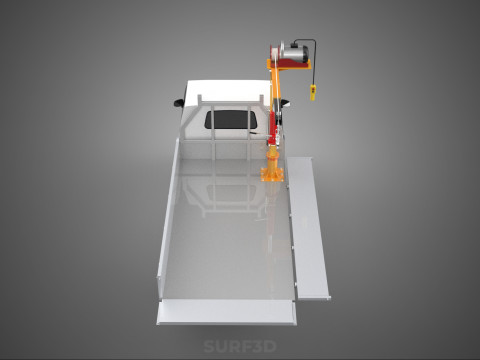

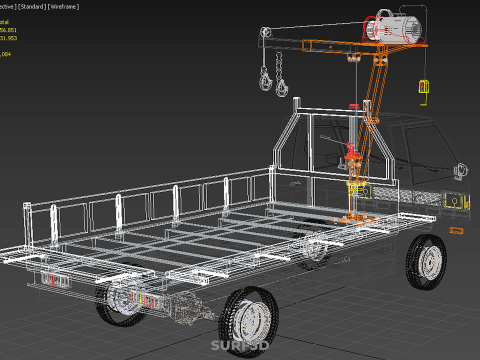

GRU LATERALE RIBALTABILE PARANCO VERRICELLO ELETTRICO PIANALE DI CARICO CANCELLO PICKUP Modello 3D

- Richiedi supporto per il prodotto

- Formati disponibili:

- ID Oggetto:593296

- Data: 2025-08-19

- Pligoni:656851

- Vertici:531953

- Animato:No

- Textured:No

- Rigged:No

- Materiali:

- Low-poly:No

- Collezione:No

- Mapping UVW:No

- Plugins Utilizzati:No

- Stampa Pronta:No

- 3D Scan:No

- Per adulti:No

- PBR:No

- AI Formazione:No

- Geometria:Poly NURBS

- UVs Aperti:Unknown

- Visualizzazioni:260

Descrizione

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

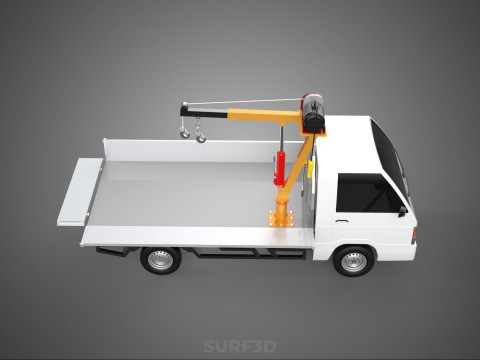

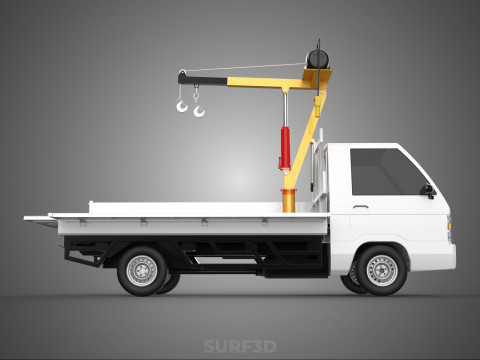

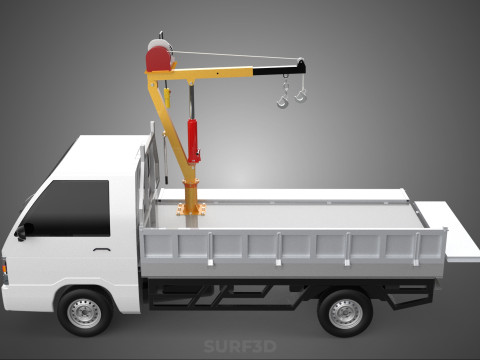

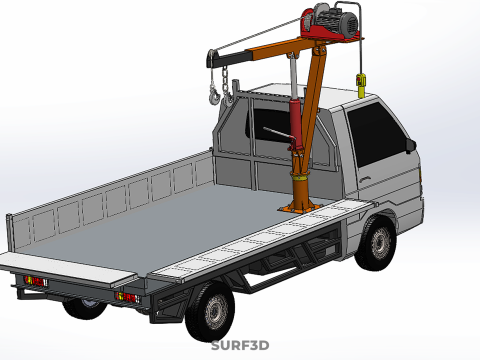

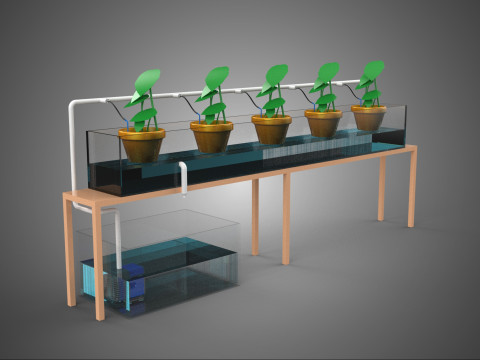

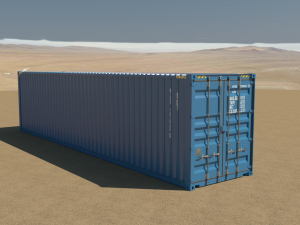

A "Drop Side Crane Hoist Electric Winch Load Bed Gate Pickup Truck" designates a specialized and highly functional variant of a standard pickup truck, extensively modified and equipped to enhance its material handling and cargo transportation capabilities. This integrated system combines the inherent mobility and utility of a light-to-medium-duty truck with advanced mechanical lifting and loading mechanisms, specifically a crane hoist powered by an electric winch, all designed to operate efficiently with a versatile drop-side load bed.

The primary purpose of such a configuration is to facilitate the efficient loading, unloading, and transportation of heavy, bulky, or unwieldy materials and equipment that would otherwise necessitate significant manual labor, external machinery, or multiple personnel. It transforms a conventional pickup truck into a self-sufficient mobile lifting and hauling platform, thereby increasing operational efficiency, mitigating physical strain on operators, and enhancing safety in diverse work environments.

**Component Breakdown:**

1. **Pickup Truck Base:** This serves as the fundamental chassis and power unit for the entire system. Its relatively compact size and maneuverability, compared to larger commercial vehicles, enable it to navigate various terrains, including urban settings, construction sites, and off-road environments. The truck's engine and electrical system provide the necessary power for both propulsion and the integrated auxiliary equipment.

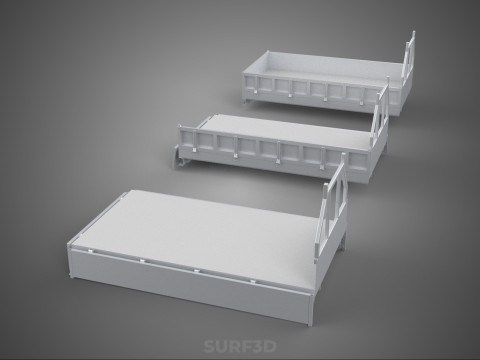

2. **Drop-Side Load Bed:** This is a specialized design for the cargo area where the side panels and often the rear gate (tailgate) are hinged at their bottom edge, allowing them to swing open downwards. This design provides significantly improved accessibility to the load bed from all three sides, greatly simplifying the process of loading and unloading materials, especially when using forklifts, external cranes, or the integrated on-board crane. The traditional "Load Bed Gate" functions as the rear access point, often designed for heavy-duty use and contributing to the overall cargo retention. When open, the drop sides create a flat, open platform, useful for oversized items or for direct access during loading.

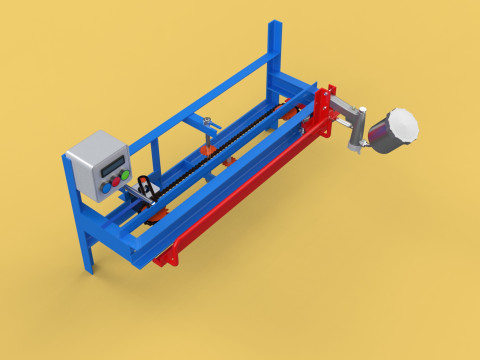

3. **Crane Hoist System:** An articulating boom or jib crane, typically mounted directly behind the truck cab or at a rear corner of the load bed. This hydraulic (more common) or manually operated arm is engineered to lift, lower, and pivot loads. Its reach, lifting capacity, and slew angle are critical specifications, carefully matched to the truck's chassis strength and intended applications. The crane's mounting point is robustly reinforced to distribute the significant stresses generated during lifting operations effectively across the vehicle's frame, ensuring stability and structural integrity.

4. **Electric Winch Integration:** The "Electric Winch" is the core lifting component integrated into the crane hoist. It comprises an electric motor, a robust gear reduction system, a drum around which a high-strength cable (either wire rope or synthetic line) is spooled, and a hook or other load attachment point. Powered directly by the truck's 12V or 24V electrical system (often necessitating heavy-duty alternators or auxiliary battery banks to meet peak current demands), the electric winch provides the controlled power required to hoist and lower loads smoothly and precisely. Its operation is commonly managed via a wired or wireless remote control, affording the operator the flexibility to control lifting tasks from a safe distance with optimal visibility of the load and surroundings. The reliance on electric power eliminates the need for external power sources, enhancing the system's self-sufficiency and operational flexibility.

**Applications:**

This versatile vehicle configuration finds extensive application across a broad spectrum of industries, including:

* **Construction and Landscaping:** For the transport and placement of building materials, tools, rocks, trees, and other heavy items on job sites.

* **Utility Services:** Utilized by telecommunications, electrical, and plumbing companies for deploying and positioning equipment such as transformers, poles, or pipe sections.

* **Specialized Delivery and Logistics:** For the precise delivery of heavy machinery components, industrial equipment, or large parcels that require on-site offloading capabilities.

* **Municipal and Maintenance Crews:** For tasks involving the installation or removal of street furniture, park equipment, or for specific waste management operations.

* **Agricultural Settings:** For handling feed bags, machinery parts, or harvested goods that require mechanical assistance.

**Advantages:**

The combination of these features offers several significant advantages:

* **Versatility:** Capable of both efficient transport and independent loading/unloading operations.

* **Efficiency:** Reduces reliance on external lifting equipment or multiple personnel, resulting in significant time and labor cost savings.

* **Safety:** Minimizes manual handling of heavy objects, thereby reducing the risk of workplace injuries.

* **Maneuverability:** Retains much of the pickup truck's inherent agility and compact footprint compared to larger, dedicated crane vehicles.

* **Cost-Effectiveness:** For many light-to-medium-duty applications, it presents a more economical solution than acquiring a standalone crane vehicle or regularly hiring external lifting services.

**Considerations:**

Critical considerations for such a setup include the truck's Gross Vehicle Weight Rating (GVWR) and payload capacity, which must accommodate the added weight of the crane and winch system, as well as the maximum load to be lifted. Stability during crane operation is paramount, often requiring the deployment of outriggers or stabilizing legs to prevent tipping, especially with heavier loads or extended reaches. The electrical system's capacity to handle the significant current draw of the electric winch is also crucial for reliable operation.

Hai bisogno di ulteriori formati?

Se hai bisogno di diversi formati, aprire un nuovo Ticket i Supporto e una richiesta per questo. Convertiamo modelli 3D a: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Conversione di formato gratuitaNon convertiamo scene 3d e formati come .step, .iges, .stp, .sldprt.!

Informazioni sull'utilizzo

GRU LATERALE RIBALTABILE PARANCO VERRICELLO ELETTRICO PIANALE DI CARICO CANCELLO PICKUP - È possibile utilizzare questo modello 3D royalty-free sia per scopi personali che commerciali, in conformità con la licenza base o estesa.La licenza base copre la maggior parte dei casi d'uso standard, tra cui pubblicità digitale, progetti di design e visualizzazione, account aziendali sui social media, app native, app web, videogiochi e prodotti finali fisici o digitali (sia gratuiti che venduti).

La licenza estesa include tutti i diritti concessi dalla licenza base, senza limitazioni d'uso, e consente l'utilizzo del modello 3D in un numero illimitato di progetti commerciali secondo i termini royalty-free.

Leggi ulteriori

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी