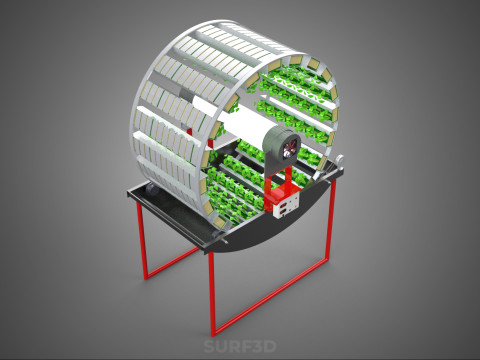

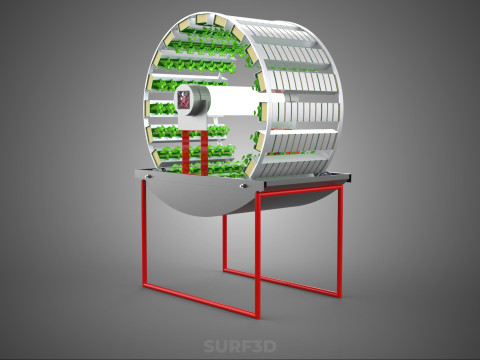

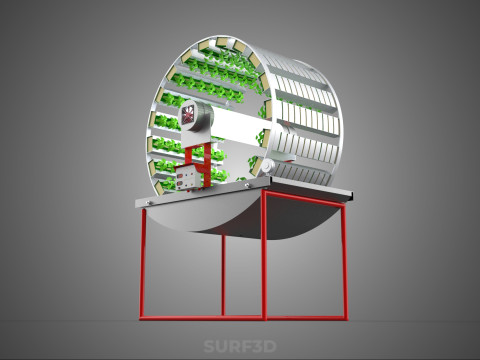

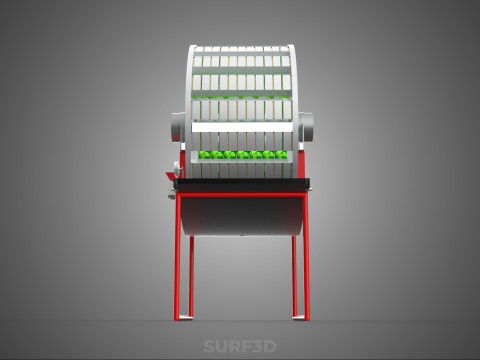

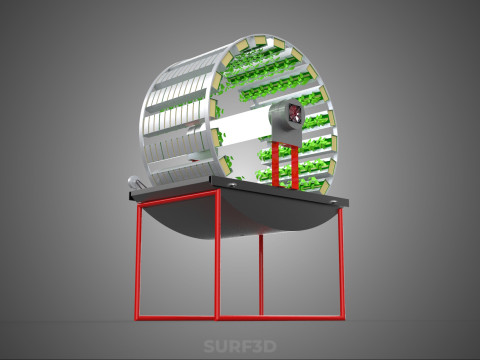

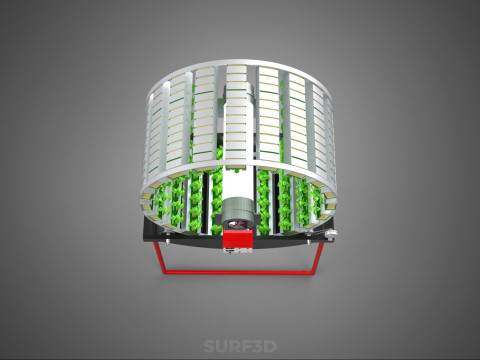

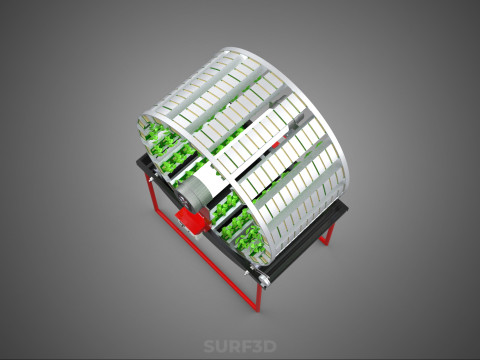

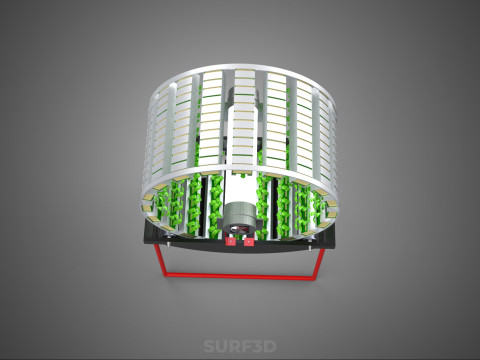

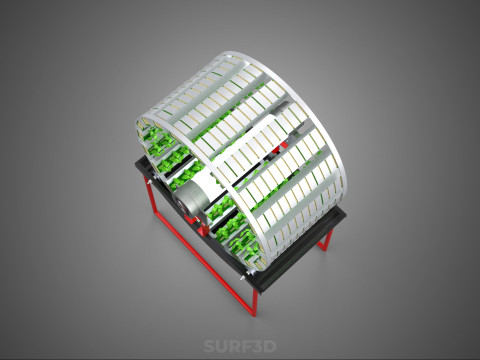

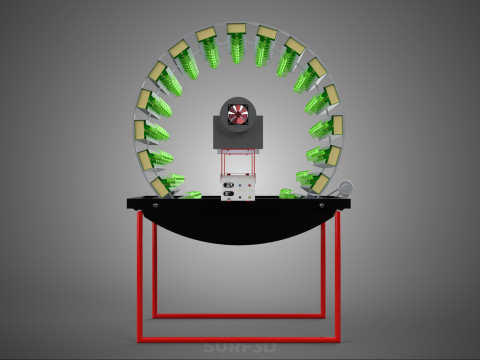

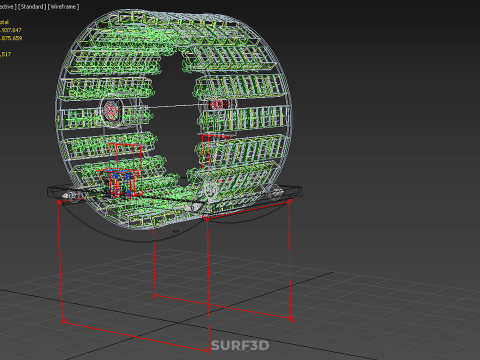

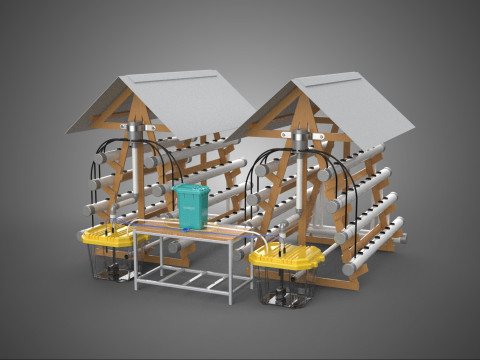

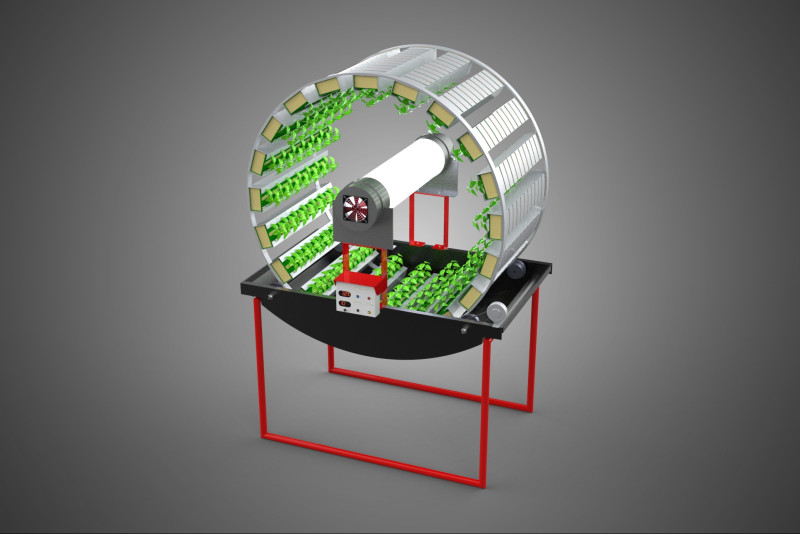

RUOTA DEL SISTEMA DI COLTIVAZIONE DI PIANTE DA GIARDINO IDROPONICO ROTANTE IOT CONTROL Modello 3D

- Richiedi supporto per il prodotto

- Formati disponibili:

- ID Oggetto:602061

- Data: 2025-09-28

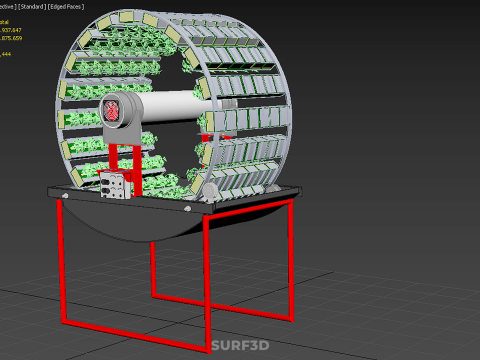

- Pligoni:2937647

- Vertici:1875659

- Animato:No

- Textured:No

- Rigged:No

- Materiali:

- Low-poly:No

- Collezione:No

- Mapping UVW:No

- Plugins Utilizzati:No

- Stampa Pronta:No

- 3D Scan:No

- Per adulti:No

- PBR:No

- AI Formazione:No

- Geometria:Poly NURBS

- UVs Aperti:Unknown

- Visualizzazioni:253

Descrizione

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

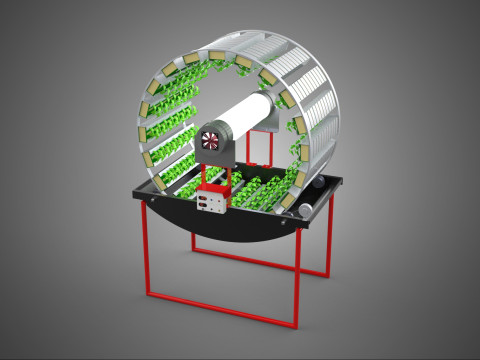

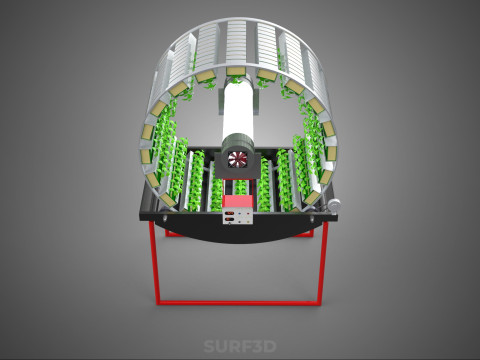

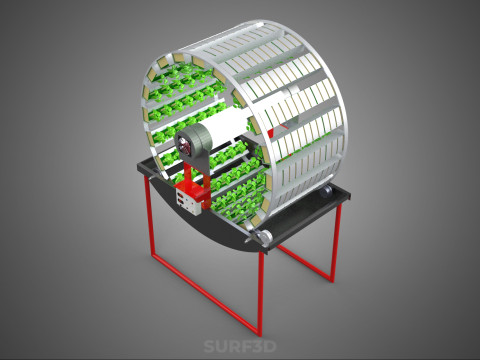

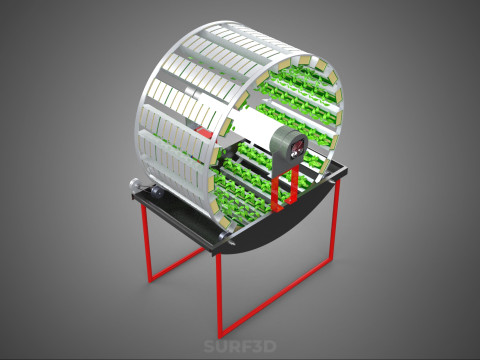

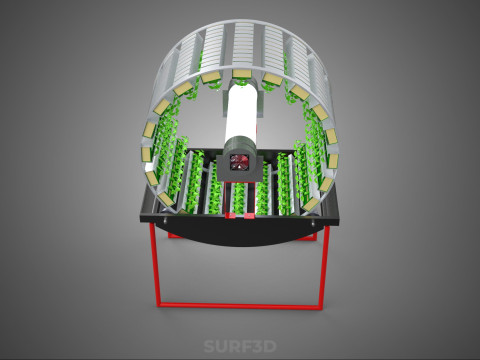

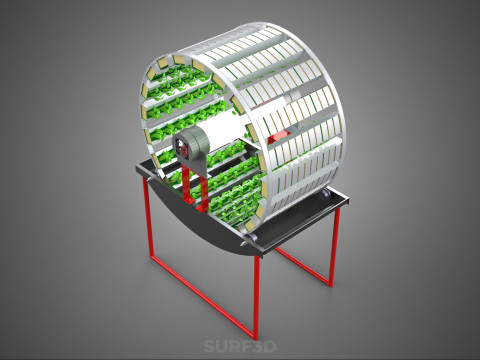

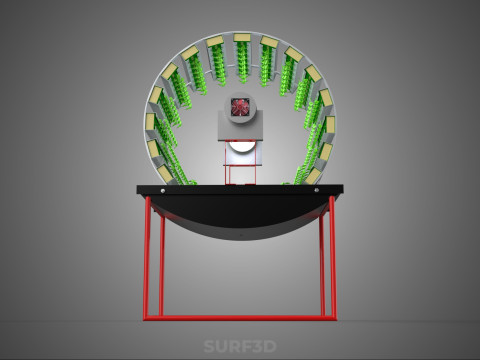

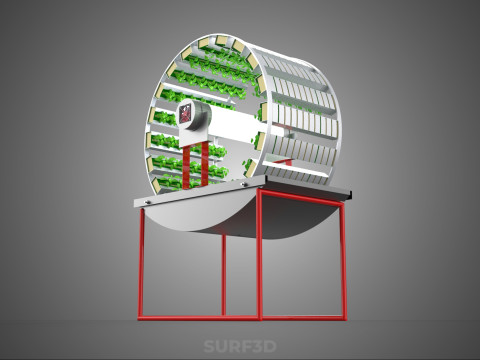

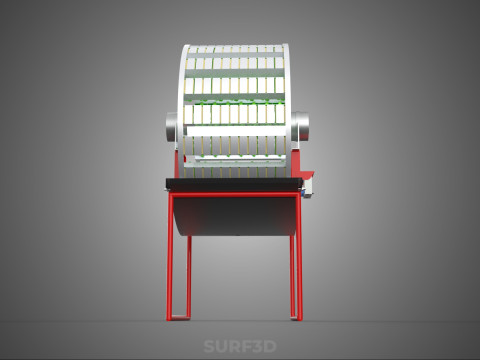

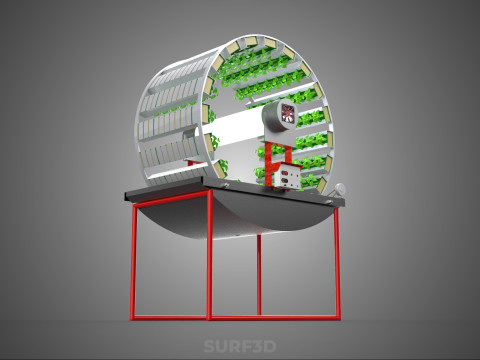

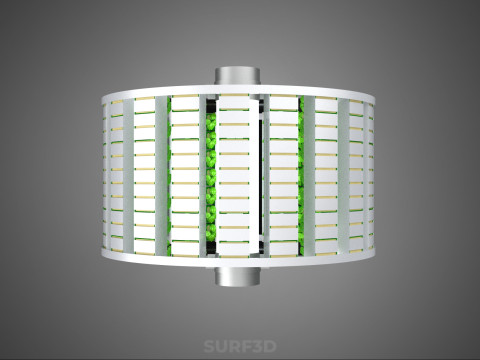

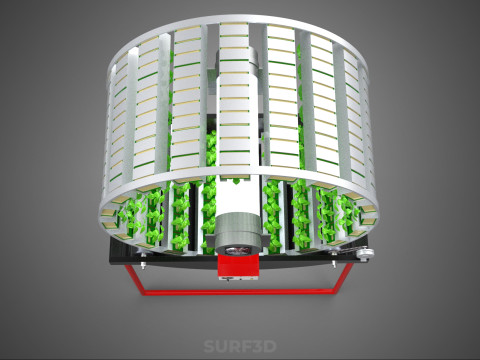

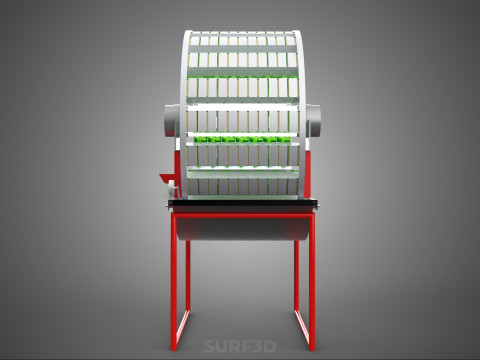

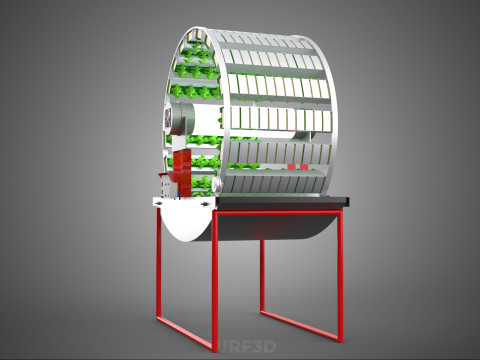

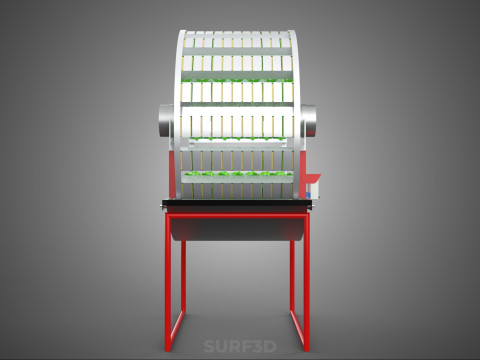

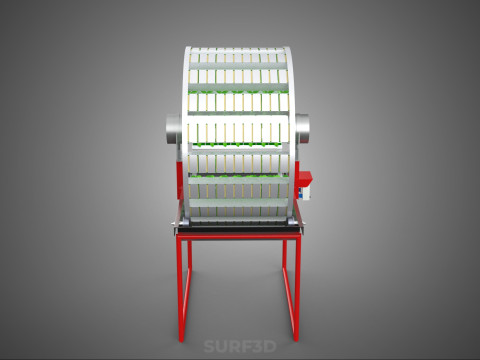

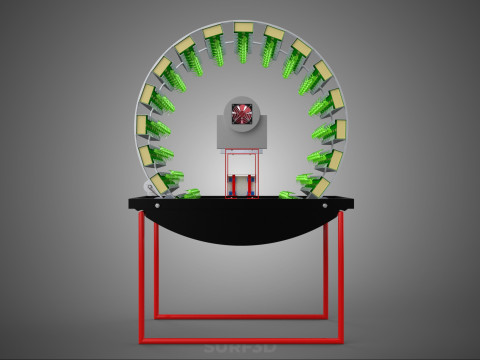

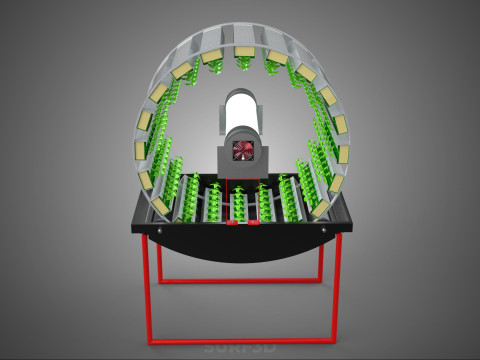

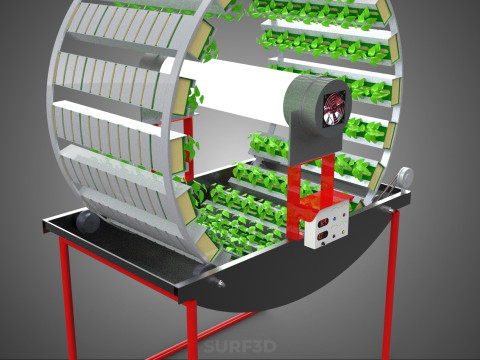

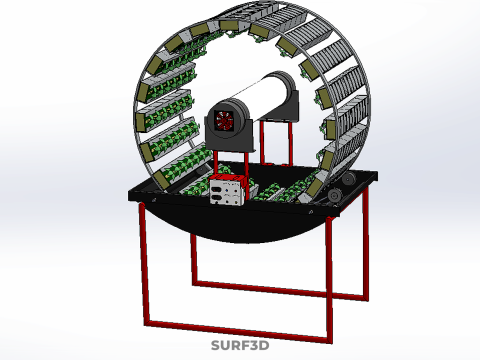

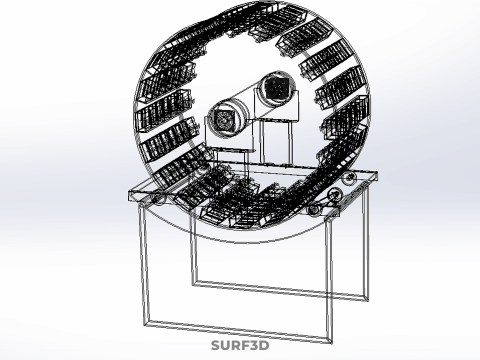

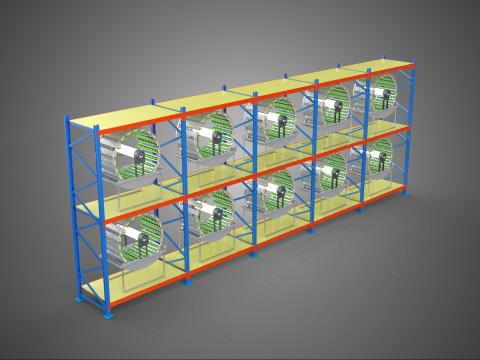

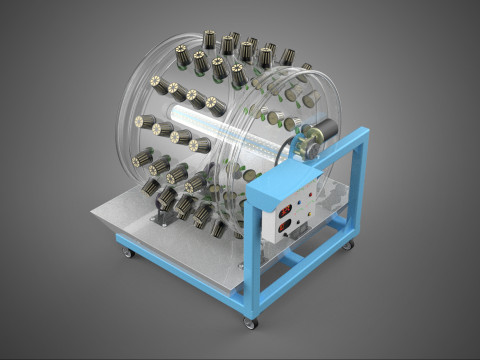

The "IOT Control Rotary Hydroponic Garden Plant Farming System Wheel" describes an advanced, integrated horticultural solution designed for cultivating plants in a soil-less environment, leveraging a rotating structure and sophisticated Internet of Things (IoT) technologies. This system merges the principles of hydroponics with vertical farming and smart automation to optimize plant growth conditions, maximize resource efficiency, and enable year-round cultivation in controlled environments.

**Core Components and Mechanism:**

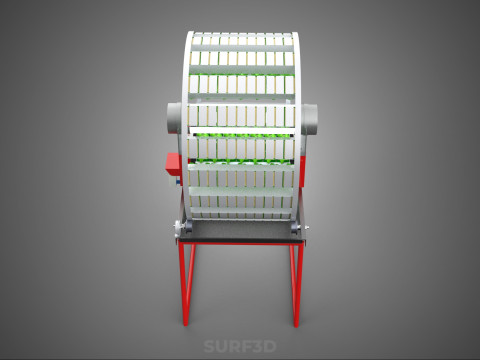

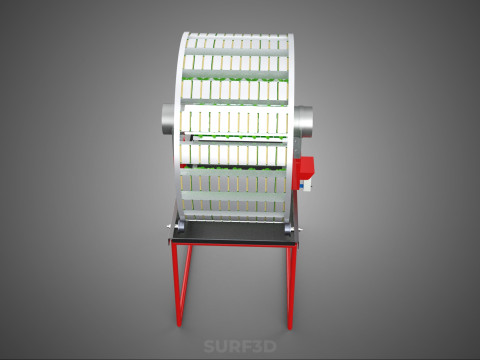

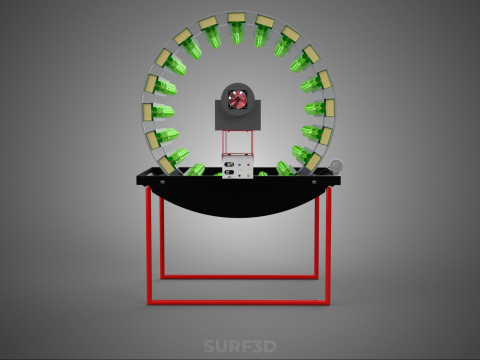

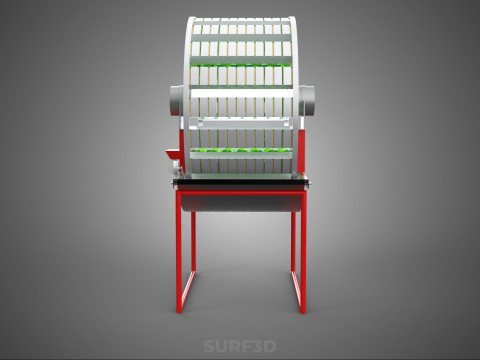

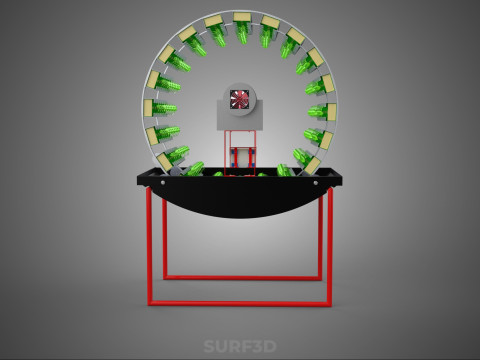

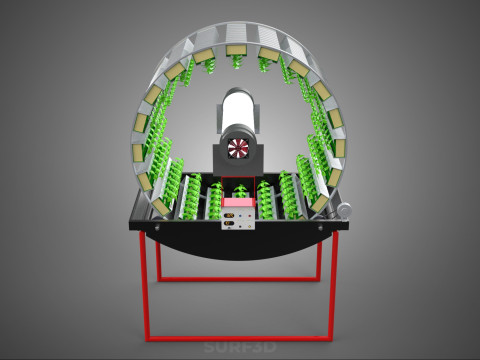

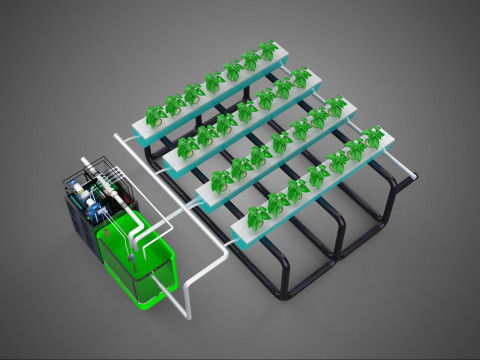

At the heart of the system is a multi-tiered, often vertically oriented, circular structure commonly referred to as a "wheel" or "rotor." This structure slowly revolves around a central axis, serving several key functions:

1. **Space Optimization:** The vertical and rotary design significantly increases plant density per unit of floor space, a hallmark of vertical farming.

2. **Uniformity:** As plants rotate, they receive equitable exposure to light, airflow, and nutrient solution, promoting consistent and balanced growth across all cultivation sites.

3. **Root Aeration:** In certain hydroponic configurations, the rotation allows for periodic exposure of plant roots to air, enhancing oxygen uptake and preventing waterlogging, which is crucial for root health.

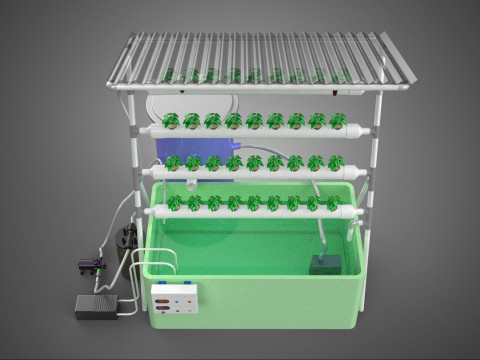

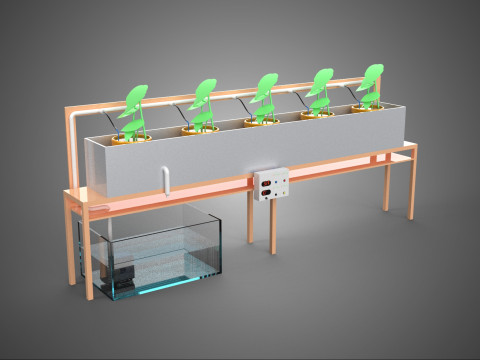

**Hydroponic Subsystem:** The cultivation aspect is entirely hydroponic, meaning plants are grown either directly in nutrient-rich water solutions or in an inert growing medium (e.g., rockwool, coco coir) that supports the plant while the roots are immersed in or regularly irrigated with the solution. Common hydroponic methods integrated into rotary systems include Nutrient Film Technique (NFT) or Deep Water Culture (DWC) variants where plant roots are continuously or intermittently bathed in the solution. A central reservoir holds the precisely formulated nutrient solution, which is circulated to the plant roots via an automated pump and a network of delivery tubes, ensuring a constant supply of essential macro- and micronutrients.

**IOT Control System:** The "IOT Control" element distinguishes this system through its integration of digital intelligence and remote connectivity. It encompasses:

* **Sensors:** A comprehensive network of environmental and solution sensors continuously monitors critical parameters, including:

* **Water Parameters:** pH levels, Electrical Conductivity (EC) (indicating nutrient concentration), water temperature, and reservoir water levels.

* **Atmospheric Parameters:** Air temperature, relative humidity, and potentially CO2 levels within the growing environment.

* **Light Parameters:** Light intensity (lux/PPFD) and spectrum.

* **Microcontroller/Processor:** A central processing unit (e.g., Raspberry Pi, Arduino, or custom embedded system) collects data from all sensors, processes it according to predefined algorithms, and executes control commands.

* **Actuators:** Based on sensor data and programmed logic, various actuators are employed to adjust and maintain optimal growing conditions. These include:

* **Pumps:** For circulating nutrient solution, dosing pH adjusters (acid/alkali), and adding concentrated nutrient solutions to maintain desired EC.

* **LED Grow Lights:** Often integrated directly into the rotary structure, these are programmable for intensity, duration, and spectral output to match plant growth stages.

* **Fans:** For air circulation, temperature regulation, and humidity control.

* **Motors:** To precisely control the speed and direction of the rotary wheel, optimizing light exposure and nutrient delivery.

* **Communication Module:** Typically Wi-Fi, Ethernet, or Bluetooth, enabling the system to connect to local networks and the internet.

* **User Interface:** A dedicated mobile application or web-based dashboard provides users with real-time monitoring of all system parameters, historical data logging, customizable alert notifications, and remote control capabilities, facilitating data-driven optimization of cultivation protocols.

**Operational Principles:**

The IOT system continuously monitors the hydroponic and atmospheric conditions. If any parameter deviates from its programmed optimal range (e.g., pH drifts, nutrient concentration falls), the intelligent algorithms trigger the relevant actuators to initiate corrective actions. For instance, if the pH drops, an alkali dosing pump might activate; if light levels are insufficient, the LED grow lights intensify or extend their operational period. The rotation speed of the wheel can also be dynamically adjusted to suit specific plant requirements or to maximize exposure to light and nutrients. All operational data is logged, enabling growers to analyze trends, fine-tune settings, and improve efficiency over time.

**Key Features and Advantages:**

* **High Space Utilization:** The vertical, rotary design significantly maximizes plant production in minimal footprint areas.

* **Water Efficiency:** Hydroponic systems recirculate water, reducing consumption by up to 90% compared to traditional soil-based agriculture.

* **Accelerated Growth and Yield:** Precise, automated control over environmental factors fosters ideal conditions, leading to faster growth cycles, higher plant health, and increased yields.

* **Reduced Labor:** Automation minimizes the need for manual monitoring, nutrient adjustment, and irrigation.

* **Pest and Disease Control:** The controlled indoor environment reduces exposure to pests, pathogens, and environmental contaminants, often eliminating the need for chemical pesticides.

* **Remote Management:** Growers can monitor and manage their farming system from anywhere with internet access.

* **Data-Driven Optimization:** Continuous data collection and analytics provide insights for informed decision-making and protocol refinement.

* **Year-Round Cultivation:** Independence from external climate and seasonal variations ensures consistent production.

* **Sustainability:** Reduced resource consumption and the potential for localized food production minimize transportation costs and carbon footprint.

Hai bisogno di ulteriori formati?

Se hai bisogno di diversi formati, aprire un nuovo Ticket i Supporto e una richiesta per questo. Convertiamo modelli 3D a: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Conversione di formato gratuitaNon convertiamo scene 3d e formati come .step, .iges, .stp, .sldprt.!

Informazioni sull'utilizzo

RUOTA DEL SISTEMA DI COLTIVAZIONE DI PIANTE DA GIARDINO IDROPONICO ROTANTE IOT CONTROL - È possibile utilizzare questo modello 3D royalty-free sia per scopi personali che commerciali, in conformità con la licenza base o estesa.La licenza base copre la maggior parte dei casi d'uso standard, tra cui pubblicità digitale, progetti di design e visualizzazione, account aziendali sui social media, app native, app web, videogiochi e prodotti finali fisici o digitali (sia gratuiti che venduti).

La licenza estesa include tutti i diritti concessi dalla licenza base, senza limitazioni d'uso, e consente l'utilizzo del modello 3D in un numero illimitato di progetti commerciali secondo i termini royalty-free.

Leggi ulteriori

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी