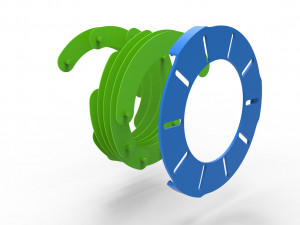

Classic Iris diaphragm 3D printmodel

$

5.00

U heeft $0.00 Credits. Koop credits

- Mogelijke formaten: Rhinoceros (.3dm) 1.44 MB3D Studio (.3ds) 2.25 MB3D Studio (.3ds) 1.15 MBAutodesk 3DS MAX (.max) 229.96 kbAutodesk 3DS MAX (.max) 259.85 kbAutodesk FBX (.fbx) 2.53 MBAutodesk 3DS MAX (.max) 452.72 kbAutodesk 3DS MAX (.max) 452.02 kbWavefront OBJ (.obj) 1.80 MBWavefront OBJ (.obj) 1002.09 kbAgisoft Photoscan (.ply) 321.46 kbSTEP (.step) 482.28 kbSTEP (.step) 230.44 kbStereolithography (.stl) 1.09 MBStereolithography (.stl) 362.86 kbRhinoceros (.3dm) 307.12 kb

- Collectie:No

- Afdruk Gereed:

- 3D scan:No

- Volwassen:No

- PBR:

- Aantal keer bekeken:5733

- Datum: 2023-05-23

- Item ID:446900

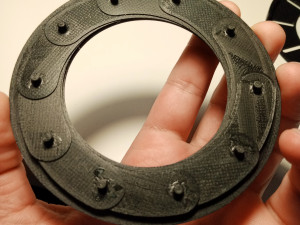

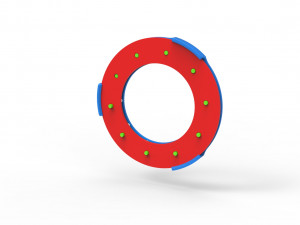

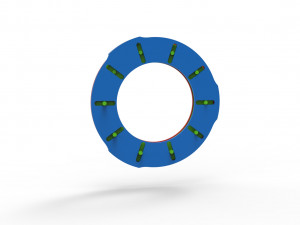

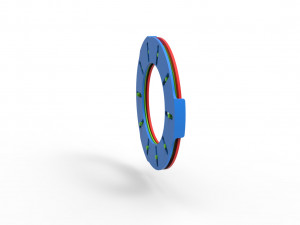

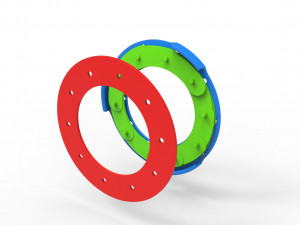

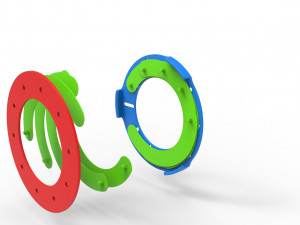

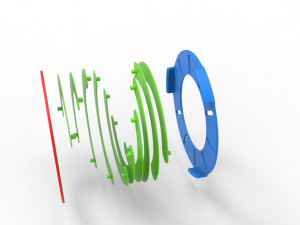

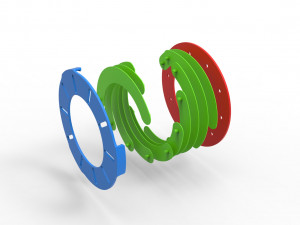

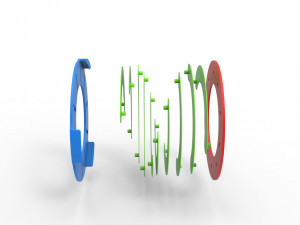

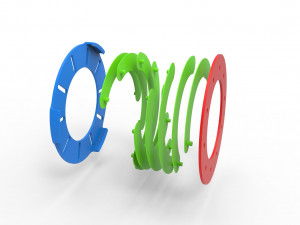

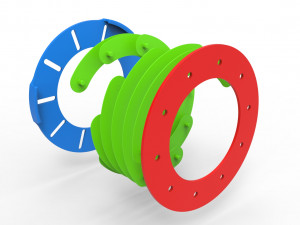

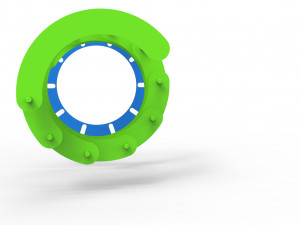

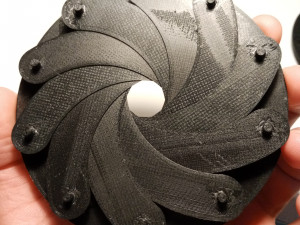

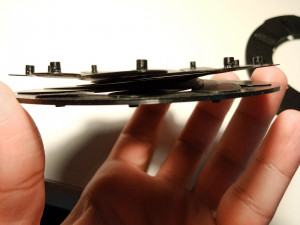

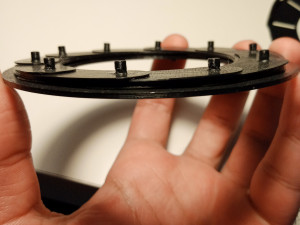

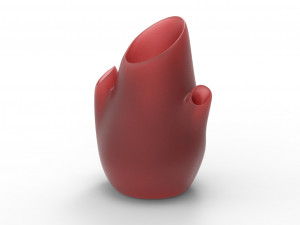

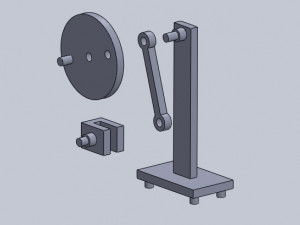

This is a classic Iris diaphragm. I have designed it with minimal thickness while ensuring strength. It is specifically made for FDM printers and PLA materials. It is crucial to produce it with high quality for the mechanism to function correctly. Please note that the scale should not be changed as it would result in malfunction. If you require a different scale, kindly inform me so that I can customize the measurements according to your equipment and dimensions.

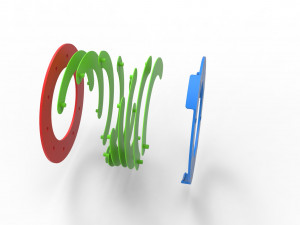

Although the diaphragm can fully close, it requires a slight modification as the current model cannot close completely.

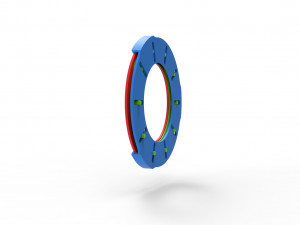

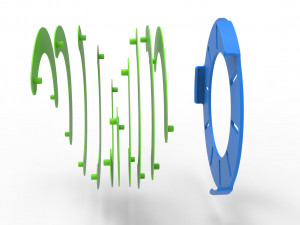

The model consists of 10 blades and 10 pins. After printing, you need to attach the pins to the blades using adhesive. I designed it this way to enable printing without the need for support structures and to expedite the printing process.

The gap between the movable parts is 0.2 mm, while the gap between the pin and the blade h o l e is 0.05 mm.

I created this model using SolidWorks 2021. Please let me know if you require the original file.

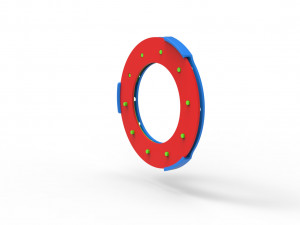

Please note that the assembly file may not accurately depict the actual bending of the blades during movement. It is challenging to simulate blade bending accurately in software. However, I have positioned them correctly, and the virtual assembly functions appropriately. The apparent position of the blades might not appear accurate.

Feel free to contact me if you need any further assistance.

Lees meerAlthough the diaphragm can fully close, it requires a slight modification as the current model cannot close completely.

The model consists of 10 blades and 10 pins. After printing, you need to attach the pins to the blades using adhesive. I designed it this way to enable printing without the need for support structures and to expedite the printing process.

The gap between the movable parts is 0.2 mm, while the gap between the pin and the blade h o l e is 0.05 mm.

I created this model using SolidWorks 2021. Please let me know if you require the original file.

Please note that the assembly file may not accurately depict the actual bending of the blades during movement. It is challenging to simulate blade bending accurately in software. However, I have positioned them correctly, and the virtual assembly functions appropriately. The apparent position of the blades might not appear accurate.

Feel free to contact me if you need any further assistance.

Meer formaten nodig?

Als u een ander formaat nodig heeft, open dan alstublieft een nieuwe Support Ticket en vraag om een ander formaat. Wij kunnen uw 3D modelen van vorm veranderen naar: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. We converteren geen 3D scènes en formaten zoals .step, .iges, .stp, .sldprt.!

Als u een ander formaat nodig heeft, open dan alstublieft een nieuwe Support Ticket en vraag om een ander formaat. Wij kunnen uw 3D modelen van vorm veranderen naar: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. We converteren geen 3D scènes en formaten zoals .step, .iges, .stp, .sldprt.!

Classic Iris diaphragm 3D printmodel 3dm, 3ds, 3ds, max, max, fbx, max, max, obj, obj, ply, step, step, stl, stl, 3dm, Van syouhannae

iris diaphragm classic eye camera photography mechanism mechanical juhannproduct lense printable adjustable optical control accessory aperture blade light tech fstopEr zijn geen opmerkingen voor dit item.

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी