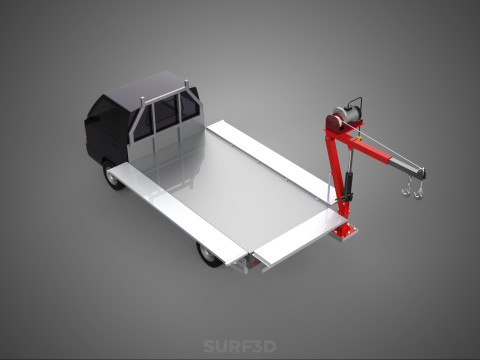

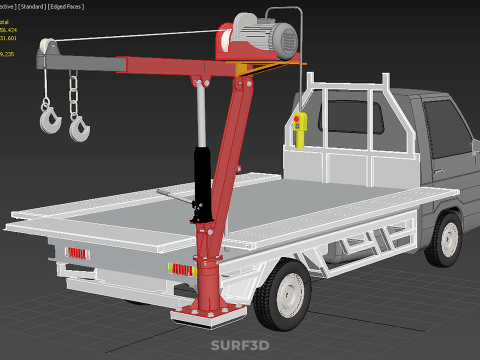

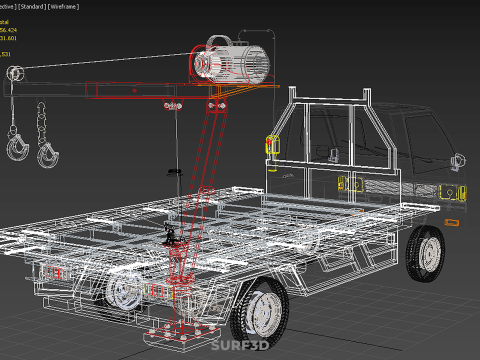

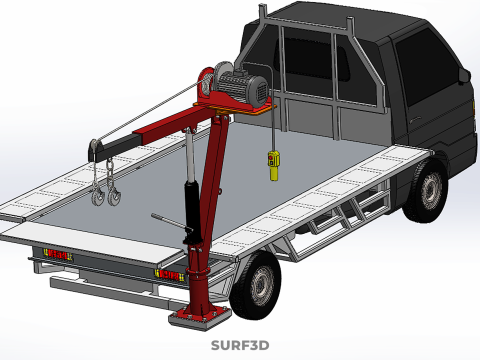

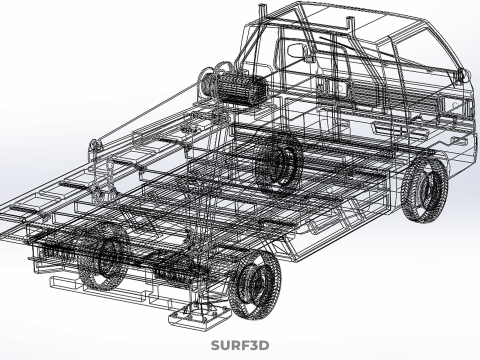

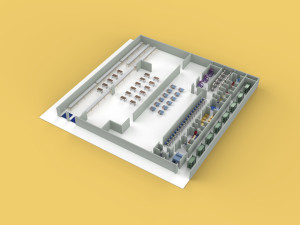

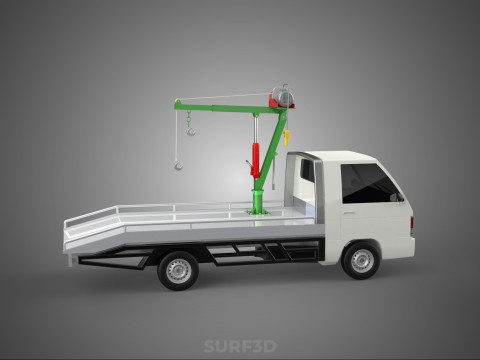

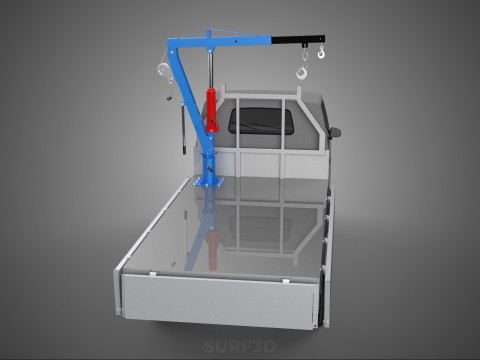

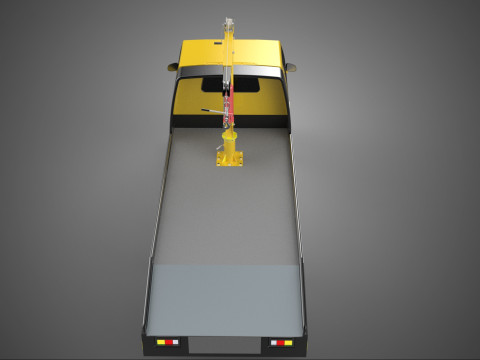

3 WAY WIDE DECK CRANE HOIST REMOTE ELECTRIC WINCH PICKUP TRUCK Model 3D

- Dostępne formaty: Wavefront OBJ (.obj) 9.20 MBSketchUp (.skp) 12.56 MBSTEP (.step) 13.04 MBGLB (.glb / .gltf) 6.26 MBAutodesk 3DS MAX (.max) 29.85 MBRhinoceros (.3dm) 40.19 MBBlender3D (.blend) 12.01 MBAutodesk AutoCAD (.dwg) 22.42 MBIGES (.iges) 9.80 MBAutodesk FBX (.fbx) 16.00 MBACIS(.sat) 20.77 MBCollada (.dae) 13.17 MB3D Studio (.3ds) 4.77 MBStereolithography (.stl) 9.74 MB

- Wielokąty:656424

- Wierzchołki:531601

- Model animowany:No

- Tekstury:No

- Oparty na szkielecie:No

- Materiał:

- Low-poly:No

- Kolekcja:No

- UVW mapping:No

- Plugins Used:No

- Gotowy do wydruku:No

- 3D Scan:No

- Adult content:No

- PBR:No

- AI Szkolenie:No

- Geometria:Poly NURBS

- Unwrapped UVs:Unknown

- Liczba wyświetleń:122

- Data: 2025-08-21

- ID produktu:593438

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

A "3 Way Wide Deck Crane Hoist Remote Electric Winch Pickup Truck" describes a highly specialized and integrated utility vehicle designed for localized material handling and lifting operations. This system combines the mobility and versatility of a standard pickup truck chassis with the robust capabilities of a compact, vehicle-mounted crane, optimized for efficient deployment in various field service, construction, and industrial applications.

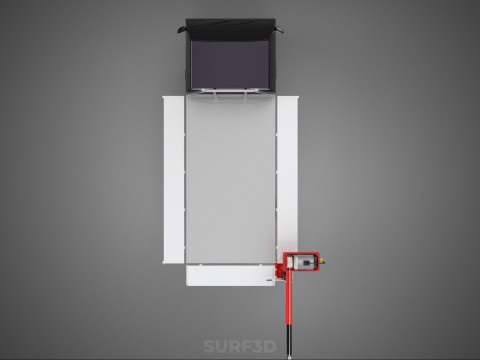

At its foundation, the system utilizes a **pickup truck** chassis, typically a light-duty or medium-duty commercial model, chosen for its inherent ruggedness, power train, and existing electrical system. The truck's chassis is often reinforced or modified to accommodate the additional weight and operational stresses imposed by the crane system. Critical to this configuration is the **wide deck**, which replaces or significantly extends the standard truck bed. This flatbed or service body design provides an expansive and stable platform, essential for mounting the crane, distributing loads, and often integrating storage compartments for tools and equipment. The wide deck also contributes to the overall stability of the vehicle during lifting operations by offering a broader base.

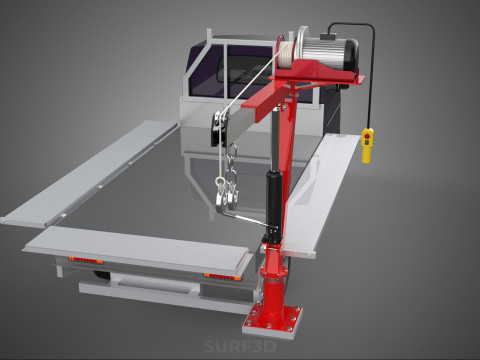

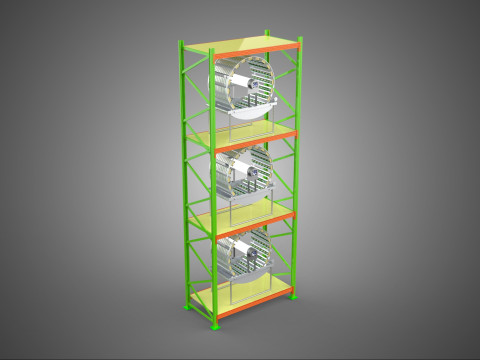

The core of the material handling capability is the **crane hoist** system. This refers to a compact utility crane, often an articulating or fixed-boom design, specifically engineered for vehicle integration. The designation "3 Way" delineates the primary degrees of operational freedom this crane typically possesses:

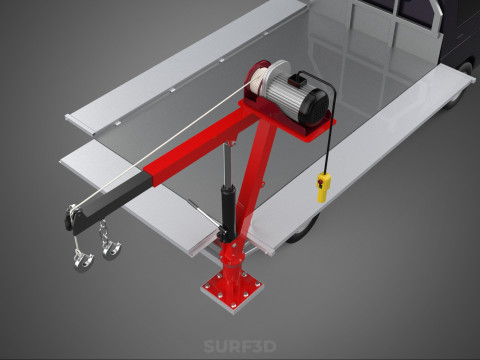

1. **Slewing (Rotation)**: The horizontal rotation of the crane mast or boom assembly, enabling the operator to position the load through a wide arc relative to the truck, commonly ranging from 180 to 360 degrees (non-continuous).

2. **Luffing (Boom Elevation)**: The vertical articulation or elevation of the crane boom, allowing the operator to raise or lower the boom's angle, thereby controlling the height and reach of the lifted load.

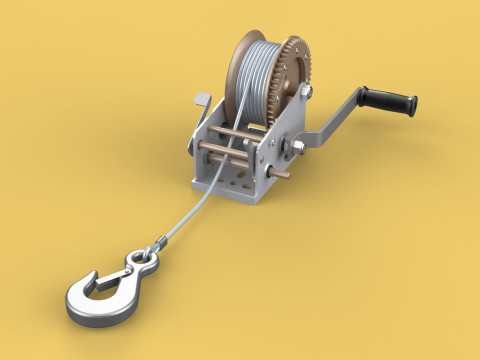

3. **Hoisting (Winch Operation)**: The vertical movement of the load itself, accomplished by the **electric winch**. This winch is the primary lifting mechanism, typically powered by the truck's 12V or 24V DC electrical system, sometimes augmented by an inverter for AC winches or dedicated auxiliary batteries. The electric winch provides precise, controlled lifting and lowering of loads via a durable steel cable terminating in a safety hook. Its electric nature ensures smooth, consistent operation without the need for an external power source or complex hydraulic lines for the lifting function (though boom articulation might be hydraulic).

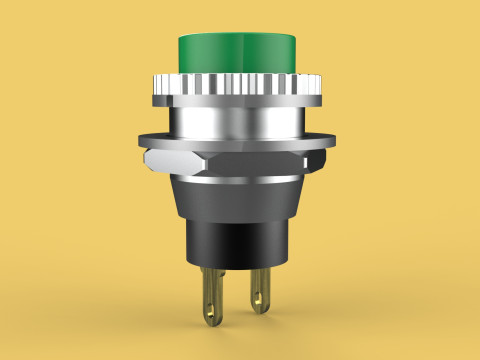

Operational control is facilitated by a **remote** system, which can be either a tethered pendant control or a wireless radio frequency (RF) remote. This feature significantly enhances safety and efficiency by allowing the operator to stand clear of the immediate load area, position themselves for optimal visibility of the lifting operation, and precisely manipulate the load from a safe distance. The remote control typically governs all "3 Way" movements, including winch operation, boom elevation, and slewing.

Applications for such a system are diverse, encompassing tasks such as lifting and placing equipment on construction sites, servicing HVAC units on rooftops, installing utility poles or transformers, loading heavy components in agricultural settings, or deploying specialized tools for field technicians. The key advantages of this integrated vehicle are its unparalleled mobility, allowing rapid deployment to various worksites; its versatility in handling a range of moderate-weight lifting tasks; enhanced safety through remote operation and reduced manual handling; and improved operational efficiency by consolidating transport and lifting capabilities into a single, road-legal unit. Critical technical considerations include the necessity for deployable outriggers or stabilizers to ensure vehicle stability during lifting operations, adherence to strict load capacity ratings (often decreasing with boom extension), and ensuring the vehicle's electrical system can adequately power the winch and control mechanisms.

KEYWORDS: Pickup truck, Service crane, Utility vehicle, Material handling, Electric winch, Remote control, Mobile crane, Hoisting equipment, Flatbed truck, Work truck, Load lifting, Articulating boom, Slewing, Luffing, DC powered, Field service, Construction equipment, Vehicle-mounted crane, Light-duty crane, Outriggers, Stabilizers, Payload capacity, Vehicle modification, Commercial vehicle, Lifting solution, Portable crane, Load manipulation, Integrated system, Worksite efficiency, Industrial applications

Jeśli potrzebny Ci plik w innym formacie, zgłoś taką potrzebę przez opcję Support Ticket Konwertujemy produkty na następujące formaty: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Nie konwertujemy scen 3D oraz formaty takie jak .step, .iges, .stp, .sldprt.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी