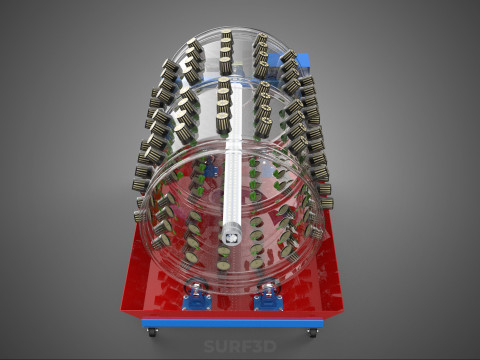

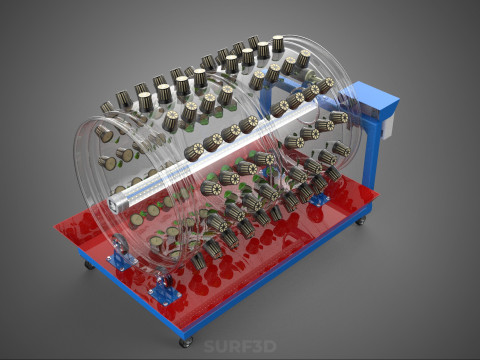

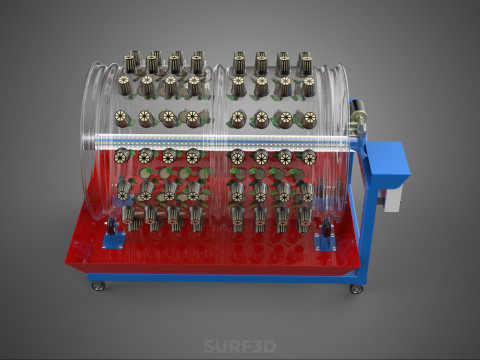

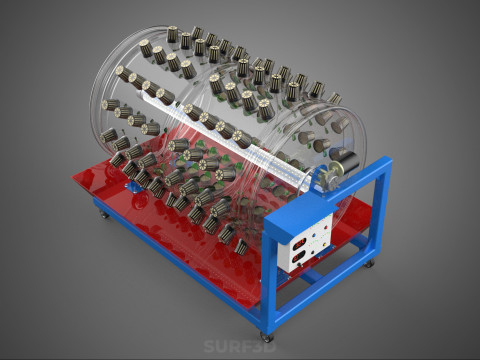

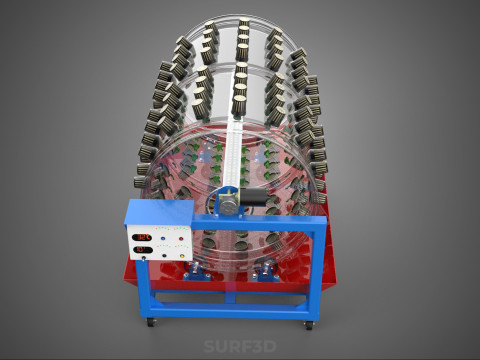

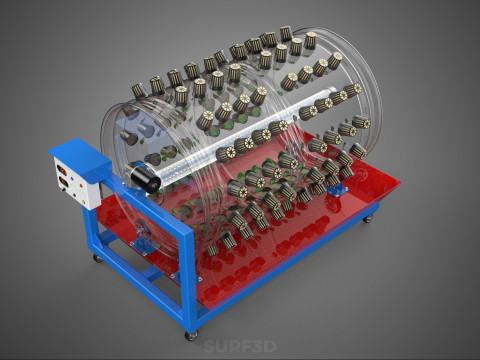

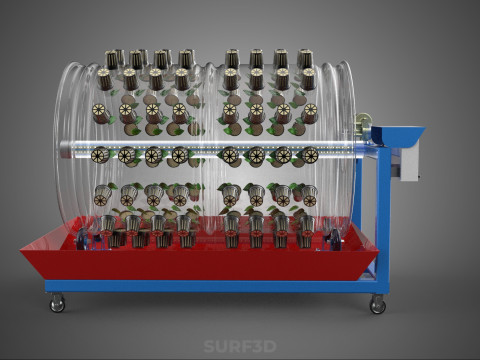

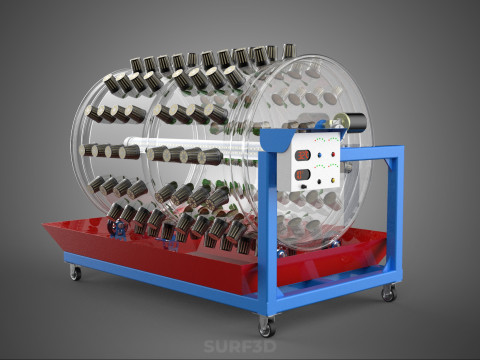

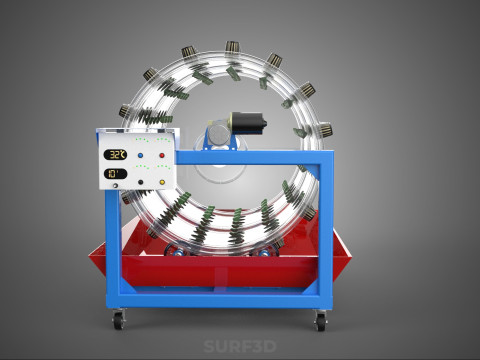

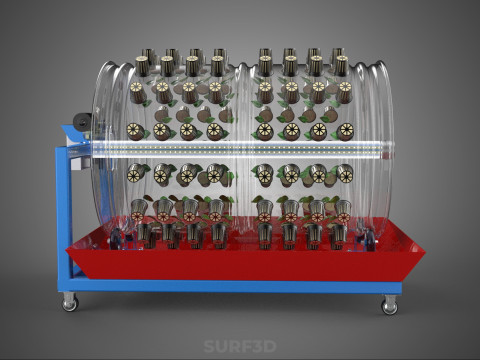

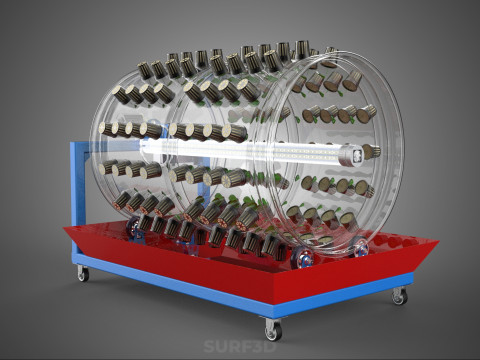

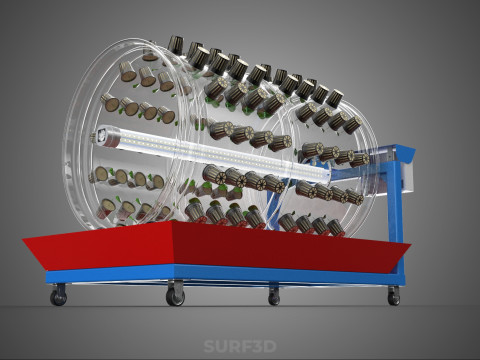

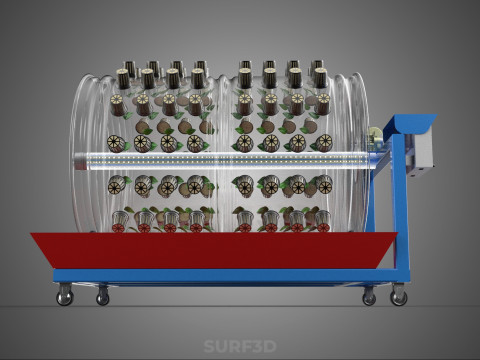

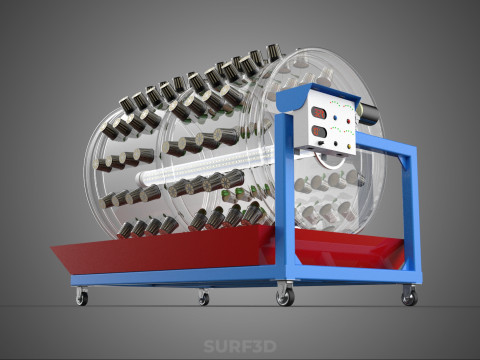

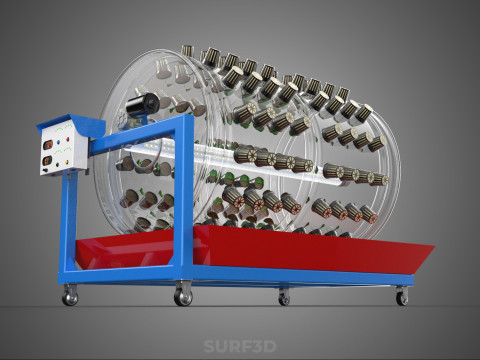

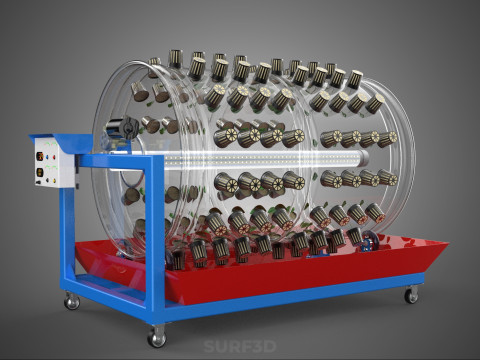

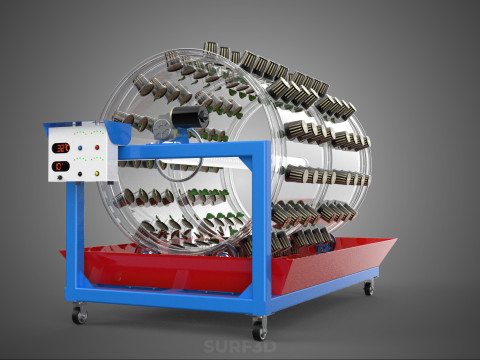

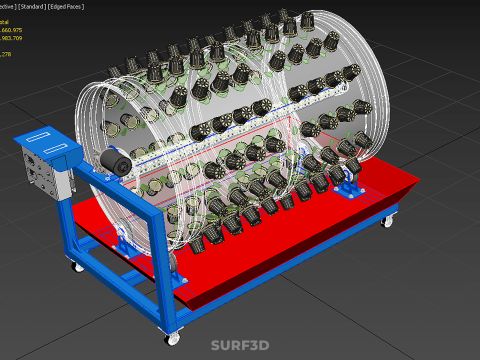

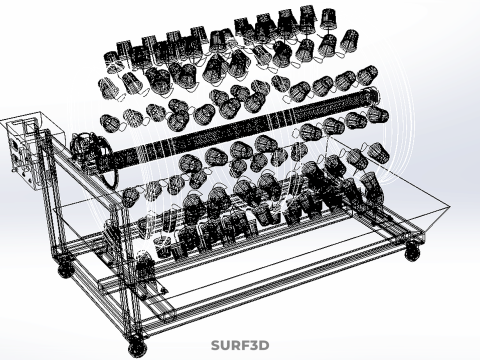

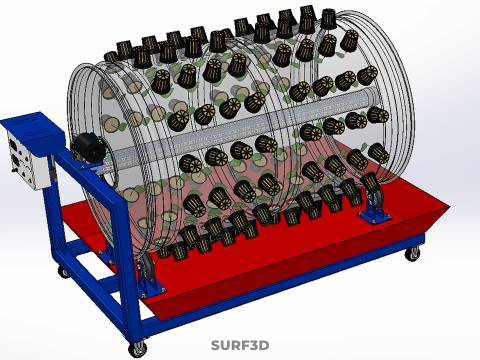

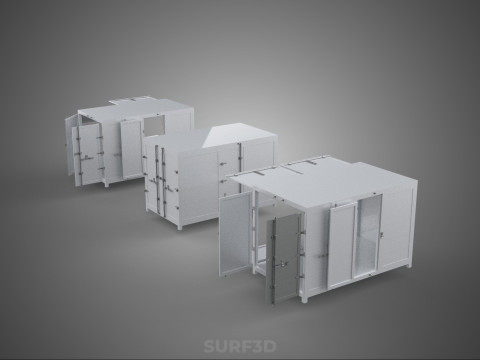

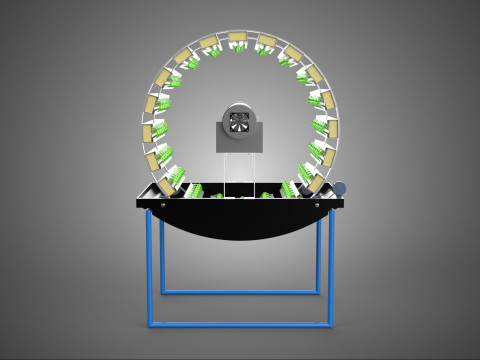

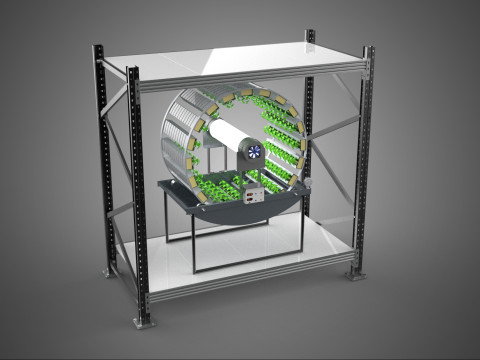

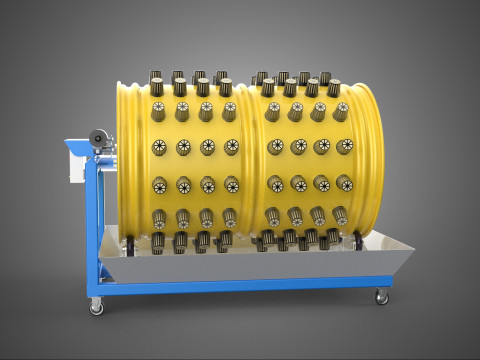

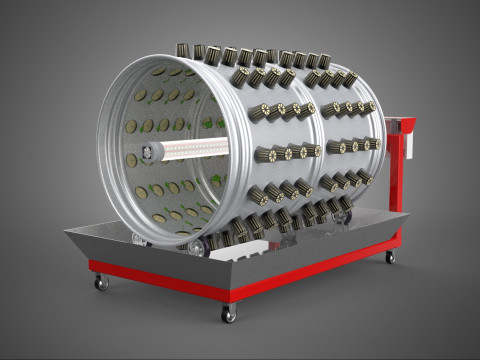

GARDENING ROTARY HYDROPONIC SPIN PLANT GROW FARM CYLINDER SYSTEM 3D Model

- Mogelijke formaten: Rhinoceros (.3dm) 12.56 MB3D Studio (.3ds) 14.63 MBBlender3D (.blend) 53.48 MBCollada (.dae) 45.06 MBAutodesk AutoCAD (.dwg) 14.40 MBAutodesk FBX (.fbx) 74.80 MBGLB (.glb / .gltf) 19.05 MBIGES (.iges) 2.73 MBAutodesk 3DS MAX (.max) 88.05 MBWavefront OBJ (.obj) 38.88 MBACIS(.sat) 37.63 MBSketchUp (.skp) 4.32 MBSTEP (.step) 2.92 MBStereolithography (.stl) 33.91 MB

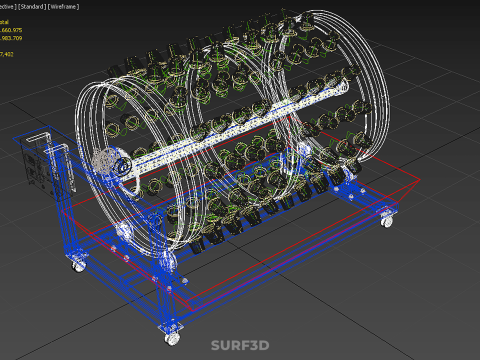

- Polygonen:3660975

- Hoekpunten:2983709

- Geanimeerd:No

- Texturen:No

- Gemanipuleerd:No

- Materialen:

- Low-poly:No

- Collectie:No

- UVW-toewijzing:No

- Plugins Gebruikt:No

- Afdruk Gereed:No

- 3D scan:No

- Volwassen:No

- PBR:No

- AI-training:No

- Geometrie:Poly NURBS

- Onverpakte UV's:Unknown

- Aantal keer bekeken:52

- Datum: 2025-10-07

- Item ID:603795

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

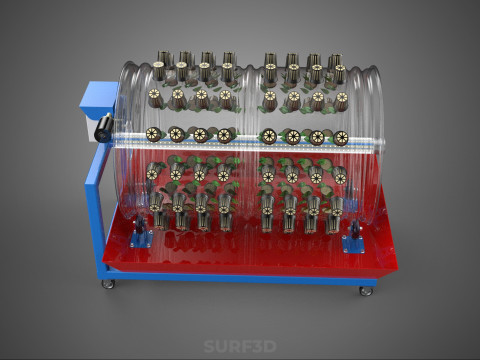

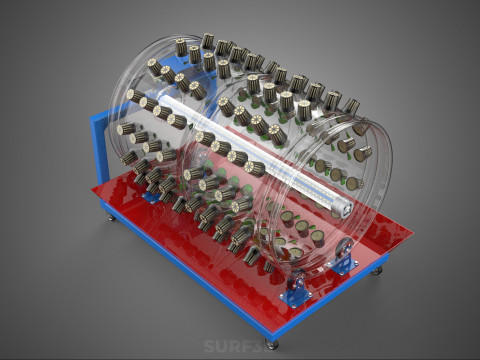

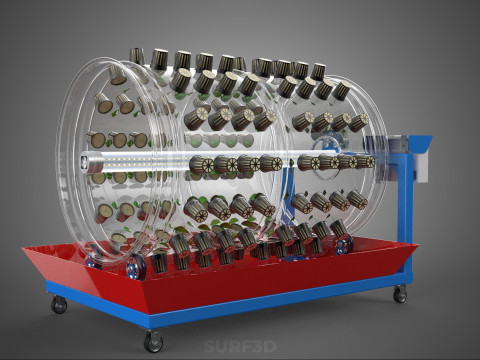

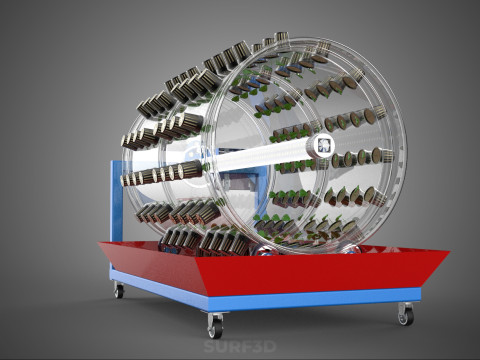

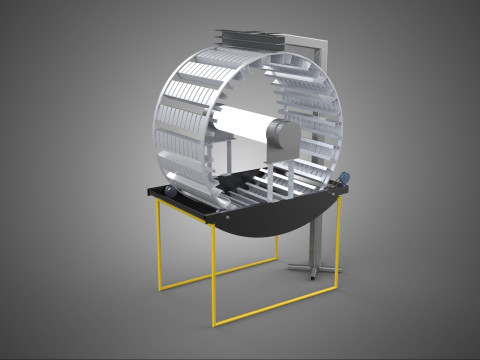

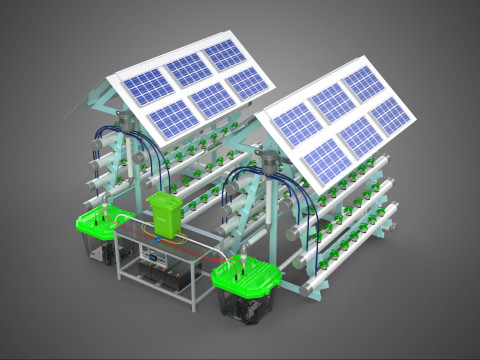

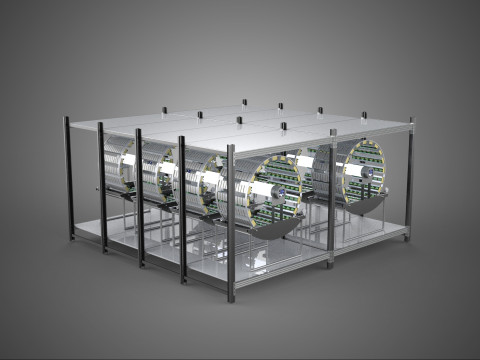

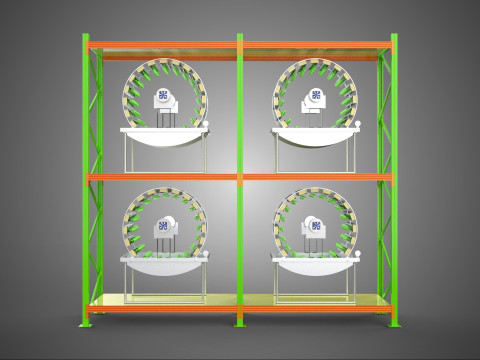

A Gardening Rotary Hydroponic Spin Plant Grow Farm Cylinder System, commonly known as a rotary hydroponic system, is an advanced form of controlled environment agriculture (CEA) that integrates soilless cultivation techniques with a mechanized rotational framework. This innovative system employs a cylindrical design where plants are arranged around a central light source and slowly rotated. The primary objective is to optimize plant growth by maximizing light exposure, enhancing nutrient delivery, and efficiently utilizing vertical space. These systems are well-suited for high-density planting in urban environments, commercial agricultural operations, and sophisticated home gardening setups.

**Core Principles and Mechanics**

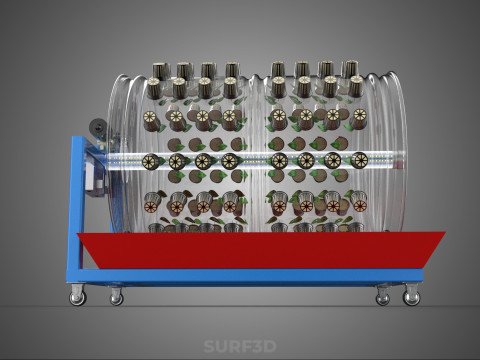

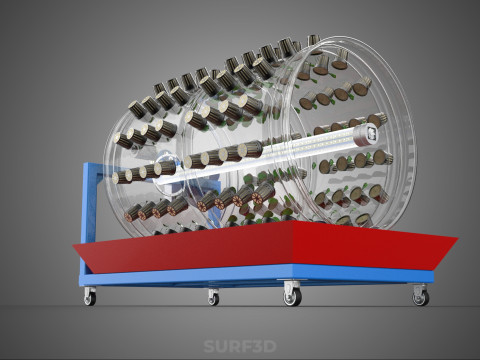

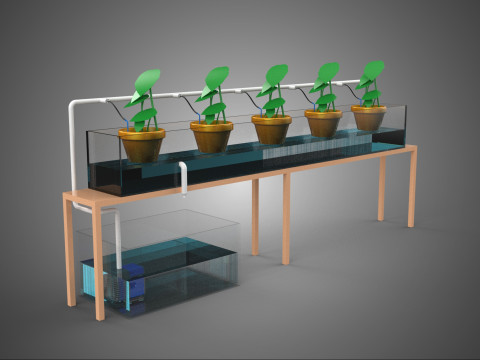

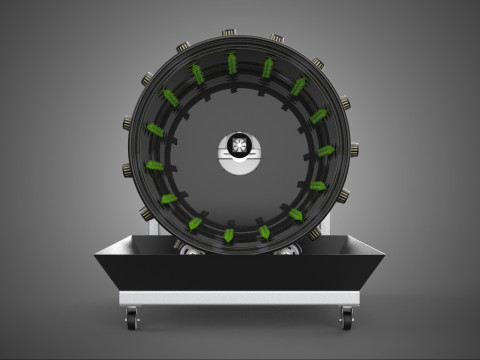

The operational principle of a rotary hydroponic cylinder system centers on optimizing environmental factors for accelerated plant development. At its core, plants are typically housed in net pots or specialized modules affixed to the inner or outer circumference of a large, drum-shaped structure. This entire cylinder slowly rotates, completing a full revolution over a period ranging from minutes to hours. A high-intensity artificial light source, commonly a powerful LED array or High-Intensity Discharge (HID) lamp, is positioned at the central axis of the cylinder, providing uniform illumination as each plant cycles through the light zone.

Nutrient delivery is achieved through hydroponic or aeroponic methods. In hydroponic variants, the plant roots may be intermittently or continuously submerged in a nutrient-rich solution via a wicking system or a thin film technique (NFT) as the cylinder rotates. More advanced systems often utilize aeroponics, where the exposed roots are periodically misted with a fine spray of nutrient solution. This intermittent wetting and drying cycle is believed to promote robust root development and efficient nutrient uptake. The constant rotation ensures that all plants receive equitable exposure to light, preventing etiolation and promoting even, vigorous growth across the entire crop.

**Key Components**

A typical rotary hydroponic cylinder system comprises several integrated components:

1. **Cylindrical Growing Chamber:** The central structure, often a drum or carousel, to which plant growth modules are attached.

2. **Central Light Source:** High-efficiency LED or HID lamps strategically placed along the rotational axis to illuminate plants.

3. **Plant Ports/Modules:** Receptacles, often net pots, designed to hold individual plants and allow root access to the nutrient delivery system.

4. **Nutrient Reservoir:** A tank located at the base of the system, storing the water and dissolved mineral nutrients.

5. **Water Pump and Irrigation System:** Responsible for circulating the nutrient solution from the reservoir to the plant roots, often through misters, drippers, or channels.

6. **Rotational Mechanism:** An electric motor and gearing system that drives the slow, continuous rotation of the growing cylinder.

7. **Control System:** Programmable timers, sensors (for pH, EC, temperature, humidity), and microcontrollers to automate lighting cycles, nutrient delivery, rotation speed, and environmental parameters.

**Operational Advantages**

Rotary hydroponic cylinder systems offer significant advantages over traditional cultivation methods:

* **Space Efficiency:** Their vertical and cylindrical design allows for an exceptionally high plant density per unit of floor area, making them ideal for urban and indoor farming where space is at a premium.

* **Accelerated Growth Rates:** Consistent and optimized exposure to light, along with continuous access to perfectly balanced nutrient solutions, can lead to significantly faster growth cycles and higher yields compared to conventional farming.

* **Water Conservation:** As closed-loop hydroponic systems, they recirculate water, reducing consumption by up to 90-95% compared to soil-based agriculture.

* **Pest and Disease Control:** The controlled, soilless environment inherently minimizes the risk of soil-borne pests and diseases, often reducing or eliminating the need for chemical pesticides.

* **Environmental Control:** The enclosed nature of these systems allows for precise regulation of temperature, humidity, CO2 levels, and light spectrum, creating optimal growing conditions irrespective of external climate.

* **Reduced Labor:** Automation of watering, nutrient delivery, and environmental monitoring significantly decreases manual labor requirements.

**Challenges and Considerations**

Despite their numerous benefits, rotary hydroponic systems present certain challenges:

* **Initial Investment:** The cost of acquiring and setting up a sophisticated rotary system, including specialized lighting and control systems, can be substantial.

* **Technical Expertise:** Operating and maintaining these systems requires a foundational understanding of hydroponics, plant physiology, and potentially basic electrical and mechanical troubleshooting.

* **Energy Consumption:** While efficient, the continuous operation of artificial lighting, pumps, and motors contributes to electricity costs.

* **Maintenance:** Regular cleaning of the system and calibration of sensors are essential to prevent algae growth, nutrient imbalances, and system malfunctions.

* **Crop Suitability:** While versatile, certain large or top-heavy plant species may not be ideally suited for the rotating environment.

**Applications**

The unique characteristics of rotary hydroponic cylinder systems make them valuable in various applications:

* **Urban Agriculture:** Producing fresh, local produce in cities with limited arable land.

* **Commercial Food Production:** High-yield cultivation of leafy greens, herbs, strawberries, and other small-to-medium sized crops.

* **Research and Education:** Providing controlled environments for plant science studies and educational demonstrations.

* **Vertical Farms:** Integrating into larger multi-story farming operations to maximize output.

Als u een ander formaat nodig heeft, open dan alstublieft een nieuwe Support Ticket en vraag om een ander formaat. Wij kunnen uw 3D modelen van vorm veranderen naar: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. We converteren geen 3D scènes en formaten zoals .step, .iges, .stp, .sldprt.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी