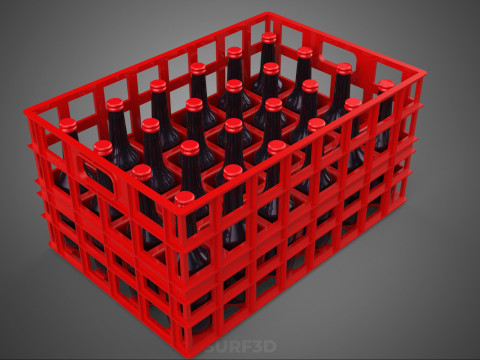

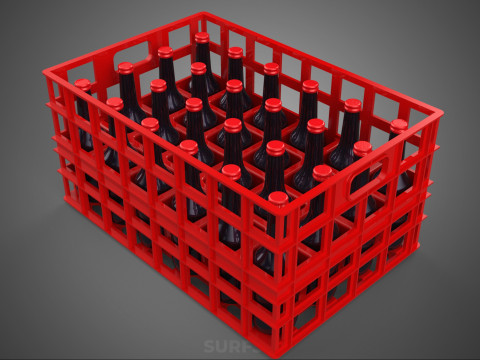

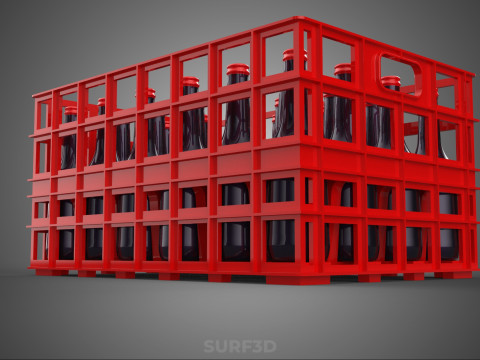

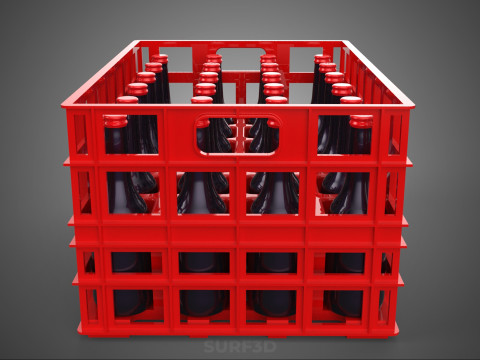

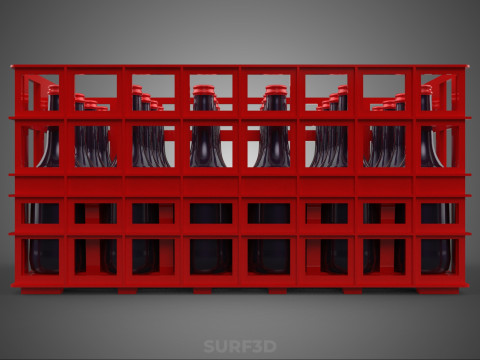

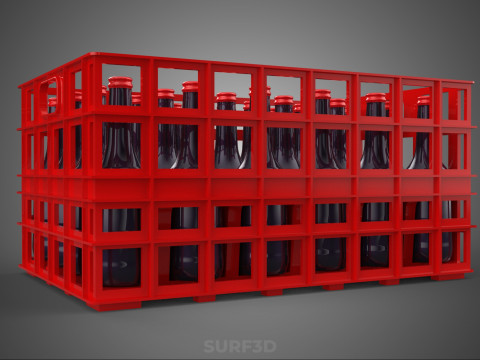

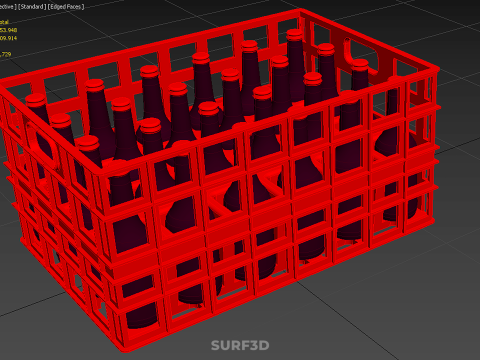

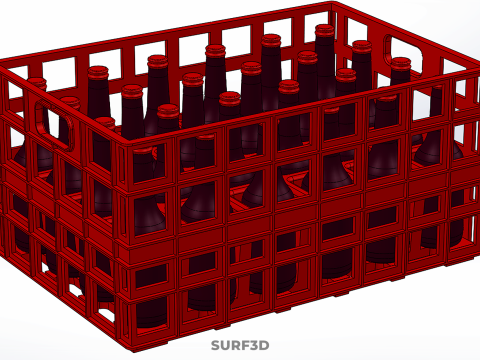

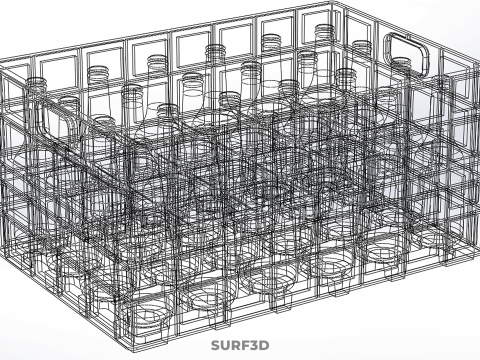

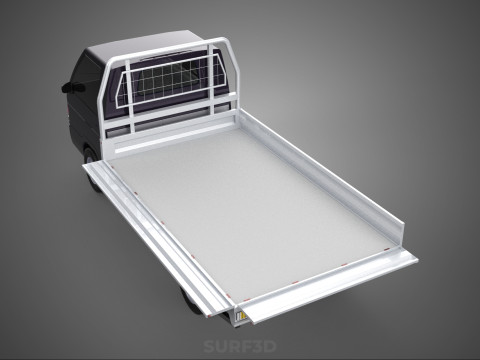

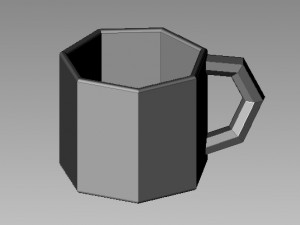

PORTA CONTENITORI PER SCATOLE IN PLASTICA PORTA BOTTIGLIE ROSSE Modello 3D

- Richiedi supporto per il prodotto

- Formati disponibili:

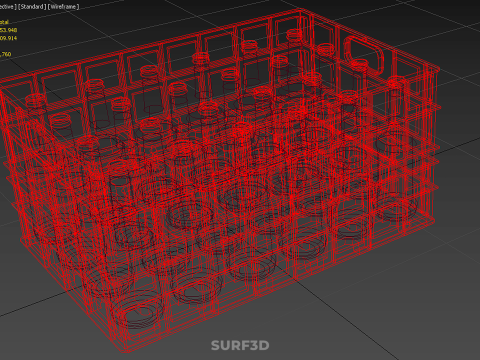

- ID Oggetto:614518

- Data: 2025-11-28

- Pligoni:153948

- Vertici:109914

- Animato:No

- Textured:No

- Rigged:No

- Materiali:

- Low-poly:No

- Collezione:No

- Mapping UVW:No

- Plugins Utilizzati:No

- Stampa Pronta:No

- 3D Scan:No

- Per adulti:No

- PBR:No

- AI Formazione:No

- Geometria:Poly NURBS

- UVs Aperti:Unknown

- Visualizzazioni:60

Descrizione

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

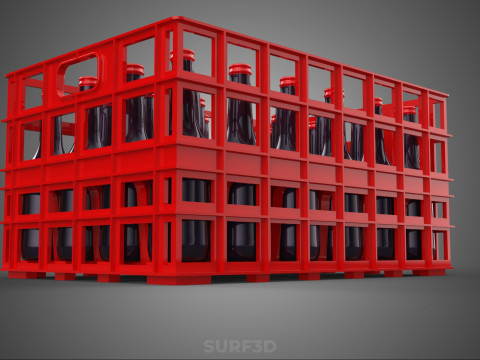

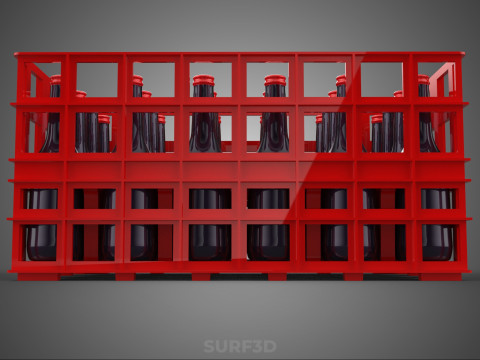

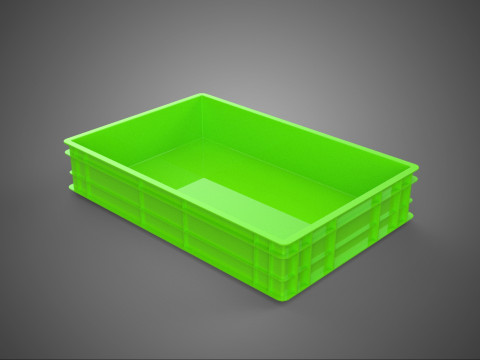

A beverage carrier, formally classified as a compartmentalized logistics container or bottle crate, is a highly durable, industrial-grade receptacle specifically engineered for the standardized transport, warehousing, and presentation of bottled soft drinks. The object defined by this title is characterized by its distinct red coloration and construction from high-density polymeric materials.

### I. Structure and Materials

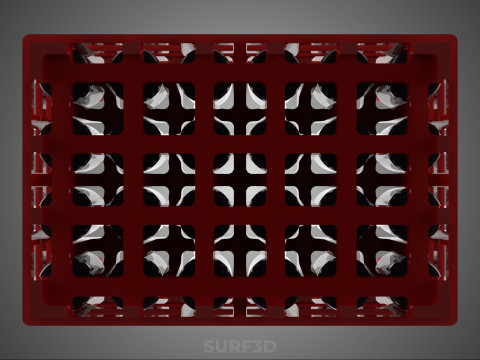

The carrier is manufactured predominantly through high-pressure injection molding, typically utilizing High-Density Polyethylene (HDPE) or, less commonly, Polypropylene (PP). These thermoplastic polymers are chosen for their exceptional resistance to impact, moisture, chemical agents (such as cleaning solutions), and environmental stress cracking, ensuring a long service life within rigorous supply chain environments.

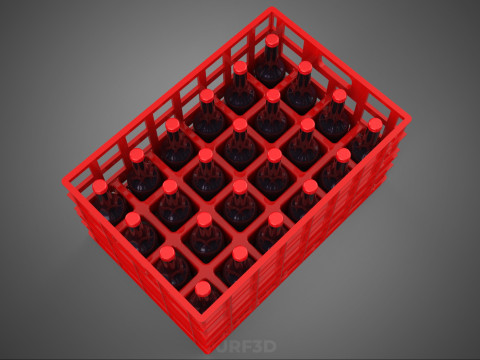

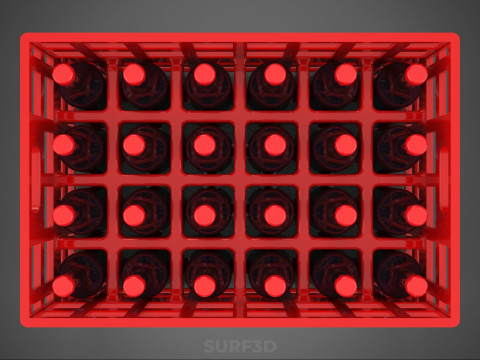

Structurally, the container features a rectangular chassis designed to accommodate a precise number of bottles, often in configurations of 12 or 24 units. The interior is divided by an integrated lattice of plastic ribs, forming individual cells that securely stabilize the bottles, preventing movement and mitigating breakage during transit and mechanical handling. The external surfaces incorporate reinforced vertical ribs and robust top and bottom rims, which contribute to the container's overall load-bearing capacity and structural rigidity, essential for multi-level stacking.

### II. Functional Role and Ergonomics

The primary function of the carrier is to serve as a reusable transport item (RTI) within a closed-loop distribution system. This contrasts with single-use cardboard packaging by significantly reducing waste and operating costs over time. Carriers facilitate efficient material handling and inventory management by ensuring uniform size and weight when filled.

Ergonomic features include integrated handholds or slots strategically placed on the peripheral walls, optimizing manual lifting and handling by personnel. Crucially, the design incorporates interlocking features, known as stacking lugs or corner feet, which interface securely with the top frame of the crate beneath, allowing for stable, high-density vertical stacking—a necessary requirement for maximizing utilization of pallet space (both Euro-pallet and ISO specifications) and warehouse vertical storage capacity. The open lattice construction often permits automated washing and sanitization cycles without specialized equipment.

### III. Significance of Color (Red)

The specified color, red, is not merely aesthetic but serves a critical function in asset management and brand identification within the logistics sector. In bottling operations, color coding is employed to rapidly delineate ownership, distinguish between product types (e.g., carbonated vs. non-carbonated, returnable vs. non-returnable systems), or identify specific regional bottling franchises. The use of a visually conspicuous color like red facilitates swift sorting, reduces the likelihood of asset loss or commingling with competitors' containers, and assists in automated optical tracking and return processes. The red pigmentation is achieved by incorporating colorants directly into the polymer resin before molding, ensuring permanence and UV resistance.

### IV. Industry Application

These plastic carriers are indispensable components of the Fast-Moving Consumer Goods (FMCG) distribution network. They are utilized throughout the entire process: from the bottling line, where automated equipment loads the filled bottles; to palletizing and warehousing; to transport via trucks or rail; and finally, to retail locations where they frequently double as temporary display units. Their standardization ensures seamless integration with automated conveyor systems, depalletizers, and robotic material handling equipment common in modern bottling plants.

KEYWORDS: Plastic, Crate, Softdrink, Carrier, Bottle, Rack, Container, Beverage, Logistics, HDPE, Injection Molding, Returnable Transport Item, RTI, Palletization, Warehousing, Distribution, Packaging, Red, Storage, Compartmentalized, Transport, FMCG, Polyethylene, Supply Chain, Stacking, Automation, Commercial, Reusable, Material Handling, Standardization

Hai bisogno di ulteriori formati?

Se hai bisogno di diversi formati, aprire un nuovo Ticket i Supporto e una richiesta per questo. Convertiamo modelli 3D a: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Conversione di formato gratuitaNon convertiamo scene 3d e formati come .step, .iges, .stp, .sldprt.!

Informazioni sull'utilizzo

PORTA CONTENITORI PER SCATOLE IN PLASTICA PORTA BOTTIGLIE ROSSE - È possibile utilizzare questo modello 3D royalty-free sia per scopi personali che commerciali, in conformità con la licenza base o estesa.La licenza base copre la maggior parte dei casi d'uso standard, tra cui pubblicità digitale, progetti di design e visualizzazione, account aziendali sui social media, app native, app web, videogiochi e prodotti finali fisici o digitali (sia gratuiti che venduti).

La licenza estesa include tutti i diritti concessi dalla licenza base, senza limitazioni d'uso, e consente l'utilizzo del modello 3D in un numero illimitato di progetti commerciali secondo i termini royalty-free.

Leggi ulteriori

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी