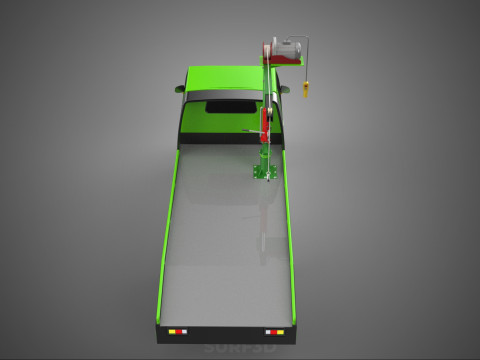

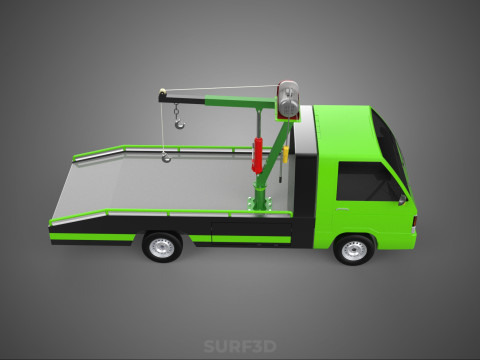

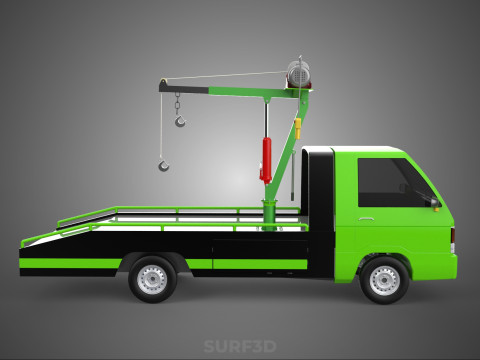

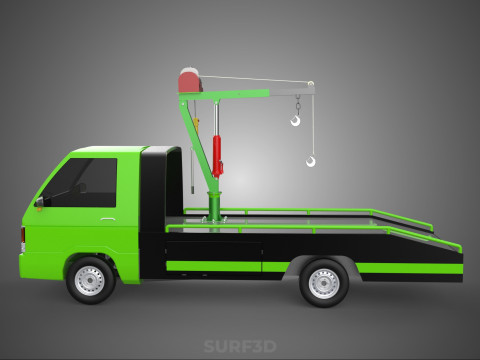

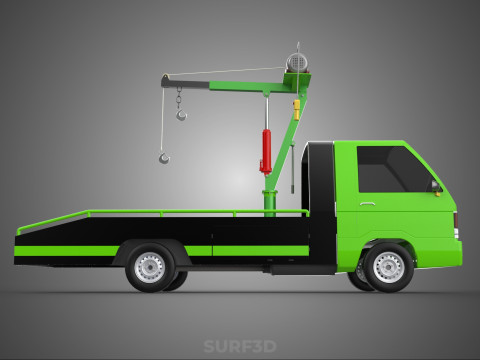

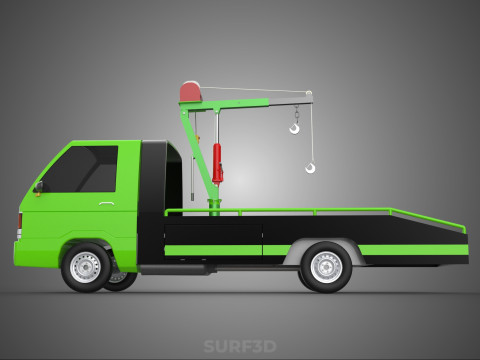

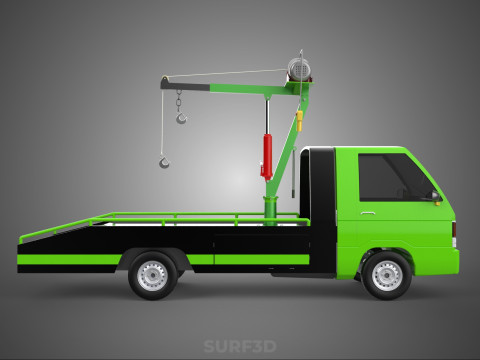

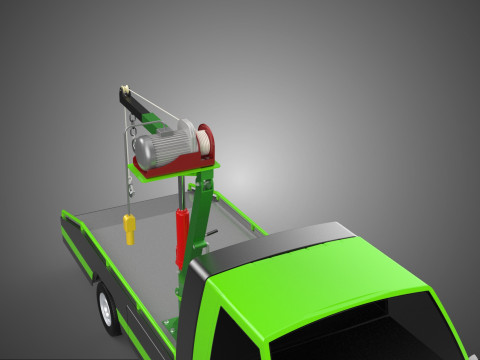

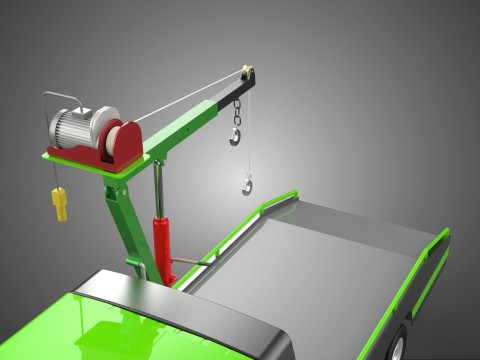

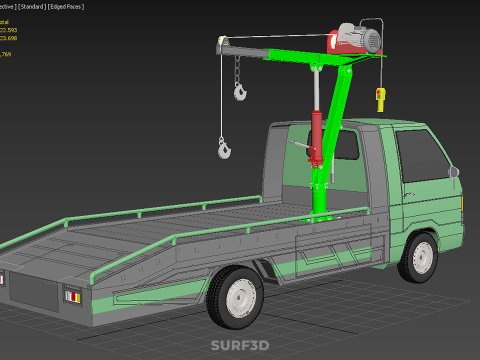

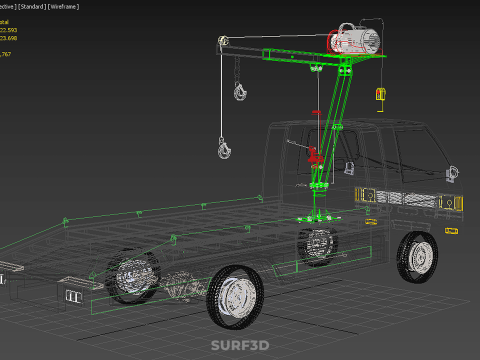

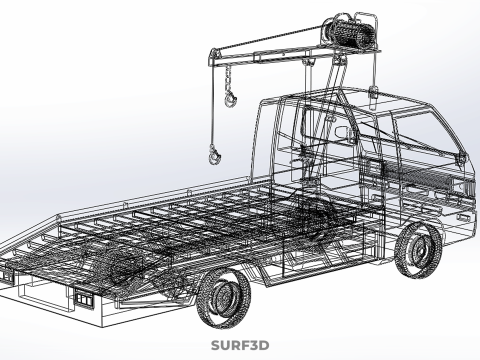

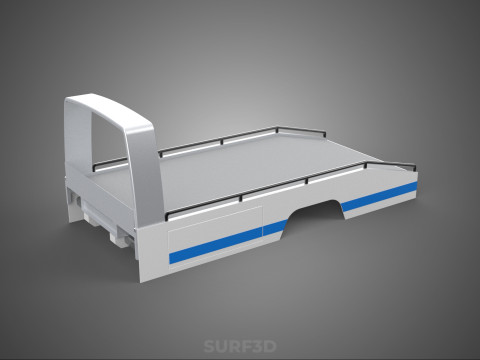

ELECTRIC WINCH HOIST REMOTE SWIVEL CRANE HOOK JIB TRUCK PICKUP 3D Model

- Mogelijke formaten: IGES (.iges) 7.04 MBStereolithography (.stl) 8.00 MBAutodesk AutoCAD (.dwg) 18.64 MBCollada (.dae) 10.67 MBACIS(.sat) 15.13 MB3D Studio (.3ds) 3.80 MBRhinoceros (.3dm) 25.73 MBGLB (.glb / .gltf) 5.10 MBAutodesk FBX (.fbx) 12.45 MBAutodesk 3DS MAX (.max) 23.71 MBBlender3D (.blend) 9.64 MBWavefront OBJ (.obj) 7.53 MBSketchUp (.skp) 8.75 MBSTEP (.step) 7.41 MB

- Polygonen:522593

- Hoekpunten:423698

- Geanimeerd:No

- Texturen:No

- Gemanipuleerd:No

- Materialen:

- Low-poly:No

- Collectie:No

- UVW-toewijzing:No

- Plugins Gebruikt:No

- Afdruk Gereed:No

- 3D scan:No

- Volwassen:No

- PBR:No

- AI-training:No

- Geometrie:Poly NURBS

- Onverpakte UV's:Unknown

- Aantal keer bekeken:229

- Datum: 2025-08-14

- Item ID:592533

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and ****ed for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

A **Truck-Mounted Electric ***ch Hoist with Remote on Swivel Jib** represents a specialized and highly versatile material handling system integrated into the chassis or cargo bed of a pickup truck. This assembly transforms a standard utility vehicle into a mobile lifting platform, designed to facilitate the safe and efficient loading, unloading, and positioning of heavy, bulky, or ******* objects that would otherwise require significant manual labor or dedicated static lifting equipment. Its primary objective is to enhance operational efficiency, improve worker safety by minimizing manual lifting, and expand the functional capabilities of a conventional light-duty truck.

The system is composed of several key interoperating components:

1. **Electric ***ch Hoist:** This is the primary lifting mechanism, comprising an electric motor, a robust gear reduction system, and a ***ding drum for a steel cable or synthetic rope. Powered typically by the truck's 12-volt or 24-volt DC electrical system, these hoists are designed for intermittent duty cycles and come in various lifting capacities, generally ranging from several hundred pounds to over a ton. Essential features often include an automatic load-holding brake that prevents back-sliding, thermal overload protection for the motor, and rugged construction to withstand demanding outdoor and industrial environments. Its core function is to provide vertical lifting and lowering capabilities, though it can also be utilized for short-distance horizontal pulling operations.

2. **Remote Control Interface:** Operation of the electric ***ch hoist is managed via a remote control unit. This can be a tethered pendant control, providing direct tactile feedback and reliability, or a wireless radio frequency (RF) remote. Wireless remotes offer significant advantages by allo***g the operator to maintain a safe distance from the load and the immediate lifting zone, providing greater freedom of movement and a comprehensive view of the lifting operation, which enhances safety and precision. Controls typically include distinct "up," "down," and an "emergency stop" function.

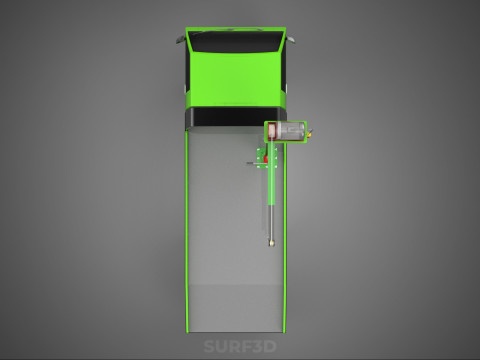

3. **Swivel Jib Crane Assembly:** The electric ***ch hoist is securely mounted onto a swivel jib crane. This component consists of a robust, articulating arm (the jib) that extends outwards from a central, pivotable base. The "swivel" capability is a critical feature, allo***g the jib arm and the suspended load to rotate through a substantial arc, commonly 270 or 360 degrees, relative to the truck's mounting point. This rotational flexibility enables the system to reach and retrieve objects positioned to the sides or rear of the vehicle, as well as to precisely place them within the truck bed or at another desired location. The jib arm is typically constructed from high-strength steel, often with a fixed or telescopic design to provide varying reach, and terminates in a heavy-duty hook equipped with a safety latch for secure load attachment.

4. **Truck Pickup Integration:** The entire ***ch and jib assembly is designed for secure and stable attachment to the chassis or within the cargo bed of a pickup truck. This integration typically involves heavy-duty bolting to reinforced structural points on the truck's frame, often necessitating the installation of a specialized mounting plate or sub-frame to distribute the lifting stresses evenly and prevent damage to the vehicle. The direct electrical connection to the truck's battery system provides the necessary power for the hoist's operation, making the entire unit self-contained and highly mobile. Proper installation and reinforcement are paramount to ensure vehicle stability during lifting operations and to maintain structural integrity.

**Operational Principles and Applications:**

To operate the system, the truck is positioned appropriately, the jib is swiveled into the desired orientation, and the load is securely attached to the hook. The operator then uses the remote control to raise or lower the item. Once lifted, the jib can be rotated to maneuver the load into the truck bed, transfer it to an adjacent location, or offload it from the vehicle. This system finds extensive utility across diverse sectors, including construction (e.g., loading tools, building materials, generators), agriculture (e.g., handling feed sacks, small machinery), landscaping (e.g., moving rocks, trees, heavy planters), industrial maintenance, mobile workshops, and general utility applications where manual lifting is impractical or poses significant ergonomic risks. It substantially improves operational efficiency, reduces the incidence of strain-related injuries, and expands the functional versatility of a standard pickup truck.

**Safety Considerations:**

Safe operation necessitates strict adherence to the system's rated weight capacities, maintaining vehicle stability (potentially requiring the use of outriggers if integrated into the crane design), regular inspection of all components including cables, hooks, and mounting hardware, and strict compliance with manufacturer guidelines. Comprehensive operator training is crucial to ensure proficient and safe utilization of the equipment.

KEYWORDS: Electric ***ch, Hoist, Remote Control, Swivel Crane, Jib Crane, Truck Crane, Pickup Truck, Material Handling, Lifting Equipment, Mobile Crane, Utility Crane, Vehicle Mounted, DC Powered, Load Lifting, Heavy Duty, Industrial Equipment, Construction Equipment, Agricultural Equipment, Compact Crane, Portable Hoist, Cargo Handling, Vehicle Accessory, Mechanical Advantage, Safety Hook, Boom Crane, Frame Mounted, Lifting Capacity, Operational Safety, Self-Contained, Versatile.

Als u een ander formaat nodig heeft, open dan alstublieft een nieuwe Support Ticket en vraag om een ander formaat. Wij kunnen uw 3D modelen van vorm veranderen naar: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. We converteren geen 3D scènes en formaten zoals .step, .iges, .stp, .sldprt.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी