" typically implies a larger, more permanent structure designed for bulk storage, whereas "container" can sometimes imply greater portability, though here they collectively describe the primary containment unit.

* **with Stand Frame:** Highlights the integral support structure, typically constructed from robust structural steel or other durable materials, which physically elevates the tank body. This frame is a critical component, contributing to the structural integrity and operational functionality of the entire system.

**Design and Construction:**

The construction of these tanks is meticulously engineered to ensure chemical compatibility, structural integrity, and operational safety, adhering to stringent design codes.

* **Tank Body:** Material selection for the tank body is paramount and dictated by the specific chemical properties (e.g., corrosivity, temperature, pressure, pH) of the stored liquid. Common materials include:

* **Carbon Steel:** Economical for non-corrosive or mildly corrosive liquids, often requiring internal linings or coatings (e.g., epoxy, rubber, glass-flake) to provide chemical resistance and prevent material degradation.

* **Stainless Steel (e.g., 304, 316L):** Preferred for corrosive chemicals, high-purity applications (e.g., pharmaceuticals, food-grade), and where hygiene is critical, offering excellent inherent corrosion resistance. Specific grades are chosen based on chemical environment.

* **Fiber-Reinforced Plastic (FRP) / Fiberglass:** Lightweight, highly corrosion-resistant to a wide spectrum of chemicals, and often used for outdoor or underground applications. It is particularly suitable for acids, caustics, and bleach solutions at ambient temperatures.

* **High-Density Polyethylene (HDPE) / Polypropylene (PP):** Suitable for highly corrosive acids and bases at ambient to moderate temperatures, often manufactured via rotational molding or extrusion welding techniques.

Tank shapes are predominantly cylindrical (vertical or horizontal) for optimal stress distribution and manufacturing efficiency, though rectangular designs are also employed where space optimization is critical.

* **Stand Frame:** The stand frame is a robust structural component, typically fabricated from heavy-duty structural steel (e.g., I-beams, H-beams, tubular sections), designed to safely support the full weight of the tank and its contents, as well as withstand environmental loads such as wind and seismic forces. Its primary functions include elevating the tank to the desired height for gravity-fed discharge, facilitating easy access for inspection and maintenance, and providing crucial clearance for pumps, secondary containment systems, or other ancillary equipment. The frame design incorporates cross-bracing and gussets for enhanced rigidity and stability, ensuring uniform load distribution. It is typically anchored securely to a reinforced concrete foundation.

* **Ancillary Components:** These tanks are comprehensively equipped with various fittings and accessories for safe, monitored, and efficient operation:

* **Inlet/Outlet Nozzles:** Strategically positioned for efficient filling, dispensing, and complete draining, often with isolation valves.

* **Ventilation Systems:** Atmospheric vents or pressure/vacuum relief valves are essential to prevent over-pressurization or vacuum formation during filling/emptying cycles and thermal expansion/contraction of the stored liquid.

* **Manways:** Access points (e.g., hinged or bolted covers) for internal inspection, cleaning, and maintenance operations.

* **Level Indicators:** Various devices such as sight glasses, float switches, ultrasonic sensors, or radar level transmitters monitor and display the liquid volume, often integrated with plant control systems.

* **Safety Features:** Overfill protection systems, emergency vents, and critical secondary containment provisions (e.g.

¿Necesita más formatos?

Si precisa un formato distinto, por favor, abra una consulta de Soporte y solicítelo. Podemos convertir modelos 3D a: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Conversión de formato libreNosotros no convertimos escenas 3d y formatos como .step, .iges, .stp, .sldprt.!

Información de uso

TANQUE DE CONTENEDOR DE ALMACENAMIENTO DE QUÍMICOS LÍQUIDOS INDUSTRIAL ESTÁNDAR - Puede usar este modelo 3D libre de regalías tanto para fines personales como comerciales, de acuerdo con la Licencia Básica o Extendida.La Licencia Básica cubre la mayoría de los casos de uso estándar, incluyendo anuncios digitales, proyectos de diseño y visualización, cuentas empresariales en redes sociales, aplicaciones nativas, aplicaciones web, videojuegos y productos finales físicos o digitales (tanto gratuitos como comerciales).

La Licencia Extendida incluye todos los derechos otorgados bajo la Licencia Básica, sin limitaciones de uso, y permite que el modelo 3D se use en un número ilimitado de proyectos comerciales bajo las condiciones de la Licencia Libre de Regalías.

Leer más

¿Garantizáis la Devolución de Dinero?

Si. Si compras un producto y encuentras errores de rendimiento o descripción, intentaremos solucionar el problema lo antes posible. Si no lo logramos, cancelaremos tu pedido y tu dinero será devuelto en 24h, desde que el producto fué descargado. Lea más condiciones aquíPalabras clave

- tanque de agua

- buque

- cilíndrico

- depósito

- estructura

- plataforma

- apoyo

- químico

- peligroso

- industrial tank

- chemical container

- chemical storage

- tanque químico

- elevated frame

- tanque elevado

- standard tank

- líquido

- recipiente

- líquido

- elevado

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी