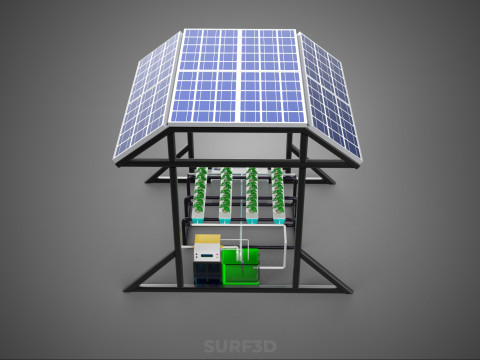

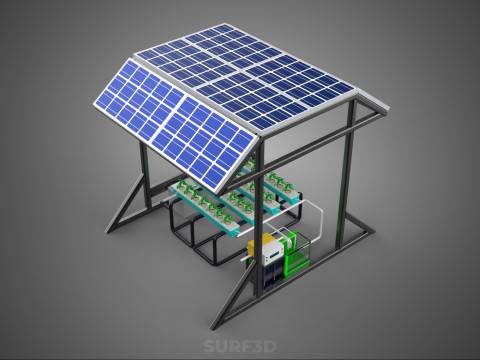

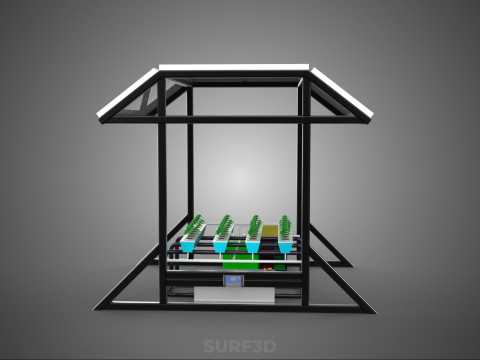

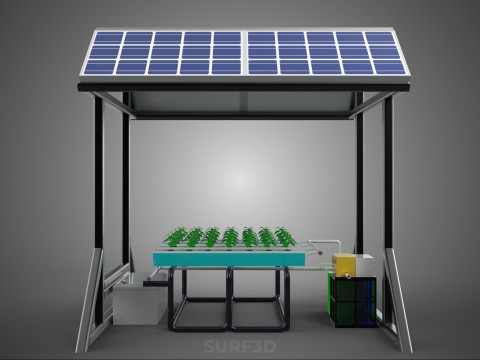

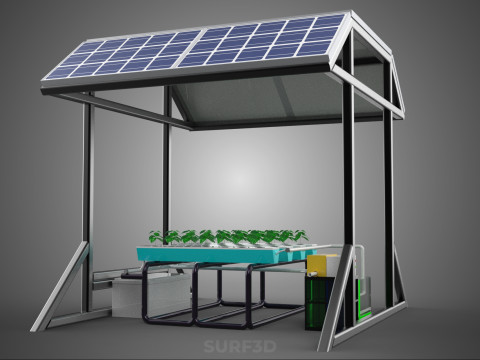

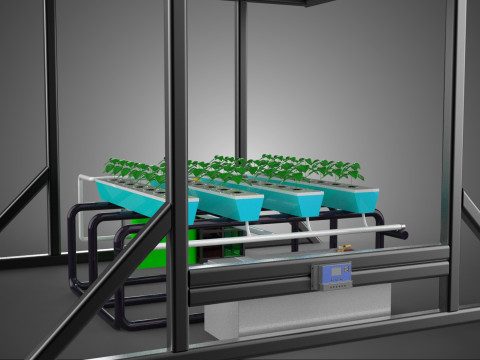

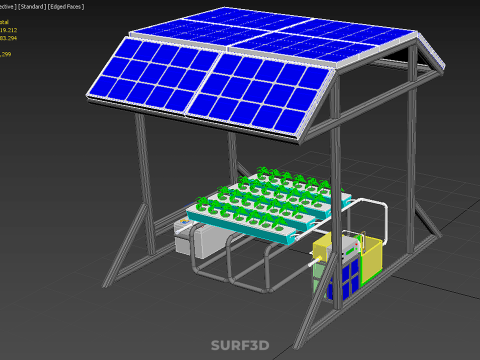

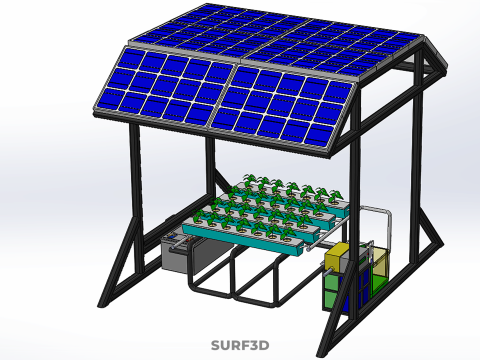

ZONNEDAK ENERGIE VERMOGEN IOT PH NUTRIËNTENCONTROLE HYDROPONIC INSTALLATIE 3D Model

- Vraag productondersteuning

- Mogelijke formaten:

- Item ID:599595

- Datum: 2025-09-17

- Polygonen:919212

- Hoekpunten:683294

- Geanimeerd:No

- Texturen:No

- Gemanipuleerd:No

- Materialen:

- Low-poly:No

- Collectie:No

- UVW-toewijzing:No

- Plugins Gebruikt:No

- Afdruk Gereed:No

- 3D scan:No

- Volwassen:No

- PBR:No

- AI-training:No

- Geometrie:Poly NURBS

- Onverpakte UV's:Unknown

- Aantal keer bekeken:258

Beschrijving

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

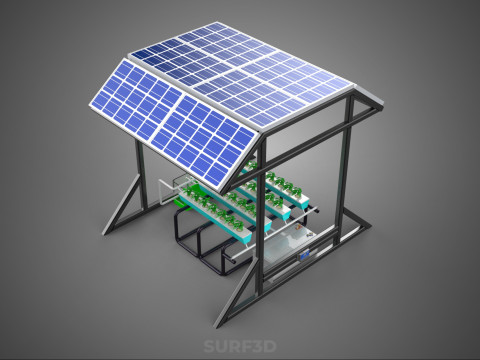

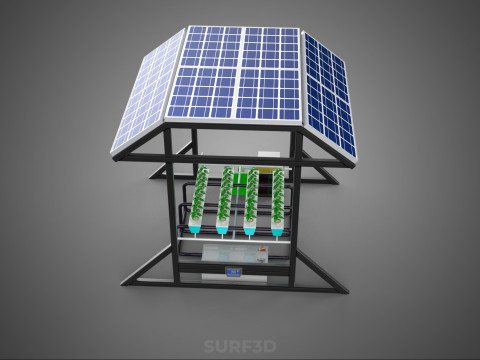

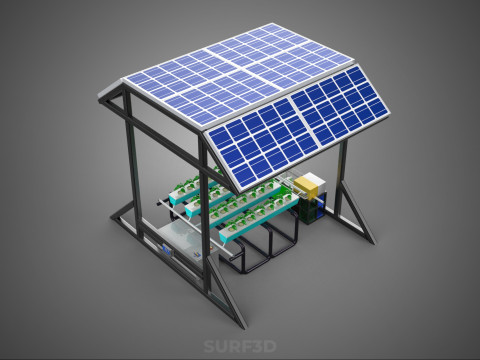

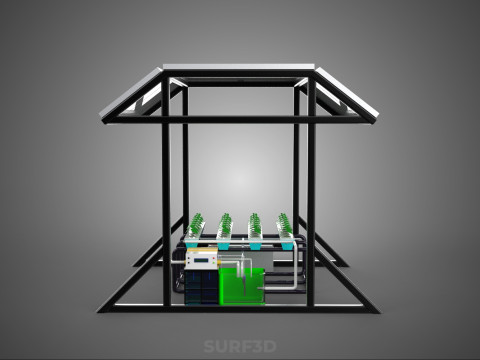

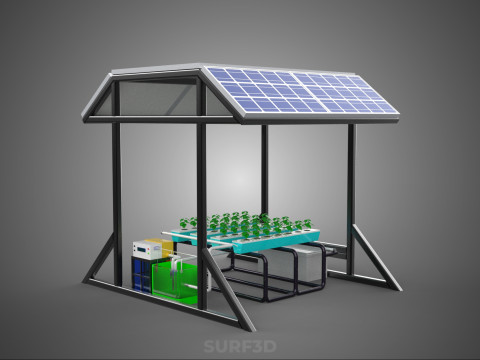

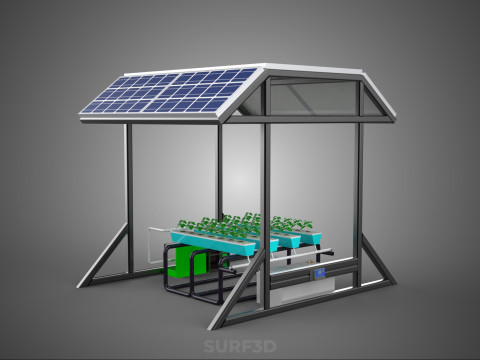

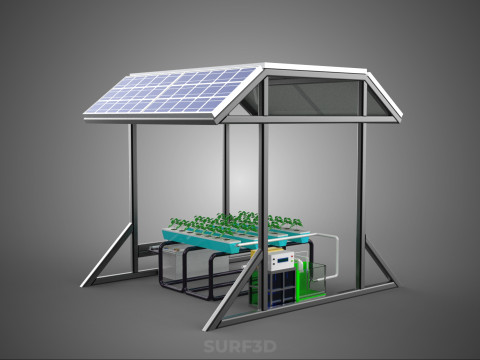

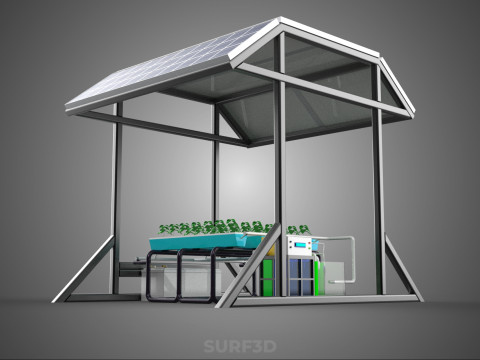

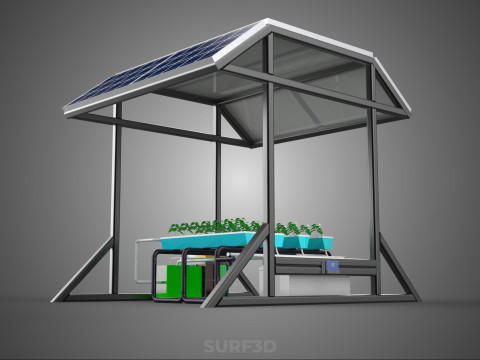

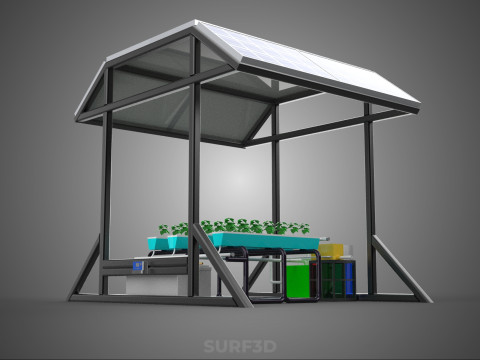

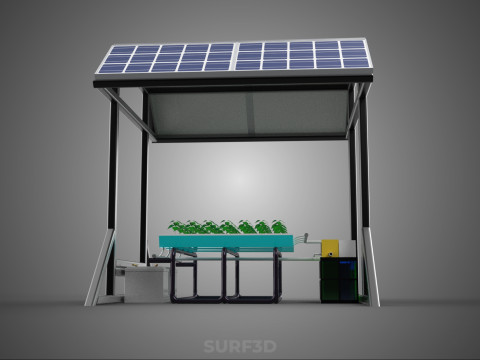

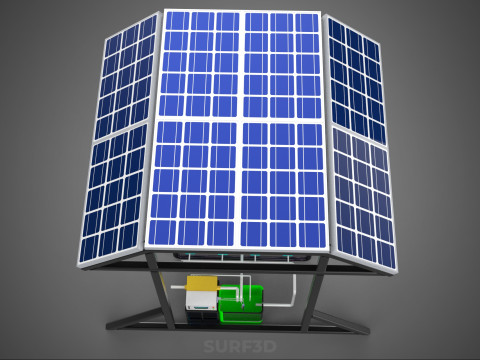

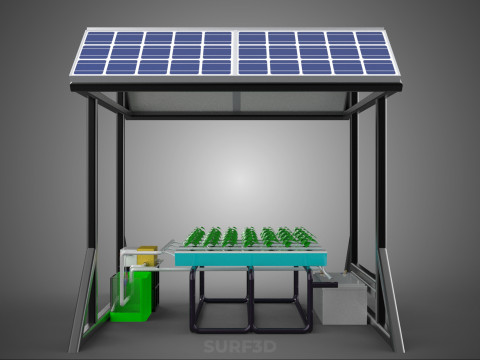

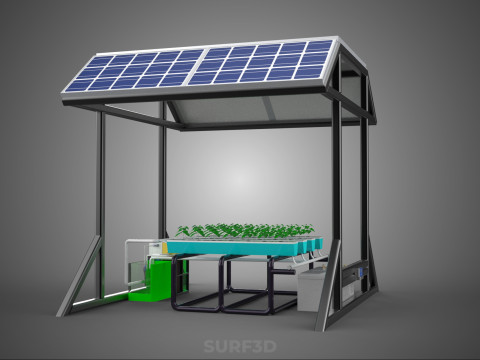

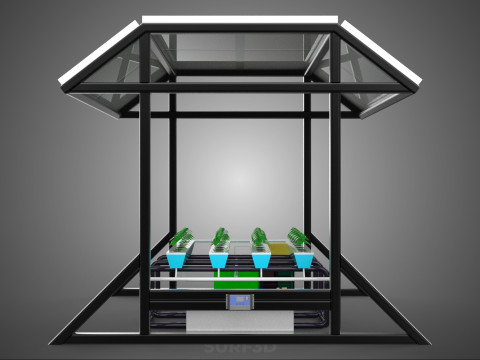

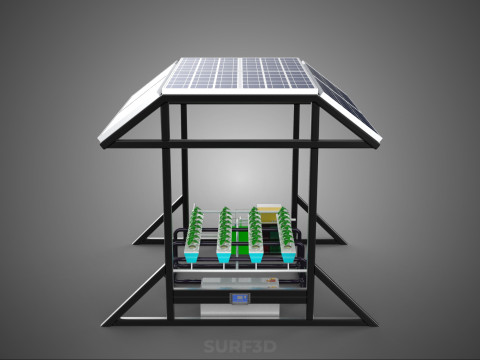

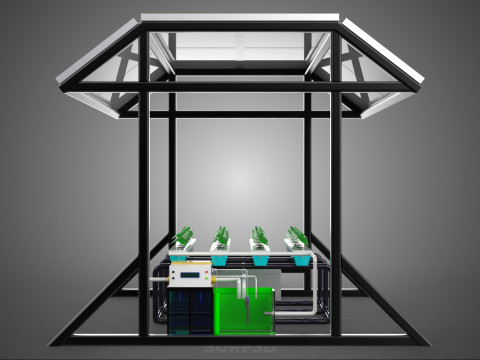

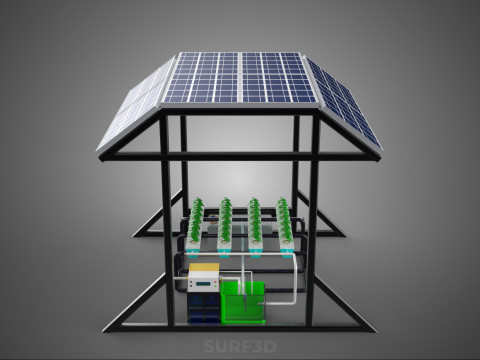

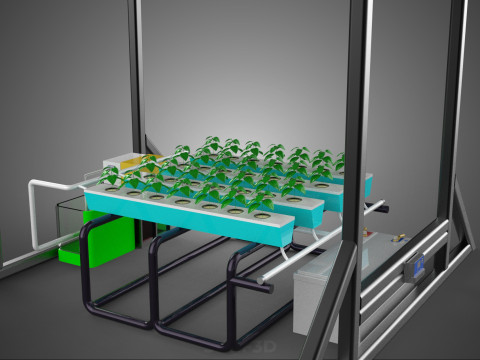

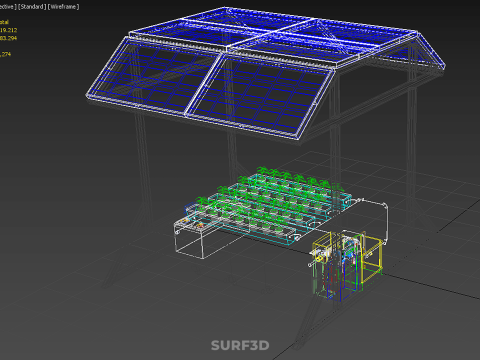

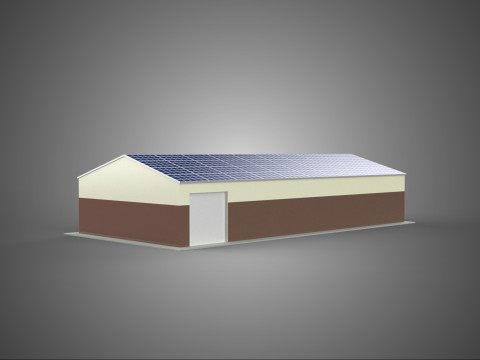

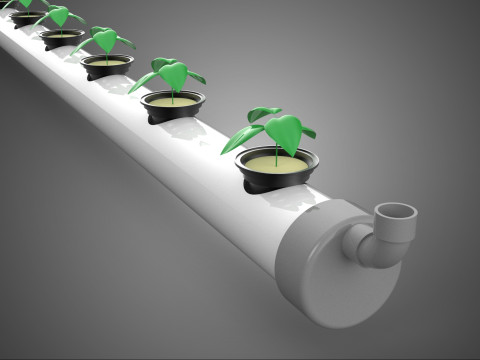

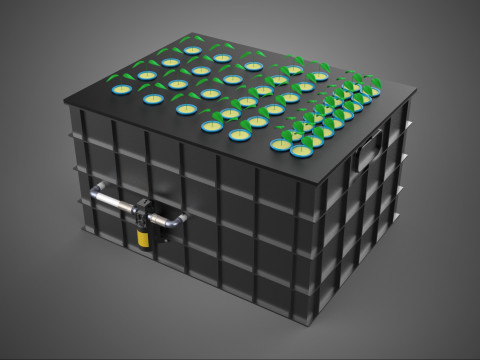

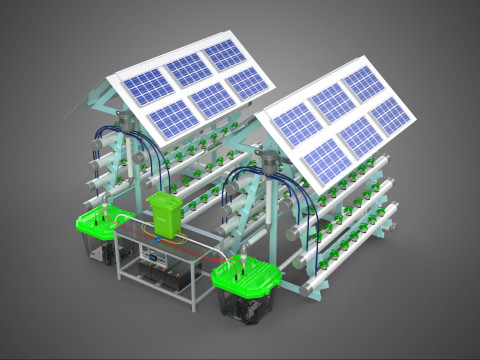

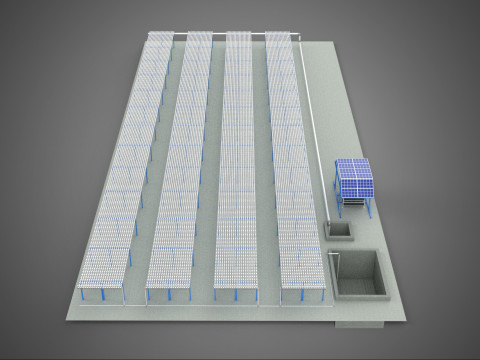

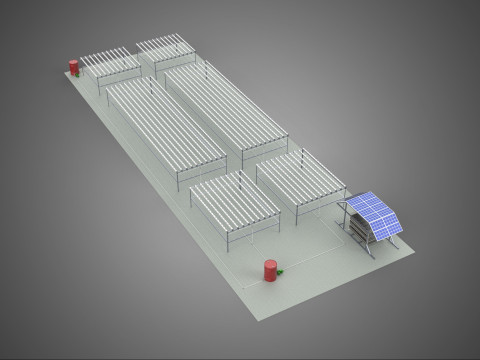

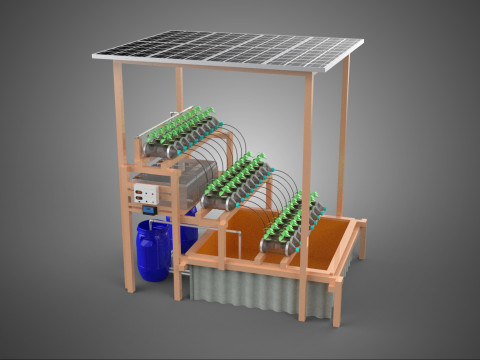

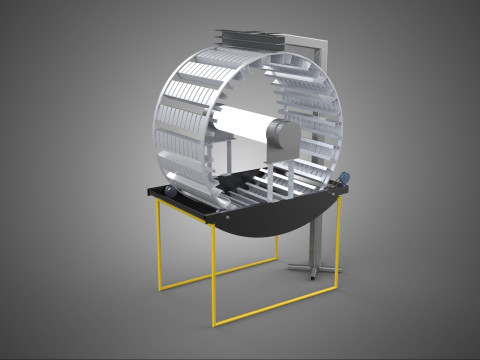

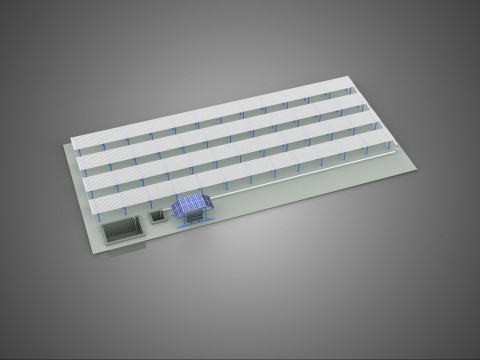

The "SOLAR ROOF ENERGY POWER IOT PH NUTRIENT CONTROL HYDROPONIC PLANT" (SREPIOTPNCHP) refers to an advanced, integrated agricultural system designed for sustainable and optimized soilless plant cultivation. This system synthesizes four primary technological pillars: renewable solar energy generation, pervasive Internet of Things (IoT) connectivity, precise pH and nutrient solution management, and hydroponic plant cultivation. It is frequently configured for rooftop installation to maximize space utilization and leverage available solar insolation for energy independence.

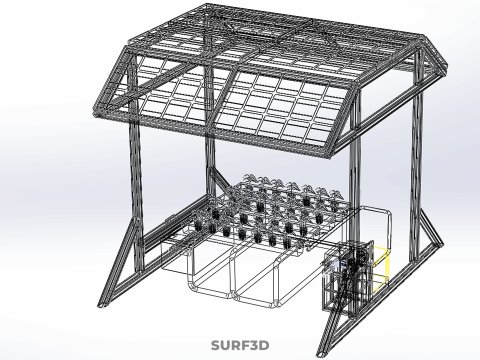

**System Architecture and Core Components:**

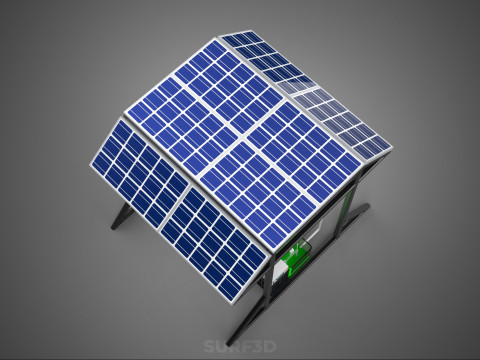

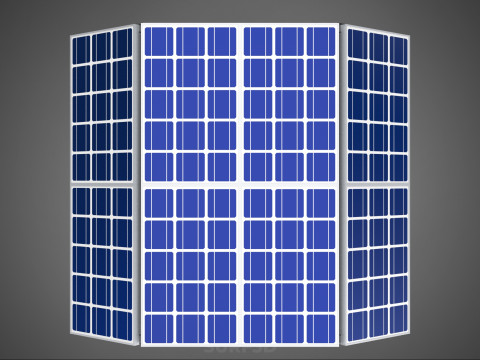

1. **Solar Roof Energy Power System:** The foundational energy source for the entire operation is solar radiation. Photovoltaic (PV) panels are typically mounted on a building's roof, efficiently converting sunlight into direct current (DC) electricity. This energy powers all system components, including pumps, sensors, control units, and communication modules. An integrated energy storage system, commonly comprising battery banks, ensures continuous operation during periods of low sunlight or at night, thereby enhancing system reliability and autonomy. Power management units, including inverters and charge controllers, regulate voltage and current, optimizing energy distribution and efficiency throughout the system.

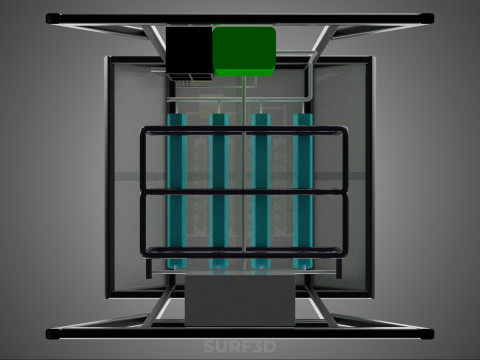

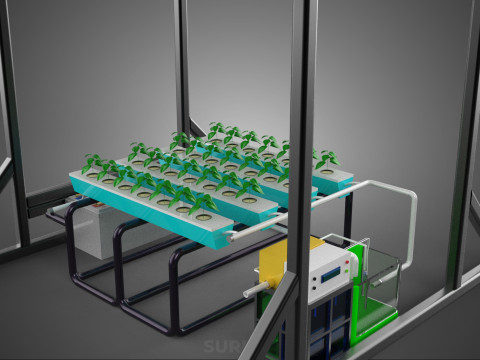

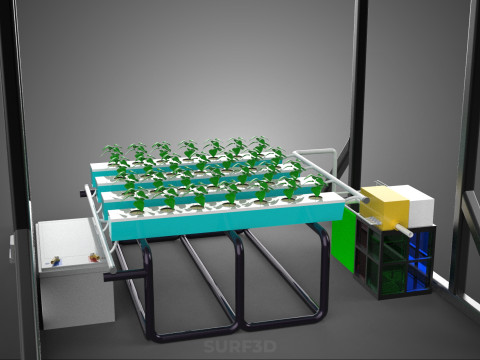

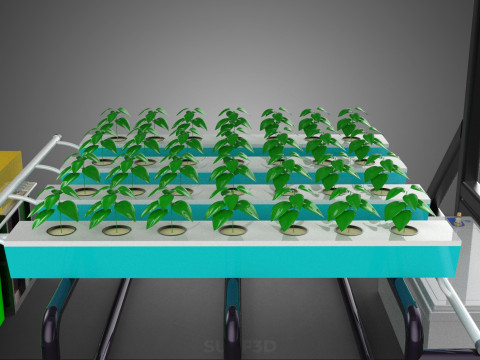

2. **Hydroponic Cultivation Unit:** At its core, the SREPIOTPNCHP facilitates hydroponics, a method of growing plants without soil, utilizing mineral nutrient solutions dissolved in water. Various hydroponic techniques, such as Nutrient Film Technique (NFT), Deep Water Culture (DWC), or recirculating drip systems, can be integrated. The unit typically includes plant growth channels or reservoirs, a centralized nutrient solution reservoir, and a recirculation system equipped with pumps to deliver the nutrient-rich water to plant roots in a controlled manner.

3. **Internet of Things (IoT) Integration:** IoT technology forms the intelligent backbone of the SREPIOTPNCHP, enabling automation, remote monitoring, and data-driven decision-making. It involves a network of interconnected sensors, actuators, and computing devices that collect, transmit, and analyze environmental and operational data.

* **Sensors:** Critical parameters such as pH levels, Electrical Conductivity (EC) (a direct indicator of nutrient concentration), water temperature, solution levels within the reservoir, ambient air temperature, relative humidity, and light intensity are continuously monitored by an array of specialized digital and analog sensors.

* **Microcontrollers and Edge Devices:** Data from these sensors is collected and pre-processed by local microcontrollers (e.g., Arduino, Raspberry Pi) or specialized edge computing devices. These devices can perform real-time data analysis and execute immediate control actions based on pre-programmed thresholds.

* **Data Transmission:** Processed data is transmitted wirelessly (e.g., Wi-Fi, LoRa, cellular, Ethernet) to a centralized, often cloud-based, platform. This enables robust data storage, trend analysis, and the application of machine learning algorithms for predictive insights and long-term optimization.

* **User Interface:** Operators access real-time system status, historical data, and control parameters through a secure web-based dashboard or mobile application, enabling comprehensive remote management and intervention from any location.

4. **pH and Nutrient Control System:** This constitutes the precision agriculture component, critical for maintaining optimal plant health and maximizing yield.

* **Feedback Control Loop:** Based on continuous real-time sensor data for pH and EC, the integrated IoT system implements an automated feedback control loop.

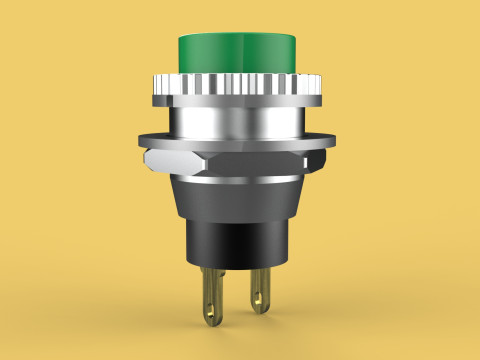

* **Actuators:** If pH levels deviate from the optimal range (which is specific to the plant species being cultivated), automated peristaltic or solenoid pumps precisely inject measured amounts of pH-adjusting solutions (e.g., pH up/down acids or bases) into the nutrient reservoir. Similarly, if EC levels fall below the desired threshold, nutrient dosing pumps replenish concentrated stock solutions (macro and micronutrients), ensuring a consistently optimal nutrient profile.

* **Algorithms:** Advanced control algorithms, such as Proportional-Integral-Derivative (PID) controllers, are often employed to maintain stable and precise environmental conditions, minimizing fluctuations that could induce plant stress and impede growth.

**Operational Principles and Advantages:**

The SREPIOTPNCHP operates autonomously, continuously monitoring and adjusting environmental factors crucial for robust plant growth. Solar panels generate the electrical power, which is stored and then utilized to operate all active components. IoT sensors feed data to a central controller, which, based on pre-set parameters, user inputs, or AI-driven optimization, activates dosing pumps to precisely adjust pH and nutrient concentrations. This intelligent automation provides several significant advantages:

* **Sustainability:** Reduced reliance on grid electricity through solar power generation, minimized water usage (up to 90% less than traditional field farming due to recirculation), and elimination of soil-borne pests and diseases, thereby reducing or eliminating the need for chemical pesticides.

* **Resource Efficiency:** Precise, real-time control over nutrient delivery prevents waste and ensures optimal uptake by plants, leading to higher yields, faster growth cycles, and improved crop quality.

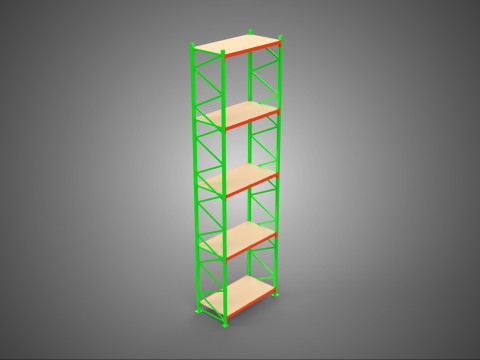

* **Scalability and Adaptability:** The modular nature of these systems makes them suitable for diverse applications, ranging from small-scale urban gardens and research projects to larger commercial installations, and they are adaptable to various crop types.

* **Remote Management:** Enables efficient monitoring and control from any internet-connected location, significantly reducing labor costs and allowing for expert intervention without physical presence.

Meer formaten nodig?

Als u een ander formaat nodig heeft, open dan alstublieft een nieuwe Support Ticket en vraag om een ander formaat. Wij kunnen uw 3D modelen van vorm veranderen naar: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Gratis formaatconversieWe converteren geen 3D scènes en formaten zoals .step, .iges, .stp, .sldprt.!

Gebruiksinformatie

ZONNEDAK ENERGIE VERMOGEN IOT PH NUTRIËNTENCONTROLE HYDROPONIC INSTALLATIE - U kunt dit royaltyvrije 3D model gebruiken voor zowel persoonlijke als commerciële doeleinden, in overeenstemming met de Basislicentie of Uitgebreide Licentie.De Basislicentie dekt de meeste standaard use cases, waaronder digitale advertenties, ontwerp- en visualisatieprojecten, zakelijke socialmedia-accounts, native apps, webapps, videogames en fysieke of digitale eindproducten (zowel gratis als verkocht).

De Uitgebreide Licentie omvat alle rechten die worden verleend onder de Basislicentie, zonder gebruiksbeperkingen, en staat toe dat het 3D model wordt gebruikt in onbeperkte commerciële projecten onder royaltyvrije voorwaarden.

Lees meer

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी