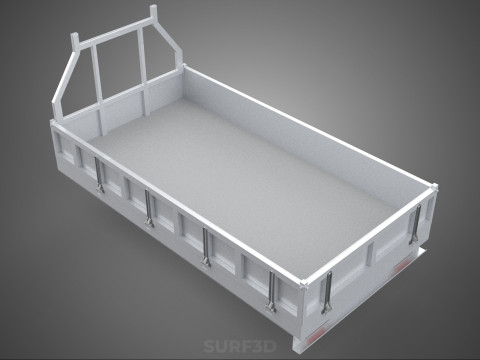

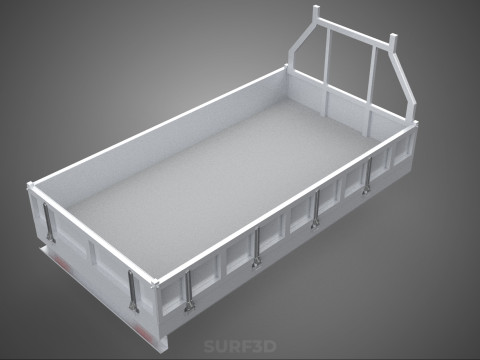

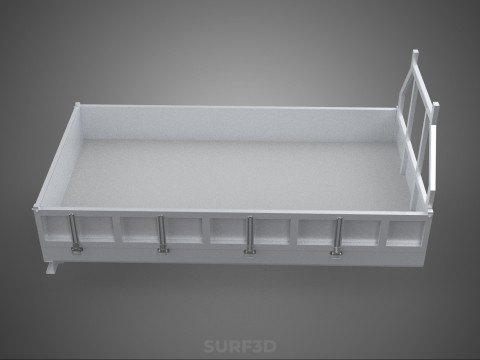

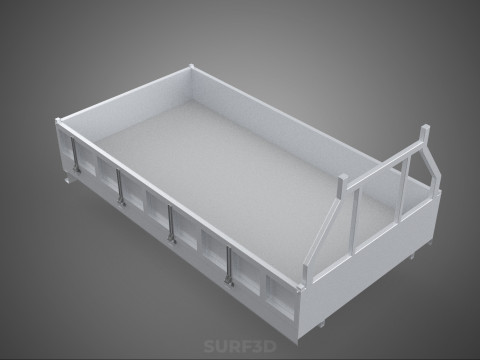

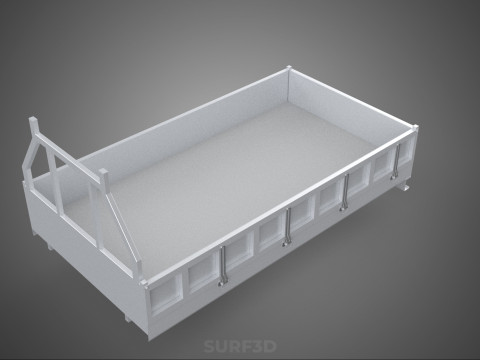

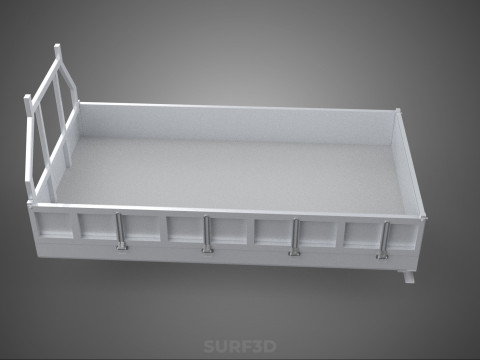

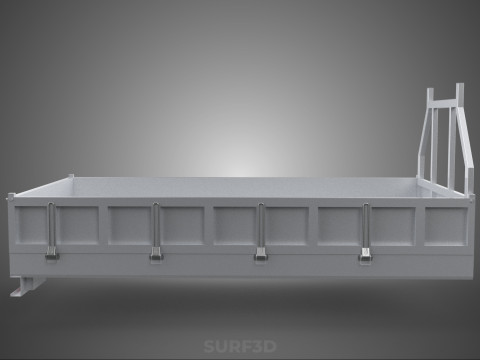

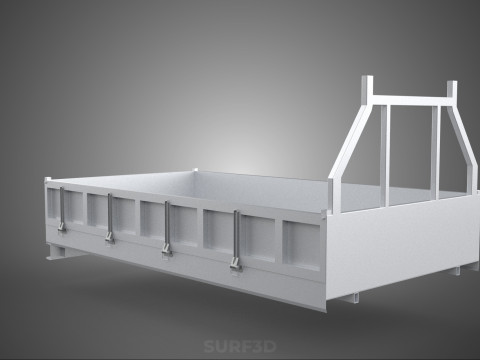

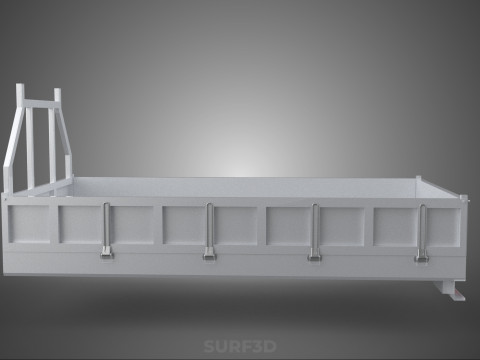

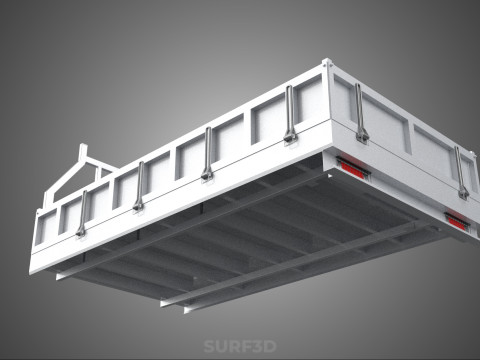

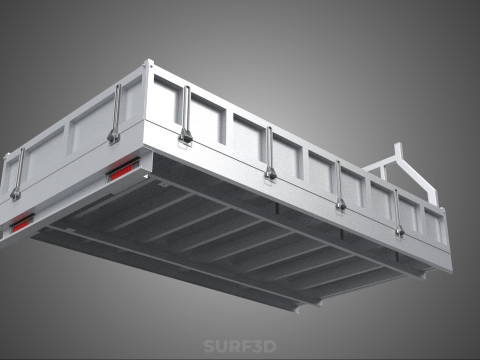

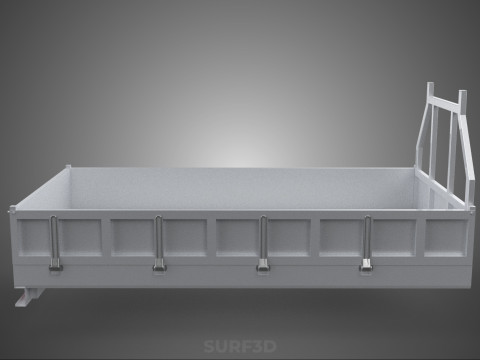

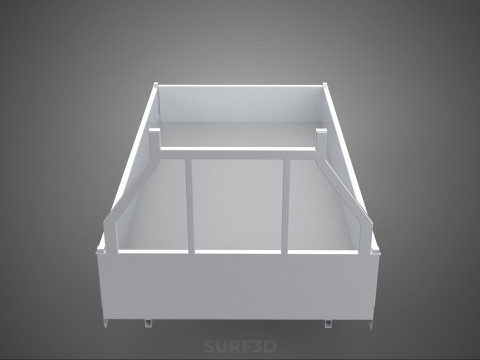

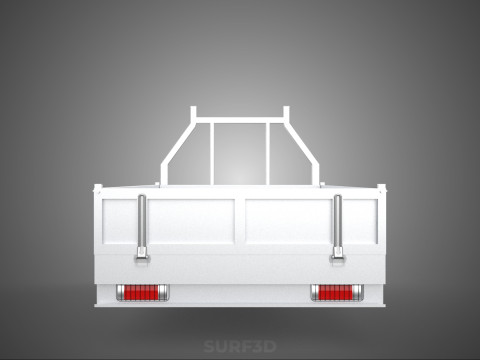

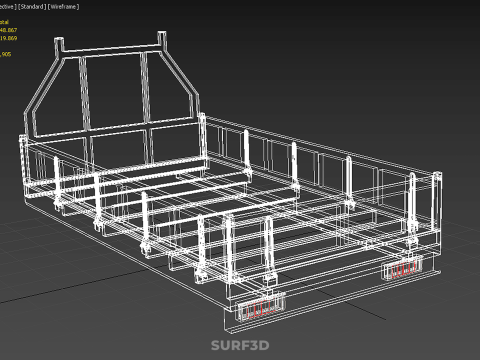

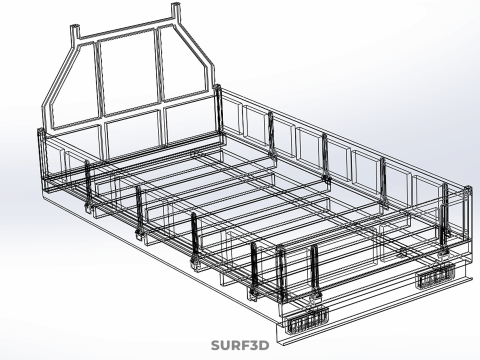

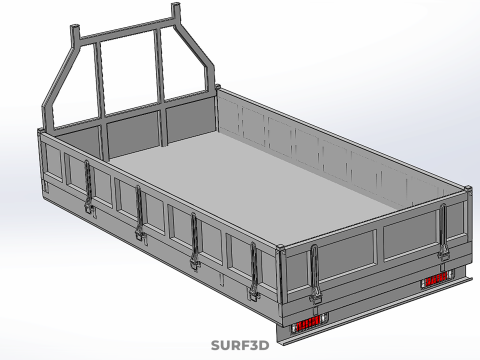

CARGO BED PICKUP TRUCK PLATFORM FRAME HEADBOARD BACK TRAY RACK Model 3D

- Dostępne formaty: Rhinoceros (.3dm) 15.25 MB3D Studio (.3ds) 933.78 kbBlender3D (.blend) 2.62 MBCollada (.dae) 2.54 MBAutodesk AutoCAD (.dwg) 4.13 MBAutodesk FBX (.fbx) 3.85 MBGLB (.glb / .gltf) 1.15 MBIGES (.iges) 2.94 MBAutodesk 3DS MAX (.max) 6.40 MBWavefront OBJ (.obj) 1.76 MBACIS(.sat) 4.70 MBSketchUp (.skp) 4.07 MBSTEP (.step) 5.02 MBStereolithography (.stl) 1.94 MB

- Wielokąty:148867

- Wierzchołki:119869

- Model animowany:No

- Tekstury:No

- Oparty na szkielecie:No

- Materiał:

- Low-poly:No

- Kolekcja:No

- UVW mapping:No

- Plugins Used:No

- Gotowy do wydruku:No

- 3D Scan:No

- Adult content:No

- PBR:No

- AI Szkolenie:No

- Geometria:Poly NURBS

- Unwrapped UVs:Unknown

- Liczba wyświetleń:210

- Data: 2025-07-29

- ID produktu:590085

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

A **Cargo Bed Platform Frame with Headboard Back Tray Rack for Pickup Truck** is a specialized aftermarket or original equipment manufacturer (OEM) accessory system designed to significantly enhance the utility, organization, and cargo-carrying capacity of light and medium-duty pickup trucks. This integrated system combines an elevated load-bearing surface within the truck bed with a protective barrier for the cab and an extended overhead rack for oversized items. It is primarily utilized by tradespeople, utility services, and outdoor enthusiasts requiring robust solutions for transporting diverse and often cumbersome loads.

**I. Components and Functionality**

The system comprises three primary interconnected components:

* **Cargo Bed Platform Frame:** This is a sub-frame structure installed directly within the pickup truck's cargo bed. Its fundamental purpose is to create a raised, flat, and typically level load-bearing surface above the original bed floor, often extending over the wheel wells. This design innovation accomplishes several objectives:

* **Two-Tier Loading:** It enables the creation of a distinct lower storage area beneath the platform, ideal for tools, equipment, or smaller items, while maintaining a clear, expansive upper surface for primary cargo.

* **Maximizing Usable Space:** By elevating the primary load floor, it effectively mitigates the intrusion of wheel wells, thereby maximizing flat, usable cargo area.

* **Protection:** The platform protects the original truck bed floor from impact, abrasion, and spills.

* **Load Distribution:** Engineered to distribute weight efficiently across the truck's frame, enhancing stability and safety.

Materials commonly used include high-strength steel or lightweight aluminum alloys, often finished with a powder coat for corrosion resistance and durability. The platform may incorporate integrated tie-down points, drainage channels, or modular attachment points for further customization.

* **Headboard:** Positioned at the extreme front of the truck bed, directly behind the vehicle's cab, the headboard serves as a crucial vertical barrier. Its primary function is the protection of the truck's rear window, cab structure, and occupants from shifting cargo during acceleration, braking, or cornering. Beyond its protective role, the headboard frequently serves as a robust mounting point for auxiliary lighting, work lights, tool racks, or as the foundational support structure for the integrated back tray rack. Like the platform frame, it is typically constructed from durable steel or aluminum and designed to withstand significant impact forces.

* **Back Tray Rack (or Overhead Rack/Lumber Rack):** This component represents a structural extension, typically originating from the headboard and extending horizontally over the truck's cab, or in some configurations, as a separate rear upright structure. The nomenclature "back tray rack" often implies a design integrated with the headboard that provides an elevated platform or set of cross-bars for carrying items that exceed the length of the truck bed. Its core function is to facilitate the secure transport of oversized materials such as lumber, ladders, piping, kayaks, or other lengthy equipment that cannot be safely contained within the confines of the bed alone. These racks are designed for high load capacities and often feature adjustable cross-bars, multiple tie-down points, and an aerodynamic profile to minimize wind resistance.

**II. Design Principles and Applications**

The design philosophy behind these integrated systems emphasizes modularity, structural integrity, and user-centric functionality. Systems are engineered to be robust, capable of handling significant dynamic loads, and often feature bolt-on installations that may or may not require drilling into the truck's frame or bed. Compatibility is generally ensured through specific designs tailored to various truck makes and models, though universal-fit options with adjustable components also exist.

The principal advantages of deploying a Cargo Bed Platform Frame with Headboard Back Tray Rack include:

* **Increased Cargo Versatility:** Allows for the simultaneous transport of a wide array of cargo, from tools and small items beneath the platform to long materials and equipment on the rack.

* **Enhanced Organization:** Provides structured storage, reducing clutter and improving efficiency for professionals.

* **Superior Load Security:** Multiple integrated tie-down points and the stable platform significantly improve the safety of transported goods.

* **Cab Protection:** Shields the vehicle's cabin from potential damage by forward-shifting cargo.

* **Operational Efficiency:** Reduces the need for trailers for long items, improving maneuverability and fuel economy.

**III. Variations and Customization**

Variations of this system can include platforms with integrated drawers or compartments, removable panels for specialized access, and headboards with integrated lighting or tool mounts. Rack systems may feature different load capacities, adjustable heights, or specialized attachments for specific equipment like conduit carriers or utility boxes, further enhancing the system's adaptability to diverse professional and recreational needs.

KEYWORDS: Pickup truck accessory, cargo management, truck bed organizer, platform frame, headboard, back tray rack, ladder rack, lumber rack, utility truck, equipment storage, tool organization, cargo capacity, load security, cab protection, aftermarket accessory, modular design, heavy-duty, commercial vehicle, contractor gear, outdoor equipment, elevated storage, durable construction, aluminum, steel, tie-down points, weight distribution, utility system, professional grade, vehicle customization, truck bed solution.

Jeśli potrzebny Ci plik w innym formacie, zgłoś taką potrzebę przez opcję Support Ticket Konwertujemy produkty na następujące formaty: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Nie konwertujemy scen 3D oraz formaty takie jak .step, .iges, .stp, .sldprt.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी